Blodgett 20E-KLS, 40E-KLS, 60E-KLS, 100E-KLS, 80E-KLS User Manual

KLS-E Series

ELECTRIC STATIONARY FLOOR KETTLE INSTALLATION - OPERATION - MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Manufacture Service Questions: 866-518-3977

PART NUMBER 170092 REV B (04/11)

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the consignee to inspect the container upon receipt of same and to determine the possibility of any damage, including concealed damage. WE suggest that if you are suspicious of damage to make a notation on the delivery receipt. It will be the responsibility of the consignee to file a claim with the carrier. We recommend that you do so at once.

2 OM-KLS-E

IMPORTANT - READ FIRST - IMPORTANT

CAUTION: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING INSTRUCTIONS, CAUTIONS, AND SAFETY INSTRUCTIONS CONTAINED IN THIS MANUAL.

WARNING: THIS UNIT IS INTENDED FOR USE IN THE COMMERCIAL HEATING, COOKING AND HOLDING OF WATER AND FOOD PRODUCTS, PER THE INSTRUCTIONS CONTAINED IN THIS MANUAL. ANY OTHER USE COULD RESULT IN SERIOUS PERSONAL INJURY OR DAMAGE TO THE EQUIPMENT AND WILL VOID WARRANTY.

WARNING: KETTLE MUST BE INSTALLED BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO GROUND UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT EQUIPMENT SURFACES. DIRECT SKIN CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT FOOD OR WATER IN THE KETTLE. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

CAUTION: DO NOT OVER FILL THE KETTLE WHEN COOKING, HOLDING OR CLEANING. KEEP LIQUIDS A MINIMUM OF 2-3” (5-8 cm) BELOW THE KETTLE BODY RIM TO ALLOW CLEARANCE FOR STIRRING, AND BOILING.

WARNING: TAKE SPECIAL CARE TO AVOID CONTACT WITH HOT KETTLE BODY OR HOT PRODUCT WHEN ADDING INGREDIENTS, STIRRING OR TRANSFERRING PRODUCT TO ANOTHER CONTAINER.

CAUTION: KEEP FLOORS IN FRONT OF KETTLE WORK AREA CLEAN AND DRY. IF SPILLS OCCUR, CLEAN IMMEDIATELY, TO AVOID SLIPS OR FALLS.

WARNING: FAILURE TO CHECK SAFETY VALVE OPERATION PERIODICALLY COULD RESULT IN PERSONAL INJURY AND/OR DAMAGE TO EQUIPMENT.

WARNING: WHEN TESTING, AVOID ANY EXPOSURE TO THE STEAM BLOWING OUT OF THE SAFETY VALVE. DIRECT CONTACT COULD RESULT IN SEVERE BURNS.

WARNING: TO AVOID INJURY, READ AND FOLLOW ALL PRECAUTIONS STATED ON THE LABEL OF THE WATER TREATMENT COMPOUND.

WARNING: BEFORE REPLACING ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY.

WARNING: KEEP WATER AND SOLUTIONS OUT OF CONTROLS AND ELECTRICAL EQUIPMENT. NEVER USE A HIGH PRESSURE HOSE TO CLEAN KETTLE SURFACES.

CAUTION: MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN. WEAR RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ THE WARNINGS AND FOLLOW THE DIRECTIONS ON THE LABEL OF THE CLEANER TO BE USED.

CAUTION: USE OF ANY REPLACEMENT PARTS OTHER THAN THOSE SUPPLIED BY THE MANUFACTURER OR AN AUTHORIZED DISTRIBUTORS CAN CAUSE OPERATOR INJURY AND DAMAGE TO THE EQUIPMENT, AND WILL VOID ALL WARRANTIES.

OM-KLS-E 1

IMPORTANT - READ FIRST - IMPORTANT

IMPORTANT: SERVICE PERFORMED BY OTHER THAN FACTORY AUTHORIZED PERSONNEL WILL VOID WARRANTIES.

WARNING: DO NOT HEAT AN EMPTY KETTLE. EXCESSIVE STEAM PRESSURE COULD DEVELOP.

