Bosch Power Tools 1365, 1364K, 1364, 1365K User Manual

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 13 Ver la página 24

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1364

1365

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 1

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

S

AVE THESE INSTRUCTIONS

-2-

Work Area

Keep your work area clean and well lit.

Clutter ed benches and dark area s invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep by-standers, children, and visitors

aw ay wh ile o pera t ing a pow e r to o l.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

sti l l does not f i t , co n t a c t a qualifi e d

electrician to install a polarized outlet. Do

not change the plug in any way. Double

Insulation eliminates the need for the

three w i r e grounded power c o r d and

grounded power supp ly system. Be for e

plugging in the tool, be certain the outlet

voltage supplied is within the voltage marked

on the nameplate. Do not use “AC only” rated

tools with a DC power supply.

Av oid b ody c onta ct wi th gr ound ed

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician’s rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W." These cords are rated for outdoor use

and reduce the risk of electric shock. Refer to

“Recommended sizes of Extension Cords” in

the Accessory section of this manual.

Personal Safety

Stay alert, watch what you are doing and

us e c ommo n sens e w hen op erat ing a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your

ha ir, cloth ing, and glov es aw ay from

moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

Keep handles dry, clean and free from oil and

grease.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used

for appropriate conditions.

Tool Use and Care

Us e c l amps or ot her pr a ctic al w ay t o

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

!

WARNING

Power Tool Safety Rules

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 2

-3-

Abrasive Cut-Off Machine Safety Rules

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories , or st ori ng th e too l. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of children and

ot her un trai n ed pe r sons . To ols ar e

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind

and are easier to control. Any alteration or

modification is a misuse and may result in a

dangerous condition.

Check for mi sal ignment o r b ind ing of

moving parts, breakage of parts, and any

other condition that may affect the tools

op erat i on. If damag ed, ha ve the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop a

periodic maintenance schedule for your tool.

Us e only a cces sories th at are recommende d by the manufact ure r for yo ur

model. Accessories that may be suitable for

one tool, may become hazardous when used

on another tool.

Service

Tool service must be performed only by

qu alif i ed repai r pe r sonn el. Serv ice or

ma inte nance per form ed b y un quali fied

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury . Certain cleaning

agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Always use wheel guard, foot plate and

auxiliary handle with this abrasive cut off

machin e . The gua r d must alw a y s be

secure l y a t t a ched to th e tool an d

positioned for maximum safety, so the

least amount of wheel is exposed on the

operators side of the tool. A guard protects

operator from broken wheel fragments. The

foo t plat e and auxili a r y han d l e pro v i d e

additional guarding, stability and control in

cut off applications.

Abrasive cut off wheels must be rated for

at least the speed recommended on the

to o l wa rning la b e l. Whe els a nd o t her

accessories running over rated speed can fly

apart and cause injury.

Hold tool by insulated gripping surfaces

when performing an operation where the

ab r a s i ve wh e els m a y co n t a c t hi d d en

wiring or its own cord. Contact with a “live”

wire will make exposed metal parts of the

tool “live” and shock the operator.

Always be certain that the wheel guard,

foot plate a n d aux i l i a r y handle a r e

reassembled and securely fastened to the

ma c h i ne w h e n ch a nging t he p o i n t of

operation from fire forward to fire reverse

or af t e r ch a n g ing the whe e l s . A tool

missing an essential safety component is

dangerous to operate.

Wear pr o p e r ap p a r e l while using an

abrasive cut off machine. Face shield or at

least s afe ty goggles, dust mask, leather

gloves and shop apron capable of stopping

small wheel or workpiece fragments.

This machine is not intended to be used

with Wet Diamond Wheels. Using water or

other liquid coolants with this machine may

result in electrocution or shock. Use of Dry

Diamond Wheels is acceptable.

Use only Type 1 abrasive cut off wheels

with the correct size arbor hole. Never use

damaged or incorrect wheel flanges or

round nut. Other types of wheels are not

intended to apply load on periphery and may

shatter. Wheels with arbor holes that do not

match the mounting hardware of the tool will

run eccentrically, vibrate excessively and will

cause loss of control.

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 3

Do not gr i n d on th e side of Ty p e 1

abrasive cut off wheels. Side forces applied

to these wheels may cause them to shatter.

Do not use this tool with “Woodcarving”

blade or standard wood cutting toothed

blades. These blades are not intended for

this machine and can create loss of control

during use.

