Broan L100L, L200L, L150L, L250L, L300L User Manual

|

MODELS |

|

L100L • L150L • L200L • L250L • L300L |

LOSONE SELECT® |

Page 1 |

|

|

VENTILATORS |

|

In-Line • 120V |

|

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1.Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or telephone number listed in the warranty.

2.Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as a tag, to the service panel.

3.Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction codes and standards.

4.Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s guideline and safety standards such as those published by the National Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5.When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

6.Ducted fans must always be vented to the outdoors.

7.To reduce the risk of fire, use only metal ductwork.

8.If this unit is to be installed over a tub or shower, it must be marked as appropriate for the application and be connected to a GFCI (Ground Fault Interrupter) - protected branch circuit.

9.Never place a switch where it can be reached from a tub or shower.

10.This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1.Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

2.Always turn hood ON when cooking at high heat or when cooking flaming foods.

3.Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

4.Use proper pan size. Always use cookware appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1.SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT.

2.NEVER PICK UP A FLAMING PAN — You may be burned.

3.DO NOT USE WATER, including wet dishcloths or towels - violent steam explosion will result.

4.Use an extinguisher ONLY if:

A.You know you have a Class ABC extinguisher and you already know how to operate it.

B.The fire is small and contained in the area where it started.

C.The fire department is being called.

D.You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

CAUTION

1.For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2.To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off power unit.

3.If ventilator is installed in an unconditioned space (such as an attic): Surround the ventilator with thermal insulation - to minimize possible condensation.

4.Please read specification label on product for further information and requirements.

TABLE OF CONTENTS

This manual is divided into sections as follows:

•“TYPICAL INSTALLATION”

This section shows a common installation in new and existing, frame construction.

-Mounting (new construction)

-Mounting (existing construction)

-Wiring

-Ducting (straight through blower discharge)

•“MOUNTING OPTIONS”

•“WIRING OPTIONS”

-Wiring Plate Position

•“DUCTING OPTIONS”

-Blower Discharge Positions

-Ducting (right angle blower discharge)

•“USE AND CARE”

•“SERVICE PARTS”

•“WARRANTY”

Installer: Leave this manual with the homeowner.

Homeowner: Use and Care information on page 3.

MODELS L100L • L150L • L200L • L250L • L300L

TYPICAL INSTALLATION

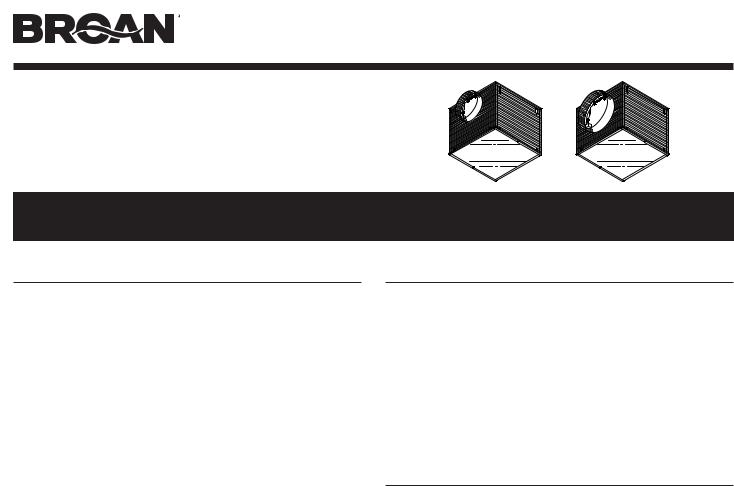

MOUNTING (New Frame Construction)

ROUND DUCT* |

Mounting brackets |

|

factory-shipped in |

|

position for ½” |

|

ceiling material. |

ADDITIONAL

1½” FRAMING CEILING JOIST (16” centers shown)

MOUNTING

SCREW

Blower factory-shipped in straight through discharge position.

Factory-shipped unit installed in new construction.

