bosch CC 220 User Manual

Antriebsund Steuerungstechnik

CC 220

Connection Conditions

Part 1 and Part 2

Version 103

Automationstechnik

CC 220

Connection Conditions

Part 1 and Part 2

1070 073 301-103 (95.05) GB

(Z25 WJ and D25 GJ)

E 1995

by Robert Bosch GmbH,

All rights reserved, including applications for protective rights. Reproduction or handing over to third parties are subject to our written permission.

Discretionary charge 40.– DM

Contents

CC 220

Connection conditions

Contents

New or amended modules/sections (in relation to the previous edition of the manual) are identified with a • ‘". In the manual itself such changes are identified by means of correction bars in the margin.

Connection conditions part 1

Page

Safety notes ‘

Foreword ‘

1.System configuration

1.1 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. ‘ 1 − 1 |

1.2 |

Card rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 4 |

1.2.1 |

NC card rack 1.0 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 − 5 |

1.2.2 |

NC/PLC card rack 1.0 5/8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 − 6 |

1.2.3 |

NC/CL3 card rack 1.0 5/7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 6 |

1.2.4 |

Slot variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 7 |

1.3 |

Operating panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 14 |

1.3.1 |

14" standard colour panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 14 |

1.3.2 |

12" monochrome panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 25 |

1.3.3 |

14" special colour panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 34 |

1.4 |

Extended modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 51 |

1.4.1 |

MTB1 I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 51 |

1.4.2 |

Handwheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 59 |

1.4.3 |

ASCII keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 59 |

1.4.4 |

DNC interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 60 |

1.5 |

PLC couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 69 |

1.5.1 |

PIC 250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 70 |

1.5.2 |

CL 300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 72 |

1.5.3 |

PC 600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 73 |

1.5.4 |

Limits to PLC program generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 76 |

1.5.5 |

Possible PLC couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 78 |

1.5.6 |

PLC modules (AG/NC3 S, AG/Z S, E24/DC 95 way) . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 1 − 81 |

1.6 |

External expansion units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 87 |

1.6.1 |

DCR cassette player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 87 |

1.6.2 |

MiniCass cassette player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 89 |

1.6.3 |

Punched tape reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 91 |

1.6.4 |

Diskette unit CC disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 95 |

1.6.5 |

PG4 programming unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 96 |

1.6.6 |

XTRANS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 96 |

1.6.7 |

Biburn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 1 − 96 |

Contents − 1

Contents

CC 220

Connection conditions

2.Dimensions, installation and connection conditions

2.1 |

Dimensions − card rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 2 − 1 |

2.1.1 |

NC card rack 1.0 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 2 − 1 |

2.1.2 |

NC/PLC card rack 1.0 5/8 and NC/CL3 card rack 1.0 5/7 . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 − 2 |

2.2 |

Dimensions − operating panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 − 3 |

2.2.1 |

12" monochrome panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 − 3 |

2.2.2 |

14" colour panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 4 |

2.3 |

Dimensions − MTB1 I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2 − 5 |

2.4 |

Dimensions − ASCII keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 − 5 |

2.5 |

Dimensions − handwheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 6 |

2.6 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 7 |

2.6.1 |

Operating panel installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 7 |

2.6.2 |

Installing drawer with keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 8 |

2.6.3 |

Installing the MTB1 I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 9 |

2.6.4 |

Installing the electronic handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 9 |

2.6.5 |

Installing the card rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 10 |

2.7 |

Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 12 |

2.7.1 |

General data for power supply(ies) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 12 |

2.7.2 |

24 V power supply modules for load and logic supply . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 13 |

2.7.3 |

PE conductor and screening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 14 |

2.7.4 |

Interference suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 15 |

2.7.5 |

Voltage connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 17 |

2.7.6 |

Notes on switch cabinet construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 21 |

2.8 |

Field service conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 22 |

2.9 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 2 − 24 |

3.Plug in modules

3.1 |

CP/MEM5 computer/memory module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. ‘ 3 − 2 |

3.2 |

SERVO i servo loop interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 10 |

3.2.1 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 10 |

3.2.2 |

Measuring system inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 12 |

3.2.3 |

8 way analog input, high Speed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 3 − 22 |

3.2.4 |

Probe inputs / 5 V probe power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 26 |

3.2.5 |

Analog setpoint outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 29 |

3.3 |

I/O 24/0.2 module with PIC 250 (digital I/O with integrated PLC) . . . . . . . . . . . . . . . . . . |

‘ 3 − 31 |

3.4 |

NC PLC bit module (bit coupler) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 39 |

3.5 |

NC PLC Word3 module (word coupler) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 42 |

3.6 |

SCP2 module (serial couple processor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 45 |

3.7 |

PC I/O S module with intigratet PIC 250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 50 |

3.8 |

PS 75 power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

‘ 3 − 53 |

Contents − 2

Contents

CC 220

Connection conditions

Connection conditions part 2

Page

4.Digital interface

4.1 |

Interface tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 4 − 1 |

4.1.1 |

Signals from PLC to CNC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 4 − 2 |

4.1.2 |

Signals from CNC to PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 4 − 8 |

4.1.3 |

PLC input addresses of the MTB1 I/O inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 − 14 |

4.1.4 |

PLC output addresses of the MTB1 I/O outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 − 16 |

4.1.5 |

Signals to the machine (PIC 250 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 − 17 |

4.1.6 |

Signals from the machine (PIC 250 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 − 18 |

4.2 |

Signal descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 − 20 |

4.2.1 |

Control inputs (PLC outputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 − 22 |

4.2.2 |

Control outputs (PLC inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 − 92 |

4.3 |

Other signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 − 144 |

|

Ready2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 − 144 |

|

MTB I/O inputs/outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 − 144 |

|

High Speed I/O of the SERVO i control loop card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 − 145 |

4.4 |

Signal register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 − 150 |

Parts list ‘

Glossary

Contents − 3

Contents

CC 220

Connection conditions

Contents − 4

Safety notes

CC 220

Connection conditions

Safety notes

Pictograph and symbol explanations

The following warning stickers can be attached to control units themselves to draw attention to certain points:

’ Danger of electrocution!

’ Danger of battery leakage!

’ Danger: electrostatic components!

’ Remove plug before opening!

’Bolts only for PE conductor connection!

’ Only for cable screen connection!

Symbols used in the manual:

To draw attention to particular points:

IMPORTANT

IMPORTANT

(Under this heading are contained supplementary explanations, recommenda tions, information and tips)

To draw your attention to particular safety critical points or instructions:

CAUTION

CAUTION

(Damage to equipment can result if instructions are not observed! For example, files can be erased or modules can be damaged. Failure to observe instructions will invalidate the guarantee.)

CAUTION

CAUTION

(Damage to equipment or even personal injury can result if instructions are not

!observed.)

Safety notes

CC 220

Connection conditions

READY2 signal

Owing to the particular, safety critical significance with regard to drive movements or the evaluation of CNC digital I/Os, we draw your attention to the control signal READY2 (for relay contact, see section PS 75 in this manual; also the •Other sig nals" section of the chapter •Digital interface" in the manual •Connection condi tions part 2").

CAUTION

CAUTION

The READY2 contact must be networked to the emergency stop circuit!

!The control is not ready if the READY2 contact is open! For this reason all dan gerous functions must be made safe immediately after opening the contact!

System components / plug in modules

CAUTION

CAUTION

−All plug in modules may only be inserted or removed when the control is switched off!

