Black & Decker CS1010, CS1020 User Manual

7-1/4” (184mm) Circular Saws

INSTRUCTION MANUAL

Catalog Nos. CS1000, CS1010, CS1020

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

1-800-54-HOW-TO (544-6986)

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR BLACK & DECKER PRODUCT,

CALL 1-800-54-HOW-TO (544-6986)

BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION AVAILABLE, CATALOG No., TYPE No., AND DATE CODE (e.g. 0130M). IN MOST CASES, A BLACK & DECKER REPRESENTATIVE CAN RESOLVE YOUR PROBLEM OVER THE PHONE. IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL. YOUR FEEDBACK IS VITAL TO BLACK & DECKER.

KEY INFORMATION YOU SHOULD KNOW:

•A sharp blade will improve performance dramatically.

•A dull blade will cause slow, inefficient cutting.

•Always support work properly. (See illustrations on work support in this manual.)

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE

SERVICIO Y PÓLIZA DE GARANTÍA. ADVERTENCIA:

LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

Cat. # CS1000, CS1010, CS1020 |

Form. # 605806-00 |

(OCT02-2) |

Copyright © 2002 Black & Decker |

Printed in China |

GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

WARNING! Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

•Keep your work area clean and well lit. Cluttered benches and dark areas invite accidents.

•Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks which may ignite the dust or fumes.

•Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

ELECTRICAL SAFETY

•Double insulated tools are equipped with a polarized plug (one blade is wider than the other.) This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electri-

cian to install a polarized outlet. Do not change the plug in any way. Double insulation

eliminates the need for the three wire grounded power cord and grounded power supply system.

eliminates the need for the three wire grounded power cord and grounded power supply system.

•Avoid body contact with grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is grounded.

•Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

•Do not abuse the cord. Never use the cord to carry the tools or pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric shock.

•When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.” These cords are rated for outdoor use and reduce the risk of electric shock.

PERSONAL SAFETY

•Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury,

•Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing , and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts. Air vents cover moving parts and should be avoided.

•Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your finger on the switch or plugging in tools that have the switch on invites accidents.

•Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left attached to a rotating part of the tool may result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables better control of the tool in unexpected situations.

•Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

•Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body is unstable and may lead to loss of control.

•Do not force tool. Use the correct tool for your application. The correct tool will do the job better and safer at the rate for which it is designed.

•Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch is dangerous and must be repaired.

•Disconnect the plug from the power source before making any adjustments, changing accessories, or storing the tool. Such preventative safety measures reduce the risk of starting the tool accidentally.

•Store idle tools out of reach of children and other untrained persons. Tools are dangerous in the hands of untrained users.

•Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges are less likely to bind and are easier to control.

•Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the tools operation. If damaged, have the tool serviced before using. Many accidents are caused by poorly maintained tools.

•Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool, may become hazardous when used on another tool.

SERVICE

•Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel could result in a risk of injury.

•When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

SPECIFIC SAFETY RULES

DANGER! Keep hands away from cutting area and blade. Keep your second hand on auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be cut by the blade.

DANGER! Keep hands away from cutting area and blade. Keep your second hand on auxiliary handle, or motor housing. If both hands are holding the saw, they cannot be cut by the blade.

•Keep your body positioned to either side of the saw blade, but not in line with the saw blade. KICKBACK could case the saw to jump backwards. (See “Causes and Operator Prevention of Kickback.”)

•Do not reach underneath the work. The guard can not protect you from the blade below the work.

•Check lower guard for proper closing before each use. Do not operate saw if lower guard does not move freely and close instantly. Never clamp or tie the lower guard into the open position. If saw is accidentally dropped, the lower guard may be bent. Raise the lower guard with the Retracting Handle and make sure it moves freely and does not touch the blade or any other part, at all angles and depth of cut.

•Check the operation and condition of the lower guard spring. If the guard and the spring are not operating properly, they must be serviced before use. Lower guard may operate sluggishly due to damaged parts, gummy deposits, or a buildup of debris.

•Lower guard should be retracted manually only for special cuts such as “Pocket Cuts” and “Compound Cuts.” Raise lower guard by Retracting Handle. As soon as blade enters the material, lower guard must be released. For all other sawing, the lower guard should operate automatically.

•Always observe that the lower guard is covering the blade before placing saw down on bench or floor. An unprotected, coasting blade will cause the saw to walk backwards, cutting whatever is in its path. Be aware of the time it takes for the blade to stop after switch is released.

