BOSCH GST 65, GST 65 B, GST 65 E, GST 65 BE User Manual

OBJ_BUCH-286-001.book Page 1 Tuesday, October 24, 2006 12:54 PM

GST 65

GST 65 B

GST 65 E

GST 65 BE

PROFESSIONAL

Operating Instructions

Petunjuk-Petunjuk untuk Penggunaan

Hõëng dÿn s¥ dông

Instructions d’emploi

ÁU~²Ýœ ÈULM¼«—

OBJ_BUCH-286-001.book Page 2 Tuesday, October 24, 2006 12:54 PM

English . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Bahasa Indonesia . . . . . . . . . . . . . . . . . Halaman 33

Tiøng Vi·t . . . . . . . . . . . . . . . . . . . . . . .Trang 40

Français . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

ΔΤϔλ 56 |

vÝ—U . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

ϪΤϔλ 62 |

2 |

|

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 3 Tuesday, October 24, 2006 12:54 PM

3 |

|

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 4 Tuesday, October 24, 2006 12:54 PM

2

1

6 |

|

|

3 |

5 |

4 |

GST 65 |

|

PROFESSIONAL |

|

A |

|

8 |

8 |

|

|

7 |

7 |

|

5 |

8 |

8 |

|

5 |

4 |

1 609 929 K70 • 24.10.06 |

OBJ_BUCH-286-001.book Page 5 Tuesday, October 24, 2006 12:54 PM |

|

||

B |

C |

|

|

9 |

|

|

|

3 |

3 |

|

|

10 |

11 |

||

|

|||

|

|

12 |

|

D |

E |

|

|

|

13 |

|

|

3 |

10 |

|

|

14 |

|

||

F |

|

|

G |

|

|

|

|

|

18 |

15 |

16 |

17 |

15 |

16 |

5 |

|

|

|

1 609 929 K70 • 24.10.06 |

OBJ_BUCH-286-001.book Page 6 Tuesday, October 24, 2006 12:54 PM

General Power Tool Safety

Warnings

|

Read all safety warnings and all |

|

WARNING |

||

instructions. Failure to follow the |

||

|

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-oper- ated (cordless) power tool.

1)Work area safety

a)Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b)Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

c)Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2)Electrical safety

a)Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

b)Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c)Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

d)Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e)When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f)If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) or an earth leakage circuit breaker (ELCB). Use of a GFCI or an ELCB reduces the risk of electric shock.

3)Personal safety

a)Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

b)Use personal protective equipment. Always wear eye protection. Protective equipment such as dusk mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

c)Prevent unintentional starting. Ensure the switch is in the off position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

d)Remove any adjusting key or wrench before turning the power tool on. A wrench or a key that is left attached to a rotating part of the power tool may result in personal injury.

e)Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

f)Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

g)If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dustrelated hazards.

4)Power tool use and care

a)Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it is designed.

b)Do not use the power tool if the switch does not turn it on or off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

c)Disconnect the plug from the power source and/or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

|

6 | English |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 7 Tuesday, October 24, 2006 12:54 PM

d)Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e)Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f)Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

g)Use the power tool, accessories, tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

5)Service

a)Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Power Tool-specific Safety

Warnings

fKeep hands away from the sawing range. Do not reach under the workpiece. Contact with the saw blade can lead to injuries.

fApply the power tool to the workpiece only when switched on. Otherwise there is danger of kickback when the cutting tool jams in the workpiece.

fPay attention that the base plate 3 rests securely on the material while sawing. A jammed saw blade can break or lead to kickback.

fWhen the cut is completed, switch off the power tool and then pull the saw blade out of the cut only after it has come to a standstill. In this manner you can avoid kickback and can place down the power tool securely.

fUse only sharp, flawless saw blades. Bent or unsharp saw blades can break or cause kickback.

fDo not brake the saw blade to a stop by applying side pressure after switching off. The saw blade can be damaged, break or cause kickback.

fUse suitable detectors to determine if utility lines are hidden in the work area or call the local utility company for assistance. Contact

with electric lines can lead to fire and electric shock. Damaging a gas line can lead to explosion. Penetrating a water line causes property damage or may cause an electric shock.

f Hold the power tool only by the insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own power cord. Contact with a “live” wire will also make exposed metal parts of the power tool “live” and shock the operator.

f Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

f Do not work materials containing asbestos.

Asbestos is considered carcinogenic.

f Take protective measures when dust can develop during working that is harmful to one’s health, combustible or explosive. Example: Some dusts are regarded as carcinogenic. Wear a dust mask and work with dust/chip extraction when connectable.

fKeep your workplace clean. Blends of materials are particularly dangerous. Dust from light alloys can burn or explode.

fAlways wait until the power tool has come to a complete stop before placing it down. The tool insert can jam and lead to loss of control over the power tool.

fDo not use the power tool with a damaged cord. Do not touch the damaged cord and pull the plug from the outlet when the cord is damaged while working. Damaged cords increase the risk of an electric shock.

fConnect power tools that are used in the open via a ground fault circuit interrupter (GFCI).

