Page 1

EN

Auto Revers

OPERATION MANUAL

Page 2

2

WARNING

!

Follow the user's manual requirements to ensure

durable and trouble-free operation of the unit

Disconnect the unit from power supply prior to any connection,

servicing and repair operations.

Only qualified electricians with a work permit for electrical units up

to 1000 V are allowed for installation and maintenance.

The present user’s manual should be carefully read before

beginning works.

Single-phase power mains must comply with the acting local electrical

norms and standards.

Fixed electrical wiring must be equipped with an automatic

circuit breaker.

The unit must be connected to power mains through a QF automatic

circuit breaker integrated into the fixed wiring system. The gap between

the circuit breaker contacts on all poles must be not less than 3 mm.

Check the unit for any visible damage of the impeller and the casing

before starting installation. The casing internals must be free of any

foreign objects that can damage the impeller blades.

The unit design is constantly being improved, thus some models may be slightly different

from those described in this manual.

Page 3

While mounting the unit, avoid compression of the casing!

Deformation of the casing may result in the motor jam and

noisy operation.

Misuse of the unit and any unauthorized modifications are not allowed.

Take steps to prevent ingress of smoke, carbon monoxide, and other

combustion products into the room through open chimney flues

or other fire-protection devices. Sufficient air supply must be provided

for proper combustion and exhaust of gases through the chimney

of fuel burning equipment to prevent back drafting.

Sufficient air supply must be provided for proper combustion and

exhaust of gases through the chimney of fuel burning equipment

to prevent back drafting.

Transported air must not contain any dust or other solid impurities,

sticky substances, or fibrous materials.

3

WARNING

!

Follow the user's manual requirements to ensure

durable and trouble-free operation of the unit

Page 4

Do not use the unit in a hazardous or explosive environment containing

spirits, gasoline, insecticides, etc.

Do not close or block the intake or extract vents in order to ensure

the efficient air flow.

Do not sit on the unit and do not put objects on it.

The timer circuit is under mains voltage.

4

WARNING

!

Follow the user's manual requirements to ensure

durable and trouble-free operation of the unit

Page 5

The unit is allowed to be used by children aged from 8 years old

and above and persons with reduced physical, sensory, or mental

capabilities or no experience and knowledge provided that they

have been given supervision or instruction regarding safe use of

the unit and understand the risks involved.

Do not allow children to play with the unit.

Unit cleaning and maintenance must only be performed by children

under adult supervision.

THE PRODUCT MUST BE DISPOSED SEPARATELY

AT THE END OF ITS SERVICE LIFE. DO NOT DISPOSE

IT AS UNSORTED MUNICIPAL WASTE.

5

WARNING

!

Follow the user's manual requirements to ensure

durable and trouble-free operation of the unit

Page 6

DELIVERY SET

1. Fan:1 piece;

2. Control unit: 1 piece;

3. 5-wire cable: 4 m;

4. Self-tapping screws with expansion anchors: 12 pieces each

5. User's manual;

6. Packing box.

BRIEF DESCRIPTION

The unit is an axial extract fan for extract and/or supply ventilation of small and medium-sized domestic

spaces. The fan is compatible with 150 mm air ducts.

The fan has a white plastic casing and automatic louvres.

The Auto Revers fans are designed for wall-mounted configurations.

OPERATION GUIDELINES

The fan is designed for connection to a 220…240 V/50 Hz single-phase alternating current mains.

о о

The units are suitable for operation at ambient air temperatures from +1 C to +45 C.

The units meet the requirements of IP24 hazardous parts access and water ingress protection standard.

The fan requires no grounding.

The fan is designed for extended periods of continuous operation without disconnection from the

electric mains.