Abrasive C ut Off W hee ls must have a

maximum safe operating speed greater

than the “no load RPM” marked on the

tool’s nameplate. Wheels running over the

rated speed can fly apart and cause injury.

Before each use inspect the cut off wheel

for chips and cracks. Do not use a wheel

that may be damaged. Install a new wheel

if tool was dropped. When installing a

new wheel carefully handle individual cut

off wheels to avoid chipping or cracking.

Run the tool at no load for one minute,

hold ing the tool in the dire ction away

from peo p l e . Wh e e l s wi t h fl a w s wi l l

normally break apart during this time .

Fragments from a wheel that bursts during

op erati on w ill fly aw ay a t great vel ocit y

possibly striking you or bystanders.

Do not use a cut off wheel that is larger

than the maximum recommended size for

your tool, or worn down damaged wheels

from larger abrasive cut off machines.

Whee ls intended f or larger tools are not

suitable for the higher speed of a smaller

tool, these wheels may easily burst and the

fragments strike you or bystanders.

Position the cord clear of the spinning

wheel. Do not wrap the cord around your

arm or wrist. If you lose control and have

the cord wrapped around your arm or wrist, it

may entrap you and cause injury.

Keep your body positioned to either side

of the wh e el, b ut n o t in li ne w i th t h e

wheel. It is important to support the tool

properly and to position your body such as to

minimize body exposure from the possible

wheel binding and the recoil of the tool.

Keep hands away from cutting area and

wheel . Ke e p y o u r s e c o n d h a n d o n

auxiliary handle. Hold the machine firmly

to prevent loss of control. NEVER place

your hand behind the wheel since the

machine may recoil over your hand. Do

not attempt to remove cut material when

wheel is moving. If both hands are holding

the machine, they cannot be cut by the wheel

Do not “jam” the abrasive wheel into the

work, ap p l y e x c e s s i v e p r e s s u r e o r

attempt to use large depths of cut while

using this machine. Let the rotating wheel

do the work, Abrasive Cut Off Machines are

intended to “cut” the material in a series of

shallow depth of cuts. See the instructions for

depth of cut later in this manual.

Avoid bouncing and snagging the wheel,

especially when working corners, sharp

edges etc. This can cause loss of control

and machine’s recoil.

Do not run the machine while carrying it

at your side. Accidental contact with the

spinni n g wh e e l could result in se r i o u s

personal injury.

Never lay the tool down until the motor

has come to a complete standstill. The

spinning wheel can grab the surface and pull

the tool out of your control.

Do not use the abrasive cut off machine

near flammable materials. Sparks from the

wheel could ignite these materials.

Never cut or attempt to cut magnesuum

with this tool. The dust generated when

cutting magnesuum is highly flammable and

may be explosive under certain conditions.

Regularly clean the tool’s air vents by

compressed air. Excessive accumulation of

powdered metal inside the motor housing

may cause electrical failures.

Causes and Operator Prevention of Recoil:

Recoil is a sudden reaction to a pinched,

bound or misa ligned rotat ing w heel. The

wheel may stall and cause an uncontrolled

machine to back out of the kerf toward the

operator when the machine is in the “fire

forward” position, if the machine is set in the

“reverse fire” position the machine may tend

to walk away from the operator.

If an abra s i ve w h e el o r di a m ond w h eel

becomes twisted or misaligned in the cut, the

side of the wheel that is entering into the

material can dig into the top surface of the

material causing the wheel to climb out or

recoil out of the kerf either toward or away

from the operator, depending on t he fire

forward or reverse fire orientation.

Abra sive whe els may also shat ter under

these conditions causing pieces or fragments

to strike or i m p a l e t h e o p erator and

bystanders. Recoil or shattered wheels are

the result of tool misuse and/or incorrect

operating procedures or conditions and can

-4-

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 4

be avoided by taking proper precautions as

given below:

Maintain a firm grip with both hands on

the machine handles and position your

body and arm to allow you to resist recoil

forces. Recoil forces can be controlled by

the operator, if proper precautions are taken.

When wheel is binding, or w h e n

interrupting a cut for any reason, release

the trigg e r a n d h o l d t h e m a c h i n e

motionless in the material until the wheel

comes to a complete stop. Never attempt

to r emo ve the mac hin e from t he work

while the wheel is in motion or recoil may

occur. Investigate and take corrective action

to eliminate the cause of wheel binding.