Functional Description

Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

While reading the operating instructions, unfold the graphics page for the tool and leave it open.

Intended Use

The power tool is intended for making separating cuts and cut-outs in wood, plastic, metal, ceramic plates and rubber while resting firmly on the workpiece. It is suitable for straight and curved cuts with miter angles to 45°. The saw blade recommendations are to be observed.

|

1 609 929 K70 • 24.10.06 |

|

|

English | 7 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 8 Tuesday, October 24, 2006 12:54 PM

Technical Data

Jigsaw |

|

GST 65 |

GST 65 E |

|

|

GST 65 B |

GST 65 BE |

|

|

PROFESSIONAL |

PROFESSIONAL |

Article number |

|

3 601 E09 1.. |

3 601 E09 2.. |

Stroke rate control |

|

– |

z |

Rated power input |

W |

400 |

400 |

Output power |

W |

230 |

230 |

Stroke rate at no load n0 |

spm |

3100 |

500 – 3100 |

Stroke |

mm |

18 |

18 |

Cutting capacity, max. |

|

|

|

– in wood |

mm |

65 |

65 |

– in aluminum |

mm |

12 |

12 |

– in non-alloy steel |

mm |

3 |

3 |

Bevel cuts (left/right), max. |

° |

45 |

45 |

Weight according to EPTA-Procedure 01/2003 |

kg |

1.7 |

1.7 |

Protection class |

|

/ II |

/ II |

The values given are valid for nominal voltages [U] of 230/240 V. For lower voltages and models for specific countries, these values can vary.

Please observe the article number on the type plate of your power tool. The trade names of individual tools may vary.

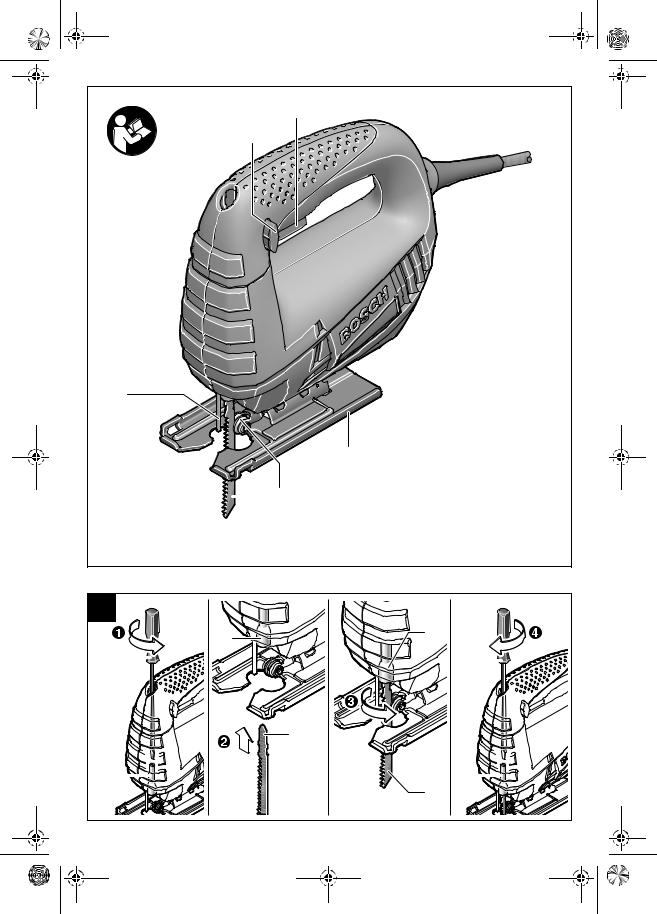

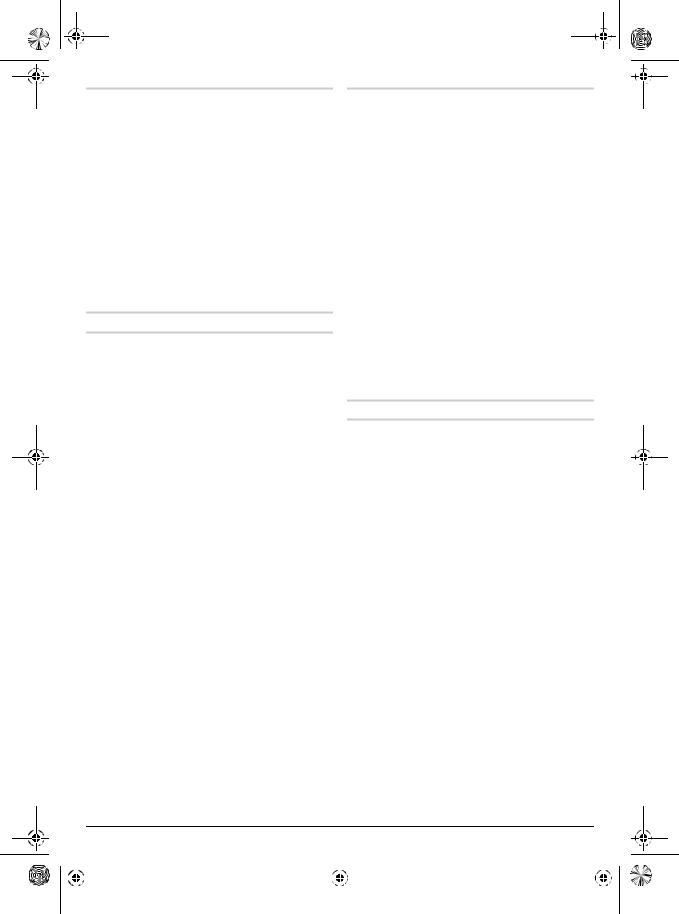

Product Features

The numbering of the product features refers to the illustration of the power tool on the graphics page.