−Unauthorised opening or removal of CNC components or improperly carried

!out repairs can result in death, physical injury or serious damage to equip ment!

−After removal or opening of casing or protective guards, or after opening the

!switch cabinet it is possible that certain system components will be exposed which are live and dangerous!

−Repairs or maintenance of CNC components may only be carried out by the

!Bosch Service Department or by maintenance centres authorised by Bosch.

−The modules contain components which can be destroyed by static dis charges! For this reason, ensure equipotential bonding before touching a module or components of the module.

−Plug in modules should only be transported in antistatic packaging!

−Do not place plug in modules on conductive surfaces, as this can result in buffered data being lost!

Screen connection / PE conductor connection

CAUTION

CAUTION

−Screen connections on the front side of the plug in modules can only be used for connecting cable screening and not for connecting a protective earth (PE)!

−Cable screening must have large surface contact with the strain relief clamp in the case of conductive plug housing. If no metallic/conductive plug hous ing can be used, the cable screening of the screen connection must be con nected to the respective module (taper pin)! Conductive plug housing is rec ommended.

Safety notes

CC 220

Connection conditions

Interfaces / interface modules

CAUTION

CAUTION

−Inadequate screening reduces immunity to interference and can lead to sys

!tem faults! Refer to the section •PE conductors and screening" in the chapter •Dimensions, installation and connection conditions", and to the respective pin assignment plans and diagrams given!

−Incorrect assignment of interface leads can destroy the interface chips! For this reason, check that the pin assignment is correct before using the inter face leads.

−Static discharges can destroy interface chips! For this reason, ensure equi potential bonding before touching the module/interface.

−In the case of interfaces which link together units in different locations (re

!gardless of the distance or supply system), the user must ensure absolute equipotential bonding between the units to be linked before the initial start up! Data terminal units to be coupled must be connected to the net work.

−Observe the connection conditions of the data terminal unit! If the data ter minal unit does not allow the interface cable to be connected or discon nected when voltage is applied, then the panel/CNC and the data terminal unit must also be switched off! Recommendation: only connect or discon nect connection cables when voltage is not applied.

Safety notes

CC 220

Connection conditions

Foreword

CC 220

Connection conditions

Foreword

This manual describes software version •Z25 WJ" for control unit CC 220 M and •D25 GJ" for control unit CC 220 T.

IMPORTANT

IMPORTANT

The group operating mode DIAGNOSIS contains instructions for the current con trol unit software version which may be accessed via the softkey DIAGNOSTIC CONTROL or SOFTWARE VERSION.

As the title suggests, this manual contains information required for normal oper ation of the control unit. For reasons of clarity, however, not every detail of every possible control variant can be included. Similarly, as the control unit is usually only part of a larger installation or system, not every conceivable aspect of integration, operation or maintenance is covered.

Your Bosch service branch or customer advisory service will be pleased to help you if you require more detailed information. Please contact them also if problems with the control unit should arise which are not sufficiently dealt with in this manual.

This manual is intended for technically qualified personnel.

CAUTION

CAUTION

Configuration, commissioning or maintenance may only be carried out by suitably

!qualified personnel! Such personnel must be able to recognise the dangers which can be caused by mechanical, electrical or electronic equipment.

Please consult our comprehensive training program. An overview of courses may be found on the inside front cover of this manual. Our training centre will be pleased to provide you with further information (Tel: 06062 / 78258).

Foreword

CC 220

Connection conditions

System configuration |

CC 220 |

General |

Connection conditions |

|

|

1.System configuration

1.1General

The CC 220 is a modular system, i.e. the various functional areas such as com puter, control loops etc. are located on separate plug in modules.

The card rack is provided to accommodate all the required plug in modules. It combines the individual modules to form a single electrical and mechanical entity (logic section). Three different types of card rack are available (NC card rack 1.0 5, NC/PLC card rack 1.0 5/8 and NC/CL3 card rack 1.0−5/7).

The control and the operator communicate (displays, inputs) via the operating panel. The panel is available as a 12" monochrome version (with grey tones) or as a 14" colour version.

Module MTB1 I/O is available as an additional module to the panel. Here signal cables can be connected to and from the machine panel, e.g. pushbuttons, lamps, handwheels, potentiometers, etc. These signals are then transmitted to the PLC via the CNC.

The ASCII keyboard is available also as an additional panel module for easy input (e.g. when programming the machine or using the CC 220 as a programming sta tion). A drop down drawer is available for space saving installation of the key board on the machine.

External CARD RACK add on

units (serial)

|

PLC |

|

|

COUPLING |

|

PANEL |

(Bit or |

|

word) |

||

|

||

|

ext. |

|

|

DNC |

|

|

computer |

ASCII |

MTB1 I/O |

keyboard |

|

CNC system configuration: overview

1 − 1

System configuration |

CC 220 |

General |

Connection conditions |

|

|

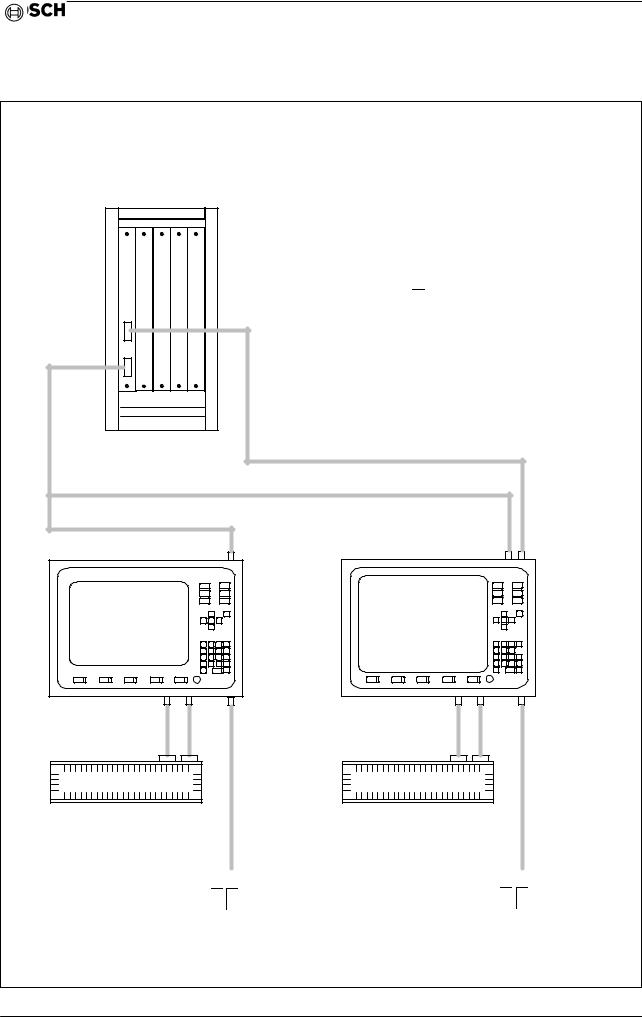

System configuration CC 220

CP/MEM5 |

SERVOi |

BLANKPANEL |

I/O |

PS75 |

X21 |

|

|

|

|

Example:

NC card rack

containing CP/MEM5 Servo i, I/O 24/0.2 and PS 75

and monochrome or colour panel

X22

|

|

X22 |

|

X22 |

X21 |

|

|

|

|

|

|

12" |

|

|

|

|

|

monochrome |

|

|

14" |

|

|

paper white |

|

or |

|

|

|

|

colour |

|

|

||

(order no. 063 |

|

|

(order no. 063 554) |

|

|

547) |

|

|

|

|

|

|

|

|

|

|

|

X62 |

X61 |

X71 |

X62 |

X61 |

X71 |

X62 |

X61 |

|

X62 |

X61 |

|

MTB1 I/O |

|

|

MTB1 I/O |

|

|

|

|

ASCII keyboard |

|

|

|

|

ASCII keyboard |

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 − 2

System configuration |

CC 220 |

General |

Connection conditions |

|

|

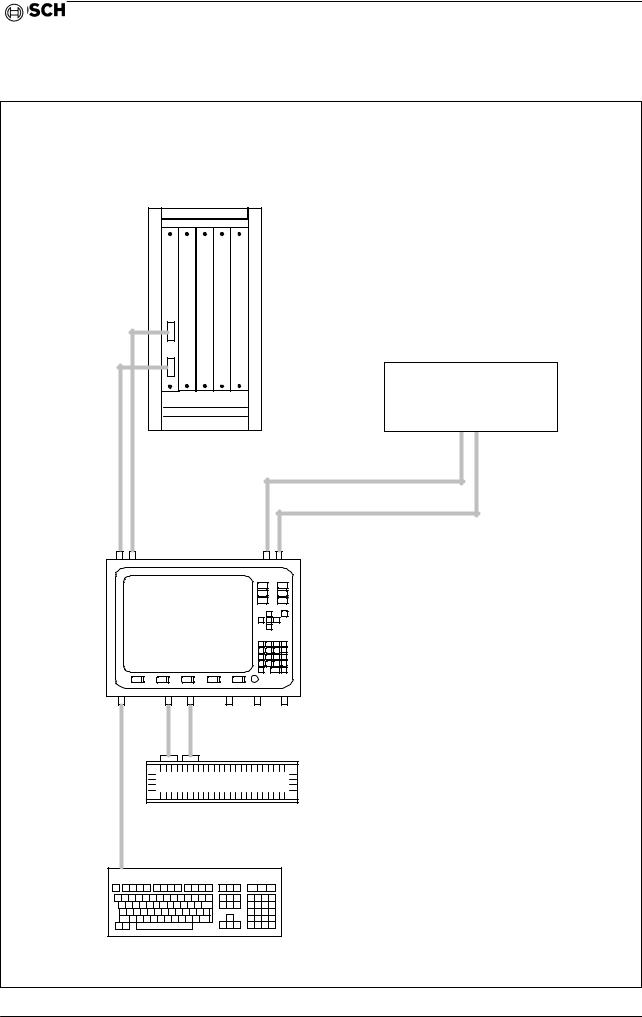

System configuration CC 220 with special colour panel for integrating a PC

|

|

|

|

|

A further PC apart from the CNC can be con |

|

|

|

|

|

nected to the special colour panel (order no. |

|

|

iSERVO PANELBLANK |

|

75PS |

071339) with this configuration. |

|

X21 |

I/O |

nal. |

||

|

CP/MEM5 |

|

|

|

An MF2 keyboard is coupled to the panel in |

|

|

|

|

|

stead of the CNC ASCII keyboard. |

|

|

|

|

|

The panel can be connected to either the CNC |

|

|

|

|

|

or the PC by changing over via an interface sig |

|

X22 |

|

|

|

|

|

|

|

|

|

PC without monitor |

|

|

|

|

|

Keyboard cable (max. 25m) |

|

|

|

|

|

VGA cable (max. 25m) |

X22 |

X21 |

|

|

X33 |

X23 |

|

|

|

|

|

|

|

|

14" |

|

|

|

|

colour |

|

|

|

|

|

(order no. 071 339) |

|

|||

X32 |

|

X62 |

|

|

|

X61 |

|

|

|

X71 X31 X12

X62 X61

MTB1 I/O

MF2 keyboard

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 − 3

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

1.2Card rack

Three different card rack versions are available for the CC 220:

‘NC card rack 1.0 5

NC logic section with max. 5 plug in modules.

‘NC/PLC card rack 1.0 5/8

NC PLC I/O logic section with max. 5 plug in modules and 8 PLC I/O modules.

‘NC/CL3 card rack 1.0 5/7

NC PLC I/O logic section with max. 5 plug in modules and the

CL300 modules: power supply module NT301/300, central processing unit ZE300 and 5 PLC modules (permissible combinations according to the basic unit GG300 K).

CAUTION

CAUTION

The card rack must be connected using the earthing stud on the PE conductor sys

!tem. The earthing stud is located on the inside of the card rack, directly next to the left cable bushing opening (facing the front).

The individual plug in modules contain components which can be destroyed by static discharges! For this reason, ensure equipotential bonding before touching the modules or components of the modules.

Please refer to the chapter •Dimensions, installation and connection conditions" for information on dimensions and instructions for installation, electrical connec tions and maintenance.

The section •PLC couplings" gives possible PLC couplings to the CNC.

