Bradford-White EF User Manual

ULTRA HIGH EFFICIENCY COMMERCIAL GAS WATER HEATER

(EF Series Models)

VERSION INTERNET

Ambler, PA 19002

Tech. Service (800) 334-3393

Service Parts (800) 538-2020

Warranty Service (800) 531-2111

Part No. 238-44445-00B 03/04

|

REFERENCE |

ONLY |

|

|

|

||

|

WARNING: If the information in |

||

|

these instructions is not followed |

||

|

exactly, a fire or explosion may |

||

FOR |

result causing property damage, |

||

personal injury or death |

|||

|

|||

|

- Do not store or use gasoline or other |

||

|

flammable vapors and liquids in the |

||

|

vicinity of this or any other appliance |

||

|

- WHAT TO DO IF YOU SMELL GAS |

||

|

∙ Do not try to light any appliance. |

||

|

∙ Do not touch any electrical switch; do |

||

|

not use any phone in your building. |

||

|

∙ Immediately call your gas supplier |

||

|

from a neighbor’s phone. Follow the |

||

|

gas supplier’s instructions. |

||

|

∙ If you cannot reach your gas supplier, |

||

|

call the fire department. |

||

|

- Installation and service must be |

||

|

performed by a qualified installer, service |

||

|

agency or gas supplier |

||

INSTALLATION/OPERATING MANUAL

WITH TROUBLESHOOTING GUIDE

PLACE THESE INSTRUCTIONS ADJACENT TO WATER HEATER AND NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

SECTION I: IMPORTANT INFORMATION

READ CAREFULLY

This gas -fired water heater is design certified by CSA International under the American National Standard, Z21.10.3 (as indicated on the rating plate) and CAN/CGA 4.3-M (as indicated on the rating plate) available from CSA Standards Association, 178 Rexdale Blvd., Etobicoke, Ontario, Canada M9W 1R3.

This water heater must be installed in accordance with local codes. In the absence of local codes, it

Canada CAN/CGA B149.1 Natural Gas Installation Code (Latest Edition) or CAN/CGAONLYB149.2 Propane Installation Code (Latest Edition).

must be installed in compliance with the National Fuel Gas Code (ANSI Z223.1-Latest Edition), or in

The following terms are used throughout this manual to bring attention to the presence of hazards at various risk levels, or to important information concerning product life.

|

DANGER |

|

|

|

|

CAUTION |

|

|

|

|

|

|

|

|

|

|

|

|

Indicates an imminently |

|

|

|

Indicates potentially hazardous |

|

||

|

hazardous situation which, if not |

|

|

situation which, if not avoided, |

|

|||

|

avoided, will result in death, |

|

|

|

may result in moderate or minor |

|

||

|

serious injury or substantial |

|

|

|

injury or property damage. |

|

||

|

property damage. |

|

|

|

|

REFERENCE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

|

|

FOR |

NOTICE |

|

||

|

|

|

|

|

||||

|

Indicates a potentially hazardous |

|

|

Indicates special instructions on |

|

|||

|

situation which, if not avoided, |

|

|

|

installation, operation or |

|

||

|

could result in death, serious |

|

|

|

maintenance which are |

|

||

|

injury or substantial property |

|

|

|

important but not related to |

|

||

|

damage. |

VERSION |

|

|

personal injury hazards. |

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

INTERNET |

|

NOTICE |

|

|

||||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

This water heater has a limited warranty. The warranty for this water heater is valid only if the water heater has been installed, maintained and operated in accordance with these instructions.

I |

IMPORTANT INFORMATION................ |

2 |

II |

SPECIFICATIONS.................................... |

5 |

III |

GENERAL INFORMATION.................... |

6 |

IV |

INSTALLATION INSTRUCTIONS......... |

9 |

V |

WATER CONNECTIONS....................... |

15 |

VI |

VENTING................................................ |

18 |

VII |

GAS CONNECTIONS............................ |

31 |

VIII |

ELECTRICAL CONNECTIONS........... |

33 |

IX |

OPERATING INSTRUCTIONS............. |

34 |

X |

MAINTENANCE.................................... |

37 |

XI |

TROUBLE SHOOTING GUIDE............ |

41 |

XII |

PARTS LIST........................................... |

43 |

2

DANGER

DANGER

DO NOT store or use gasoline or other flammable, combustible, or corrosive vapors and/or liquids in the vicinity of this or any other appliance.

DO NOT install any damaged venting system components. If damage is evident then please contact the supplier where the water heater was purchased or the manufacturer listed on the rating plate for replacement parts.

Use only vent terminals provided or factory authorized terminals for venting this water heater.

This water heater is equipped with an adjustable thermostat to control water temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns resulting in serious personal injury and/or death. The temperature at which injury occurs varies with the person’s age and the time of exposure. The slower response time of disabled persons increases the hazards to them. NEVER allow small children to use a hot water tap, or to draw their own bath water. NEVER leave a child or disabled person unattended in a bathtub or shower.