1 Lock-on button for On/Off switch

2 On/Off switch

3 Base plate

4 Guide roller

5 Saw blade*

6 Contact protector

7 Screwdriver

8 Stroke rod

9 Splinter guard*

10Screw(2x)

11Scale for miter angle

12Angle gauge**

13Bolt hole

14Positioning pin/mark

15Lead for the parallel guide

16Locking screw for parallel guide*

17Parallel guide with circle cutter*

18Centering tip of the parallel guide*

*The accessories illustrated or described are not included as standard delivery.

**Commercially available (not included in the delivery scope)

Assembly

Replacing/Inserting the Saw Blade

fBefore any work on the power tool itself, pull the mains plug.

fWhen mounting the saw blade, wear protective gloves. Danger of injury when touching the saw blade.

Selecting a Saw Blade

An overview of recommended saw blades can be found at the end of these instructions. Use only T-shank saw blades. The saw blade should not be longer than required for the intended cut.

Use a thin saw blade for narrow curve cuts.

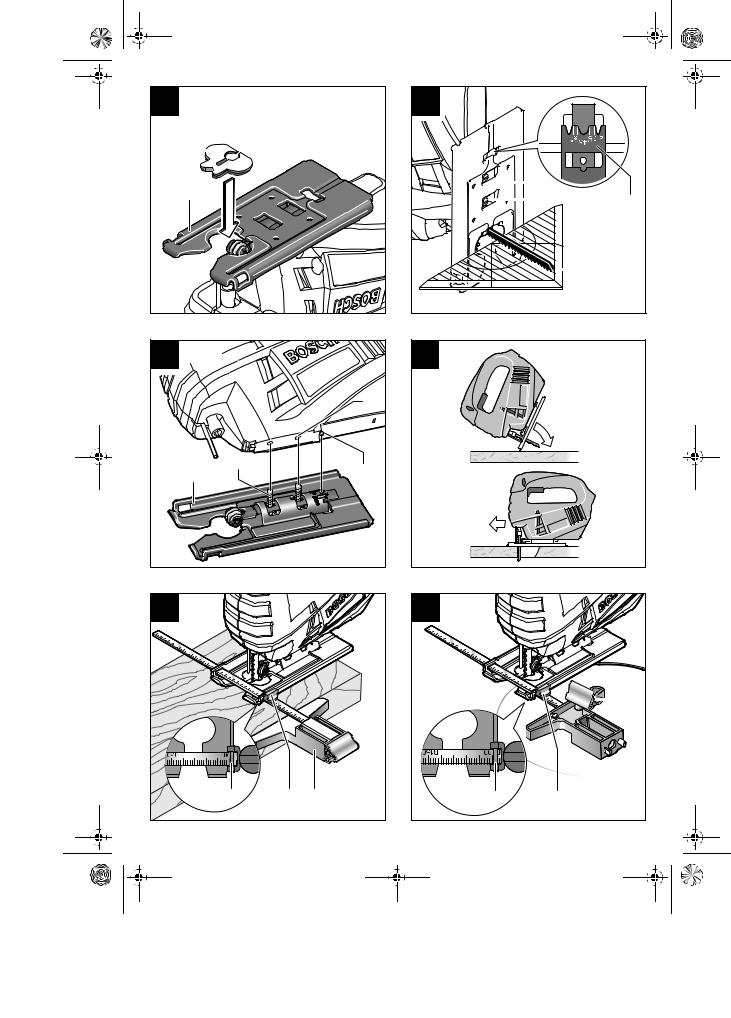

Inserting the Saw Blade (see figure A)

•Loosen the screws 10 until the assembly plate with the guide roller 4 can be moved toward the rear.

•Insert the screwdriver 7 from above into the stroke rod 8 and turn approx. 3 – 4 turns in counterclockwise direction.

•Insert the saw blade 5 lateral to the cutting direction into the stroke rod 8.

•Turn the saw blade 5 so that the toothing faces toward the cutting direction. Pull the saw blade 5 a little downward until it engages.

•Insert the screwdriver 7 from above into the stroke rod 8 and turn in clockwise direction until the saw blade 5 is locked.