CAUTION: Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

2 OM-KLS-E

Table of Contents

ImportantOperatorWarnings |

.......................................................page1-2 |

References .................................................................................... |

page 3 |

Equipment Description ............................................................... |

page 4 |

Inspection and Unpacking ............................................................ |

page 5 |

Installation ..................................................................................... |

page 6 |

Initial Start-Up ................................................................................ |

page 7 |

Operation ................................................................................... |

page 8-9 |

Sequence of Operation ............................................................... |

page 10 |

Maintenance ........................................................................... |

page 11-12 |

Cleaning ................................................................................. |

page 13-14 |

Troubleshooting .................................................................... |

page 15-16 |

Parts List ............................................................................... |

page 17-18 |

Wiring Diagram .......................................................................... |

page 19 |

Service Log .......................................................................... |

page 20-21 |

References

KLENZADE SALES CENTER ECOLAB. Inc. 370 Wabasha

St. Paul, Minnesota 55102 800/352-5326 or 612/293-2233

NATIONAL FIRE PROTECTION ASSOCIATION

60 Battery March Park

Quincy, Massachusetts 02269

NFPA/70 - The National Electrical Code

ECONOMICS LABORATORY, INC.

St. Paul, Minnesota 55102

NSF INTERNATIONAL

789 N. Dixboro Rd.

P.O. Box 130140

Ann Arbor, Michigan 48113-0140

UNDERWRITERS LABORATORIES, INC.

333 Pfingsten Road

Northbrook, Illinois 60062

ZEP MANUFACTURING CO.

1310-T Seaboard Industrial Blvd.

Atlanta, Georgia 30318

OM-KLS-E 3

Equipment Description

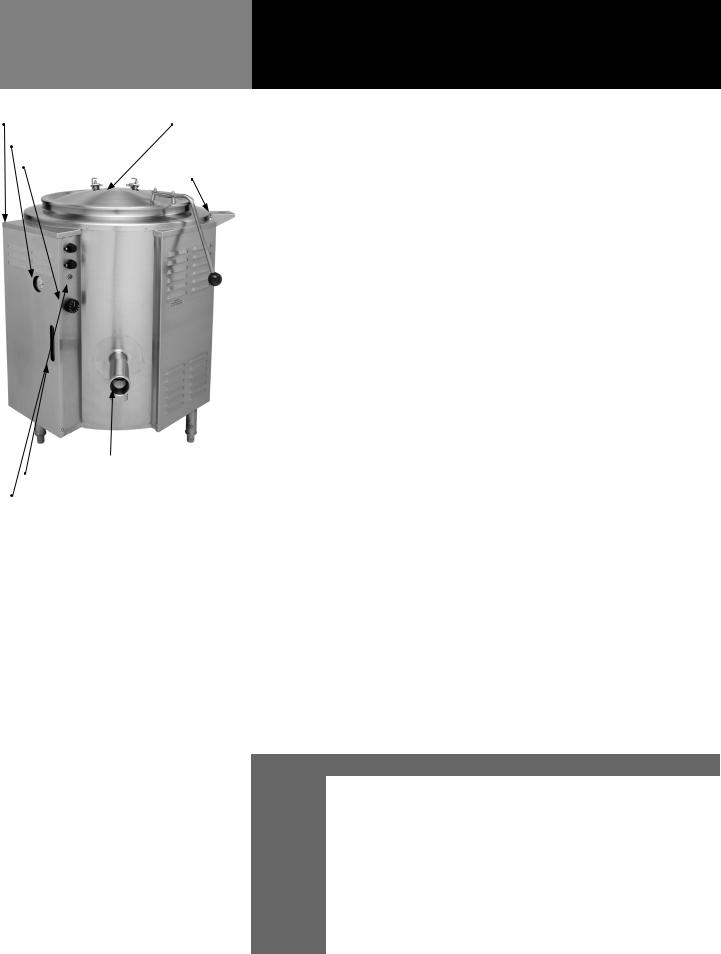

Control housing |

Cover |

Pressure/vacuum gauge |

|

Thermostat dial |

Faucet bracket |

|

Tangent drawoff

Tangent drawoff

Water gauge glass Indicator lamp

4 OM-KLS-E

Blodgett Model KLS-E are floor-mounted, tilting, steam-jacketed kettles which have thermostatically controlled, self-contained, electrically-heated steam supplies and appropriate controls, mounted on a sturdy base. Heat produced by electric heating elements boils water in a reservoir below the jacket to produce steam under pressure.

The kettle is surrounded by air-insulated stainless steel sheathing. Stainless steel panels enclose all of the controls. Three stainless steel, tubular legs support the unit. Kettles are available in 20, 40, 60, 80 and 100 gallon capacities. Kettle bodies are welded into one piece. Models are all equipped with a sanitary tangent draw-off (product faucet) valve and a stainless steel strainer. This standard draw-off is two inches in diameter, and uses a compression disc valve. The unit is controlled with a thermostat, which turns electric power on or off, and sets the cooking temperature.