1 − 4

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

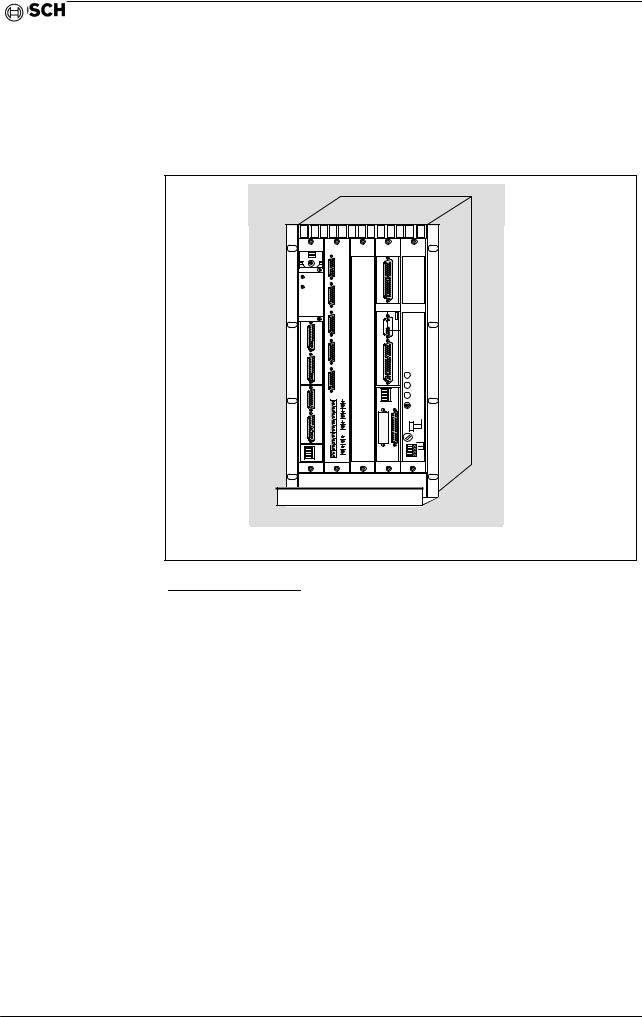

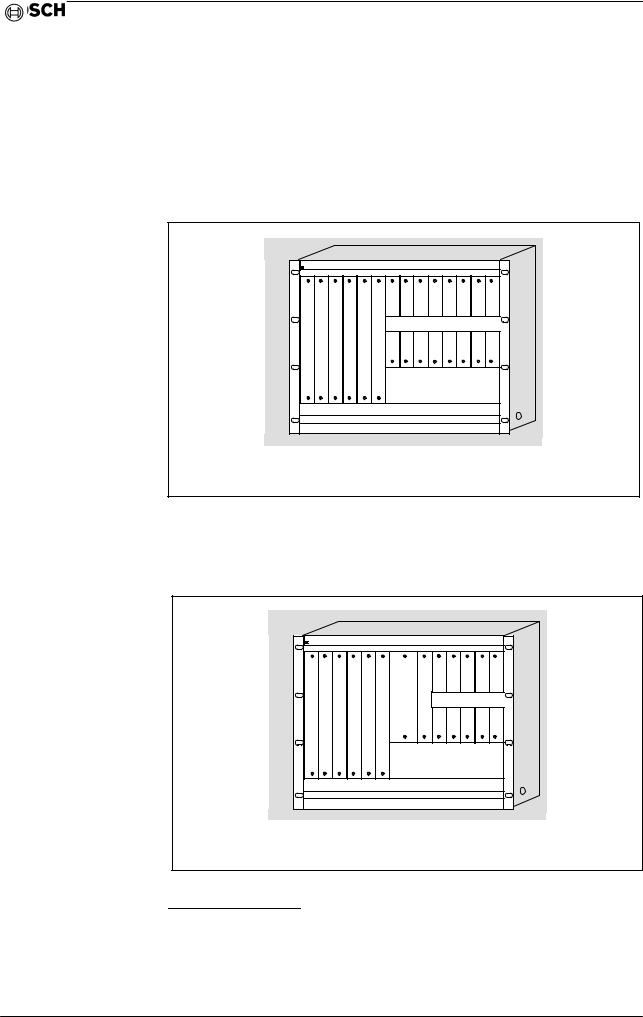

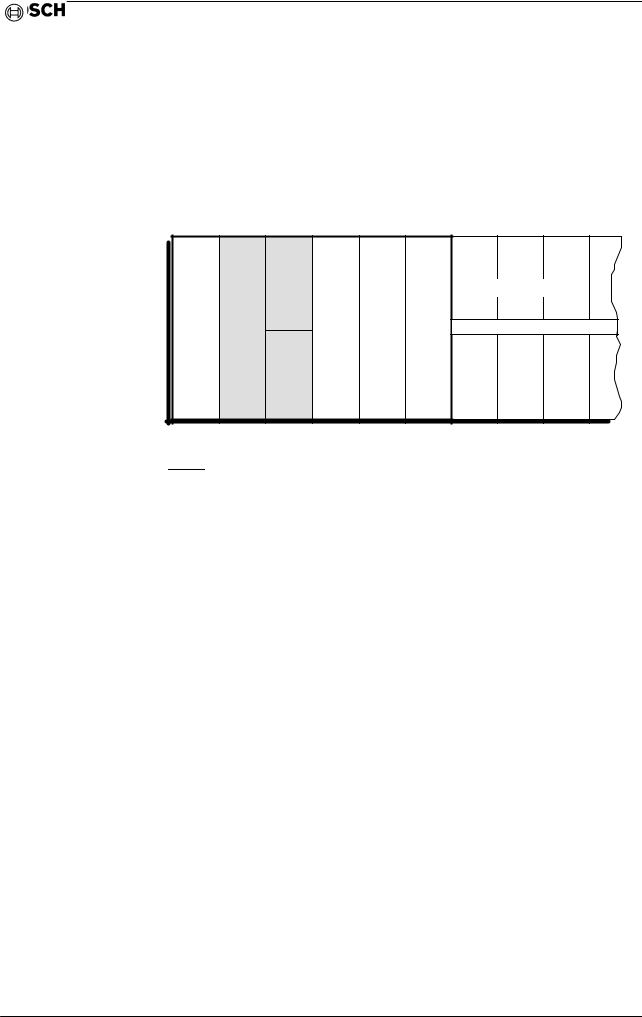

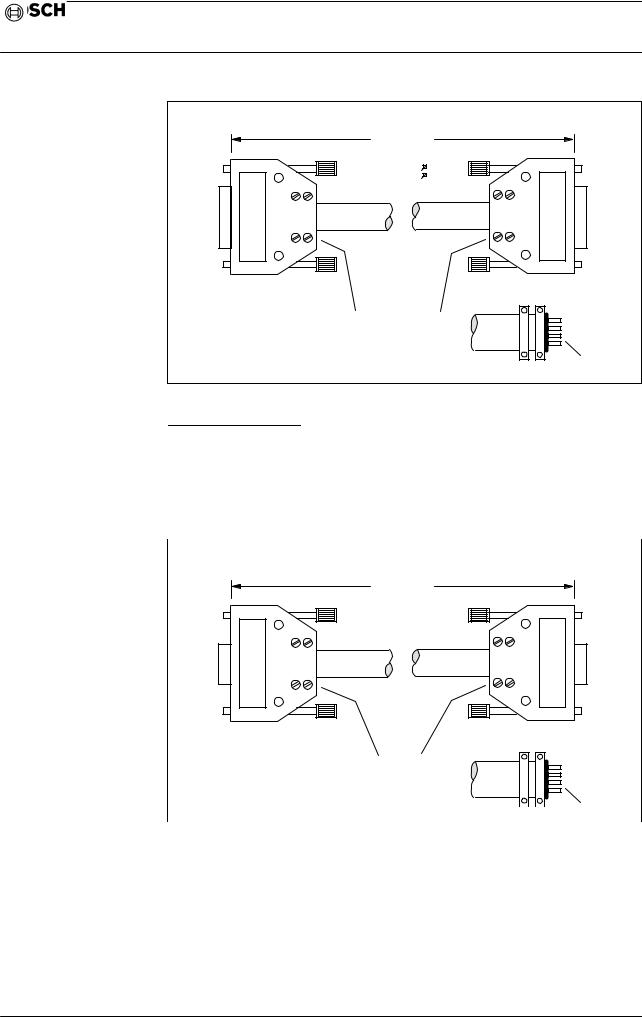

1.2.1NC card rack 1.0 5

This rack is designed to accommodate a maximum of 5 CNC plug in modules.

The fan unit beneath the switch group is driven with 24 VDC.

O

O

I

I

Example:

NC card rack fitted with the modules CP/MEM5, Servo i card

I/O 24/0.2 and PS 75

Ordering information

Type |

No. |

|

|

NC card rack 1.0 5 |

065 610 |

Fan unit 24 2 |

054 092 |

1 − 5

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

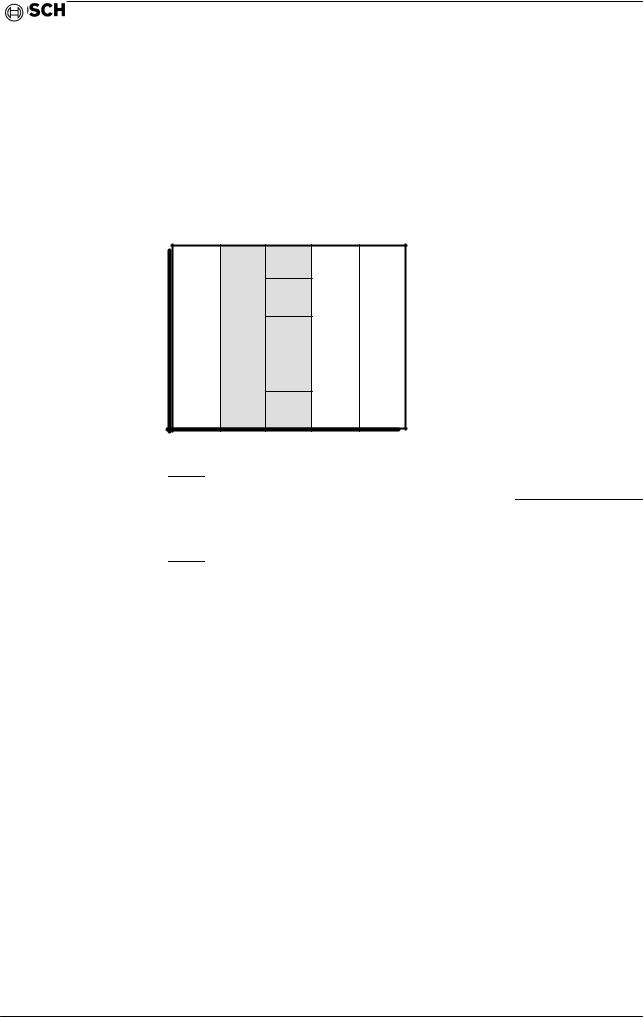

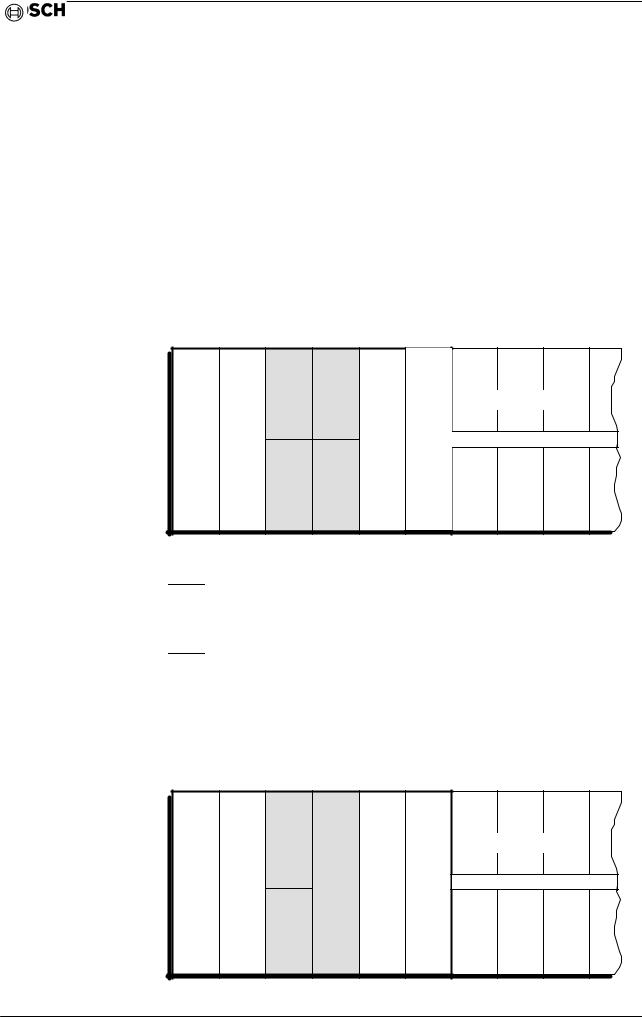

1.2.2NC/PLC card rack 1.0 5/8

The CNC section is enlarged to accommodate PLC I/O modules. A total of 8 slots are available for PLC I/O modules.

The ventilation unit beneath the PLC switch groups (24 VDC) is prewired to the fan unit.

CP/MEM5 |

SERVOi |

BLANKPANEL |

PC−I/O−S |

PS75 |

BLANKPANEL |

I/O |

I/O |

I/O |

I/O |

I/O |

I/O |

I/O |

I/O |

|

|

|

|

|

|

|

|

I/O BUS |

|

|

|

||

Example:

NC/PLC card rack fitted with the modules CP/MEM5, Servo i card,

PC I/O S, PS 75 and PLC I/O cards

1.2.3NC/CL3 card rack 1.0 5/7

The ventilation unit beneath the PLC switch groups (24 VDC) is prewired to the fan unit.

CP/MEM5 |

SERVOi |

BLANKPANEL |

NC−PLC−BIT |

PS75 |

BLANKPANEL |

NT300 |

ZE300 |

I/O |

I/O |

I/O |

I/O |

I/O |

|

I/O BUS |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||

Example:

NC/CL3 card rack fitted with the modules CP/MEM5, Servo i card,

NC PLC bit coupler, PS 75 and CL 300

Ordering information

Type |

No. |

|

|

NC/PLC card rack 1.0 5/8 |

066 750 |

incl. fan unit |

|

NC/CL3 card rack 1.0 5/7 |

066 860 |

incl. fan unit |

|

1 − 6

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

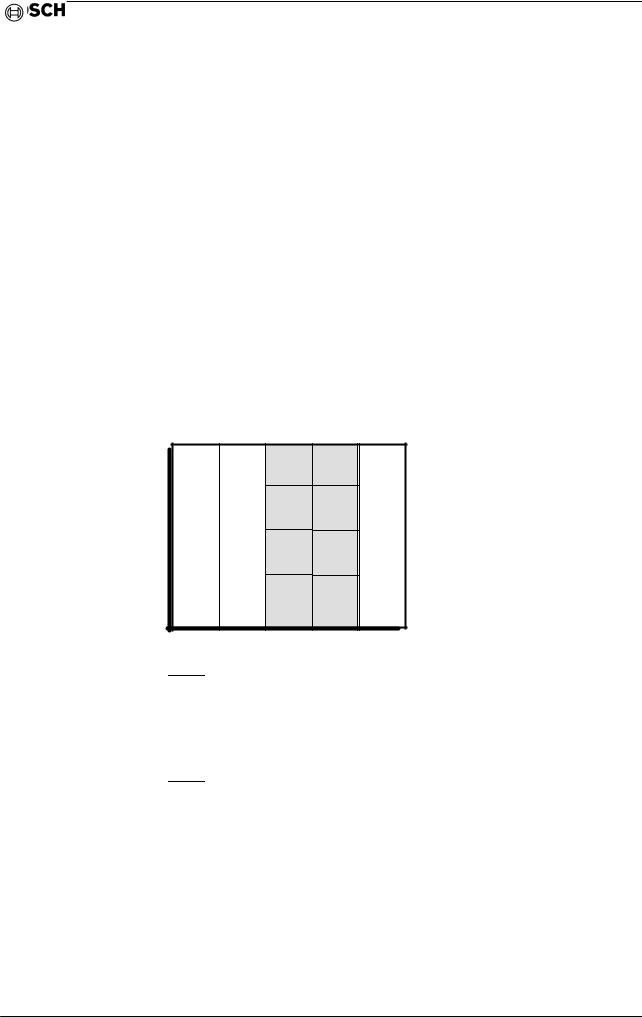

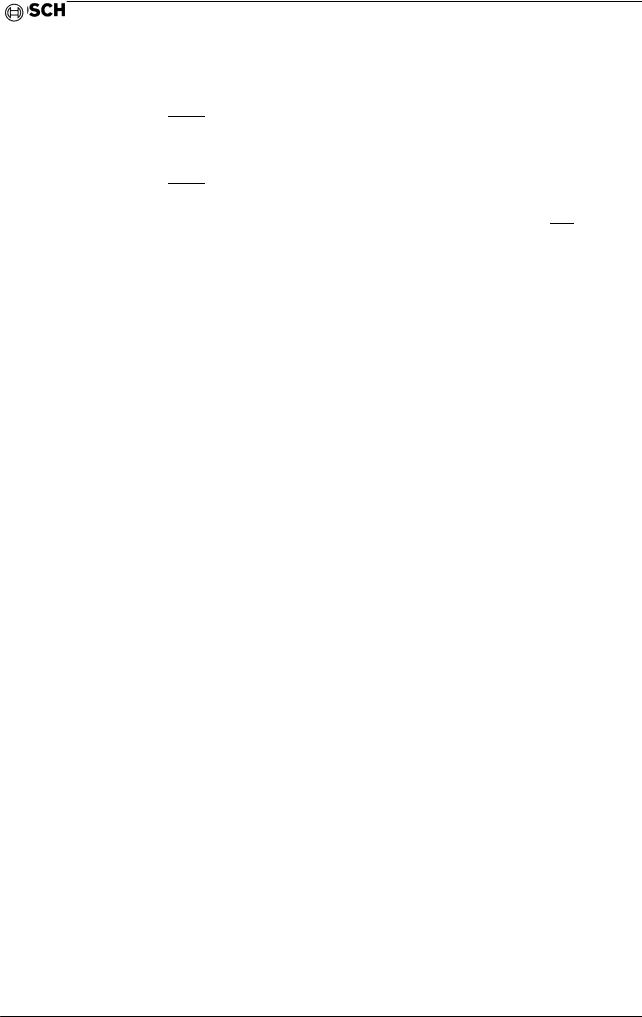

1.2.4Slot variations

The diagrams schematically depict the possible slot variations for the NC card rack 1.0 5, the NC/PLC card rack 1.0 5/8 and the NC/CL3 card rack 1.0 5/7 re spectively.

NC card rack 1.0 5

‘CP/MEM5, computer/memory module

−Max. 512 kByte RAM (user memory)

−Max. 1 MByte EPROM (customer EPROM)

−Max. 128 kByte EEPROM

‘Power supply module PS 75

−The power supply module supplies the internal voltages for the logic circuits of all plug in modules.

1. |

5. |

Slot |

|

CP/ |

|

|

|

PS 75 |

|

|

|

|

|

|||

|

MEM5 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Slot 1 and 5

In all card racks, slots 1 and 5 are reserved for modules CP/MEM5 and PS75.

1 − 7

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

‘Servo types, servo loop modules (servo cards)

−Servo 4i with 4 analog setpoint outputs and 3 measuring system inputs

−Servo 6i with 7 analog setpoint outputs and 6 measuring system inputs

−Servo i EXE3/S with 3 integrated EXEs.

If no SCP2 cards are used, or a second I/O card is used, then 2

Servo i cards may be connected.

Note that the total number of system axes is limited to 8!

2. |

3. |

Slot |

BLANK

PANEL

Second

I/O

SERVO

CARD

SERVO

CARD

SCP2

Slot 2

Slot 2 is provided for the first Servo i card respectively in all card rack versions (Servo 4i, Servo 6i, Servo i EXE3).

Slot 3

Slot 3 is provided for either a second servo card (Servo 4i, Servo 6i, Servo i EXE3), a second I/O card (without PIC250) or one SCP2 card. The fitting of slots 2 and 4 is decisive. A dummy cover is used instead of a second servo or I/O card or the SCP card.

1 − 8

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

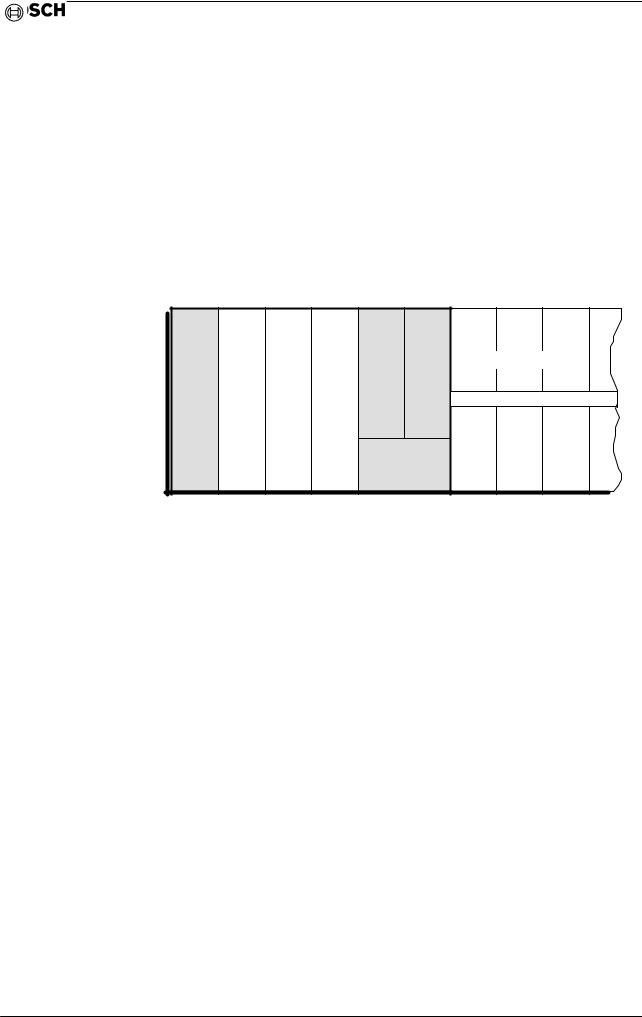

‘PLC alternatives

−I/O 24/0.2 with PIC 250

I/O card with 64 inputs and 40 outputs and internal PLC (PIC 250). A second I/O card (without PIC 250) can be fitted.

−Bit coupling

NC PLC bit coupler, connection module to external PLC (PC600, CL300).

−Word coupling

NC PLC word coupler (WK3); Connection module to external PLC (PC600). Used only with CC 220 M.

−PC I/O S coupling

Direct coupling with PLC I/O cards housed in the combination rack or an external rack.

‘DNC versions

EDNC (additional card available for modules I/O 24/0.2 with PIC250, PC I/O S, NC PLC bit and NC PLC word3)

LSV2 DNC (as for EDNC)

LSV2 DNC with SCP2 (only if no second servo card or second I/O card is fitted)

3. |

4. |

Slot |

BLANK |

I/O |

|

PANEL |

24/0.2 |

|

Second |

NC−PLC |

|

I/O |

|

|

BIT |

|

|

|

|

|

SERVO |

NC−PLC |

|

card |

WORD*) |

|

SCP2 |

PC− |

|

I/O−S |

|

|

|

|

|

|

*) CC220M only |

|

Slot 3

Slot 3 is provided for either a second I/O card (without PIC250), a second servo card (Servo 4i, Servo 6i, Servo i EXE3) or one SCP card. The fitting of slots 2 and 4 is decisive. If the slot is not fitted, it is covered with a dummy cover.

Slot 4

This slot is provided for either an I/O card (with PIC250), the NC PLC bit coupling card, the NC PLC word3 (CC 220 M only) or the PC I/O S coupling card.

The section •PLC couplings" gives information on the possible individual PLC couplings.

1 − 9

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

NC/PLC card rack 1.0 5/8 or NC/CL3 card rack

‘CP/MEM5 computer/memory module

−Max. 512 kByte RAM (user memory)

−Max. 1 MByte EPROM (customer EPROM)

−Max. 128 kByte EEPROM

‘Power supply module PS 75 or PS 200

−The power supply module supplies the internal voltages for the logic circuits of all plug in modules.