•Push the assembly plate with the guide roller 4 forwards until it faces against the back of the saw blade and tighten the screws 10 again.

f Check the tight seating of the saw blade. A loose saw blade can fall out and lead to injuries.

|

8 | English |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 9 Tuesday, October 24, 2006 12:54 PM

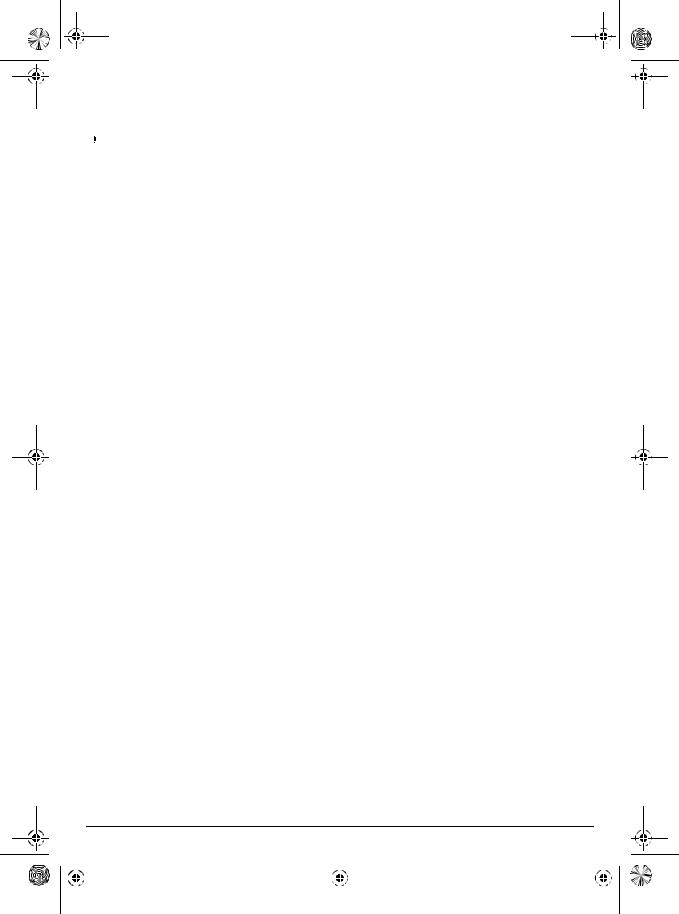

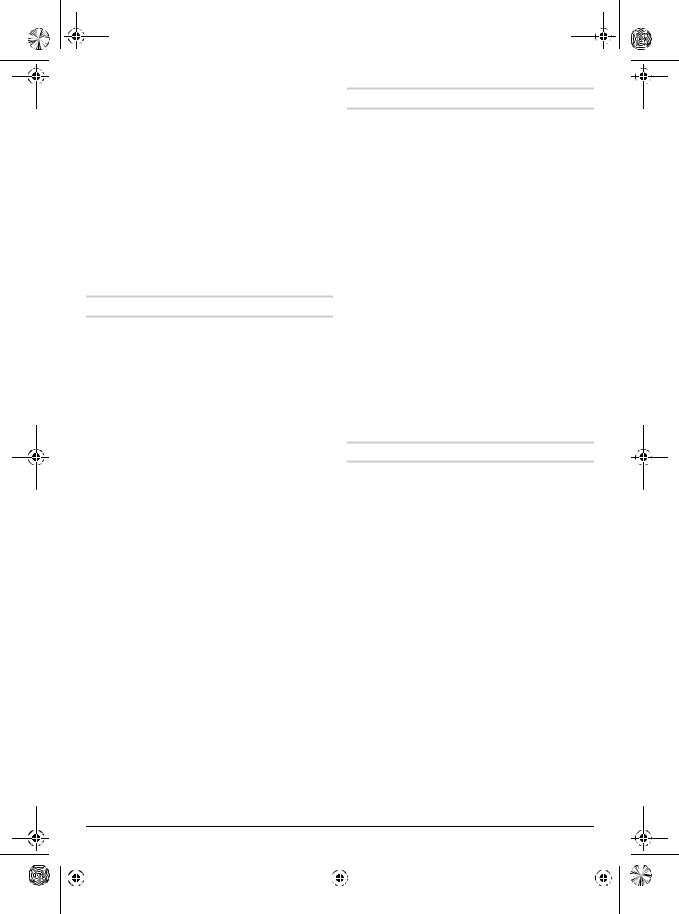

Splinter Guard (see figure B)

fBefore any work on the power tool itself, pull the mains plug.

The splinter guard 9 (accessory) can prevent fraying of the surface while sawing wood. The splinter guard can only be used for certain saw blade types and only for cutting angles of 0°. When sawing with the splinter guard, the base plate 3 must not be moved back for cuts that are close to the edge.

Press the splinter guard 9 from the bottom into the base plate 3.

Operation

Operating Modes

fBefore any work on the power tool itself, pull the mains plug.

Adjusting the Cutting Angle (see figure C)

The base plate 3 can be swivelled by 45° to the left or right for bevel cuts.

•Loosen the screws 10 and lightly push the base plate 3 in the direction of the saw blade 5.

•For adjustment of precise bevel angles, the base plate has adjustment notches on the left and right at 0° and 45°. Swivel the base plate 3 to the desired position according to the scale 11. Other bevel angles can be adjusted using a protractor.