Instruments are provided to show what is happening inside the unit:

•Water gauge glass: shows the level of water within the steam jacket

•Pressure/vacuum gauge: shows the steam pressure and if there is air in the jacket

•Indicator lamp: Lights when the kettle is being heated

Automatic controls within the unit:

•Contactor: Controlled by the thermostat, turns heating element power on or off

•Low-water cutoff: Turns off power to keep heating elements from overheating if water loss exposes them above the water level.

•Safety valve: Releases steam if jacket pressure gets too high

The jacket is filled at the factory with water that contains rust inhibitors. When air is removed from the jacket, the kettle efficiently provides a uniform heating temperature range of 150°F to approximately 270°F (65 to 132°C). This range allows the kettle to be used for warming, simmering, boiling or braising.

The interior of the kettle is polished to a 180 emery grit finish and the exterior is given a uniform Number 3 finish. The unit is ASME shop inspected and registered with the National Board for working pressures up to 30 PSI.

Optional equipment for the kettles includes:

•Three inch draw-off valve

•1/4” perforated or solid disc strainer

•Basket inserts

•Water fill faucets

•Automatic water filler

•Kettle brush kit

Model |

20E-KLS |

40E-KLS |

60E-KLS |

80E-KLS |

100E-KLS |

|

Capacity |

20 gallons |

40 gallons |

60 gallons |

80 gallons |

100 gallons |

|

(75 liter) |

(150 liter) |

(226 liter) |

(300 liter) |

(378 liter) |

||

|

||||||

|

|

|

|

|

|

|

Inside |

26 in |

32 in |

36 in |

38 in |

38 in |

|

Diameter |

(66 cm) |

(81 cm) |

(91 cm) |

(96.5 cm) |

(96.5 cm) |

|

|

|

|

|

|

|

|

Rim Height |

37 in |

37 in |

40 in |

44 in |

44 in |

|

(94 cm) |

(94 cm) |

(102 cm) |

(112 cm) |

(112 cm) |

||

|

||||||

|

|

|

|

|

|

|

Total Width |

26 in |

32 in |

36 in |

38 in |

38 in |

|

(66 cm) |

(81 cm) |

(91 cm) |

(96.5 cm) |

(96.5 cm) |

||

|

||||||

|

|

|

|

|

|

|

Front-to- |

38 in |

48 in |

47 in |

49 in |

49 in |

|

Back |

(97 cm) |

(123 cm) |

(120 cm) |

(125 cm) |

(125 cm) |

|

|

|

|

|

|

|

Inspection & Unpacking

CAUTION

THIS UNIT IS VERY HEAVY. INSTALLER SHOULD OBTAIN HELP AS NEEDED TO LIFT THIS WEIGHT SAFELY.

CAUTION

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT. TAKE CARE TO AVOID PERSONAL INJURY OR DAMAGE TO THE UNIT BY STAPLES LEFT IN THE WALLS OF THE CARTON.

The unit will arrive in a heavy carton.

Inside it will be banded to a skid.

The unit will arrive in a heavy shipping carton and will be banded to a skid. Immediately upon receipt, inspect the carton carefully for exterior damage.

Carefully cut any polyester straps around the carton and detach the sides of the box from the skid. Pull the carton up off the unit.

Thoroughly inspect the unit for concealed damage. Report any shipping damage or incorrect shipments to the delivery agent.

Write down the model number, serial number, and installation date, and retain this information for future reference. Space for these entries is provided at the top of the Service Log at the back of this manual. Keep this manual on file and available for operators to use.

When installation is to begin, carefully cut any straps which hold the unit on the skid. Lift the unit straight up off the skid. Examine packing materials to be sure that loose parts are not discarded with the materials.

OM-KLS-E 5

Installation

WARNING

INSTALLATION OF THE KETTLE MUST BE DONE BY PERSONNEL QUALIFIED TO WORK WITH ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT.