•NEVER hold piece being cut in your hands or across your leg. It is important to support the work properly to minimize body exposure, blade binding, or loss of control.

•Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its own cord. Contact with a “live” wire will also make exposed metal parts of the tool “live” and shock the operator.

•When ripping, always use a rip fence or straight edge guide. This improves the accuracy of cut and reduces the chance for blade binding.

•Always use blades with correct size and shape (diamond vs. round) arbor holes. Blades that do not match the mounting hardware of the saw will run eccentrically, causing loss of control.

•Never use damaged or incorrect blade washers or bolts. The blade washers and bolt were specially designed for your saw, for optimum performance and safety of operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK:

•Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator.

•When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back toward the operator.

•If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and jump back toward operator.

•Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

a.Maintain a firm grip with both hands on the saw and position your body and arm to allow you to resist KICKBACK forces. Kickback forces can be controlled by the operator, if proper precautions are taken.

b.When blade is binding, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material into the blade comes to a complete stop. Never attempt to remove the saw from the work or pull the saw backward while the blade is in motion or KICKBACK may occur. Investigate and take corrective actions to eliminate the cause of blade binding.

c.When restarting a saw in the workpiece, center the saw blade in the kerf and check that the saw teeth are not engaged into the material. If saw blade is binding, it may walk up or KICKBACK from the workpiece as the saw is restarted.

d.Support large panels to minimize the risk of blade pinching and KICKBACK. Large panels tend to sag under their own weight. Support must be placed under the panel on both sides, near the line of cut and near the edge of the panel.

e.Do not use dull or damaged blade. Unsharpened or improperly set blades produce narrow kerf causing excessive friction, blade binding, and KICKBACK.

f.Blade depth and bevel adjusting locking levers must be tight and secure before making cut. If blade adjustment shifts while cutting, it may cause binding and KICKBACK.

g.Use extra caution when making a “Pocket Cut” into existing walls or other blind areas. The protruding blade may cut objects that can cause KICKBACK.

SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES: CIRCULAR SAWS

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

CAUTION: Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

CAUTION: Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this product may contribute to hearing loss.

•Snagging the lower guard on a surface below the material being cut can momentarily reduce operator control. The saw can lift partially out of the cut increasing the chance of blade twist. Ensure there is sufficient clearance under the workpiece.

•When necessary to raise lower guard manually, use the retracting lever.

•KEEP THE BLADES CLEAN AND SHARP. Sharp blades minimize stalling and kickback. The use of dull and/or dirty blades can increase the saw loading causing the operator to push harder which promotes twisting.

DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep hands away from blades. Never place hands in front of or behind the path of the blade while cutting. Do not reach underneath work while blade is rotating. Do not attempt to remove cut material when blade is moving.

DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep hands away from blades. Never place hands in front of or behind the path of the blade while cutting. Do not reach underneath work while blade is rotating. Do not attempt to remove cut material when blade is moving.

