Bodine 07410292 Wiring Diagrams

Contact Us:

Tel: 1-800-7BODINE (U.S. only)

Tel: 773-478-3515

Fax: 773-478-3232

E-mail: service@bodine-electric.com

Corporate Web:

www.bodine-electric.com

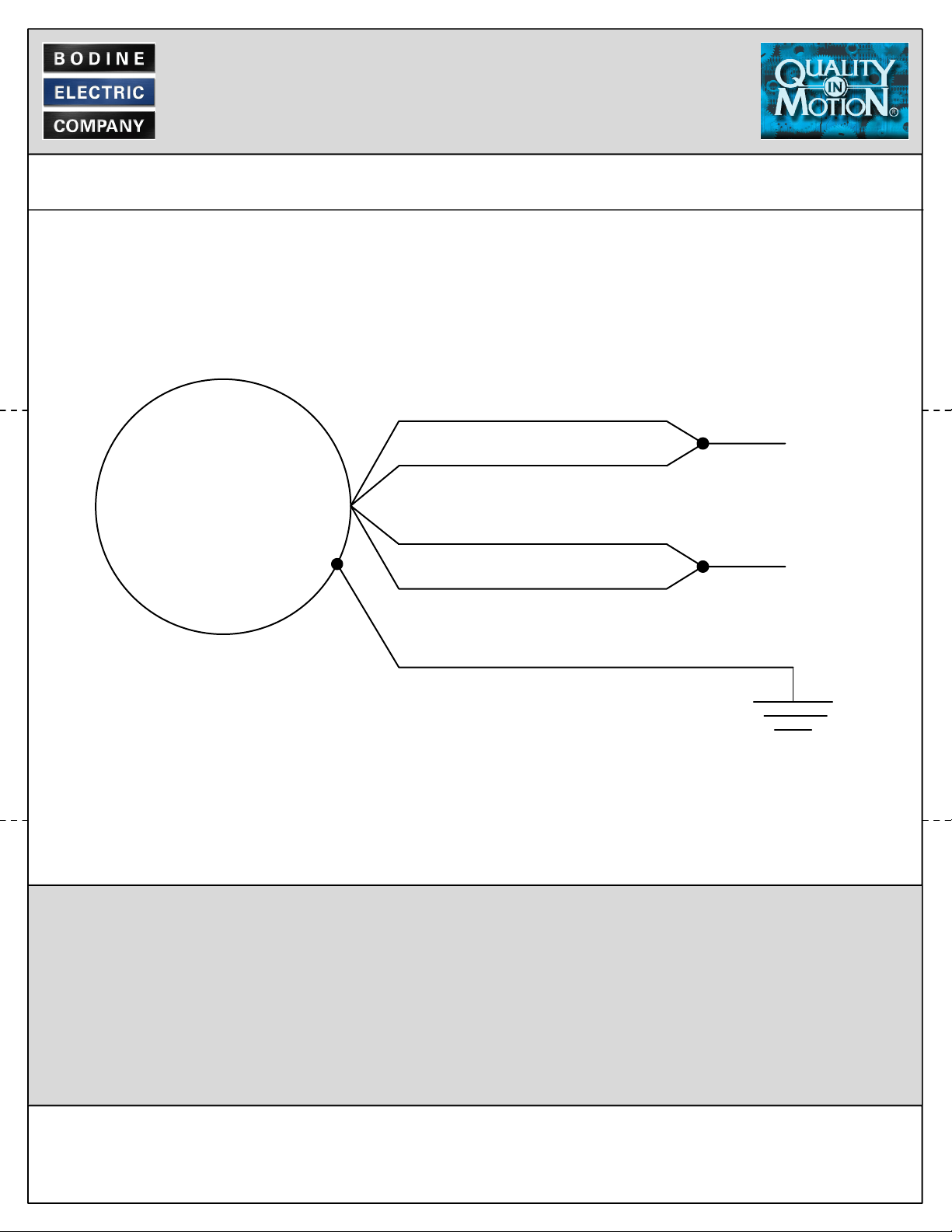

CONNECTION DIAGRAM 07410292

1-Phase 4-Wire Reversible

Black-Yellow Tracer

Blue-Yellow Tracer

Motor

Black

Blue

Green-Yellow Tracer

Direction of Rotation: Clockwise

To reverse direction of rotation,

transpose Black-Yellow Tracer & Black leads.

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products manufactured by it to be free of defects in workmanship and materials when used under Normal

Operating Conditions and when applied in accordance with nameplate specifications. This warranty shall be in effect for a period of twelve months from date

of purchase or eighteen months from date of manufacture, whichever comes first.