•Afterwards, push the base plate 3 to the stop toward the power cable.

•Push the assembly plate with the guide roller 4 forwards until it faces against the back of the saw blade and tighten the screws 10 again.

The splinter guard 9 can not be inserted for miter cuts.

Offsetting the Base Plate (see figure D)

For sawing close to edges, the base plate 3 can be offset to the rear.

•Completely unscrew the screws 10.

•Lift the base plate 3 off and offset it in such a manner that the front screw 10 can be screwed into the rear bolt hole 13. The second screw 10 is not required for sawing with the base plate offset.

•Push the base plate 3 toward the positioning pin/mark 14 until it engages and slide the assembly plate with the guide roller 4 forwards against the saw blade back. Then tighten the screw 10.

Sawing with the base plate 3 offset is possible only with a bevel angle of 0°. In addition, the parallel guide with circle cutter 17 (accessory) as well as the splinter guard 9 may not be used.

Starting Operation

fObserve correct mains voltage! The voltage of the power source must agree with the voltage specified on the type plate of the power tool.

Switching On and Off

To start the power tool, press the On/Off switch 2 and keep it pressed.

To lock the pressed On/Off switch 2, push the lock-on button 1 toward the right or left.

To switch off the machine, release the On/Off switch 2. When the On/Off switch 2 is locked, press it first and then release it.

After longer periods of work at low stroke rate, the machine can heat up considerably. Remove the saw blade from the power tool and allow the machine to cool down by running it for approx. 3 minutes at maximum stroke rate.

Controling the Stroke Rate (GST 65 E/GST 65 BE)

Increasing or reducing the pressure on the On/Off switch 2 enables stepless stroke-rate control of the switched-on machine.

Light pressure on the On/Off switch 2 results in a low stroke rate. Increasing the pressure also increases the stroke rate.

When the On/Off switch 2 is locked, it is not possible to reduce the stroke rate.

Working Instructions

f When working small or thin work pieces, always use a sturdy support or a saw table (accessory).

Check wood, press boards, building materials, etc. for foreign objects such as nails, screws or similar, and remove them, if required.

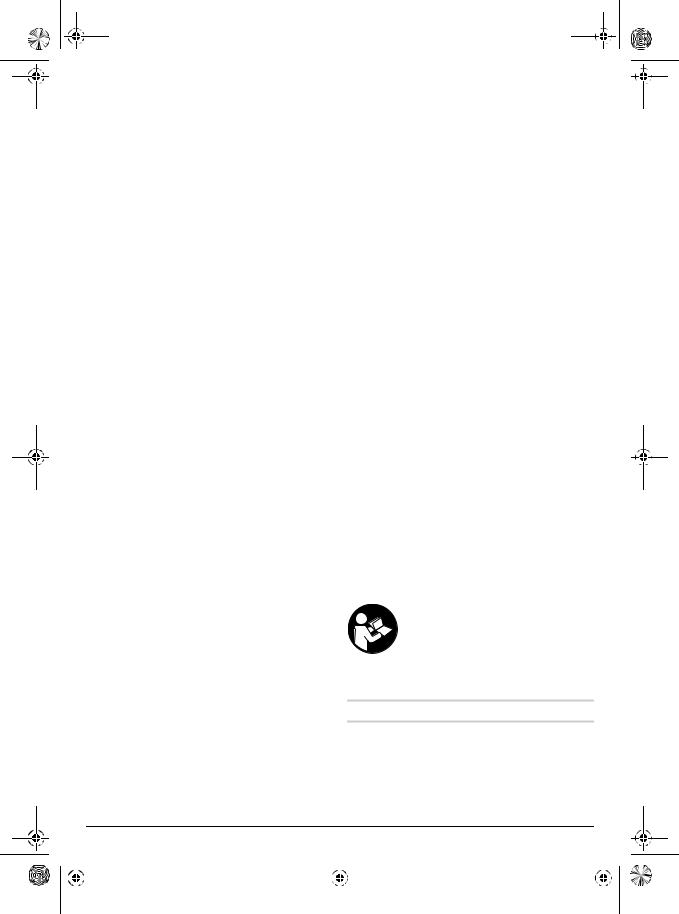

Plunge Cutting (see figure E)

fThe plunge cutting procedure is only suitable for working soft materials such as wood, plaster board or similar! Do not work metal materials with the plunge cutting procedure!

Use only short saw blades for plunge cutting. Plunge cutting is possible only with the bevel angle set at 0°.

Place the machine with the front edge of the base plate 3 on to the workpiece without the saw blade 5 touching the workpiece and switch on. For machines with stroke rate control, select the maximum stroke rate. Firmly hold the machine against the workpiece and by tilting the machine, slowly plunge the saw blade into the workpiece.

