Blodgett SC-10DS User Manual

Project

Item No.

Quantity

Model SC-6DS (6 pan convection steamer operating on direct steam)

Model SC-10DS (10 pan convection steamer operating on direct steam)

Model SC-16DS (16 pan convection steamer operating on direct steam)

STEAMER EXTERIOR CONSTRUCTION

304 #4 finish stainless steel

Welded stainless steel door with removable inner stainless steel liner

Full perimeter door gasket

Positive lock and seam mechanism with spring release on door

Stainless steel control housing

One piece welded 316 stainless steel cooking chamber

Coved corners

Stainless steel pan supports

Stainless steel drip trough integrally connected to drain

CABINET BASE CONSTRUCTION

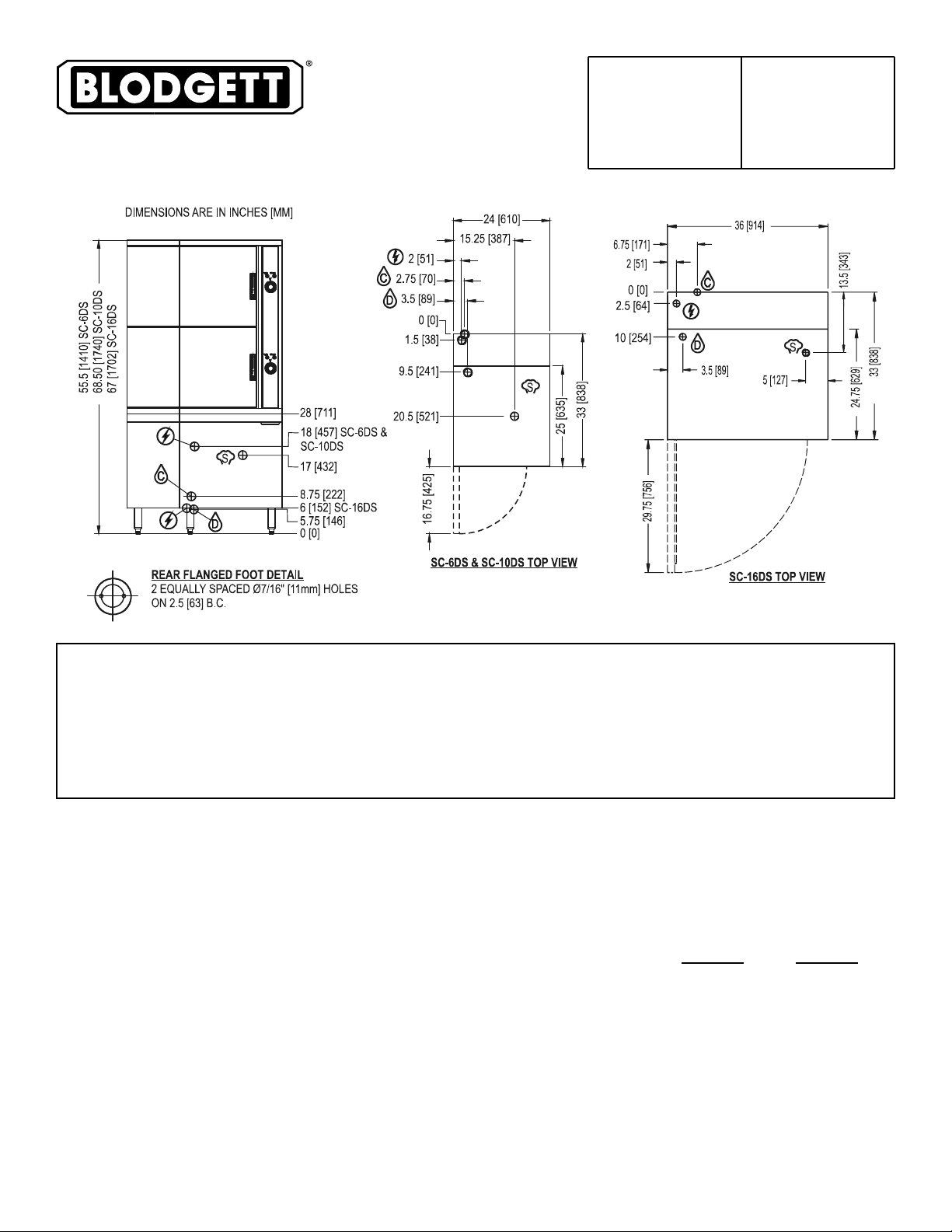

24” (610 mm) wide cabinet base for SC-6DS and SC-10DS

36” (914 mm) wide cabinet base for SC-16DS

Full perimeter painted angle iron frame

Reinforced steamer mountings

Stainless steel exterior

Hinged door(s) with magnetic latch

6” (152 mm) stainless steel legs with adjustable bullet feet on front and

adjustable flanged feet on rear for securing to floor

OPERATION

Pressureless steam operation

Separate controls for each compartment

Controls accessible through removable side panel

On/off power switch with indicator light

Ready indicator light

Cooking indicator light

60 minute electric timer with audible alarm to signal end of cook cycle

Steam flow to the cooking chamber is cut off when the door is opened

during the cooking cycle and reactivated when the door is closed

STANDARD FEATURES

115 VAC, 1 phase, 60 Hz for controls

Electromechanical controls

Steam condensing drain

One year parts and labor steamer warranty*

Five year limited steamer door warranty*

* For all international markets, contact your local distributor.

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

36” (914 mm) wide cabinet base for SC-6DS and

SC-10DS

Stainless steel frame

Stainless steel rear panel

Spray and rinse assembly

Ball float trap

Load compensating timer

Correctional package

One year extended warranty

SC-DS

Convection Steamer on an

Cabinet Base Operating on Direct Steam

SC-DS CONVECTION STEAMER

CAPACITY

Model SB-6DS is comprised of two 3 pan compartments

Model SB-10DS is comprised of two 5 pan compartments

Model SB-16DS is comprised of two 8 pan compartments

SC-6DS shown

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

SC-DS CONVECTION STEAMER

SHORT FORM SPECIFICATIONS

Provide Blodgett model SC-6DS (6 pan), SC-10DS (10 pan) or SC-16DS (16 pan) convection steamer operating on direct steam. The SC-6DS and SC-10DS shall be mounted on a 24”

wide base (an optional 36” base is available). The SC-16DS shall be mounted on a 36” wide base. The SC-6DS is comprised of two 3 pan compartments. The SC-10DS is comprised of