When r e s t a r t i n g a m a c h i n e i n a

workpiece, center the wheel in the kerf

and check that the sides of the wheel are

not engaged into the material. If wheel is

binding, it may walk up or recoil from the

workpiece as the machine is restarted.

Support large panels to minimize the risk

of wheel pinching and recoil. Large panels

tend to sag under their own weight. Supports

must be placed under the panel on b oth

sides, near the line of cut and near the edge

of the panel.

Wheel depth adjusting locking levers/nuts

must be tight and secure before making a

cut. If depth adjustment shifts while cutting, it

may cause binding and recoil. Using the

machi ne with an excessiv e d epth of cut

setting increases loading on the unit and

susceptibility to twisting of the wheel in the

kerf. It also increases the surface area of the

wheel available for pinching under wheel

twisting conditions or misalignment.

Use extra caution when making a “Pocket

Cut” into exist ing wal ls or other blind

areas. The protruding wheel may cut objects

that can cause recoil.

Some d u s t cr e a t e d by

po w e r sa n ding, s awing,

grinding, drilling, and other construction

activities contains chemicals known to

caus e cancer, b i r t h de f e c t s or o t h e r

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Yo u r ri s k fr om these e xposure s va r ies,

depending on how often you do this type of

work . To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such

as thos e dus t mask s tha t are spec i a l ly

designed to filter out microscopic particles.

-5-

!