When the base plate 3 fully lays on the workpiece, continue sawing along the desired cutting line.

|

1 609 929 K70 • 24.10.06 |

|

|

English | 9 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 10 Tuesday, October 24, 2006 12:54 PM

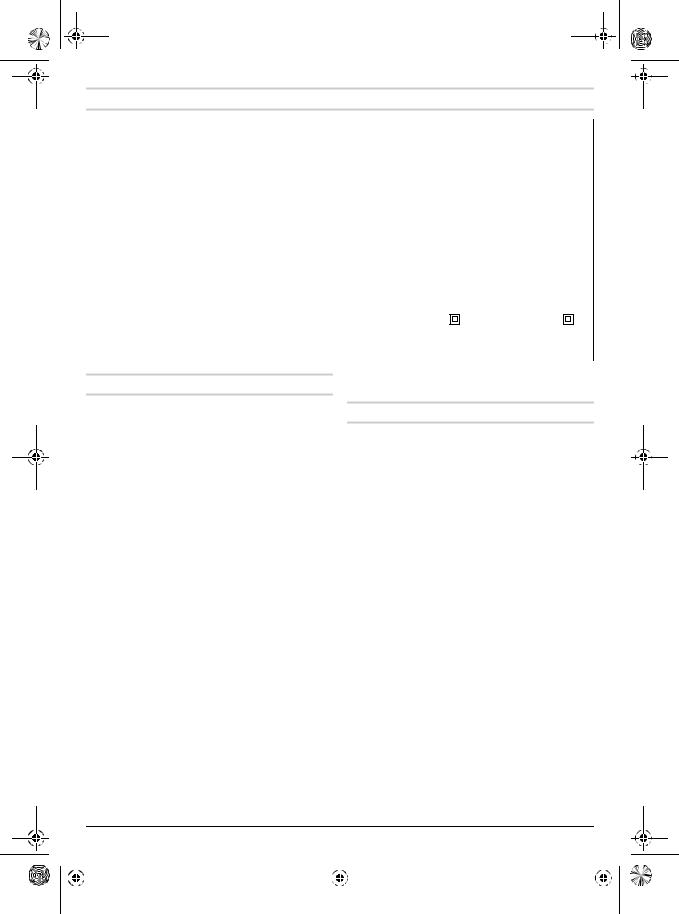

Parallel Guide with Circle Cutter (Accessory)

For cuts using the parallel guide with circle cutter 17 (accessory), the thickness of the material must not exceed a maximum of 30 mm.

Parallel cuts (see figure F): Loosen the locking screw 16 and slide the scale of the parallel guide through the lead 15 in the base plate. Set the desired cutting width as the scale value on the inside edge of the base plate. Tighten the locking screw 16.

Circular cuts (see figure G): Set the locking screw 16 to the other side of the parallel guide. Slide the scale of the parallel guide through the lead 15 in the base plate. Drill a hole in the workpiece centered in the section to be sawn. Insert the centering tip 18 through the inside opening of the parallel guide and into the drilled hole. Set the radius as the scale value on the inside edge of the base plate. Tighten the locking screw 16.

Coolant/Lubricant

When sawing metal, coolant/lubricant should be applied alongside cutting line because of the material heating up.

Maintenance and Service

Maintenance and Cleaning

fBefore any work on the power tool itself, pull the mains plug.

fFor safe and proper working, always keep the power tool and the ventilation slots clean.

Clean the saw blade holder regularly. For this, remove the saw blade from the machine and lightly tap out the power tool on a level surface.

Heavy contamination of the power tool can lead to malfunctions. Therefore, do not saw materials that produce a lot of dust from below or overhead.

f In extreme working conditions, conductive dust can accumulate in the interior of the power tool when working with metal. The protective insulation of the power tool can be degraded. The use of a stationary extraction system is recommended in such cases as well as frequently blowing out the ventilation slots and installing a ground fault circuit interrupter (GFCI).

Lubricate the guide roller 4 occasionally with a drop of oil.

Check the guide roller 4 regularly. If worn, it must be replaced through an authorized Bosch after-sales service agent.

If the power tool should fail despite the care taken in manufacturing and testing procedures, repair should be carried out by an after-sales service center for Bosch power tools.

In all correspondence and spare parts orders, please always include the 10-digit article number given on the type plate of the power tool.

Service and Customer Assistance

Exploded views and information on spare parts can be found under:

www.bosch-pt.com

In case of a claim, repair or purchase of replacement parts or in case of queries or other problems, please contact your local dealer or Bosch representative.

People’s Republic of China

Website: www.bosch-pt.com.cn

China Mainland

Bosch Power Tools (China) Co., Ltd. 567, Bin Kang Road

Bin Jiang District 310052 Hangzhou, P.R.China

Service Hotline: . . . . . . . . . . . . . . . . . . 800 8 20 84 84. . . . . . . . . . . . . . . . . . . . . . . . +86 571 87 77 43 38 Fax . . . . . . . . . . . . . . . . . . . . . . . . +86 571 87 77 45 02

HK and Macau Special Administrative Regions

Melchers (H.K.) Ltd, Room 1210 Shun Tak Centre, West-Tower

168 – 200 Connaught Road, Central Hong Kong Customer Service Hotline: . . . . . . . +852 25 89 15 61 Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . +852 25 48 79 14 E-Mail: bosch@melchers.com.hk