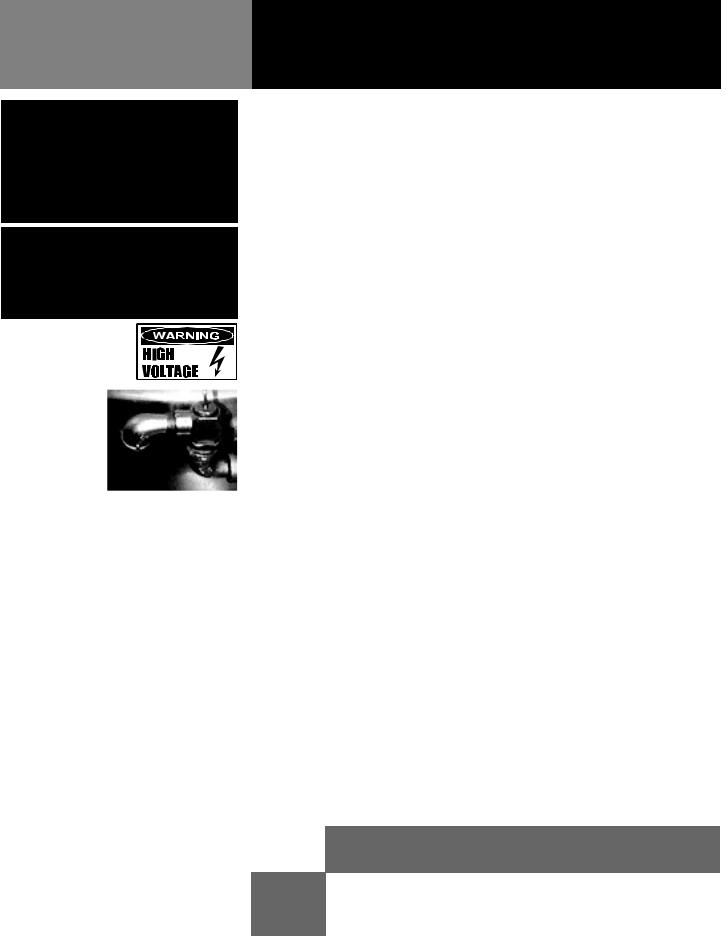

DANGER

ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE TO GROUND UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

The kettle is provided with complete internal wiring and is ready for immediate connection. Wiring diagrams are provided in this manual and on the inside of the control housing service panel. Any mechanical or electrical changes must be approved by Food Service Engineering Department.

The completed unit has been operated at the factory to test all controls and heater elements.

1.Set the kettle in place and level it by turning the bullet feet to adjust leg length. Allow clearance around the unit for cleaning, maintenance and service.

2.Confirm that the jacket water level is above the mid point of the gauge glass. If the level is low, follow the instructions under “Jacket Filling and Water

Treatment,” Pages 11 - 12.

3.The open end of the elbow on the outlet of the safety valve must face downward. If it does not, turn it to the correct position.

4.Provide electrical power specified on the equipment electrical information plate.

Observe local codes and/or The National Electrical Code in accordance with ANSI/NFPA 70 - (current edition).

5.The equipment is shipped ready for three phase operation. Refer to the wiring diagram for single phase operation.

6.Bring in the electrical supply through opening on control housing that is located below the thermostat dial. An opening is provided for 1-1/4” (35mm) conduit fitting.

Water tight, 90° elbow connection is recommended. Incoming power connections are made at the terminal block.

Observe local codes and/or The National Electrical Code in compliance with ANSI/NFPA 70 (latest edition). When there is a choice between applicable codes

Blodgett recommends following the more stringent code. (A BX connection is not recommended.)

7.Electrically ground the unit at the terminal provided.

8.Check the following to confirm that your kettle is properly installed:

•Room for cleaning and servicing

•The kettle is level

•The correct amount of water is in the kettle jacket

•Safety valve is pointed down

•Unit is connected with a waterproof electric power supply of the proper voltage, phase and amperage rating

|

20E-KLS |

40E-KLS |

60E-KLS |

80E-KLS |

100E-KLS |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

KW |

AMP |

KW |

AMP |

KW |

AMP |

KW |

AMP |

KW |

AMP |

|

|

|

|

|

|

|

|

|

|

|

208 Volts |

11 |

30 |

22 |

60 |

32 |

90 |

32 |

90 |

32 |

90 |

|

|

|

|

|

|

|

|

|

|

|

240 Volts |

12 |

29 |

24 |

58 |

36 |

87 |

36 |

87 |

36 |

87 |

|

|

|

|

|

|

|

|

|

|

|

480 Volts |

12 |

14 |

24 |

28 |

36 |

44 |

36 |

44 |

36 |

44 |

|

|

|

|

|

|

|

|

|

|

|

*All three phase. Single phase is also available, except on 60E-KLS, 80E-KLS and 100E-KLS.

6 OM-KLS-E

Loading...

Loading...