WARNING

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 5

-6-

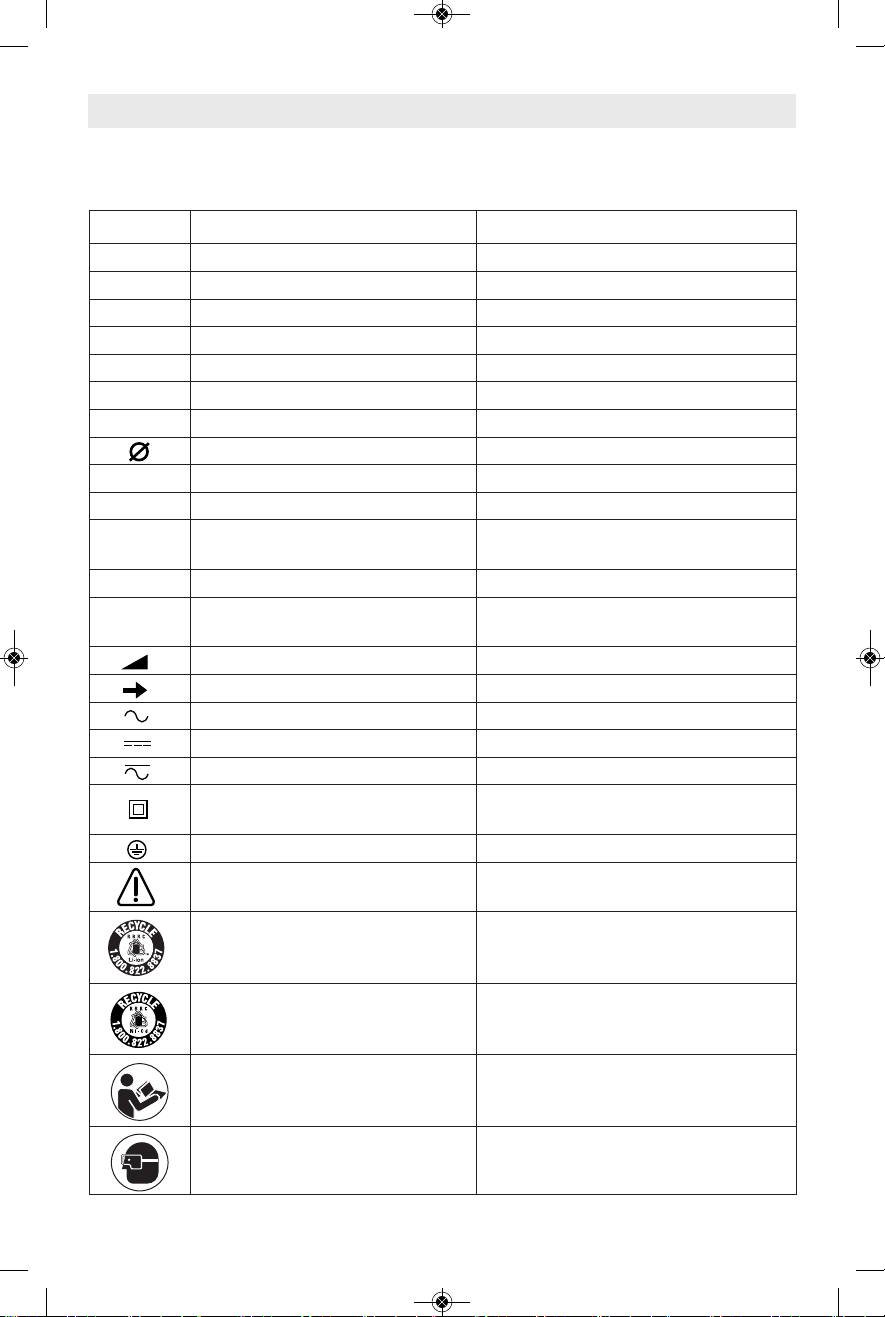

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Manufacturers rated speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