Failure to properly install the vent and air intake (if applicable) system could result in property damage, personal

This water heater requires regular maintenance and service to operateREFERENCEsafely. Follow the instructions contained in |

|

injury, or death |

ONLY |

WARNING

WARNING

Improper installation, adjustments, alteration, service or maintenance can cause property damage, personal injury or loss of life. Failure to follow all instructions in the proper order can cause personal injury or death. Read and understand all instructions, including all those provided with the appliance before installing, starting-up, operating, maintaining or servicing this appliance. Keep this manual and literature in legible condition with this water heater for reference by owner and service technician.

Installation is not complete unless a temperature and pressureFORrelief valve is installed into the proper location at the top of this water heater.

this manual.

Installation, maintenance, and service must be performed only by an qualified, skilled and knowledgeable installer or service provider.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are properly operating when the installation is complete.

This water heater is suitable for installation on combustible flooring. Do not install water heater on carpeting.

DO NOT operate this water heater without first being certain it is filled with water.

DO NOT tamper with or alter the water heater and/or controls.

DO NOT operate water heater with jumpered or absent controls or safety devices.

VERSION

under water.

DO NOTINTERNEToperate water heater if any external part has been under water. Immediately call a qualified service agency to inspect the appliance and to replace any part of the control system including gas controls, which has been

DO NOT attempt to use this water heater with any gas other than the type listed on the rating plate. Do not attempt to convert this water heater for use with a gas other than the type for which it is equipped. Failure to use the proper gas can create an unsafe condition resulting in property damage, bodily injury, or death. Consult your local gas supplier or gas company if there are any questions.

DO NOT operate this water heater if the input rate exceeds the rate shown on the water heater rating plate.

This water heater contains very hot water under high pressure. Do not unscrew any pipe fittings nor attempt to disconnect any components of this water heater without positively assuring the water is cool and is not under pressure. Always wear protective clothing and equipment when installing, starting up or servicing this water heater to prevent scald injuries. Do not rely on the temperature gauges to determine the temperature. Do not touch any components unless they are cool.

This water heater must be properly vented and connected to an approved vent system in good condition. DO NOT operate water heater with the absence of an approved vent system. A clean and unobstructed vent system is necessary to allow noxious fumes that could cause injury or loss of life to vent safely and will contribute toward maintaining the water heater’s efficiency.

3

WARNING

WARNING

This water heater needs fresh air for safe operation and must be installed so there are provisions for adequate combustion and ventilation air. Insufficient air supply will cause a recirculation of combustion products resulting in contamination that may be hazardous to life. This will result in carboning or sooting of the combustion chamber, burners, and flue tubes and creates a risk of asphyxiation.

This water heater requires its own separate venting system. DO NOT connect the exhaust vent into an existing vent pipe or chimney.

Water heater materials of construction, products of combustion and the fuel contain carbon monoxide, nitrogen

oxides, aldehydes and/or other toxic or harmful substances which can cause death or serious injury and which are ONLY

known to the state of California to cause cancer, birth defects and other reproductive harm. Always use proper safety clothing, respirators and equipment when servicing or working nearby this water heater.

Flammable items, pressurized containers or any other potential fire hazardous articles must never be placed on or adjacent to the water heater. Open containers of flammable material should not be stored or used in the same room

with this water heater. |

REFERENCE |

Insulation blankets are not required for this water heater. This water heater meets or exceeds the ASHRAE/IES 90.1b (latest edition) standards with respect to insulation and standby loss requirements.

Hydrogen gas can be produced in an operating water heater that has not had water drawn from the tank for a long period of time (generally two weeks or more). Hydrogen gas is extremely flammable. To prevent the possibility of injury under these conditions, we recommend the hot water faucet to be open for several minutes at the kitchen sink before you use any electrical appliance, which is connect to the hot water system. If hydrogen is present, there will be an unusual sounds such as air escaping through the pipes as hot water begins to flow. Do not smoke or have open flame near the faucet at the time it is open.

WARNINGFOR

WARNINGFOR

IF YOU SMELL GAS:

Liquefied petroleum gases/propane gas is heavier than air and will remain at floor level if there is a leak. Basements, crawl spaces, closetsVERSIONand areas below ground level will serve as pockets for accumulation of leaking gas. Before lighting, smell all around the appliance area for gas. Be sure to smell next to the floor.

∙ DO NOT try to light any appliance.

∙ DO NOT touch any electric switch; do not use any telephone in your building.

∙ Immediately call your gas supplier from a telephone in another building. Follow the gas supplier’s

∙ INTERNETinstructions.

If you cannot reach your gas supplier, call the fire department.

DO NOT OPERATE THE APPLIANCE UNTIL THE LEAKAGE IS CORRECTED!