INSTALLATION

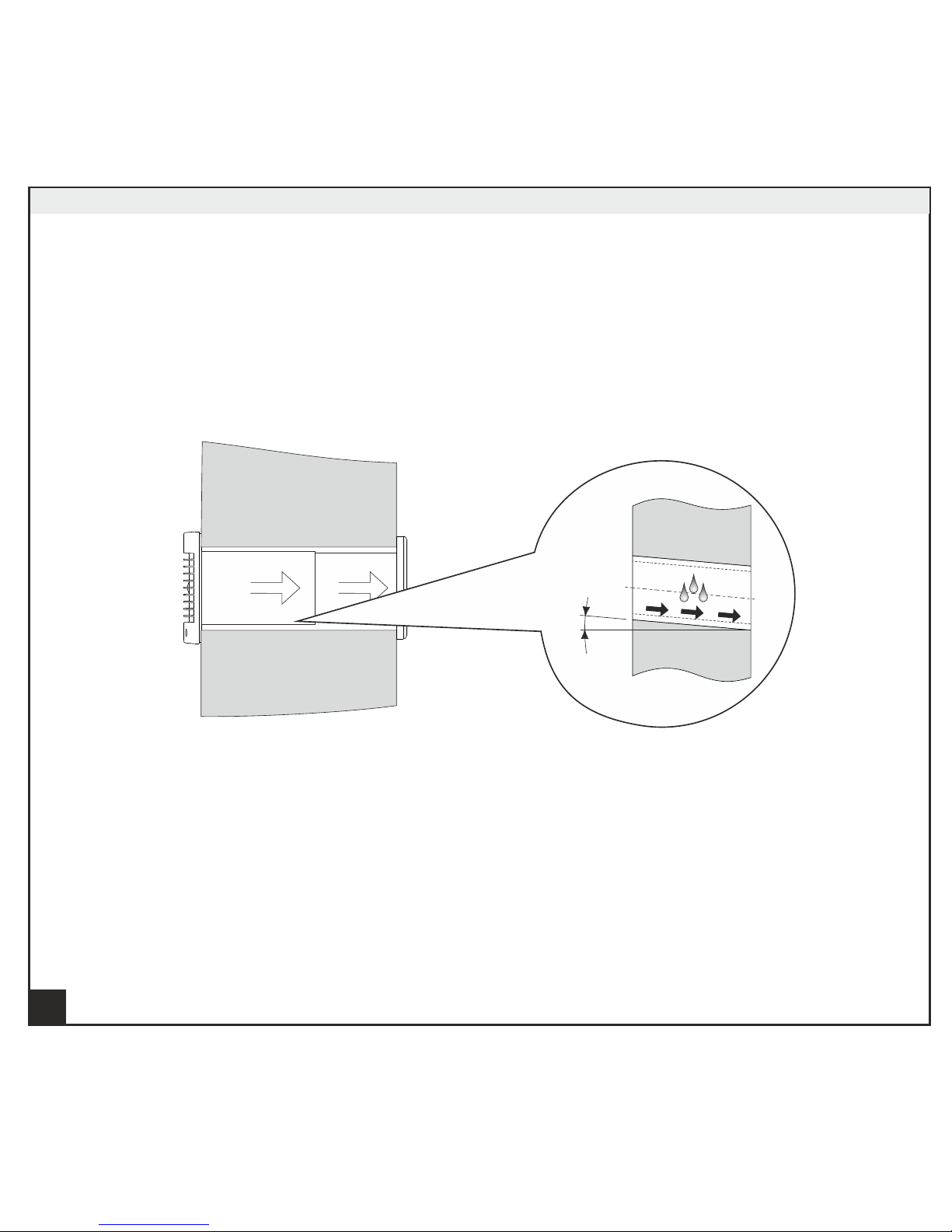

The Auto Revers fan installation steps are as follows:

1. Cut off power supply (Fig. 2).

2. Remove the front panel of the fan (Fig. 3).

3. Mark the holes on the wall (Fig. 4).

4. Drill the holes in the wall and insert the expansion anchors (Fig. 5).

5. Remove the self-tapping screws securing the cable clamping plate and remove the plate (Fig. 6). Route the

power and control leads into the casing. Secure the fan casing on the wall with 4 self-tapping screws.