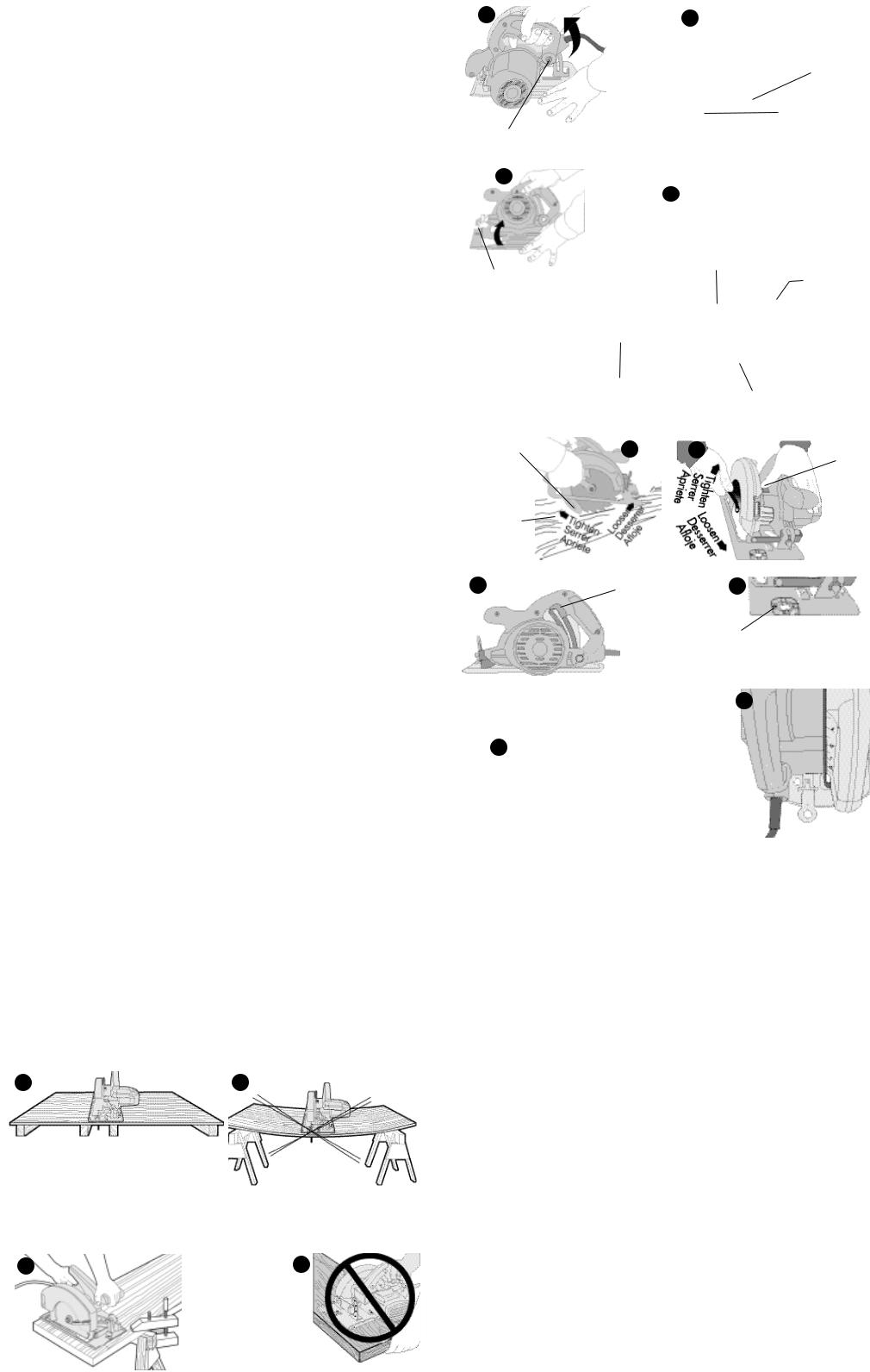

•SUPPORT LARGE PANELS. Large panels must be supported as shown (Fig. 1) in this manual to minimize the risk of blade pinching and kickback. When cutting operation requires the resting of the saw on the workpiece, the saw shall be rested on the larger portion and the smaller piece cut off.

•USE ONLY CORRECT BLADES AND BLADE ASSEMBLY COMPONENTS WHEN MOUNTING BLADES. Do not use blades with incorrect size holes. Never use defective or incorrect blade washers or bolts. Follow blade assembly procedures.

•ADJUSTMENTS. Before cutting be sure depth and bevel adjustments are tight.

•SUPPORT AND SECURE THE WORK PROPERLY. Insure that the material to be cut is clamped (Fig. 3) and solidly supported and balanced on a strong, stable and level work surface. Support the work so that the wide portion of the saw shoe is on the portion of the material that doesn’t fall after the cut is made. Never hold cut off piece by hand (Fig. 4 ). KICKBACK from blade pinch can result. Keep both hands on saw at all times.

•STAY ALERT AND EXERCISE CONTROL. Keep body positioned to one side of blade. Always maintain a firm grip and control of saw with both hands. Do not change hand grip or body position while saw is running. Take precaution to avoid injury from cut off pieces and other falling material during operation.

•VIEWING WINDOW MUST BE IN PLACE AT ALL TIMES and it must stay closed against the upper guard of the saw at all times when operating the saw. (Model CS1020 only)

•DISCONNECT SAW FROM POWER SOURCE before attempting to clean the viewing window. (Model CS1020 only)

WARNING: Do not operate your saw if window becomes damaged or fails to stay in place as noted above. Take your saw to your closest Black & Decker Service Center or authorized service facility. (Model CS1020 only)

WARNING: Do not operate your saw if window becomes damaged or fails to stay in place as noted above. Take your saw to your closest Black & Decker Service Center or authorized service facility. (Model CS1020 only)

DANGER: RELEASE SWITCH IMMEDIATELY IF BLADE BINDS OR SAW STALLS.