4

|

|

|

|

|

|

SECTION II: |

|

|

SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REFERENCE |

|

ONLY |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

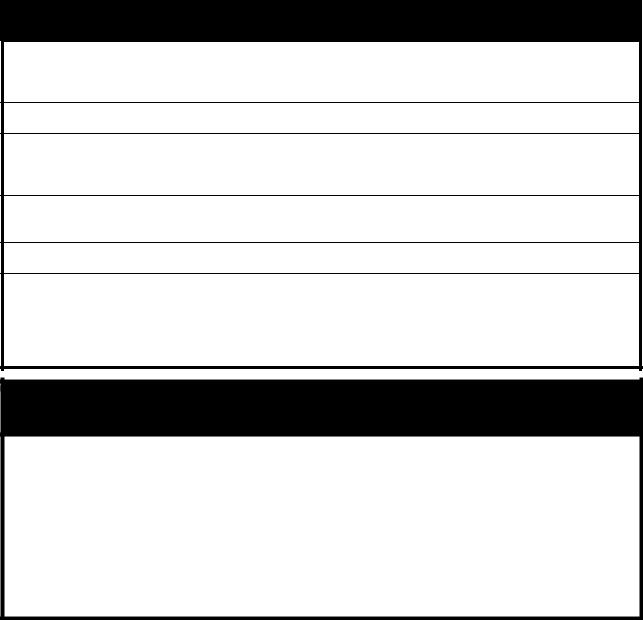

Figure 1. Dimensional Layout |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