6. Connect the power and control leads to the respective terminal blocks on the control circuit board of the fan

according to Diagram 1. Re-install the cable clamping plate.

7. Install the front panel back in place (Fig. 7).

6

Read the user's manual carefully before proceeding with installation works.

Compliance with the manual requirements ensures reliable operation and long service

life of the unit.

Keep the user's manual available as long as you use the unit.

EN

Page 7

7

EN

ATTENTION!!! Mind the length of the cable supplied while installing the control unit. If necessary,

a longer cable may be used. The recommended cable type is 5хAWG23 (5x0.25).

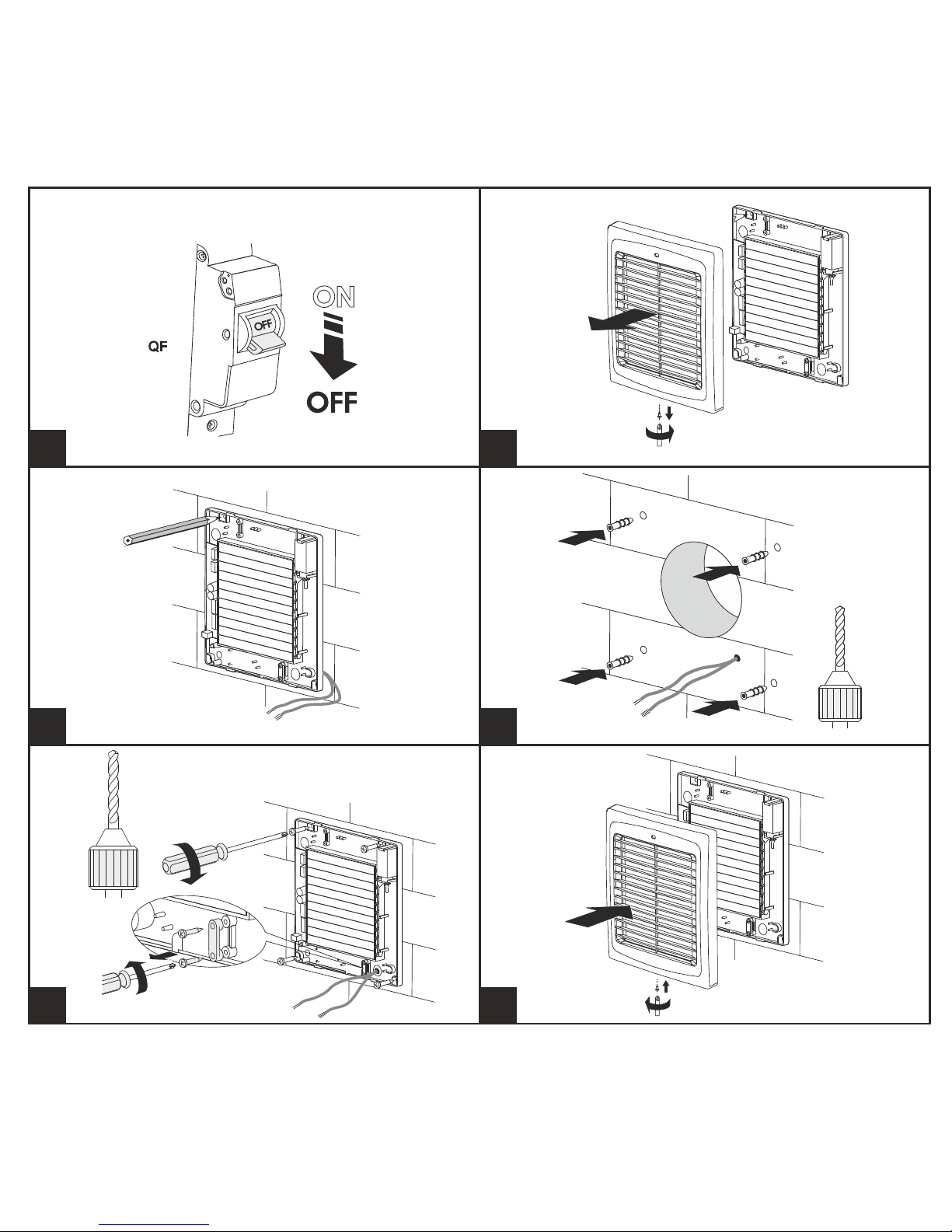

Control unit installation:

1. Make a hollow in the wall according to the control unit size (Fig. 8).

2. Remove the power and control unit buttons and plug by prying them gently with a screwdriver (Fig. 9).

3. Remove the power and control unit bezel by releasing the latches (Fig. 10).

4. Connect the power and control cable to the control units according to the wiring diagram 1.

5. Install the power and control unit into the hollow space in the wall (Fig. 11).

6. Install the frame, the buttons and the plug in the reverse order (Fig. 12).

ATTENTION! All the electrical connections to the control unit and the fan must be made using

plug-in terminal blocks. Each terminal block receptacle has a numeric marking with

a corresponding marking on the circuit board for quick and convenient connection. The colour

markings of the wires correspond to the cable supplied with the unit.

Page 8

8

FAN CONTROL

The control unit enables setting one of the four operation modes (Fig. 13):

1. Air extract mode at the low speed

2. Air extract mode at the high speed

3. Air supply mode at the low speed

4. Air supply mode at the high speed

ATTENTION! The potentiometers for speed and time control on the fan circuit board are set in the factory

for correct operation and must not be changed by the user. Any adjustment of the potentiometers is not allowed.

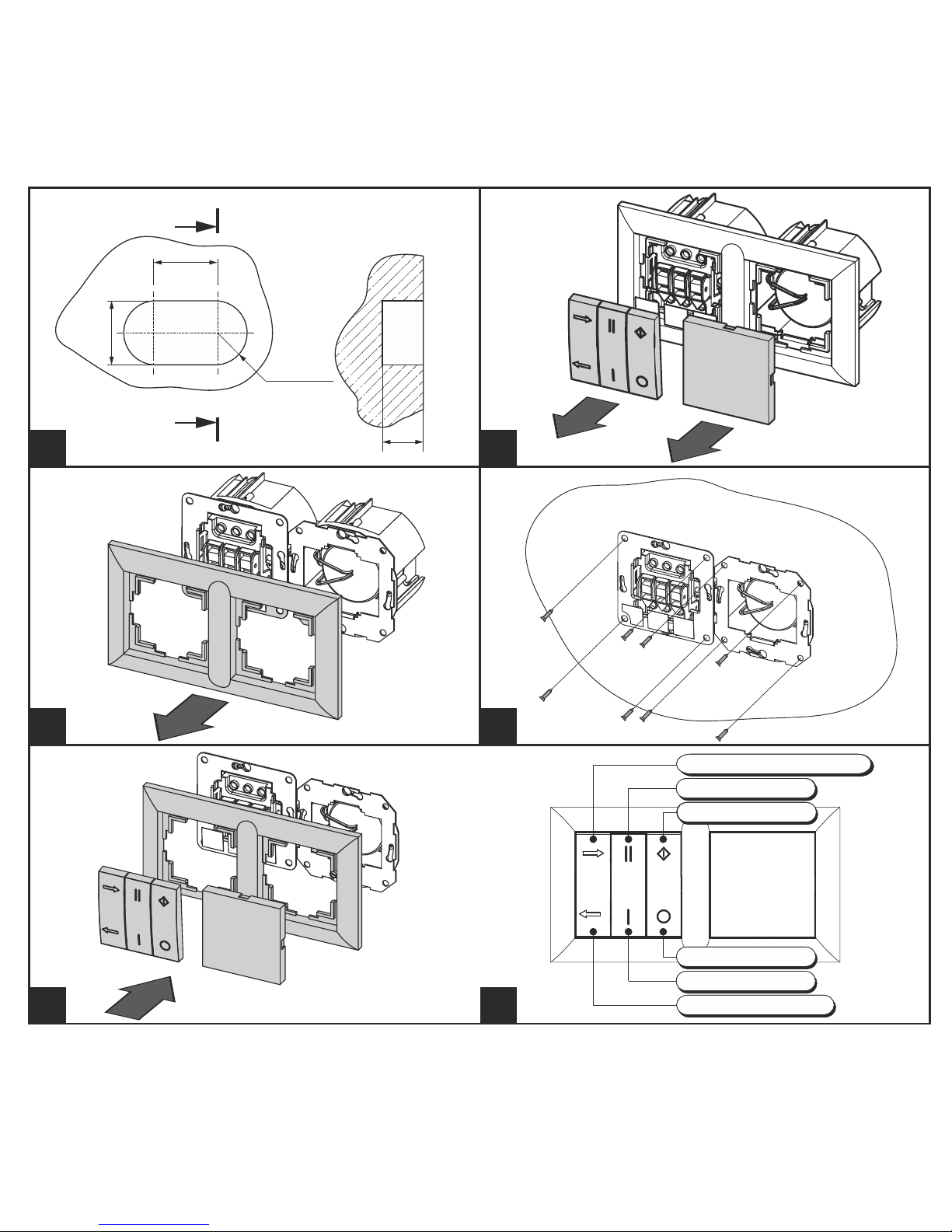

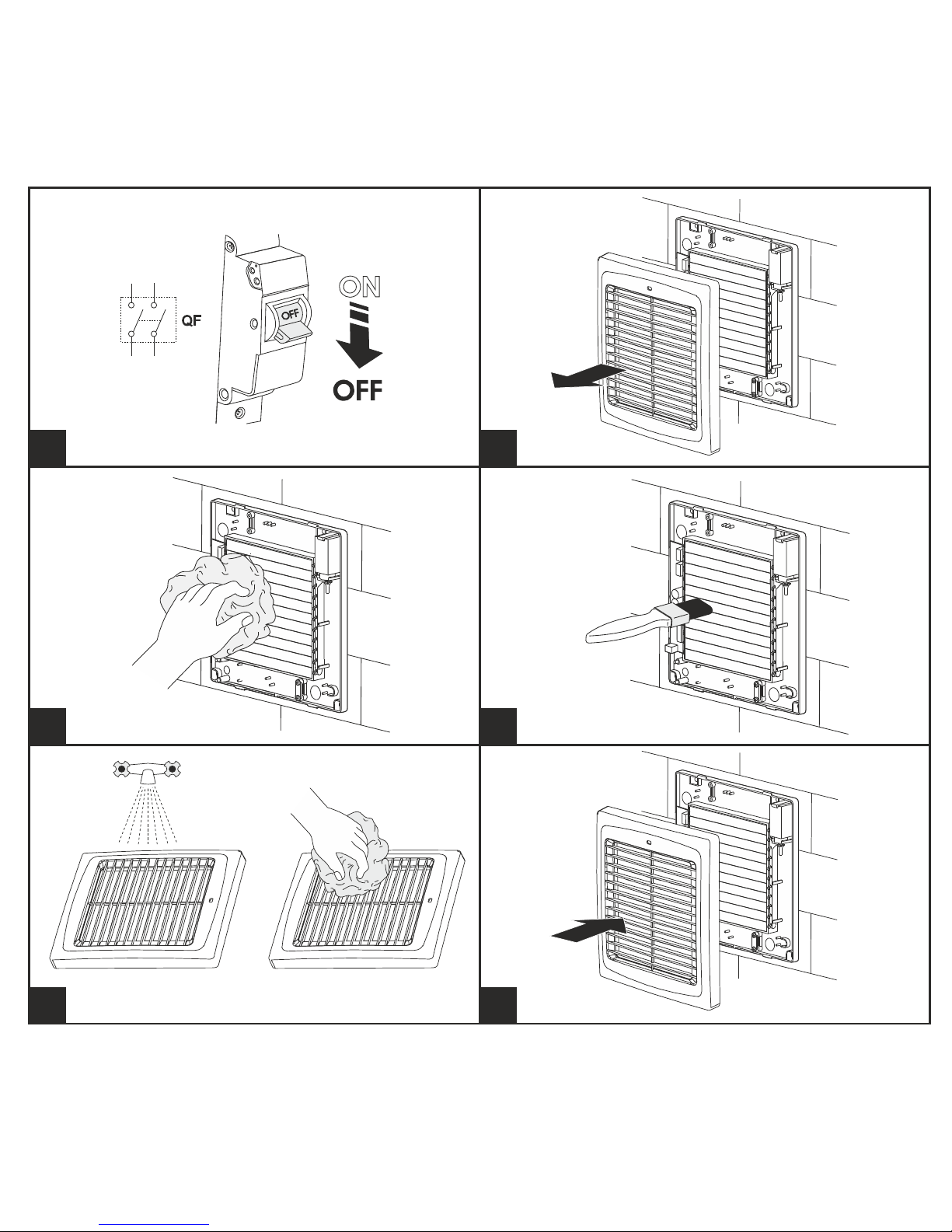

MAINTENANCE

The minimum technical maintenance interval is 6 months.

To clean the unit use a soft cloth and a brush soaked in a detergent water solution (Fig. 14–19).

ATTENTION! Avoid liquid spills on the electric components. Wipe the fan surfaces dry after cleaning.

TRANSPORTATION AND STORAGE REGULATIONS

Transportation with any transportation vehicle in the manufacturer's original package.

Store the fan in the manufacturer's original packing box in a dry ventilated premise at ambient temperatures

from +5 °C up to + 40 °C and relative humidity below 80 %.

Storage environment must not contain aggressive vapours and chemical mixtures provoking corrosion,

insulation and sealing deformation.

EN

Page 9

9

EN

Manufacturer's warranty

The product is in compliance with EU norms and standards on low voltage guidelines and electromagnetic

compatibility. We hereby declare that the product complies with the protection requirements of Electromagnetic

Council Directive 2014/30/EU, Low Voltage Directive 2014/35/EU and CE-marking Directive 93/68/EEC on the

approximation of the laws of the Member States relating to electromagnetic compatibility.

This certificate is issued following the test on the samples of the product referred to above.

Protection degree index according to IP rating against access to hazardous parts and water ingress – IP24. The fan does

not require grounding.

The manufacturer hereby warrants normal operation of the unit for 60 months after the retail sale date provided the

user's observance of the transportation, storage, installation, and operation regulations.

In case of failure due to faulty equipment during the warranty period the consumer has the right to exchange it.

If case of no confirmation of the sale date, the warranty term shall be calculated from the manufacturing date.

The replacement is offered by the Seller.

The MANUFACTURER shall not be liable for any damage resulting from any misuse of or gross mechanic

interference with the unit.

Please follow the applicable instructions.

