Operating manual

0.37–15 kW

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

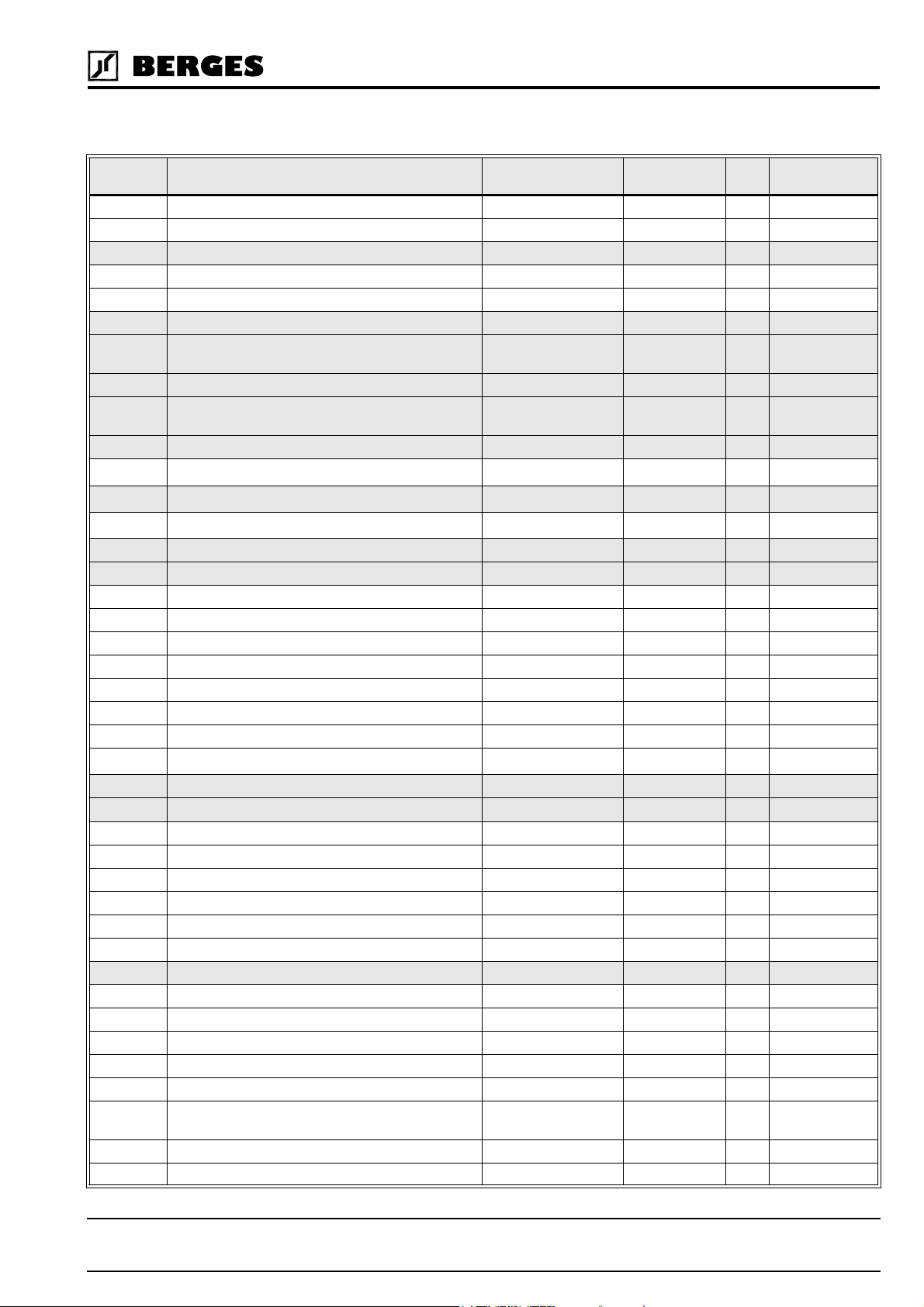

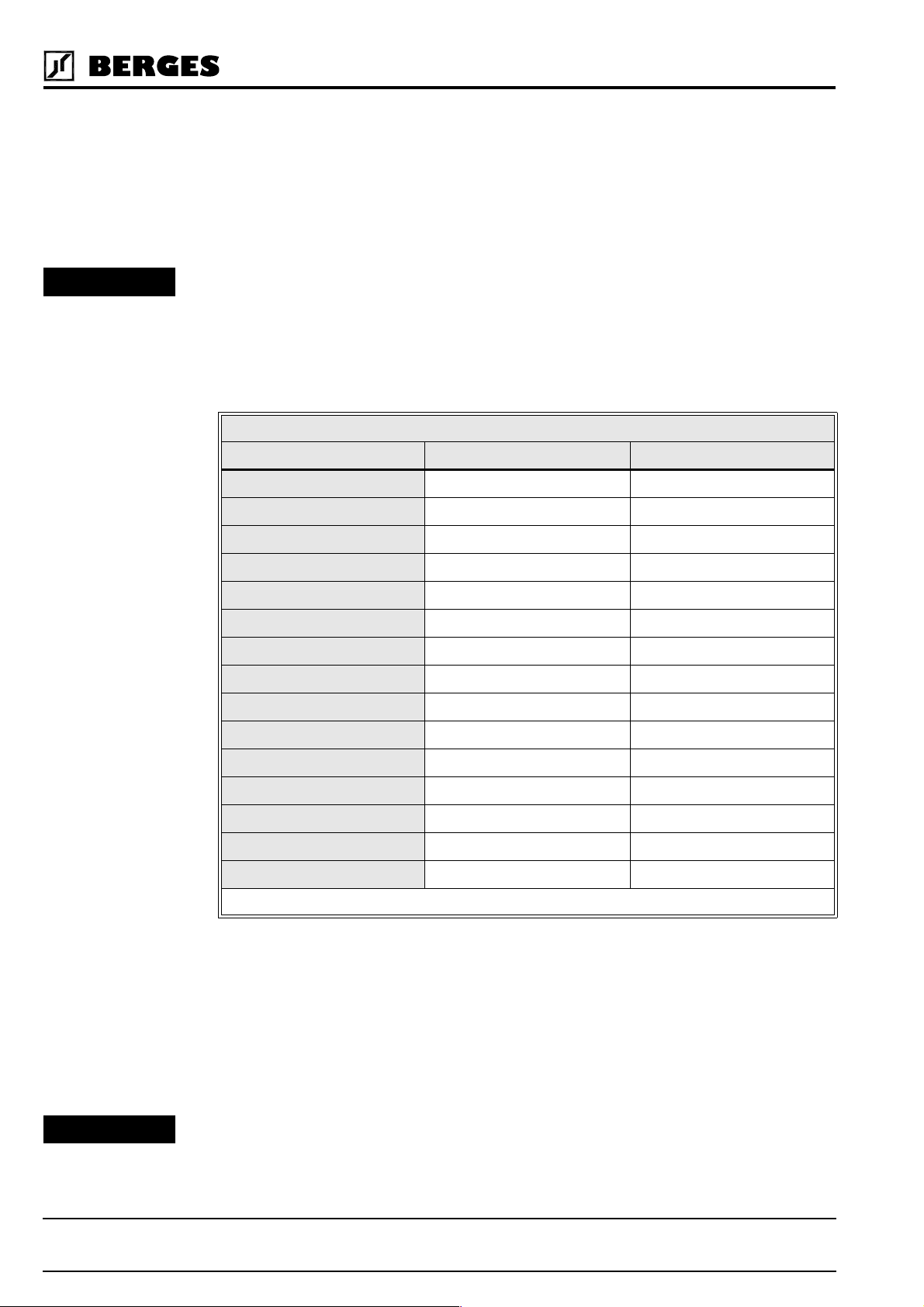

Parameter Code Summary

PARA-

METER

02-RVLVL Software Revision 35

03-IRAT Inverter Rated Current A 35

07-FLT3 Last Fault 36

08-FLT2 Second Fault 36

09-FLT1 First Fault 36

12-FOUT Motor Output Frequency 0.00–400.0 Hz 36

13-VOUT Motor Output Voltage 0–100%

14-IOUT Motor Output Current 0.00–60.00 A 36

15-LOAD Inverter Load 0–200%

17-TEMP Inverter Temperature 0.00–110.0 °C 36

1A-FSTAT Stator-Frequency

21-MODE Input Mode 3

24-FSEL Speed Setpoint Selector 0

31-FMIN Minimum Frequency 0.00 Hz 0.00–400.0 Hz 38

32-FMAX Maximum Frequency 50.00 Hz 20.00–400.0 Hz 38

33-F2 Preset Frequency 2 5.00 Hz 0.00–400.0 Hz 38