Indonesia

P. T. Multi Tehaka

Karang Anyar Permai Block B-24 Jl. Karang Anyar No. 55

Jakarta Pusat 10740 Indonesia

. . . . . . . . . . . . . . . . . . . +62 21 6 59 52 22 (5 lines) Fax . . . . . . . . . . . . . . . . . . . . . . . +62 21 6 59 52 52 – 3 sales@bosch.co.id

www.bosch.co.id

Phillippines

Robert Bosch, Inc. Zuellig Building

Sen. Gil Puyat Avenue

Makati City 1200, Metro Manila Philippines

. . . . . . . . . . . . . . . . . . . . . . . . . . . +63 2 8 17 32 31 www.bosch.com.ph

|

10 | English |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 11 Tuesday, October 24, 2006 12:54 PM

Malaysia

Robert Bosch (SEA.) Pte. Ltd. No. 8a, Jalan 13/6

Selangor Darul Ehsan

Petaling Jaya 46200 Malaysia

. . . . . . . . . . . . . . . . . . . . . . . . . . +60 3 79 58 30 00 Fax (EW Dept.) . . . . . . . . . . . . . . . +60 3 79 58 38 38 www.bosch.com.sg

Thailand

Robert Bosch Ltd. Liberty Square Building No. 287, 11 Floor Silom Road, Bangrak Bangkok 10500

. . . . . . . . . . . . +66 2 6 31 18 79 – 18 88 (10 lines) Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 38 47 83 Robert Bosch Ltd., P. O. Box 2054

Bangkok 10501, Thailand

Bosch Service – Training Centre 2869-2869/1 Soi Ban Kluay

Rama IV Road (near old Paknam Railway) Prakanong District

10110 Bangkok Thailand

. . . . . . . . . . . . . . . . . . . . . . . . +66 26 71 78 00 – 4 Fax . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 49 42 96 Fax . . . . . . . . . . . . . . . . . . . . . . . . . . +66 2 2 49 52 99

Singapore

Robert Bosch (SEA.) Pte. Ltd. 38 C Jalan Pemimpin Singapore 915701

Republic of Singapore

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +65 3 50 54 94 Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . +65 3 50 53 27 www.bosch.com.sg

Vietnam

Saigon Trade Center

37 Ton Duc Thang St Ben Nghe Ward

Dist 1

HCMC

Vietnam

. . . . . . . . . . . . . . . . +84 8 9 11 13 74 – 9 11 13 75 Fax. . . . . . . . . . . . . . . . . . . . . . . . . . . +84 8 9 11 13 76

Australia and New Zealand

Robert Bosch Australia Pty. Ltd. RBAU/SPT

1555 Centre Road P.O. Box 66

3168 Clayton/Victoria

. . . . . . . . . . . . . . . . . . . . . +61 (0)1 / 3 00 30 70 44 Fax. . . . . . . . . . . . . . . . . . . . . +61 (0)1 / 3 00 30 70 45 www.bosch.com.au

Disposal

Power tools, accessories and packaging should be sorted for environmental-friendly recycling.

Subject to change without notice.

|

1 609 929 K70 • 24.10.06 |

|

|

English | 11 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 12 Tuesday, October 24, 2006 12:54 PM

/

" "

a) 昏暗的工作场所容易导致意外。

易引燃尘埃或易燃蒸汽。

b) 害的发生机率。

c)/

d) 整工具/ ,

e) 助您在突发状况下及时控制住电动工具。

f) 首饰容易被捲入转动的机件中。

2) |

g) |

|

b) 容易遭受电击。

高操作者遭受电击的危险。

e) 低操作者遭受电击的危险。

f) 流保护开关可以预防遭受电击。

a) 用电动工具时只要稍微分心便可能发生后果严重 的意外。

b) 将故障的机器送修。

c) 必须先从插座上拔出插头并且/

d) 动工具容易发生意外。

e) 彻底执行机器的维护工作容易导致工作意外。

f) 操作。

|

12 | |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 13 Tuesday, October 24, 2006 12:54 PM

g)f

a) 器的安全性能。

f 果不小心碰触了锯片可能被割伤。

f3

f 可能造成操作者触电。

f 用手持握工件更牢固。

f 起爆炸。

f 具。

fFI-

並且/

45

|

1 609 929 K70 • 24.10.06 |

|

|

| 13 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 14 Tuesday, October 24, 2006 12:54 PM

|

|

GST 65 |

GST 65 E |

|

|

GST 65 B |

GST 65 BE |

|

|

PROFESSIONAL |

PROFESSIONAL |

|

|

3 601 E09 1.. |

3 601 E09 2.. |

|

|

– |

z |

|

|

400 |

400 |

|

|

230 |

230 |

n0 |

/ |

3100 |

500 – 3100 |

|

|

18 |

18 |

|

|

|

|

– |

|

65 |

65 |

– |

|

12 |

12 |

– |

|

3 |

3 |

/ |

° |

45 |

45 |

EPTA-Procedure 01/2003 |

|

1,7 |

1,7 |

|

|

/ II |

/ II |

230/240 V

1 |

|

2 |

|

3 |

|

4 |

|

5 |

* |

6 |

|

7 |

|

8 |

|

9 |

* |

10(2x)