Page 10

10

1

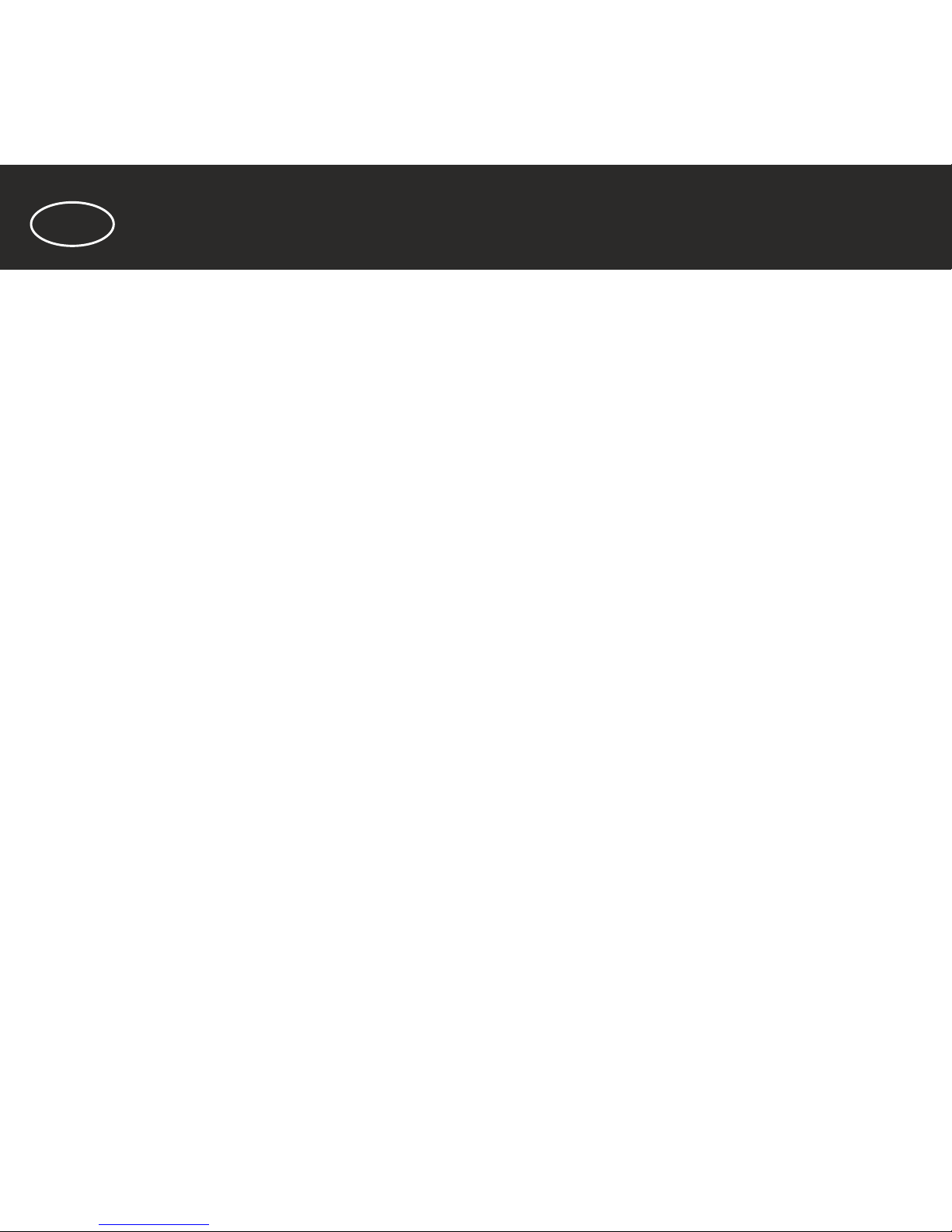

0.5°...1°

Auto Revers

Page 11

11

2 3

4 5

6 7

Page 12

48

R35

2 radii

70

70

A-A

A

A

12

8

9

10 11

12 13

Exhaust/supply* mode

High speed

Activation

Low speed

Reverse operation

Deactivation

Page 13

13

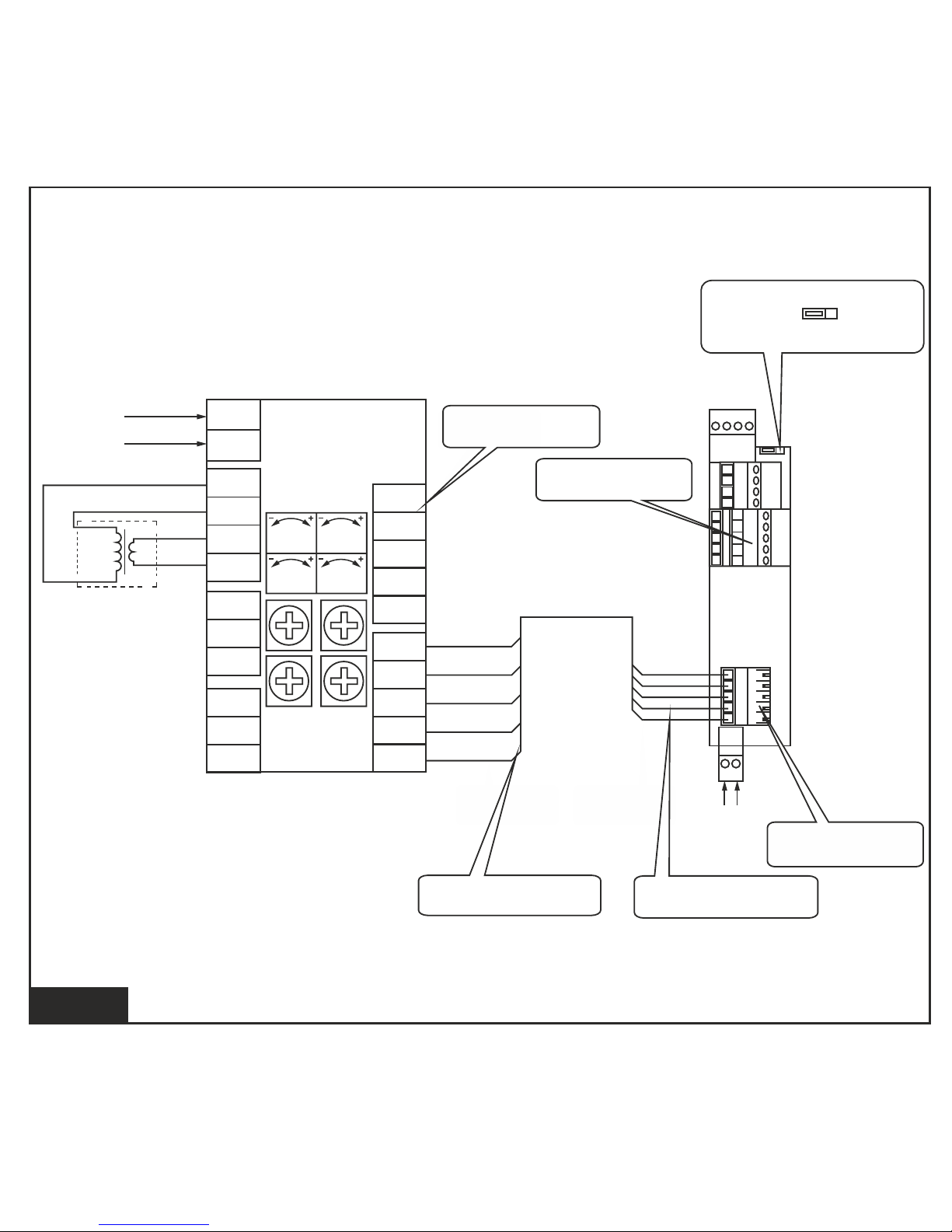

Diagram 1

31

32

L

~ 230 V

T1

Control unit

Fan

JMP1

~ 230 V

N

L

~ 230 V

N

33

35

36

Speed1 Speed2

Speed0 Timer

34

11

12

13

14

15

11

12

13

14

15

40 39 38 37

31 32

36

35

34

33

2

1

3

4

5

1

2

3

4

5

1

2

3

4

5

21

22

23

24

25

1

2

3

4

5

11

12

13

14

15

Marking "11...15" on the

controller socket connector

JMP1

Flow out

(exhaust)

White

Red

Grey

Brown

Yellow

Green

White

Marking "21…25" on the

controller socket connector

Marking "1...5" on the connecting

cable socket connector

Flow in

(supply)

White

Red

Grey

Brown

Yellow

Green

White

Marking "11...15" on the

controller socket connector

Marking "1...5" on the connecting

cable socket connector

Page 14

14

14

15

16

17

18 19

Page 15

15

CERRTIFICATE

OF ACCEPTANCE

WARRANTY

CARD

The fan is recognized as serviceable.

Stamp of the acceptance inspector

Manufacturing date

Sold by

(name of the vendor, stamp of the shop)

Date of sale

Auto Revers 150

Auto Revers

Page 16

www.blaubergventilatoren.de

Auto Revers_EN v.1(4)

Loading...

Loading...