The Bodine Electric Company will, at its option, repair, replace, or refund the purchase price of any of its products, which has been found to be defective and

is within the warranty period, provided that the product is shipped freight prepaid, with previous authorization, to Bodine Electric, or to the nearest Bodine

Authorized Service Center. At its option, all return shipments are F.O.B. Bodine’s plant or Authorized Service Center. Bodine is not responsible for removal,

installation, or any other incidental expenses incurred in shipping the product to or from Bodine.

This warranty is in lieu of any other expressed or implied warranty-including (but not limited to) any implied warranties of merchantability and/or

fitness for a particular use or purpose.

Bodine’s liability under this warranty shall be solely limited to repair or replacement of the Bodine product within the warranty period and Bodine shall not be

liable, under any circumstances, for any consequential, incidental or indirect damages or expenses associated with the warranted products.

Commutators and/or brush wear and its associated effects are a normal occurrence and are not covered by this warranty unless otherwise agreed to by

Bodine in writing.

Any Bodine product, which is damaged due to misuse, abuse, negligence or has been modified or dismantled without the knowledge or written consent of

Bodine, is not covered by this warranty.

Line

Motor/Gearmotor Serial No. _____________________ Purchase Date ____________ Installed By __________________

See Other Side for Safety, Installation, Use and Maintenance Information

Printing Instructions per SMKDI-770-01

Model: 07410292

eDOC:

Part No.:

0741029220140026

H

Gearmotor/Motor Safety,

Installation, Use, and

Maintenance Information

Thank you for selecting a gearmotor/motor from

Bodine Electric Company. With your new drive unit

you will find yourself enjoying the same high

performance and trouble free operation that has

been characteristic of Bodine products since 1905.

Bodine Electric Company prides itself on the

quality of design and manufacture of its products.

Great care is taken in an attempt to provide

products free of defects in workmanship, or

materials.

Safety

“The use of electric machines, like that of all

other utilization of concentrated power, is potentially

hazardous. The degree of hazard can be greatly

reduced by proper design, selection, installation,

and use, but hazards cannot be completely

eliminated. The reduction of hazard is the joint

responsibility of the user, the manufacturer of the

driven or driving equipment, and the manufacturer

of the machine”.

Bodine products are designed and manufactured

to comply to applicable safety standards and, in

particular, to those issued by ANSI (American

National Standards Institute), NEMA (National

Electrical Manufacturers Association), U.L.

(Underwriters Laboratories, Inc.), and CSA

(Canadian Standards Association).

Most Bodine products are “third party approved”

with respect to construction. Motors and

gearmotors having component recognition by U.L.

Inc. have a

that are CSA certified also have a or a

mark in the same location. If you need specific

information regarding the “third party approval” of

Bodine products, contact your Bodine

Representative, or the Corporate Headquarters.

However, since even well built apparatus can be

installed or operated in a hazardous manner, it is

important that the users observe safety

considerations. With respect to the load and

environment, the user must properly

and

aspects see safety standards publication No.

ANSI/NEMA MG-2.*

* Standards Publication No. ANSI/NEMA MG-2. “Safety

Standard for Construction and Guide for Selection, Installation

and Use of Electric Motors and Generators.”

Available from:

National Electrical Manufacturers Assoc.

www.nema.org

symbol on their nameplates. Those

select, install,

use

the apparatus-for guidance on all three

Selection

Before proceeding with the installation, the user

should review the application to confirm that the

proper drive has been selected. This should be

done after reading this notice and all applicable

safety standards. If in doubt, contact your Bodine

Representative or the Corporate Headquarters if

there is no Representative in your area. Any

selection or application suggestions made by

Bodine or their Representatives are only to assist

the customer-and in all cases, determination of

fitness for purpose or use is solely the customer’s

responsibility.

All nameplate ratings are based on the following

normal operating conditions

1. Duty: 8 hours per day; 5 days per week if

nameplated continuous duty (CONT), without

frequent reversals or starts and stops.

2. Ambient temperature 0°C to 40°C, unless

otherwise noted on the product nameplate.

3. Load: Uniform and free from shock or high

inertia.

4. Voltage: Within 10% of nameplate rating.

5. Frequency: Within 5% of nameplate rating.

6. Combined variation of voltage and frequency Within a total of 10% providing frequency

variation does not exceed 5%.

:

Variations from the above conditions may be

hazardous.

Installation

It is the responsibility of the equipment

manufacturer or individual installing the apparatus

to take diligent care in installing it. The National

Electrical Code (NEC), sound local electrical and

safety codes, and when applicable, the

Occupational Safety and Health Act (OSHA) should

be followed when installing the apparatus to reduce

hazards to persons and property.