per minute orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

Symbols

0

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 6

-7-

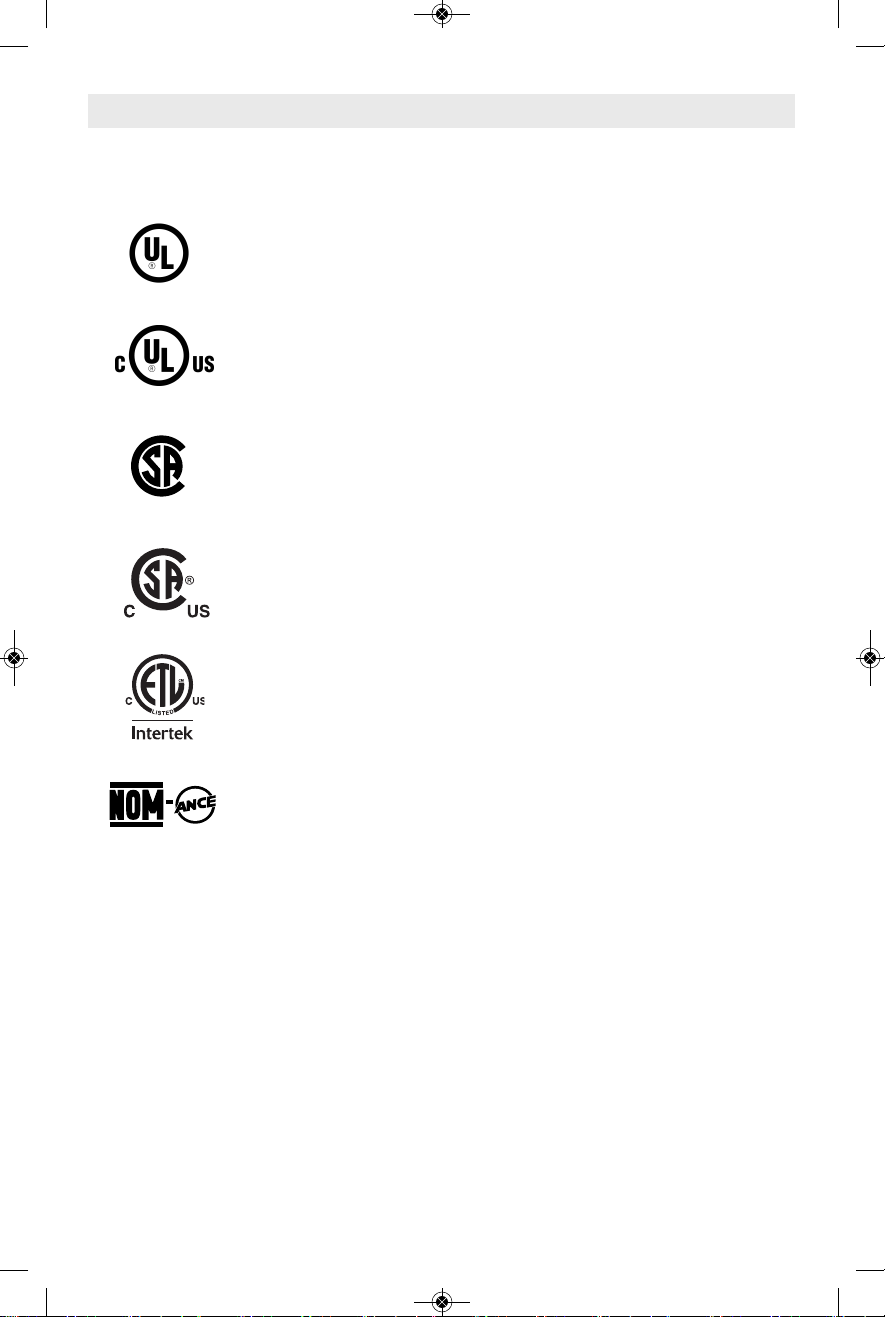

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

Th

is

s

y

m

b

o

l d

e

s

ig

n

a

te

s

th

a

t th

is

to

o

l is

lis

te

d

b

y

Un

d

e

rwrite

rs

L

a

b

o

ra

to

rie

s

,

to

Un

ite

d

Sta

te

s

a

n

d

Ca

n

a

d

ia

n

Sta

n

d

a

rd

s

.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 7

-8-

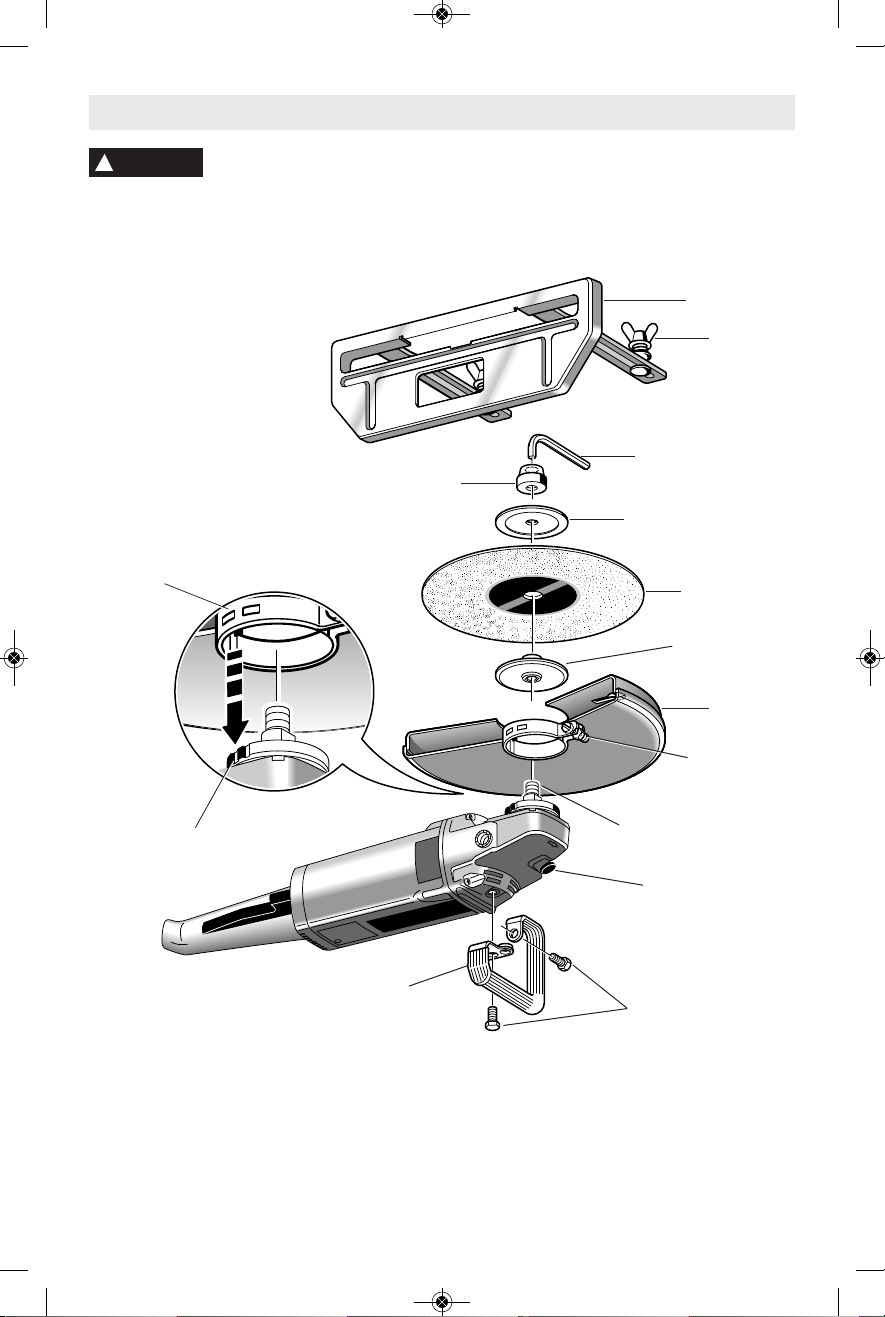

Functional Description and Specifications

Di s conne c t t h e pl ug f rom t he p o wer sou r ce b e fore mak i ng a n y

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

NOTE: For tool specifications refer to the nameplate on your tool.