Recovery GPH |

|

|

|

|

|

|

FOR |

|

|

|

DIMENSIONS ( INCHES ) |

|

|

|

|

|

|

||||||||||||||||

|

|

|

At Degree Rise |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

1st Hr. |

|

|

|

|

|

|

|

|

|

|

D |

|

E |

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

Del. |

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

H |

Front |

Space |

|

|

|

|

||||||||

|

|

Gal. |

|

|

|

|

|

Stg. |

|

|

|

|

|

|

|

Flr to |

Flr to |

Fl. to |

G |

|

Gas |

Relief Shpg. |

||||||||||||||

Input |

|

At |

|

|

|

|

|

Cap.Therm. |

|

|

|

|

Flr to |

Inlet |

T&P |

Outlet |

|

Fl. to |

|

Wtr. |

Heating |

|||||||||||||||

Rate |

100°F |

|

|

|

|

|

U. . |

Eff. |

A |

|

B |

|

Vent |

Wtr. |

Valve |

Wtr. Fl. to Air |

Gas |

Conn. |

Conn. |

Conn. Valve Wt. |

||||||||||||||||

Model No. BTU/h |

|

Rise |

40°F |

100°F 140°F Gal. |

|

% |

Ht. |

Dia. |

Outlet Conn |

Conn |

Conn |

Intake |

Conn. Dia. |

Dia. |

Dia. Open. (LBS) |

|||||||||||||||||||||

EF60T125 125,000 |

|

187 |

363.6 |

145.5 103.9 |

60 |

96.0 |

57 |

28 3/8 |

5 |

|

|

13 |

40 |

42 ¼ |

52 ½ |

53 ½ |

|

1 ½ |

1 |

|

|

¾ |

¾ |

570 |

||||||||||||

EF60T150 150,000 |

|

211 |

422.7 |

169.1 120.8 |

60 |

93.0 |

57 |

28 3/8 |

5 |

|

|

13 |

40 |

42 ¼ |

52 ½ |

53 ½ |

|

1 ½ |

1 |

|

|

¾ |

¾ |

570 |

||||||||||||

EF60T199 199,999 |

|

265 |

557.6 |

223 |

158 |

|

60 |

92.0 |

57 |

28 3/8 |

5 |

|

|

13 |

40 |

42 ¼ |

52 ½ |

53 ½ |

|

1 ½ |

1 |

|

|

¾ |

¾ |

570 |

||||||||||

EF100T150 150,000 |

|

250 |

450.5 |

180.2 |

129 |

VERSION |

|

|

5 |

|

|

13 |

60 |

62 ½ |

73 1/8 |

74 ¾ |

|

1 ½ |

1 |

|

|

¾ |

¾ |

900 |

||||||||||||

|

|

100 |

99.1 |

77 5/8 28 3/8 |

|

|

|

|

|

|||||||||||||||||||||||||||

EF100T199 199,999 |

|

309 |

597 |

238.8 |

171 |

|

100 |

98.5 |

77 5/8 28 3/8 |

5 |

|

|

13 |

60 |

62 ½ |

73 1/8 |

74 ¾ |

|

1 ½ |

1 |

|

|

¾ |

¾ |

900 |

|||||||||||

EF100T250 250,000 |

|

364 |

734.8 |

293.9 |

210 |

|

100 |

97.0 |

77 5/8 28 3/8 |

5 |

|

|

13 |

60 |

62 ½ |

73 1/8 |

74 ¾ |

|

1 ½ |

1 |

|

|

¾ |

1 |

900 |

|||||||||||

EF100T300 300,000 |

|

405 |

836.4 |

334.5 |

239 |

|

100 |

92.0 |

77 5/8 28 3/8 |

5 |

|

|

13 |

60 |

62 ½ |

73 1/8 |

74 ¾ |

|

1 ½ |

1 |

|

|

¾ |

1 |

900 |

|||||||||||

|

|

|

|

Recovery LPH |

|

|

|

|

|

|

|

|

|

|

|

|

DIMENSIONS ( MILLIMETERS) |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

At Degree Rise |

|

|

|

|

|

|

|

|

D |

|

|

E |

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

1st Hr. |

|

|

|

|

|

|

|

|

|

|

|

C |

Flr to Flr to Fl. to |

|

|

H |

|

Front |

Space |

|

|

|

|

|

||||||||||

INTERNET |

|

Stg. Therm. |

|

|

Flr to Inlet |

T&P Outlet |

|

G |

Fl. to |

Wtr. |

Heating |

Gas |

Relief Shpg. |

|||||||||||||||||||||||

Nat |

|

Del. LPH |

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

Input at 56°C |

|

|

|

|

Cap. |

Eff. |

A |

|

B |

Vent |

Wtr. Valve |

Wtr. Fl. to Air |

Gas |

Conn. |

Conn. |

Conn. Valve |

Wt. |

|||||||||||||||||||

Model No. KW |

|

Rise |

22°C 56°C 78°C Liter |

% |

Ht. Dia. Outlet Conn Conn Conn |

Intake |

Conn. |

Dia. |

Dia. |

Dia. |

Open. (KG) |

|||||||||||||||||||||||||

EF60T125 36.6 |

709.7 |

1376.8 550.7 393.4 227 |

|

96.0 |

1448 718 |

127 |

330 |

1016 |

1016 |

1359 |

1359 |

38 |

|

25.4 |

19 |

|

19 |

259 |

||||||||||||||||||

EF60T150 43.9 |

799.2 |

1600.5 640.2 457.3 227 |

|

93.0 |

1448 718 |

127 |

330 |

1016 |

1016 |

1359 |

1359 |

38 |

|

25.4 |

19 |

|

19 |

259 |

||||||||||||||||||

EF60T199 58.6 |

1003.5 |

2111.1 844.4 603.2 227 |

|

92.0 |

1448 718 |

127 |

330 |

1016 |

1016 |

1359 |

1359 |

38 |

|

25.4 |

19 |

|

19 |

259 |

||||||||||||||||||

EF100T150 43.9 |

947.2 |

1705.5 682.2 487.3 379 |

|

99.1 |

1972 718 |

127 |

594 |

1524 |

1880 |

1857 |

1899 |

38 |

|

25.4 |

19 |

|

19 |

408 |

||||||||||||||||||

EF100T199 58.6 |

1169.1 |

2260.3 904.1 645.8 379 |

|

98.5 |

1972 718 |

127 |

594 |

1524 |

1880 |

1857 |

1899 |

38 |

|

25.4 |

19 |

|

19 |

408 |

||||||||||||||||||

EF100T250 73.2 |

1378.0 |

2782.3 1112.9 794.9 379 |

|

97.0 |

1972 718 |

127 |

594 |

1524 |

1880 |

1857 |

1899 |

38 |

|

25.4 |

19 |

|

25 |

408 |

||||||||||||||||||

EF100T300 87.9 |

1531.7 |

3166.7 1266.7 904.8 379 |

|

92.0 |

1972 718 |

127 |

594 |

1524 |

1880 |

1857 |

1899 |

38 |

|

25.4 |

19 |

|

25 |

408 |

||||||||||||||||||

Table 1. Specifications

5

SECTION III: GENERAL INFORMATION

FEATURES

This water heater contains the following features:

MAIN POWER ON/OFF SWITCH – The front panel of this water heater has a lighted ON/OFF switch, which is illuminated when the main power is turned on to indicate power to the water heater.

the burner. The Hot Surface Ignition System (HSI) then ignites the gas/air fuel mixture to produceONLYflue products (combustion). The flame sensor signals the ignition module (described below), that a flame is present.

COMBUSTION SYSTEM –This water heater is equipped with a self-compensating negative pressure pre -mix

combustion system. As the blower operates, air is drawn in through the air intake and into a venturi, which pulls gas

from the gas valve. The gas and air is then mixed in the combustion blower and sent through the transition tube into

IGNITION MODULE – The ignition module provides the timing for the combustion system. A sequence of operation (S-OP) is described in “Section IX - Operating Instruction.” As the combustion system progresses through the S-OP, LED’s illuminate, allowing accurate trouble-shooting should the need arise. If a failure occurs, the system will “blink” the LED that corresponds to the failure as described in the “Section XI Troubleshooting Guide.”

ADJUSTABLE THERMOSTAT – This water heater is equipped with an adjustable thermostat to control water

temperature. Hot water temperatures required for automatic dishwasher and laundry use can cause scald burns |

||

resulting in serious personal injury and/or death. |

FOR |

REFERENCE |

|

||

|

|

|

The temperature may be adjusted from about 80°F to about 180°F. The thermostat was adjusted to 120°F before the

water heater was shipped from the factory. It is recommended that lower temperatures be used to avoid the risk of scalding. Refer to the “Warnings”VERSIONand the section on SCALDING in “Section V - Water Connections.” It is further

recommended, in all cases, that the water temperature be set for the lowest temperature, which satisfies your hot water needs. This will also provide the most energy efficient operation of the water heater and minimizes scale formation.

Setting the water heater temperature at 120°F will reduce the risk of scalds. Some states require setting the specific lower temperatures.

Should the high limit switch activate, it must be manually reset. This can be accomp lished by turning the main power on/off switch to the off position and then back to the on position and allowing the water temperature of the tank to drop below 160°F.

The top immersionINTERNETwell of the single bulb controller also contains the high limit (energy cutoff) sensor. The high limit switch interrupts the main burner gas flow should the water temperature reach approximately 200°F.