1. |

5. |

6. |

Slot |

PLC section

BLANK

PS 75 PANEL

CP/

MEM5

PS 200

In addition, slot 6 is provided with a dummy cover for NC/PLC card rack and NC/ CL3 card rack. This makes it possible in the case of both racks to use the more powerful power supply module (which requires slots 5 + 6) instead of the PS75 at slot 5 and the dummy cover at slot 6.

1 − 10

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

‘Servo types, servo loop modules (servo cards)

−Servo 4i with 4 analog setpoint outputs and 3 measuring system inputs

−Servo 6i with 7 analog setpoint outputs and 6 measuring system inputs

−Servo i EXE3/S with 3 integrated EXEs

If no SCP2 cards are used, or a second I/O card is used, then 2

Servo i cards may be connected.

Note that the total number of system axes is limited to 8!

2. |

3. |

Slot |

BLANK

PANEL

PLC section

SERVO card

SERVO card

Slot 3

Slot 3 is provided for either a second Servo i card (Servo 4i, Servo 6i, Servo i EXE3) or a dummy cover.

1 − 11

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

‘PLC alternatives

−Bit coupling

NC PLC bit coupler, connection module to external PLC (PC600, CL300).

−PC I/O S coupling (NC PLC card rack 1.0 5/8 only)

Direct coupling with PLC I/O cards housed in the combination rack or an external rack.

‘DNC versions

−EDNC (with additional card for modules PC I/O S and NC PLC bit)

−LSV2 DNC (as for EDNC)

For NC PLC card rack 1.0 5/8:

3. |

4. |

6. |

Slot |

BLANK |

PC− |

|

PLC section |

PANEL |

I/O−S |

|

|

|

|

||

SERVO |

NC−PLC |

|

|

BIT |

|

|

|

card |

|

|

|

|

|

|

Slot 3

Slot for a second servo card (Servo 4i, Servo 6i, Servo i EXE3). If the slot is not fitted it is covered with a dummy cover.

Slot 4

This slot is provided for PC I/O S or NC PLC bit coupling card. The connection be tween the NC and the PLC I/O modules is created internally via the backplane. The section •PLC couplings" gives information on possible PLC couplings.

For NC/CL3 card rack 1.0 5/7:

3. |

4. |

6. |

Slot |

BLANK

PANEL

NC−PLC

BIT

PLC section

SERVO card

1 − 12

System configuration |

CC 220 |

Card rack |

Connection conditions |

|

|

Slot 3

Slot for a second servo card (Servo 4i, Servo 6i, Servo i EXE3). If the slot is not fitted it is covered with a dummy cover.

Slot 4

Slot for the NC PLC bit coupling card. The connection between the NC and the CL300 modules is created internally via the backplane. In addition, one PLC expan sion unit with digital I/O modules can be connected via socket X11 of the NC PLC bit. No switch groups which may interrupt other units or which are addressed on the extended field (EI/EO) may be used in this expansion unit!

The section •PLC couplings" gives information on possible PLC couplings.

1 − 13

Operating panels |

CC 220 |

14" standard colour panel |

Connection conditions |

|

|

1.3Operating panels

‘14" standard colour panel

‘12" monochrome panel with grey tones

‘14" special colour panel for additional connection to PCs

Please refer to the chapter •Dimensions, installation and connection conditions" for information on dimensions and instructions for installation, electrical connec tions and maintenance.

1.3.114" standard colour panel

The 14" operating panel has graphics capabilities. The colour can be modified by machine parameters and within CPL programs.

Ordering information

Type |

No. |

|

|

Colour panel 1.0 14" |

063 554 |

The interfaces for connecting the ASCII keyboard, MTB1 I/O and CP/MEM5, an LED and a fuse may be found on the backplane of the panel. A brightness potentio meter is located on the front panel, to the left of the monitor. This is operated with a screwdriver.

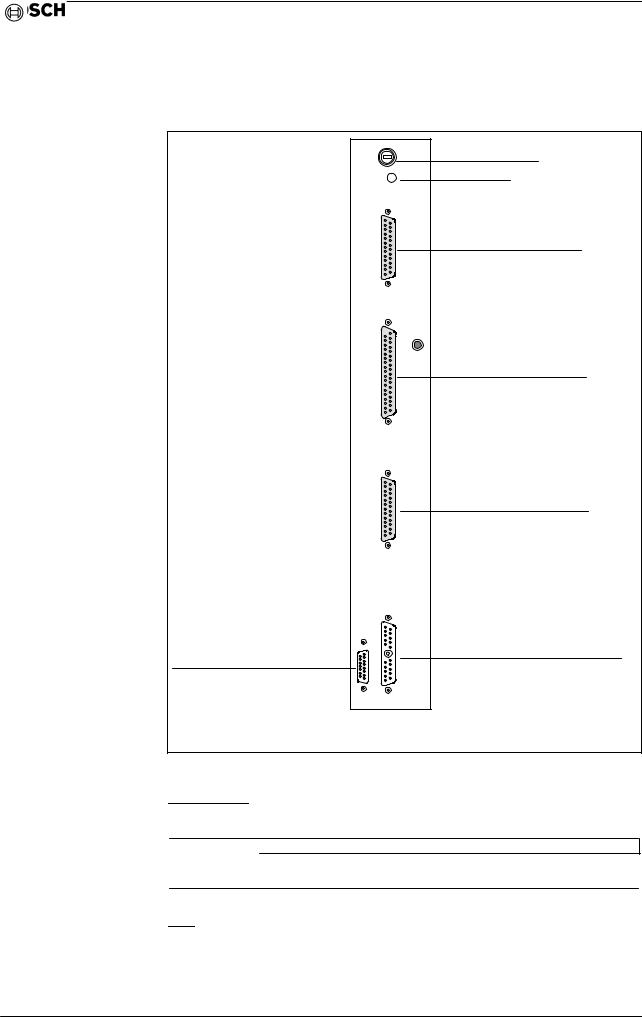

Electrical connections and controls

|

|

Connection cable |

|

|

|

|

RGB cable |

CP/MEM5 |

|

|

|

max. 25 m cable length |

||

X22 |

|

X21 |

|

|

14" |

|

|

Mains connection |

|

colour |

|

230 VAC |

||

panel |

|

|

||

|

|

|

||

X71 |

X61 |

X62 |

MTB1 I/O |

|

‘ 64 inputs |

||||

Brightness |

|

|

||

potentiometer |

|

max. 2 m |

‘ 32 outputs |

|

|

|

|

||

max. 1,5 m |

|

cable length |

Connection for |

|

cable length |

|

|

‘ 3 or 2 potentiometers |

|

|

|

|

‘ 1 digital handwheel |

|

ASCII keyboard |

|

|

||

Controls and ports at a glance |

|

|||

Brightness potentiometer

Potentiometer for adjusting screen brightness. Screen brightness can be suited to the local lighting conditions. Light filters should be used to prevent glare if necess ary.

CAUTION

CAUTION

Excessive brightness causes premature •ageing" and •burning" of the picture tube. This invalidates the guarantee!

1 − 14

Operating panels |

CC 220 |

14" standard colour panel |

Connection conditions |

|

|

‘Interface section of the colour panel

Fuse (M 4 A)

LED, green

ASCII keyboard

Socket X71, Sub D, 25 pin

MTB1 I/O

Socket X61, Sub D, 37 pin

MTB1 I/O

Socket X62, Sub D, 25 pin

CP/MEM4

Connector X21, RGB interface Sub D, 15 pin

CP/MEM4

Connector X22, Sub D, 20 pin incl. BNC socket (video signal)

Colour panel rear view (interface strip only)

Fuse (M 4 A)

Protects the 24 V= input voltage to X22.