Inspection

Examine the apparatus for damage from

shipment before connecting. Any claim(s) for

shipping damage should be made to the freight

carrier. Do not attempt to turn the output shaft of a

gearmotor with an externally applied torque arm.

Paint thickness of .003 maximum does not apply to

published dimensional values.

Mounting

Any screws or similar devices, that penetrate

the motor frame either for mounting the Bodine

product or mounting something to the product,

should be limited in length so as not to come in

contact with, or in close proximity to, intended

features that conduct electricity.

Bodine stock products are designed for

universal horizontal mounting. Vertical mounting,

with gearhead above motor is not normally

recommended. Consult the factory for custom

mounting requirements.

Connection

Follow nameplate for voltage, frequency, and

phase of power supply. See accompanying wiring

diagram as to connections for rotation (and

capacitor, resistor, relay, protector, if required).

When connecting, make sure that your

motor/gearmotor is securely and adequately

grounded-failure to ground properly may cause

serious injury to personnel.

available at:

www.bodine-electric.com

Wiring diagrams are

Wiring

For wire sizes and electrical connections refer to

the National Electrical Code (NEC), Article 430,

“Motors, Motor Circuits, and Controllers” and/or

applicable local area codes. Extension cords

should not be used.

Use

Additional Safety Considerations

The chance of electric shock, fires, or

explosions can be reduced by giving proper

consideration to the use of grounding, thermal and

over current protection, type of enclosure, and

good maintenance procedures.

The following information

foregoing safety considerations: This information is

not purported to be all-inclusive and the

aforementioned references should be consulted.

1. Bodine standard totally enclosed products are

neither explosion proof nor dust ignition proof

and are not certified for hazardous locations in

the presence of flammable/explosive gas,

vapor, or dust. When dealing with hazardous

locations, an approved or certified product is

generally the recommended approach. The

NEC and NEMA safety standards should be

consulted to determine if exceptions are

allowed.

2. Enclosed motors/gearmotors are suitable for

dirty, damp locations. For outdoor use,

enclosed motors must be protected by a IP-44

sealing kit or a cover while still allowing

adequate airflow.

supplements

the

3. Moisture will increase the electrical shock

hazard of electrical insulation. Therefore,

consideration should be given to the avoidance

of (or protection from) liquids in the area of

motors. Use of totally enclosed

motors/gearmotors will reduce the hazard if all

openings are sealed.

4. Motors/gearmotors that employ capacitors can

develop more than nameplate voltage across

the capacitor and/or capacitor winding

(depending on design). Suitable precautions

should be taken when applying such motors.

5. Do not rely upon self-locking gears or

permanent magnet, or energized motors to hold

a load in place if movement could result in

personal injury. Mechanical locking devices

should be used in such applications.

6. For motors driven by electronic controls, do not

use a function of the control for safety interlock

purposes. An independent switch or relay

should be used.

Before Starting

1. Before attempting to start, check all connections

and fuses.

2. Proper consideration should be given to rotating

members: Before starting, be sure keys,

pulleys, etc. are securely fastened.

Proper

guards should be provided to prevent hazards

to personnel while rotating.

3. Other mechanical considerations include proper

mounting and alignment of products and safe

loads on shafting and gearing.

Starting

The motor/gearmotor should be test-started in

an unloaded state (because of possible reaction

torque, the drive should be securely mounted

when starting-even when unloaded).

If the drive unit does not start promptly and run

smoothly, disconnect immediately.

If unable to correct the problem, contact your

purchase source, or a Bodine Authorized Service

Center, describing the trouble in detail. Include

the serial number, type, and other nameplate data.

Do not dismantle the product-tampering or

disassembly

voids

the warranty.

Mainentance

IMPORTANTequipment, disconnect power source (this

applies especially to equipment using automatic

restart devices instead of manual restart devices

and when examining or replacing

brushes on brush-type motors/gearmotors).

Clean regularly to prevent dirt and dust from

interfering with ventilation or clogging moving

parts.

Brush-Type Motors/Gearmotors

performance, brush-type motors and gearmotors

need periodic user-maintenance. The

maintenance interval is best determined by the

user. Inspect brushes regularly for wear (replace

in same axial position). Replace brushes as

needed.

Products Employing Capacitors

servicing motors/gearmotors employing

capacitors, always discharge the capacitor by

placing a conductor across its terminals before

touching the terminals with any part of your body.

Before

servicing or working on

-For optimum

-Before

Lubrication

All Bodine products are lubricated for life, and

do not require re-lubrication.

(All information and data are subject to change

without notice)

Part No.:

07410292

H

Loading...

Loading...