Contact your qualified installing contractor, service provider or manufacturer listed on the rating plate if continued high limit switch operation occurs.

SERVICE PANEL – The service panel is located behind the service panel access cover, which is located by the exhaust collector near the bottom of the water heater. This panel contains a differential pressure switch that monitors the pressure across the exhaust orifice. A collector high limit switch is used to monitor the ambient temperature between the first pass collector and the exhaust collector. This is a manually re-settable switch. If this switch continues to trip, please contact an authorized service agency.

6

LATCHES – The latches allow easy access for servicing the water heater from the top. Simply remove the two latches for servicing and re-latch upon completion. No tools are required to obtain access to the top of the water heater.

TEMPERATURE AND PRESSURE RELIEF VALVE –

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Keep clear of the combination temperature and pressure relief valve discharge line outlet. The |

|

|

|

|||

|

|

|

|

|

ONLY |

|

|

|

|

|

discharge may be hot enough to cause scald injury. The water is under pressure and may splash. |

|

|

|

|||

|

|

For protection against excessive temperatures and pressure, install temperature and pressure protective |

|

|

|

|||

|

|

equipment required by local codes, but not less than a combination temperature and pressure relief |

|

|

|

|||

|

|

valve certified by a nationally recognized testing laboratory that maintains periodic inspection of |

|

|

|

|||

|

|

|

|

REFERENCE |

|

|

|

|

|

|

production of listed equipment or materials as meeting the requirements of the Standard for Relief |

|

|

|

|||

|

|

Valves and Automatic Gas Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22 and the |

|

|

|

|||

|

|

Standard CAN1-4.4 Temperature, Pressure, Temperature and Pressure Relief Valves and Vacuum |

|

|

|

|||

|

|

Relief Valves. The combination temperature and pressure relief valve must be marked with a |

|

|

|

|||

|

|

maximum set pressure not to exceed the maximum working pressure of the water heater. The |

|

|

|

|||

|

|

combination temperature and pressure relief valve rating must not be less than the hourly rating of the |

|

|

|

|||

|

|

water heater |

|

|

|

|

|

|

|

|

Install the combination temperature and pressure relief valve into the opening provided and marked for |

|

|

|

|||

|

|

this purpose on the water heater. |

FOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Some models may already be equipped or supplied with an installed combination temperature |

|

|

|

|||

|

|

and pressure relief valve. Verify that the combination temperature and pressure relief valve complies |

|

|

|

|||

|

|

with local codes. If the combination temperature and pressure relief valve does not comply with local |

|

|

|

|||

|

|

discharge line. It is recommendedVERSIONthat a minimum clearance of four (4) inches (10.0 cm) be provided |

|

|

|

|||

|

|

codes, replace it with one that does. Follow the installation instructions above on this page |

|

|

|

|||

|

|

Install a discharge line so that water discharged from the combination temperature and pressure relief |

|

|

|

|||

|

|

valve will exit within six (6) inches (15.2 cm) above, or any distance below the structural floor and |

|

|

|

|||

|

|

cannot contact any live electrical part. The discharge line is to be installed to allow for complete |

|

|

|

|||

|

|

drainage of both the combination temperature and pressure relief valve and the discharge line. The |

|

|

|

|||

|

|

discharge opening must not be subjected to blockage or freezing. DO NOT thread, plug or cap the |

|

|

|

|||

|

|

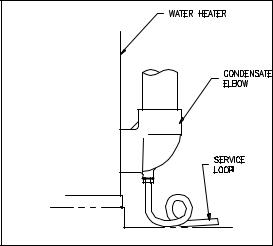

CONDENSATEINTERNETDRAIN – This water heater is a condensing type unit and requires a drain to be located |

in |

close |

||||

|

|

on the side of the water heater for servicing and maintenance of the combination temperature and |

|

|

||||

|

|

pressure relief valve. |

|

|

|

|

|

|

|

|

Do not place a valve between the combination temperature and pressure relief valve and the |

|

|

||||

|

|

tank! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

proximity to allow the condensate to drain safely. The condensate drains from the unit at the exhaust elbow located near the bottom of the unit. It is important that the condensate hose not be elevated above the exhaust elbow. The condensate build -up will block the exhaust outlet, which will cause improper operation. Refer to Figure 2 for an example of a service loop.

7

REFERENCE |

ONLY |

|

|

Figure 2. Condensate Elbow With Loop |

|

CLEANOUT – All models are equipped with a cleanout opening to aid in removal of hard water deposits from the tank bottom. If this water heater operates under hard water conditions, the following should be performed at least every 3 months: Turn off water supply and drain the water heater. Remove the cleanout jacket cover and tank cover. When cleaning the tank, care must be taken to avoid trying to break deposits loose as this could damage the glass lining and shorten the life of the water heater. After cleaning, re-install the cleanout tank cover and jacket

cover, and refill with water. |

Refer to the section, “Section X – Maintenance” in this Installation and Operating |

|

FOR |

Instruction manual for the procedures for filling and draining the water heater. |

|

SACRIFICIAL ANODES – |

Four sacrificial anode rods have been installed in the tank head to extend tank life. |

needed when using softened (or phosphate treated) water. Contact the installing contractor, or service provider that installed the water heater or the manufacturer listed on the rating plate for anode replacement information.