DANGER: RELEASE SWITCH IMMEDIATELY IF BLADE BINDS OR SAW STALLS.

GUARD AGAINST KICKBACK

•KICKBACK CAN BE CAUSED BY the saw blade becoming pinched, twisted or bound while cutting, or when the saw stalls. When the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the cut and move suddenly back toward the operator.

TO REDUCE THE RISK OF KICKBACK

•Keep a firm grip on saw with both hands at all times.

•Stay alert – exercise control.

•Support long overhanging materials. As the material is cut and weakens, it will sag, causing a pinched blade.

•Support large panels as shown (Fig. 1). Material supported only at the ends (Fig. 2) will lead to blade pinching.

•Avoid sawing overhead. Material can sag and will pinch blade.

•Keep blades sharp and clean.

•Use fence or straight edge guide when ripping. Be careful as the cut off strip can sag or twist, closing the cut and pinching the blade, leading to KICKBACK.

•Don’t force tool. Wood variables such as knots, hardness, toughness, wetness, pressure treated and freshly cut green lumber can heavily load the saw which can lead to stalling. Push the saw slower when this occurs.

•Don’t remove saw from work during a cut while the blade is moving.

•Allow saw to reach full speed before blade contacts material to be cut. Starting the saw with the blade against the work or pushed forward into cut can lead to stalling or sudden backward movement of saw.

•Never attempt to lift saw when making a bevel cut. This leads to

•Always secure work to prevent workpiece movement during cut.

•Do not try to force saw back on line if your cut begins to go off line. This can cause KICKBACK. Stop saw and allow blade to coast down to a stop. Withdraw from cut and start a new cut on the line.

•Set depth adjustment of saw such that one tooth of the blade projects below the workpiece as shown in (Fig. 6).

•Do not back up a rotating blade in the cut. Twisting the saw can cause the back edge of the blade to dig into the material, climb out of the work and run back toward the operator.

•Avoid cutting nails. Inspect for and remove all nails from lumber before cutting.

The label on your tool may include the following symbols.

V.............. |

volts |

Hz............ |

hertz |

W ............ |

watts |

min .......... |

minutes |

............ |

alternating current |

........ |

direct current |

no ............ |

no load speed |

............ |

Class II Construction |

............ |

safety alert symbol |

EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavier the cord

Minimum Gage for Extension Cords

Volts |

|

|

Total Length of Cord in Feet |

|

|

||

120V |

|

|

0-25 |

26-50 |

51-100 |

101-150 |

|

240V |

|

|

0-50 |

51-100 |

101-200 |

201-300 |

|

Ampere Rating |

|

|

|

|

|

|

|

More |

Not more |

AWG |

|

|

|

|

|

Than |

Than |

|

|

|

|

|

|

0 |

- |

6 |

18 |

16 |

16 |

14 |

|

6 |

- |

10 |

18 |

16 |

14 |

12 |

|

10 |

- |

12 |

16 |

16 |

14 |

12 |

|

12 |

- |

16 |

14 |

12 |

Not Recommended |

||

|

|

|

|

|

|

|

|

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC means your tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A rating of 120 volts AC/DC means that your tool will operate on standard 60 Hz AC or DC power. This information is printed on the nameplate. Lower voltage will cause loss of power and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does not operate, check the power supply. This tool is AC only.