Model No. 1364 1365

Maximum capacities

Abrasive wheel 12" 14"

Max. Cutting Depth 3-7/8" 4-7/8"

Arbor 7/8" 7/8"& 1"

No load RPM 5,000 4,300

AUXILIARY HANDLE

GUARD

FOOT PLATE

SPINDLE LOCK

ABRASIVE

WHEEL

GUARD

SECURING

CAP SCREW

MOUNTING BOLTS

OUTER

FLANGE

ALLEN

WRENCH

INNER

FLANGE

ARBOR

NUT

SPINDLE

LOCATING

NOTCHES

LOCATING

TABS

WING

NUT

Abrasive Cut-Off Machine

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 8

To prevent serious personal

injury, always disconnect the

plug from power source before changing

w

heels, or making any adjustments.

INSTALLING ABRASIVE WHEELS

Always use the arbor nut that has same

thread size as spindle.

1. Install inner fla nge onto spindle , with

re cess in bac k si de o f fl ange eng a ging

matching area on spindle.

2. Install abrasive wheel onto spindle.

3. Install outer flange with flat side out.

4. Thread arbor nut provided onto spindle

finger tight, depress spindle lock and tighten

wheel with the wrench provided.

Do not overtighten. Cracks in

the wh e e l can occur if

overtightened.

Do not depress spindle lock

while the tool is running.

Assembly

-9-

Al w a y s us e whe e l gu a r d ,

foot plate a n d auxiliar y

handle with this abrasive cut off machine.