The anode rods should be inspected periodically for corrosion and replaced when necessary to prolong tank life. Water conditions in your area willVERSIONinfluence the time interval for inspection and replacement of the anode rods. The use of a water softener may increase the speed of anode consumption. More frequent inspection of the anodes is

DISHWASHING MACHINE REQUIREMENTS

All dishwashingINTERNETmachines meeting the National Sanitation Foundation requirements are designed to operate with water flow pressures between 15 and 25 pounds per square inch. Flow pressures above 25 pounds per square inch, or below 15 pounds per square inch, will result in improperly sanitized dishes.

The National Sanitation Foundation also recommends circulation of 180°F water. Where this is done, the circulation should be very gentle so that it does not cause any unnecessary turbulence inside the water heater. The circulation should be just enough to provide 180°F water at the point of take-off to the dishwashing machine. Adjust flow by means of the valve in the circulation line.

8

SECTION IV: INSTALLATION INSTRUCTIONS

|

|

|

WARNING |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

INSTALLATION OF THIS WATER |

HEATER REQUIRES ABILITY EQUIVALENT |

|

|

|

|

|

|

TO THAT OF A LICENSED |

TRADESMAN IN THE FIELD INVOLVED. |

|

|||

|

|

PLUMBING, AIR SUPPLY, VENTING, GAS SUPPLY AND ELECTRICAL WORK |

|

||||

|

|

ARE REQUIRED. |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

DO NOT ATTEMPT TO LIGHT |

ANY GAS APPLIANCE IF YOU ARE |

T |

|||

|

|

Liquefied petroleum gases/propane gas is heavier than air andREFERENCEwill remain at floor level if there |

|||||

|

|

CERTAIN OF THE FOLLOWING: |

|

ONLY |

|||

|

|

∙ Liquefied petroleum gases/propane gas and natural gas have an odorant added by the |

|||||

|

|

gas supplier that aids in detection of the gas. |

|

|

|

|

|

|

|

∙ Most people recognize this odor as a “sulfur” or “rotten egg” smell. |

|

|

|

|

|

|

|

∙ Other conditions, such as “odorant fade” can cause the odorant to diminish in |

|||||

|

|

intensity, or “fade”, and not be as readily detectable. |

|

|

|

|

|

|

|

∙ If you have a diminished sense of smell, or are in any way unsure of the presence of |

|||||

|

|

gas, immediately contact your gas supplier from a telephone in another building. |

|

|

|

|

|

|

|

∙ Gas detectors are available. Contact your gas supplier or plumbing professional for |

|||||

|

|

more information. |

FOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

is a leak. Basements, crawl spaces, closets and areas below ground level will serve as pockets |

|||||

|

|

for accumulation of leaking gas. Before lighting, smell all around the appliance area for gas. |

|||||

|

|

Be sure to smell next to the floor. |

|

|

|

|

|

|

|

IF YOU SMELL GAS: |

|

|

|

|

|

∙Do not try to light any appliance.

∙Do not touch any electric switch; do not use any telephone in your building.

∙Immediately call your gas supplier from a telephone in another building. Follow the gas supplier’s instructions.

∙If you cannot reach your gas supplier, call the fire department.VERSION

DO NOT OPERATE THE APPLIANCE UNTIL THE LEAKAGE IS CORRECTED!

INTERNET WARNING

This water heater must be located in an area where leakage of the tank, water line connections, or the combination temperature and pressure relief valve will not result in damage to the area adjacent to the water heater or to lower floors of the structure. When such locations cannot be avoided, a suitable drain pan must be installed under the water heater. The drain pan depth must be suitable for draining and collecting water, and have a minimum length and width of at least four (4) inches (10.0 cm) measured from the jacket of the water heater. The drain pan, as described above, can be purchased from your plumbing professional. The drain pan must be piped to an adequate drain. The piping must be at least ¾ inch (2.0 cm) in diameter and pitched for proper drainage.

9

UNPACKING

INSPECT SHIPMENT carefully for any signs of damage.

1.All equipment is carefully manufactured, inspected and packed.

2.Any claims for damage or shortage in shipment must be filed immediately with Bradford White Corporation and noted on the Bill of Lading.

3.Remove all venting components from the combustion assembly compartment by removing the latches.