MOUNTING (Existing Frame Construction) |

|

2 X 4 FRAMING |

|

(wide side down) |

|

ROUND DUCT* |

|

CEILING JOIST |

|

;;;;yyyy |

|

(16” centers |

|

shown) |

|

MOUNTING |

|

BRACKETS |

|

(Attached to |

FINISHED |

opposite sides |

CEILING |

of housing & |

MATERIAL |

upside-down) |

|

Factory-shipped unit installed in existing construction.

*L100L & L150L use 6” round duct.

L200L, L250L, & L300L use 8” round duct.

Page 2

TYPICAL INSTALLATION

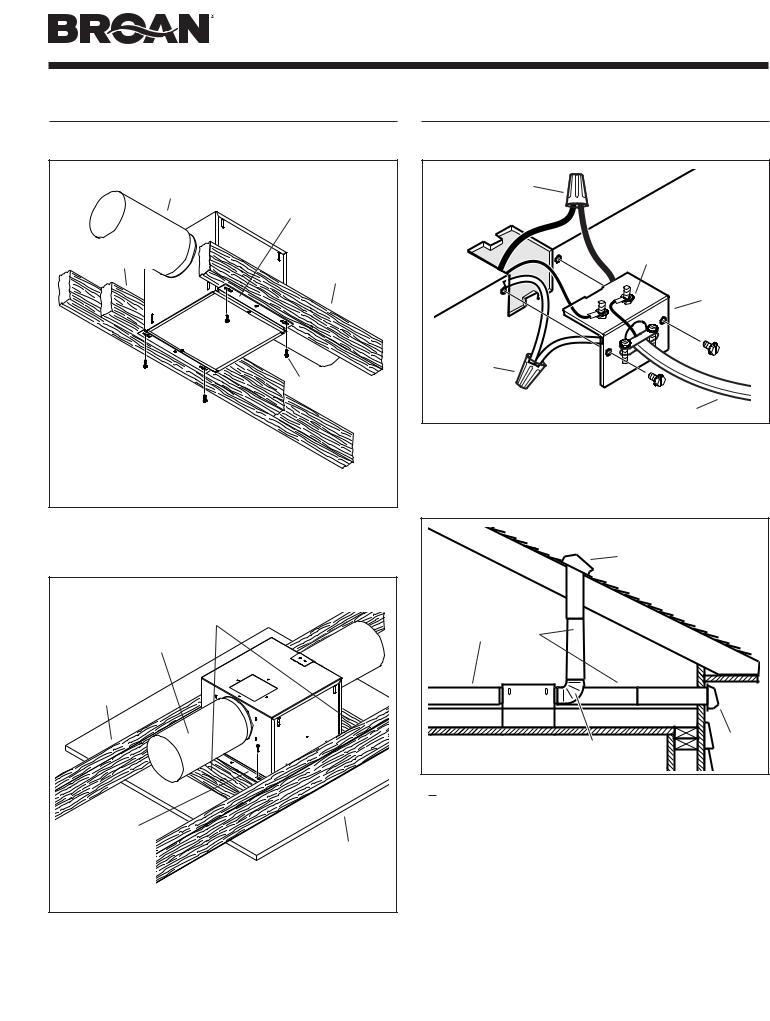

WIRING

BLACK

TO

BLACK TOP / BACK

OF HOUSING

GROUND TO

WIRING PLATE

WIRING

PLATE

WHITE

TO

WHITE

120 VAC LINE IN

Ventilator can be wired from outside of housing. Use UL approved connectors to wire per local codes.

DUCTING (Horizontal blower discharge)

ROOF CAP |

|

|

ROUND DUCT* |

|

|

ROUND |

WALL |

|

CAP |

||

ELBOW* |

||

|

Two ways to connect ductwork to a factory-shipped unit.

*L100L & L150L use 6” round duct.

L200L, L250L, & L300L use 8” round duct.

IMPORTANT:

Remove shipping tape from damper

Remove the shipping tape from the damper flap and make sure that damper flap opens and closes freely inside the ductwork. Use duct tape to make ductwork connections secure and air-tight.

Remove shipping ring from blower inlet

Remove the shipping ring from the blower inlet before operating the ventilator.