CAUTION

CAUTION

Only use the fuse type recommended. Jumpering the fuse is not permitted.

LED

The green LED indicates that the 24 V= supply voltage from the CP/MEM4 is on.

1 − 15

Operating panels |

CC 220 |

14" standard colour panel |

Connection conditions |

|

|

‘Panel − CP/MEM4

The panel is connected to the CP/MEM4 by means of the cables X21 and X22. Cable X22 contains the leads for the 24 V supply voltage for the panel, analog sig nals (potentiometers) and keyboard signals. The video sync signal is transmitted down an internal coax lead. RGB video signals are carried by cable X21.

Connector X22

20 pin sub D connector of special design with additional BNC socket for video sync signal transmission.

Pin Assignment

1AVCC

2AGND

3VREF

4IN3

5IN1

6IN4

7RESERVE 1

8RESERVE 2

9GND (PHG interface)

10+12 VP (CP interface)

11AGND

12+24 V

13PGND

14IN2

15IN0

16PGND

17+12 V (PHG interface)

18TX+

19RX+

20RS+

A1 CSYNC

Connector X21

Video interface for transmission of RGB video signals and colour monitor identifica tion. Cable assignment:

Socket X21 |

Connector X21 |

|

|

Pin |

Pin |

Core colour |

Signal |

|

|

|

|

8 |

8 |

red |

Red |

15 |

15 |

Screen (red) |

Ground red |

14 |

14 |

gn |

Green |

7 |

7 |

Screen (gn) |

Ground gn |

6 |

6 |

bl |

Blue |

13 |

13 |

Screen (bl) |

Ground bl |

5 |

|

black |

Bridge |

12 |

|

Core no. 7 |

|

|

|

||

4 |

|

black |

Bridge |

11 |

|

Core no. 8 |

|

|

|

1 − 16

Operating panels |

CC 220 |

14" standard colour panel |

Connection conditions |

Special socket, Sub D, 20 pin |

Special connector, Sub D, 20 pin |

to panel |

to CP/MEM4 |

max. 25 m |

|

Screened cable |

|

2 x 8 x 0.14 |

|

1 x 4 x 0.31 |

|

1 x mini coax section |

|

Cable diameter: |

|

11+/−0,5 mm |

|

Bending radius: |

|

single: 55 mm |

|

multiple: 110 mm |

|

Screen attachment: metal bracket from body (screen is located in between) tightened evenly left and right.

screen

Connection cable X22 panel − CP/MEM

Ordering information

Type |

No. |

Length |

|

Connection cable X22 |

048 028 |

2.5 |

m |

|

052 265 |

5 |

m |

|

048 029 |

10 |

m |

|

048 668 |

20 |

m |

|

065 617 |

25 |

m |

|

|

|

|

Special socket, Sub D, 15 pin |

|

|

Special connector, Sub D, 15 pin |

to panel |

|

|

to CP/MEM4 |

max. 25 m

Screened cable

Cable diameter: 9,1 +/−0,5 mm

Screen attachment: metal bracket from body (screen is located in between) tightened evenly left and right.

|

Connection cable X21 panel − CP/MEM 4 |

|

|

|

Screen |

||||

|

|

|

|

|

|||||

Ordering information |

|

|

|

|

|

|

|

||

|

Type |

|

No. |

Length |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RGB cable X21 |

065 620 |

2.5 m |

|

|

|

|

||

|

|

|

065 622 |

10 m |

|

|

|

|

|

|

|

|

065 624 |

25 m |

|

|

|

|

|

1 − 17

Operating panels |

CC 220 |

14" standard colour panel |

Connection conditions |

|

|

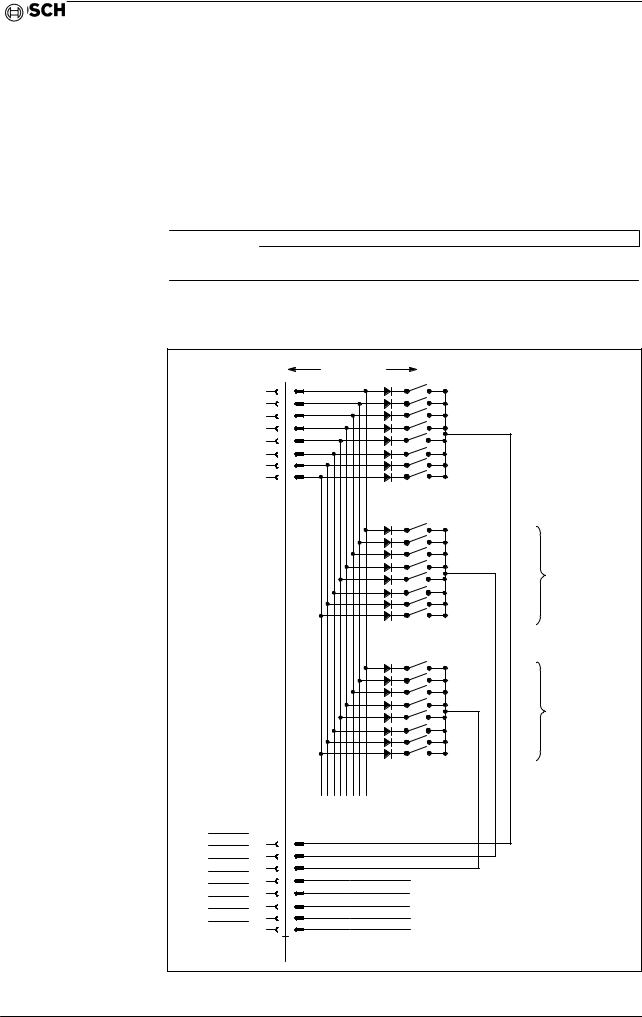

‘Connecting pushbuttons and switches to the panel (systems without MTB1 I/O)

Up to 64 switching elements (make/break contact elements and pushbuttons) can be connected to panel interface X61. Pushbuttons and switches must be suited to a switched current of approx. 3 mA (gold contacts).

Required minimum conductor cross section: 0.14 mm2. Screened cables must be used.

CAUTION

CAUTION

Signals SCAN8 to SCAN15 are LOW active!

Connection of input signals to X61:

Panel X61 |

|

from X61 to switching element |

|

|

max. 2.5 m |

||

|

|

|

|

All diodes: Type 1 N 4148

Data 0 |

21 |

Address E32.0 |

|

Data 1 |

20 |

Address E32.1 |

|

Data 2 |

2 |

Address E32.2 |

|

Data 3 |

1 |

Address E32.3 |

|

Data 4 |

3 |

Address E32.4 |

|

Data 5 |

22 |

Address E32.5 |

|

Data 6 |

4 |

Address E32.6 |

|

Data 7 |

23 |

Address E32.7 |

|

|

|

Byte E33 |

|

|

|

Byte E34 |

|

Scan 8 |

27 |

|

|

Scan 9 |

8 |

|

|

Scan 10 |

7 |

|

|

Scan 11 |

5 |

Addresses 35.0 − 35.7 |

|

6 |

|||

Scan 12 |

Addresses 36.0 − 36.7 |

||

|

|||

Scan 13 |

24 |

Addresses 37.0 − 37.7 |

|

|

|||

Scan 14 |

25 |

Addresses 38.0 − 38.7 |

|

Scan 15 |

26 |

||

Addresses 39.0 − 39.7 |

|||

|

|

||

|

|

1 − 18 |

Loading...

Loading...