|

NOTICE |

|

ONLY |

|

|

|

|

|

|

The vent terminals and the condensate elbow that is supplied with this water heater are stored at the top |

||||

in the Combustion Assembly Compartment. To access the vent terminals and condensate elbow, |

||||

unlatch the top lid and remove parts. Be sure to replace the top and relatch. |

|

|||

|

|

|

REFERENCE |

|

LOCATE WATER HEATER in front of final position before removing crate. |

|

|||

1. |

LOCATE so that venting connections will be short and direct. |

|

||

2. |

THIS WATER HEATER IS SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOOR. Do not |

|||

|

install this water heater on carpeting. |

|

|

|

3. |

FOR BASEMENT INSTALLATION, provide a solid level elevated base such as concrete. |

|||

4. |

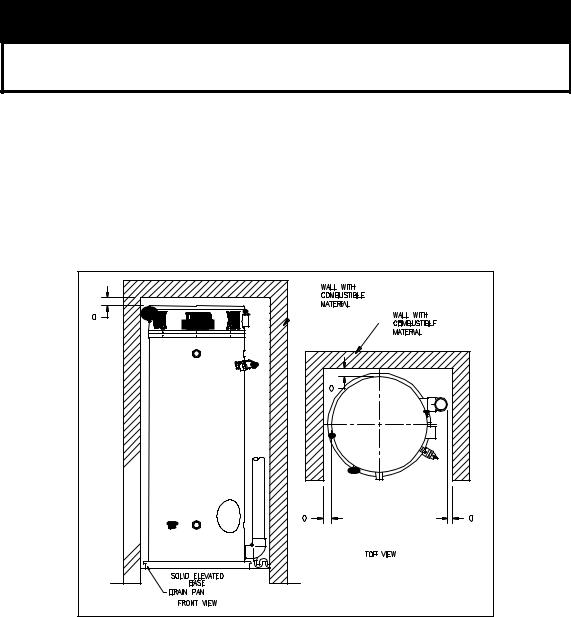

Minimum clearance to combustible material is 0” for the Top, Sides, and Rear of this water heater. |

|||

|

However, it is recommended that at least 18” from the Top, 24” from the Front, and 4” for the Sides, |

|||

|

and Rear of the water heater be provided for servicing. Clearance for servicing may be reduced down |

|||

|

to minimum clearance to combustible material, but service time and effort may be greatly increased. |

|||

|

VERSION |

FOR |

|

|

|

|

|

|

|

|

INTERNET |

|

|

|

|

Figure 3. Minimum Clearance To Combustible |

|

||

10

REMOVE CRATE

1.Remove all banding and pry off crate sides carefully so as not to damage the water heater.

2.Carefully roll/lift the water heater from the crate base.

CAUTION

CAUTION

Do not drop water heater. Do not bump water heater jacket against floor.

Do not bump exhaust vent pipe against crate or other objects. This will damage the heater and cause it to be inoperable or create nuisance problems.

|

|

|

ONLY |

|

MOVE WATER HEATER TO PERMANENT POSITION by sliding or walking. Place drain pan underneath |

|

|||

water heater |

|

|

||

INSTALL TEMPERATURE AND PRESSURE RELIEF VALVE (if not already installed). |

|

|

||

|

|

|

|

|

|

|

REFERENCE |

|

|

|

|

WARNING |

|

|

Temperature and pressure relief valve discharge piping must be piped near floor to eliminate potential of severe burns . Do not pipe in any area where freezing could occur. Do not install any shut-off valves, plugs or caps to the temperature and pressure relief valve or piping.

CAUTION

CAUTION

If building cold water supply has a back-flow preventer,FORcheck valve or water meter with check valve, provisions for thermal expansion of water in the hot water system must be provided.

Temperature setting should not exceed safe temperature at fixtures. See water temperature control warning on page 16. If higher preheat temperatures are necessary to obtain adequate booster output, add an anti-scald valve for hot water supplied to fixtures.

LOCATIONINTERNET

VERSIONDANGER

KEEP APPLIANCE AREA CLEAR AND FREE OF COMBUSTIBLE MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND LIQUIDS.

This water heater must be located in an area where the general public does not have access to set temperatures.

AIR REQU REMENTS

1.Do not obstruct the flow of combustion and ventilating air.

2.For safe operation, adequate air is needed for combustion and ventilation. Sooting may result in serious damage to the water heater and risk of fire or explosion. It can also create a risk of asphyxiation. Such a condition often will result in a yellow, luminous burner flame, causing carboning or sooting of the combustion chamber, burner and flue tubes.

11

MECHANICAL EXHAUSTING OF ROOM AIR

1.Where an exhaust fan is installed in the same room with this water heater and combustion air is drawn from inside the room, sufficient openings for air must be provided in the walls. UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO THE ROOM THROUGH THE WATER HEATER’S VENTING SYSTEM, CAUSING POOR COMBUSTION THAT MAY BE HAZARDOUS TO LIFE. SOOTING MAY RESULT IN SERIOUS DAMAGE TO THE WATER HEATER AND RISK OF FIRE OR EXPLOSION WHICH CAN ALSO CREATE A RISK OF ASPHYXIATION. Refer to local codes and /or National Fuel Gas Code for proper air opening sizing.

UNCONFINED SPACE

1. |

In buildings of conventional frame, brick or stone construction, unconfined spaces may provide adequate |

|

air for combustion and ventilation. |

2. |

If the unconfined space is within a building of tight construction (buildings using the following |

|

construction: weather stripping, heavy insulation, caulking, vapor barrier, etc.), airONLYfor combustion and |

|

ventilation must be obtained from outdoors. This may be accomplished by piping air directly to the water |

|

REFERENCE |

|

heater from outside or providing opening or ducts in the wall. The installation instructions for confined |

spaces in tightly constructed buildings must be followed to ensure adequate air supply.