1 |

2 |

Wrong |

||

Incorrect |

||||

|

|

|

|

Incorrecto |

Correct |

|

Support work near cut |

|

|

Correct |

Soutenir la pièce près de la ligne de coupe. |

|

||

Correcto |

Apoye la pieza cerca del corte |

|

||

|

|

|

Material bends |

causing heavy loads or kickback |

|

|

|

Le matériau plie |

de la lame causant de lourdes |

|

|

|

surcharges ou des rebonds. |

|

|

|

|

El material oprime el |

ocasionando sobrecarga o contragolpe |

|

|

|

|

|

3 |

|

Correct |

4 |

|

|

Correct |

|

||

|

|

Correcto |

|

|

Wrong

Incorrect

Incorrecto

5 |

6 |

depth: one tooth below surface of wood |

|

|

Profondeur appropriée : une dent sous la |

|

|

surface du bois. |

|

|

Profundidad correcta: un diente debajo de la |

|

|

superficie de madera |

|

|

Tip of tooth |

|

|

Bout de la dent |

|

|

Punta del diente |

|

Surface of wood |

|

Depth adjustment knob |

Surface du bois |

|

Superficie de madera |

|

|

Bouton de réglage de la profondeur |

|

|

Perilla de ajuste de profundidad |

|

|

7

adjustment knob

réglage pour coupes en biseau de ajuste de bisel

guard inférieur inferior

inutile

8

Direction of teeth

Sens des dents

Dirección de los dientes

Outer clamp

Rondelle de

Roldana de

Inner clamp washer

Rondelle de fixation interne

Roldana de sujeción interior

Saw spindle

Saw spindle

Arbre de la scie

Flecha de la sierra

Blade clamping screw

Vis de fixation de la lame

Tornillo de sujeción del disco

9a |

9b |

Spindle lock

Dispositif de verrouillage de l’arbre

Seguro de la flecha

Interrupteur à détente

Gatillo interruptor

Kerf plate screw

Vis de la plaquette amovible

Tornillo de la placa de corte

|

13 |

|

coupes en retrait seulement |

Warning: When blade starts |

|

retraction |

||

para cortes de bolsillo |

||

|

||

|

Avertissement : Lorsque la |

|

|

à découper, |

|

|

immédiatement le |

|

|

rappel. |

|

|

Advertencia: Cuando el |

|

|

el corte, suelte |

|

|

inmediatamente la palanca |

|

|

retráctil |

ASSEMBLY/ADJUSTMENT SET-UP

CUTTING DEPTH ADJUSTMENT |

|

Adjust depth of cut using depth adjustment lever. |

(Figs. 5 & 6) for proper setting. Tighten |

lever securely. |

|

BEVEL ANGLE ADJUSTMENT |

|

Adjust bevel angle (Fig. 7) using bevel |

knob and bevel scale. Tighten knob |

securely. |

|

WARNING: Always unplug saw from power |

before any of the following operations. |

ATTACHING AND REMOVING THE BLADE |

|

NOTE: The first time the blade bolt is |

from saw without a blade installed, it |

may be necessary to place the blade wrench |

bolt head and tap it sharply in the |

counter clockwise direction. |

|

Retract lower guard and assemble blade and |

washer as shown (Fig. 8). Insure large |

surface of washer is toward blade. Use scrap |

(Model CS1000 & CS1010) or spindle |

lock (Model No. CS1020K only) to prevent |

rotation. |

Tighten blade securely as shown (Fig. 9A (Model |

& CS1010) or Fig. 9B (Model No. |

CS1020K only). Never engage spindle lock while blade is turning. |

|

OPERATING INSTRUCTIONS

WARNING: To reduce the risk of serious |

injury, read, understand and follow all |

important safety warnings and instructions prior |

tool. |

READ SAFETY WARNINGS AND INSTRUCTIONS. ) |

|

With unit unplugged, follow all assembly, |

set up instructions. |

Make sure lower guard operates. Select the proper |

for the material to be cut. |

•Measure and mark work for cutting.

•Support and secure work properly (See Safety Rules and Instructions).

• Use appropriate and required safety equipment |

Safety Rules). |

• Secure and maintain work area (See Safety |

|

• With plug inserted and guard closed, make sure |

turns saw on and off. |

WARNING: It is important to support the |

properly and to hold the saw firmly to |

prevent loss of control which could cause |

injury. Fig. 3 illustrates recommended |

hand position. |

|

SWITCH |

|

To operate the tool, depress the trigger switch |

in Fig. 10. The tool will continue to run |

as long as the trigger is depressed. |

|

To turn the tool off, release the trigger switch. |

is no provision for locking the tool on, |

and the switch should never be locked on by any other means. |

|

KERF PLATE ADJUSTMENT (MODEL CS1020K ONLY) |

|

Adjust kerf plate (Fig. 11) to read zero when the |

scale reads zero by loosening the kerf |

plate screw and sliding the plate as necessary. |

mark on kerf plate with drawn pencil line |

and advance blade into cut. The kerf plate has |

for zero bevel and 45 degree bevel |

cutting. |

|

POCKET CUTTING (SEE FIG. 12)

POCKET CUTTING IS USED TO CUT A HOLE IN A PIECE OF MATERIAL WITHOUT CUTTING FROM THE SIDE.

• Measure and mark work.

Loading...

Loading...