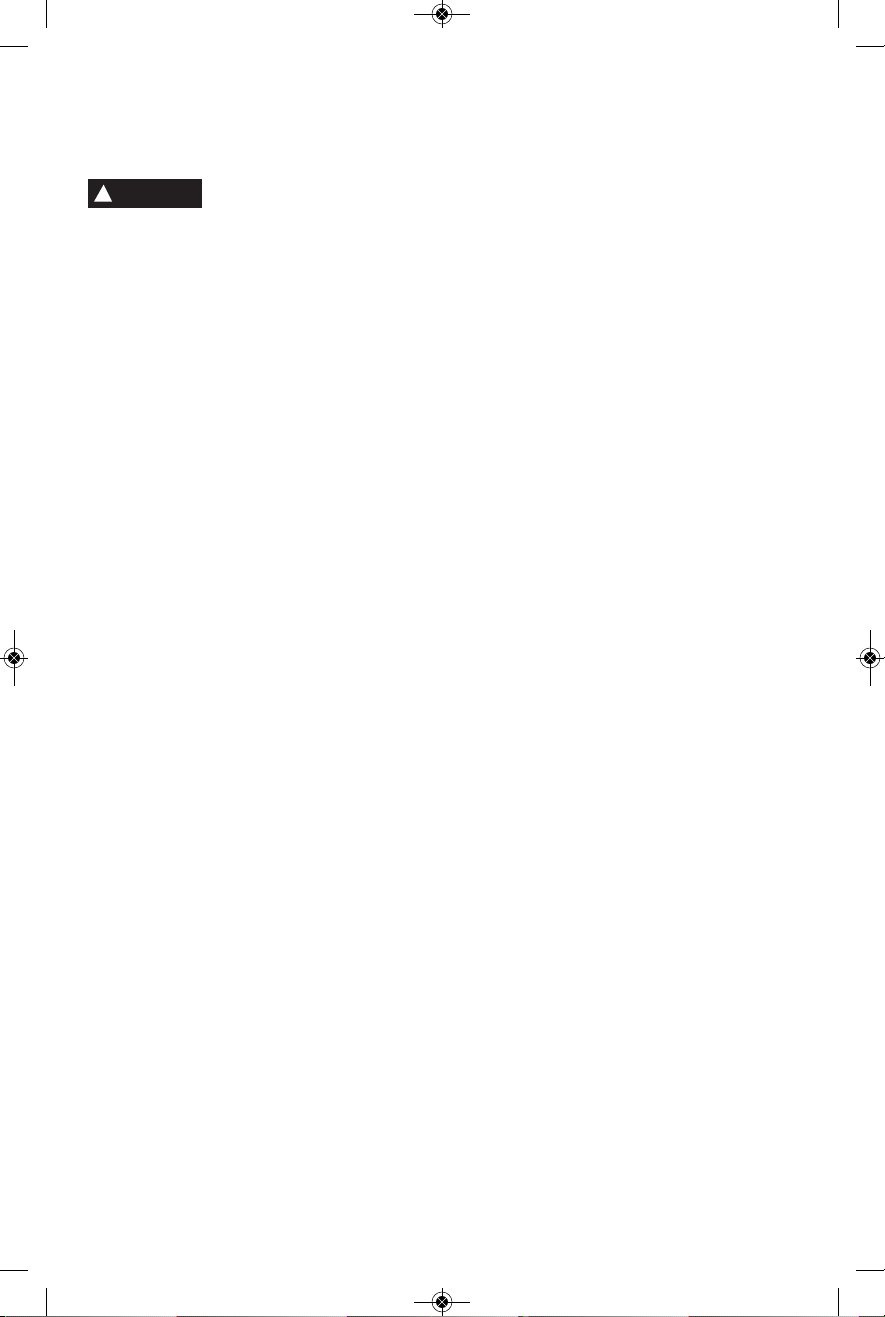

PADDLE SWITCH

WITH "LOCK-OFF" FEATURE

The Paddle Switch enables the operator to

control switch functions of "Lock-OFF", and

"ON/OFF".

TO UNLOCK SWITCH AND TURN TOOL

"ON": Push the paddle lever FORWARD

(toward the spindle) then squeeze the paddle

lever.

TO SWITCH TOOL "OFF": Release pressure

on the paddle lever. The switch is spring

loaded a nd will retu rn to "OFF" posi tion

automatically.

SIDE HANDLE

The side handle, used to guide and balance

the tool can be bolted to either side of the

sp indle ho using de pendi ng o n person al

preference and comfort. Always use the side

handle for maximum control and ease of

operation.

ADJUSTING DEPTH OF CUT

Loosen wing nuts, raise or lower foot plate to

desired depth, and securely tighten wing nuts

by hand.

To prevent r e c o i l and

damage to the tool, always

adjust the foot plate to a depth of so the inner

or ou t e r flanges ne v e r contacts the

workpiece surface.

!

WARNING

!

WARNING

Operating Instructions

!

WARNING

!

CAUTION

WING

NUT

WING

NUT

FOOT

PLATE

0

1

PADDLE

SWITCH

!

WARNING

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 9

-10-

OPERATING THE TOOL

Following a few simple tips will reduce wear

on the tool and it will reduce the chance of

injury to the operator.

This ma c h i n e i s n o t

intended to be used with

Wet Diamond Wheels. Using water or other

liquid coolants with this machine may result

in el e c t r o c u t i o n or shock. Us e of Dry

Diamond Wheels is acceptable.

APPLICATIONS

This tool is intended for cutting the following

materials.

1/8˝ maximum thick sheet steel.

Concrete cinder blocks and bricks.

Reinfo r c i n g r o d - g e n e r a l l y under 3/4˝

diameter.

1/8˝ concrete wire mesh.

Corrugated floor and ceiling forms (concrete

forms).

Electrical conduit 1/8˝ wall thickness.

1/8” maximum thick structural forms such as:

channels, angles, plate and etc.

ABRASIVE WHEELS

Use aluminum oxide wheels for cutting metal.

Use silicon carbide wheels for cutting

masonry.

Use dry diamond wheels for cutting concrete.

Dry diamond wheel stay cooler, clogs less

and last longer.

1 Before running a cut-off machine, inspect

the cutting wheel for chips or cracks. Replace

bad wheels immediately. New wheels should

be run in at no load or at least a minute in

direction away from the presence of other

people. Imperfect wheels will normally break

apart during this time.

2. An abrasive cut-off machine must NEVER

be opera ted without the a ttached guard

se c u red i n pla c e . Th e gu a r d sh o uld b e

rotated into the position where maximum

protection is provided for the operator from

sparks and wheel periphery.

3. Proper appar el f or operating the t ool

includes eye protection, leather gloves, dust

mask and a shop apron.

4. W i t h the tool in the "OFF" p o s i t i o n ,

be c ome f a miliar wit h ha n dling the too l .

Control the head of the tool with the side

handle. Control the cutting edge of the wheel

with the switch handle. Always use both

hands when operating the tool.