MODELS

L100L • L150L • L200L • L250L • L300L

Page 3

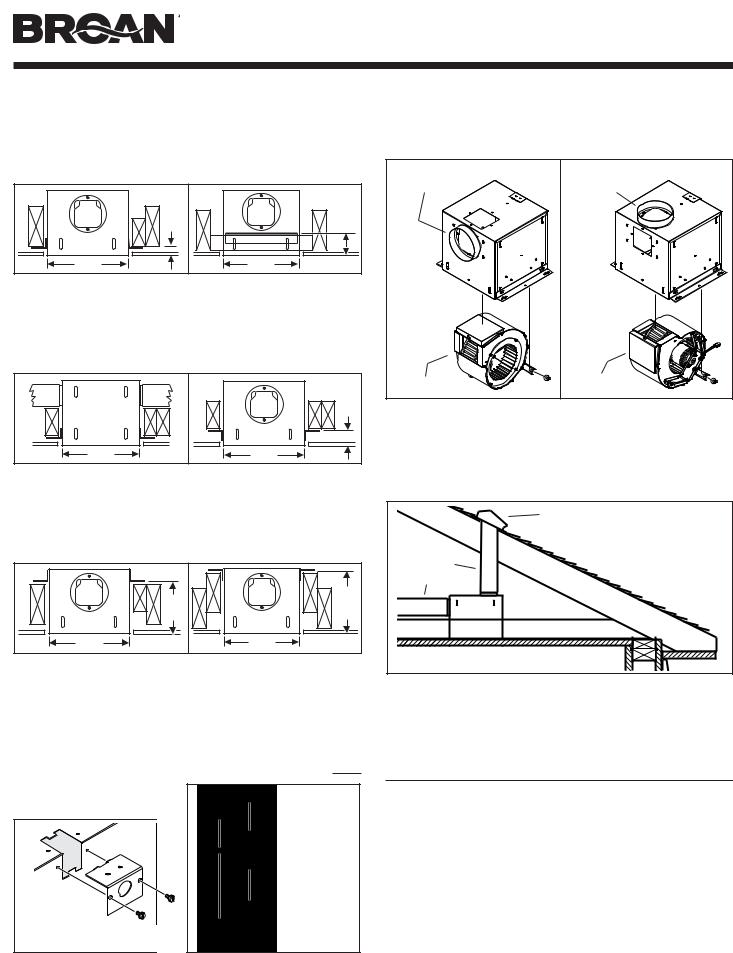

MOUNTING OPTIONS |

|

DUCTING OPTIONS |

¼-20 hex nuts secure mounting brackets to housing. Loosen and re-tighten or remove and replace nuts as necessary for desired mounting bracket position.

11/8" |

1½" |

to |

|

MAX. |

2½" |

|

@@ÀÀ;;yy |

12¼" |

12¼" |

Mounting brackets in |

Mounting brackets flipped |

factory-shipped position. |

over and mounted to outlet |

(Outlet parallel to joists.) |

sides of housing. |

(New construction) |

(Outlet parallel to joists.) |

|

(Existing construction) |

|

11/2" |

|

to |

|

21/2" |

12¼" |

12¼" |

Mounting brackets mounted |

Mounting brackets flipped |

to outlet sides of housing. |

over to give approx. 1” |

(Outlet perpendicular to joists.) |

more clearance. |

(New construction) |

(Outlet parallel to joists.) |

|

(New construction) |

91/2" |

10 3/4" |

|

to |

||

to |

||

11 3/4" |

||

101/2" |

||

12¼" |

12¼" |

Mounting brackets mounted |

Mounting brackets flipped |

to top of sides of housing. |

over and mounted to top of |

(Outlet parallel to joists.) |

sides of housing. |

(New or existing construction) |

(Outlet parallel to joists.) |

|

(New or existing construction) |

BLOWER DISCHARGE POSITIONS

DUCT |

DUCT |

CONNECTOR |

CONNECTOR |

Change blower & duct connector positions for right angle discharge.