two 5 pan compartments. The SC-16DS is comprised of two 8 pan compartments. Unit shall be constructed of satin finish 304 stainless steel with a one piece welded stainless steel cooking chamber with coved corners. The door shall have a removable inner liner of stainless steel with full perimeter gasket seal, an outer liner of one-piece all welded stainless steel, and a

positive lock and seal mechanism with spring release. Each compartment shall have removable stainless steel pan supports. A stainless steel drip trough integrally connected to collect

and drain condensate with the doors open. The control housing shall be constructed of stainless steel with a full access removable panel. The controls shall include an on/off power switch

with LED, a ready indicator light, cooking indicator light, and a 60 minute electric timer with audible alarm that signals the end of the cook cycle. Steam flow to the compartment shall be

cut off when the door is opened during the cook cycle and shall be reactivated when the door is closed. The cabinet base shall have full perimeter painted angle iron frame, reinforced

counter, stainless steel exterior, hinged doors and 6” (152 mm) stainless steel legs with adjustable bullet feet on the front and flanged feet on the rear for securing to floor. Provide options

and accessories as indicated.

WATER SUPPLY:

Water quality is a major factor affecting the performance of your steamer. If you

are unsure of water quality, consult a local water treatment specialist and have the

water analyzed. Your water supply must be within these general guidelines:

Total dissolved solids: Less than 60 PPM Total alkalinity: Less than 20 PPM

Silica: Less than 13 PPM Chlorine: Less than 1.5 PPM

pH Factor: 7.0 - 8.5

Water which fails to meet these standards should be treated by installation of a

water conditioner. Failure or malfunction of this steamer due to poor water quality

is not covered under warranty.

WATER & DRAIN CONNECTIONS:

Drain 2” (51mm) IPS piped to open floor drain. No solid connection.

24” length before open air opening (no bends or elbows)

Cold Water 3/8” (10mm) tubing at 25-50 PSI (170-345 kPa)

Appliance is to be installed with backflow protection in accordance with Federal,

State or Local codes.

STEAM CONNECTIONS:

3/4” inlet for incoming steam at a minimum of 80 lbs/hour

at 10 psi (36kg/hr at 69 kPa).

POWER SUPPLY:

1/2” (13 mm) conduit connection to controls. 2 amps per

compartment

SHIPPING INFORMATION:

Approx. Weight: w/24” base w/36” base

SC-6DS 500 lbs. (227 kg) 550 lbs. (249 kg)

SC-10DS 600 lbs. (272 kg) 650 lbs. (295 kg)

SC-16DS n/a 750 lbs. (340 kg)

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

NOTE: The company reserves the right to make

substitutions of components without prior notice.

APPROVAL/STAMP

P/N S00031 Rev F (12/09)

Loading...

Loading...