12**

14/

16*

17*

18*

*

**

/

f 拔出插头。

f 被割伤。

(T-

A

•10 4

•7 83 4

•5 8

•5 5

•7 85

•4 10

f 害您。

|

14 | |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 15 Tuesday, October 24, 2006 12:54 PM

B |

|

|

f 拔出插头。

9 0 3

9 3

f 拔出插头。

C

345

•10 5 3

•3 045 11

•3

•4 10

9

D 3

•10

•3 1013 10

•3 14 4 10

3 0 179

f 标示的电压一致。

/

2

2 1

2 2

3

(GST 65 E/GST 65 BE)

2

2

2

上拔除。

E

f 可以在金属上进行潜锯。

0

3 5

3

1730

F : 1615

16

|

1 609 929 K70 • 24.10.06 |

|

|

| 15 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 16 Tuesday, October 24, 2006 12:54 PM

G : 1615 18

16

/

剂或润滑剂。

f 拔出插头。

f 高工作品质和安全性。

垢。

不可以仰头锯割会产生大量灰尘的工件。

fFI-

4

4

的顾客服务处修理。

10

www.bosch-pt.com

询。

www.bosch-pt.com.cn

567

310052 . . . . . . . . . . . . . . . . . . . . . 800 8 20 84 84

. . . . . . . . . . . . . . . . . . . . . . . .+86 571 87 77 43 38. . . . . . . . . . . . . . . . . . . . . . . .+86 571 87 77 45 02

香港上环干诺道中168 – 2001210

. . . . . . . . . . . . . . . . . . +852 25 89 15 61. . . . . . . . . . . . . . . . . . . . . . . . . . +852 25 48 79 14bosch@melchers.com.hk

和废弃的包装材料。

|

16 | |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 17 Tuesday, October 24, 2006 12:54 PM

/

" "

a) 昏暗的工作場所容易導致意外。

易引燃塵埃或易燃蒸汽。

合適的插座可以降低遭受電擊的危險。

b) 容易遭受電擊。

高操作者遭受電擊的危險。

e) 低操作者遭受電擊的危險。

f) 流保護開關可以預防遭受電擊。

a) 用電動工具時只要稍微分心便可能發生後果嚴重 的意外。

b) 害的發生機率。

c)/

d) 整工具/ ,

e) 助您在突發狀況下及時控制住電動工具。

f) 首飾容易被捲入轉動的機件中。

g) 體。

b) 將故障的機器送修。

c) 必須先從插座上拔出插頭并且/

d) 動工具容易發生意外。

e) 徹底執行機器的維護工作容易導致工作意外。

f) 操作。

|

1 609 929 K70 • 24.10.06 |

|

|

| 17 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 18 Tuesday, October 24, 2006 12:54 PM

g)f

a) 器的安全性能。

f 果不小心碰觸了鋸片可能被割傷。

f3

f 可能造成操作者觸電。

f 比用手持握工件更牢固。

f 起爆炸。

f 具。

fFI-

並且/

翻開折疊

45

|

18 | |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 19 Tuesday, October 24, 2006 12:54 PM

|

|

GST 65 |

GST 65 E |

|

|

GST 65 B |

GST 65 BE |

|

|

PROFESSIONAL |

PROFESSIONAL |

|

|

3 601 E09 1.. |

3 601 E09 2.. |

|

|

– |

z |

|

|

400 |

400 |

|

|

230 |

230 |

n0 |

/ |

3100 |

500 – 3100 |

|

|

18 |

18 |

|

|

|

|

– |

|

65 |

65 |

– |

|

12 |

12 |

– |

|

3 |

3 |

/ |

° |

45 |

45 |

EPTA-Procedure 01/2003 |

|

1,7 |

1,7 |

|

|

/ II |

/ II |

230/240 V

1 |

|

2 |

|

3 |

|

4 |

|

5 |

* |

6 |

|

7 |

|

8 |

|

9 |

* |

10(2x)

12**

14/

16*

17*

18*

*

**

/

f 拔出插頭。

f 被割傷。

(T-

A

•10 4

•7 83 4

•5 8

•5 5

•7 85

•4 10

f 害您。

|

1 609 929 K70 • 24.10.06 |

|

|

| 19 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OBJ_BUCH-286-001.book Page 20 Tuesday, October 24, 2006 12:54 PM

B |

|

|

f 拔出插頭。

9 0 3

9 3

f 拔出插頭。

C

345

•10 5 3

•3 045 11

•3

•4 10

9

D

3

•10

•3 1013 10

•3 14 4 10

3 0 179

f 標示的電壓一致。

/

2

2 1

2 2

3

(GST 65 E/GST 65 BE)

2

2

2

上拔除。

E

f 可以在金屬上進行潛鋸。

0

3 5

3

1730

F : 1615

16

|

20 | |

|

|

1 609 929 K70 • 24.10.06 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...