BLOWER |

BLOWER |

Blower and duct connector |

Blower and duct connector |

in straight through dis- |

in right angle discharge |

charge position. |

position. |

(Factory shipped) |

|

DUCTING (Right angle blower discharge)

ROOF CAP |

ROUND |

DUCT* |

Typical ductwork connection to a ventilator converted to right angle discharge.

*L100L & L150L use 6” round duct.

L200L, L250L, & L300L use 8” round duct.

WIRING OPTIONS

WIRING PLATE

POSITION

VERTICAL

POWER

CABLE

CONNECTION

HORIZONTAL POWER

CABLE CONNECTION

Wiring plate mounts to side or top of housing.

USE AND CARE

Ventilator is designed for continuous operation. If desired, it may be controlled using an on/off switch or an electronic, variable speed control. Follow wiring instructions packed with control, and adhere to all local and state codes, and the National Electrical Code.

WARNING: To reduce the risk of electric shock, disconnect from power supply before servicing.

To clean blower assembly: Remove access panel, unplug blower from housing, remove blower mounting nuts, and carefully remove blower from housing. Use appropriate vacuum attachment or a soft cloth and mild soap or detergent to clean blower discharge area and wheel. DO NOT ALLOW WATER TO ENTER MOTOR. Make sure blower assembly is completely dry before reinstalling.

Motor is permanently lubricated. Do not oil or disassemble motor.