1.When drawing combustion air from inside a conventionally constructed building to a confined space, such a space shall be provided with two permanent openings.

∙The top opening is to be located within twelve (12) inches of the enclosure top and the bottom opening within twelve (12) inches of the enclosure bottom.

∙Each opening shall have a free area of at least one square inch per 1000 Btu/h of the total input of all appliances in the enclosure, but not less than 100 square inches.

2.If the confined space is within a building of tight construction, air for combustion and ventilation must be obtained from outdoors. This may be accomplished by piping air directly to the water heater from outside or providing opening or ducts in the wall. When directly communicating with the outdoors through vertical ducts, two permanent openings, located in the above manner, shall be provided.

∙Each opening shall have a free area of not less than one square inch per 4000 Btu/h of the total input of all appliances in the enclosure.

∙If horizontal ducts are used, each opening shall have a free area of not less than one square inch per 2000 Btu/h of the total input of all appliances in the enclosure.

3.If the water heater is installed as a direct vent (outside air piped directly to the water heater), then additional opening, other than the opening for the air intake, are not required. However, adequate ventilation air must be provided in all cases to prevent increased room temperature.

CHEMICALINTERNETVAPOR CORROSION

Corrosion of the flue ways and vent system will occur if air for combustion contains certain chemical vapors. Such corrosion may result in poor combustion and create a risk of asphyxiation. Spray can propellants, cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride, waxes and process chemicals are corrosive. Products of this sort should not be stored near the water heater or outside by the air intake (if applicable).

12

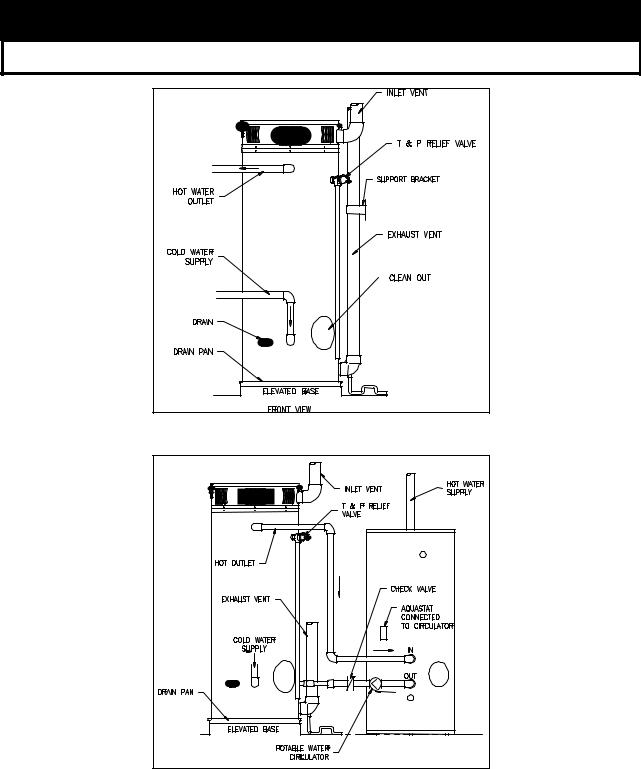

TYPICAL INSTALLATION ILLUSTRATION

CAUTION

CAUTION

If building cold water supply has a back-flow preventer, check valve or water meter with check valve provisions for thermal expansion of water in the hot water system must be provided.

|

|

REFERENCE |

ONLY |

|

FOR |

|

|

|

|

|

|

Figure 4. Typical Front Inlet Connection |

|

||

VERSION |

|

|

|

INTERNET |

|

|

|

Figure 5. Typical Front Inlet Connect with Storage Heater

13

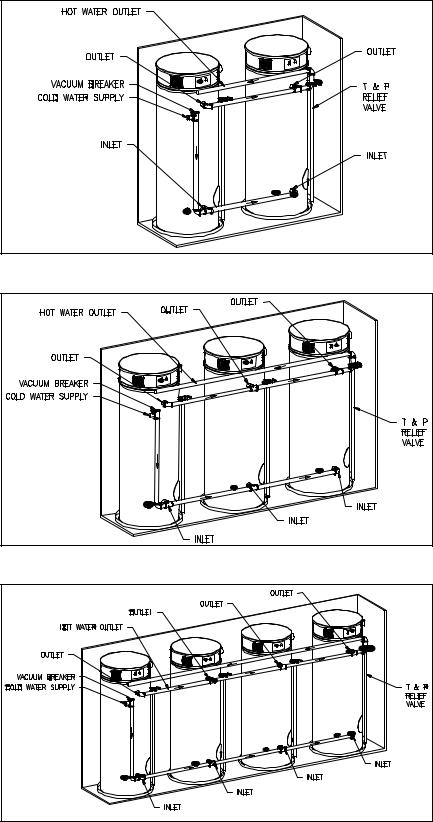

Figure 6. Typical Two Water Heater Connection |

ONLY |

||

|

|||

|

FOR |

REFERENCE |

|

|

|

|

|

Figure 7. Typical Three Water Heater Connection |

|

||

VERSION |

|

|

|

INTERNET |

|

|

|

Figure 8. Typical Four Water Heater Connection

14

Loading...

Loading...