5. Never drop the tool. Set the tool down

gently, but never on the wheel.

6. CUTTING CONCRETE will throw large

amoun t s o f d u s t i n t o t h e s u r r o unding

area.

Prote c t i v e dust masks a r e str o n g l y

recommended for breathing protection for the

operator and other nearby workers.

7. Due to the size and weight of the cut-off

machine it is not recommended to be used

overhead or in any position that would not

allow proper control. Ladders or scaffolding

are not considered solid support structures.

8. Avoid overloading tool. Do not allow the

wheel to bind or stall. Many cuts, especially

int o soli d conc r e t e , re q u ire su c cessive

passes. Do not expose any more abrasive

wheel than necessary to cut with normal

amount of pressure applied to tool. Begin

cutting from the edge of the material, starting

with about 1" wheel exposed. Do not force

the tool; l oad it norm ally. Dependi ng on

mater i a l hardness a n d density, make

su ccess ively de eper pas ses u ntil cut is

complete.

FIRE FORWARD/FIRE REVERSE

Model s 13 6 4 & 1365 are sh i p p e d with

abrasive Cutoff Machine set up in fire forward

position. Both can be easily converted to fire

re v e r se po sition w ithout a ny ad ditional

accessories.

Fire forward position directs sparks, dust and

debris away from the operator.

Fire reverse position changes direction of

ro t ation so spa r ks, d ust a nd d ebris are

thrown toward the operator.

The proper fire position depends on how the

tool is being held, direction of travel, and

personal preference. Always remember the

reason for this feature is to direct sparks,

dust and debris away from the operator.

FIRE REVERSE APPLICATIONS

Below are a few examples of when you may

want to change your tool to the reverse fire

position.

• When cutting in a vertical position to direct

debris toward your feet instead of you face.

• When pulling the tool through the workpiece

instead of pushing the tool.

• When working in confined areas close to a

wall.

• Personal comfort.

!

WARNING

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 10

-11-

REVERSING FIRE DIRECTION

However we strongly recommend having this

ta sk perfo rmed by an au thor ized Bo sch

Service center.

1. Disconnect the plug from the power source.

2. Remove abrasive wheel.

3. Loosen wing nuts enough to allow screw

heads to slide out of foot plate mounting

holes provided in guard, and remove foot

plate.

4. Remove the four gear housing screws and

rotate gear housing 180˚. Replace housing

screws and securely tighten screws.

5. Loosen guard securing cap screw and

rotate guard for maximum wheel coverage

and securely tighten guard s ecuri ng cap

screw with the wrench provided.

6. Remove the auxiliary handle mounting

bolts, reposition handle using auxiliary hole in

handle, replace mounting bolts and securely

tighten handle.

7. Re-as semb le f oot plate and abras ive

wheel.

Service

Preventi ve maint ena nce

perfo r m e d by unauthorized per so n nel may result in misplacing

of internal wires and components which

could cause s e r i ous h a z a r d . We

recommend that all tool service be performed

by a Bosch Factory Service Center or Autho rized Bosch Service Station.

TOOL LUBRICATION

Your Bosch tool has been properly lubricated

and is ready to use. It is recommended that

tools with gears be regreased with a special

gear lubricant at every brush change.

CARBON BRUSHES

The brushes and commutator in your tool

have been engineered for many hours of

depend a b l e service. To maintain p e a k

efficiency of the motor, we recommend every

two to six months the brush es be examined.

Only genuine Bosch replace ment brushes

specially designed for your tool should be

used.

BEARINGS

After about 300-400 hours of operation, or at

every second brush change, the bearings

should be replaced at Bosch Factory Service

Center or Au thorized Bosch Service Station.

Bearings which become noisy (due to heavy

load or very abrasive material cut ting) should

be replaced at once to avoid overheating or

motor failure.

Cleaning

To avoid accidents always

dis connect the tool from

th e powe r sup p l y be f o re cl e aning o r

performing any main tenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety gog gles when

cleaning tools with compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not at tempt to clean by inserting pointed

objects through openings.

Ce rtai n clean ing age nts

and sol v e n t s d a m a g e

plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning

solven t s , a m m o n i a a n d h o u s e hold

detergents that contain ammonia.

!

WARNING

!

WARNING

Maintenance

!

CAUTION

BM 1609929C59 06-10 :BM 1609929C59 06/10 6/24/10 8:10 AM Page 11

Loading...

Loading...