|

|

|

|

|

|

|

MODELS |

|

|

|

|

|

L100L • L150L • L200L • L250L • L300L |

||

|

|

|

|

|

|

|

Page 4 |

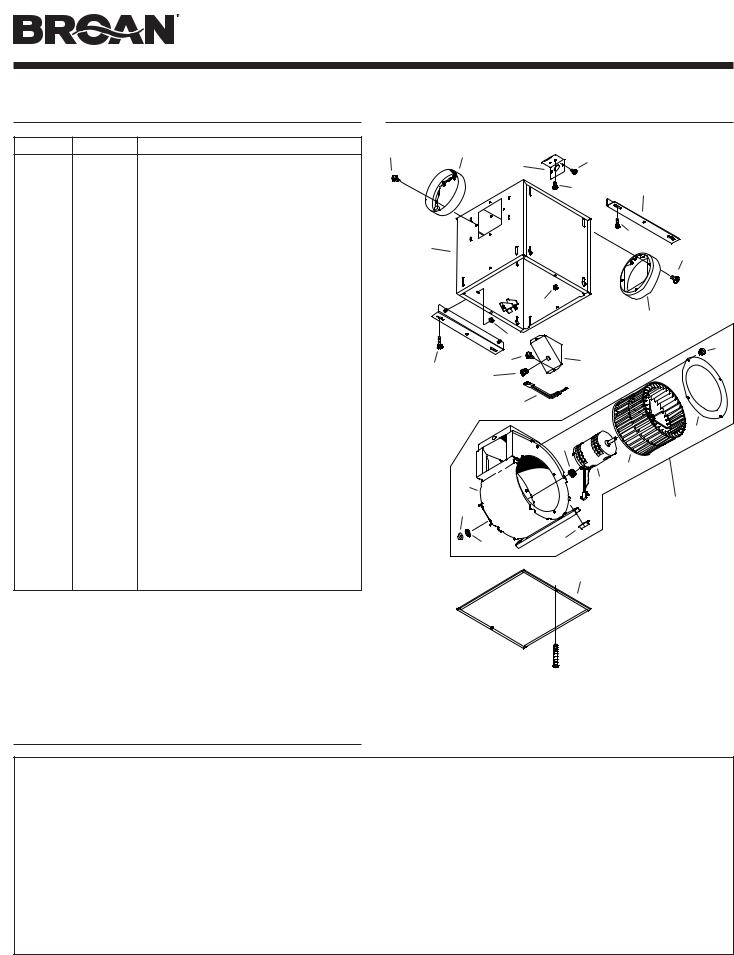

SERVICE PARTS |

SERVICE PARTS |

|

|||||

KEY NO. PART NO. |

DESCRIPTION |

5 |

|

3 |

5 |

|

|

1 |

97014735 |

Housing Assembly (L100L & L150L) |

|

|

8 |

|

|

|

97014736 |

Housing Assembly (L200L, L250L, & L300L) |

|

|

|

|

|

|

|

|

|

|

|

||

2 |

97014728 |

Mounting Bracket (2 req.) |

|

|

|

9 |

2 |

3 |

97014760 |

Damper Assembly (6” dia.) |

|

|

|

|

|

|

97014761 |

Damper Assembly (8” dia.) |

|

|

|

|

|

4 |

99390098 |

Duct Connector (6” dia.) |

|

|

|

|

|

5 |

99390099 |

Duct Connector (8” dia.) |

|

|

|

|

22 |

99150415 |

Screw, 8-18 x ¼ (12 req.)* |

|

1 |

|

|

5 |

|

6 |

98005513 |

Wire Box Cover |

|

|

|

||

|

|

|

|

||||

7 |

99400035 |

Strain Relief Bushing |

|

|

|

|

|

8 |

98005512 |

Wiring Plate |

|

|

|

|

|

9 |

99150471 |

Ground Screw, 10-32 x ½ (2 req.) |

|

|

|

|

|

10 |

97014774 |

Scroll Assembly (L100L & L150L) |

|

|

|

20 |

|

|

97014775 |

Scroll Assembly (L200L, L250L, & L300L) |

|

|

|

|

4 |

11 |

98009399 |

Inlet Ring |

|

|

|

|

|

|

|

|

|

|

|||

12 |

99110805 |

Blower Wheel |

|

|

16 |

|

5 |

13 |

99080481 |

Motor (L100L) |

|

|

5 |

|

|

|

99080482 |

Motor (L150L) |

|

22 |

6 |

|

|

|

99080483 |

Motor (L200L) |

|

7 |

|

|

|

|

99080484 |

Motor (L250L) |

|

|

|

|

|

|

|

|

|

|

|

||

|

99080485 |

Motor (L300L) |

|

|

18 |

|

|

14 |

99260558 |

Lock Nut, 8-32 (4 req.)* |

|

|

|

|

|

15 |

99250959 |

Washer (4 req.)* |

|

|

|

|

|

16 |

99100491 |

Grommet (4 req.) |

|

|

|

|

11 |

|

|

Blower Assembly, Complete |

|

|

|

16 |

|

|

|

|

|

|

|

||

|

|

(Includes Key Nos. 5 & 10-17) |

|

|

|

|

|

|

97014800 |

(L100L) |

|

|

|

|

12 |

|

97014801 |

(L150L) |

|

|

|

|

|

|

|

|

10 |

13 |

|

||

|

97014802 |

(L200L) |

|

|

|

||

|

97014803 |

(L250L) |

|

|

14 |

|

BLOWER |

|

97014804 |

(L300L) |

|

|

|

||

17 |

99260477 |

Nut, ¼-20 (6 req.)* |

|

|

|

|

ASSEMBLY |

18 |

97006039 |

Wire Harness |

|

|

15 |

17 |

|

19 |

98009417 |

Access Panel |

|

|

|

||

20 |

99420470 |

Cover Nut (2 req.) |

|

|

|

|

|

21 |

99150472 |

Cover Mounting Screw (2 req.) |

|

|

|

19 |

|

22 |

99150591 |

Screw, 10-16 x 7/8 (4 req.)* |

|

|

|

|

|

|

|

|

|

|

|||

Order replacement parts by PART NO. - not by KEY NO. * Standard hardware - may be purchased locally.

21

21

WARRANTY

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its products that such products will be free from defects in materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS AND TUBES. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of an implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or phone number stated below (b) give the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you must present evidence of the original purchase date.

In the U.S., contact: Broan-NuTone, 926 West State Street, Hartford, WI U.S.A. 53027 (1-800-637-1453)

In Canada, contact: Broan-NuTone Canada, 1140 Tristar Drive Mississauga, Ontario L5T 1H9 (1-888-882-7626)

99042723H

Loading...

Loading...