34-F3 Preset Frequency 3 20.00 Hz 0.00–400.0 Hz 38

35-F4 Preset Frequency 4 40.00 Hz 0.00–400.0 Hz 38

36-F5 Preset Frequency 5 50.00 Hz 0.00–400.0 Hz 38

37-F6 Preset Frequency 6 0.00 Hz 0.00–400.0 Hz 38

38-F7 Preset Frequency 7 0.00 Hz 0.00–400.0 Hz 38

39-FTL Minimum Frequency in Torque Limit 10.00 Hz 0.00–400.0 Hz 39

41-RSEL Ramp Selector 0

42-ACC1 Acceleration Time 1 3.00 s 0.10–600.0 s 39

43-DEC1 Deceleration Time 1 3.00 s 0.10–600.0 s 39

44-ACC2 Acceleration Time 2 1.00 s 0.10–600.0 s 40

45-DEC2 Deceleration Time 2 1.00 s 0.10–600.0 s 40

46-DECTL Deceleration Time in Torque Limit 1.00 s 0.10–30.00 s 40

47-DCBRK DC Brake Time 0.20 s 0.00–5.00 s 40

48-DCVLT DC Brake Voltage 2/3 of

51-VSEL V/Hz Characteristic Selector 0 0–5 40

52-BOOST Voltage Boost 8.00% 0.00–25.00% 41

53-FKNEE V/Hz Knee Frequency 50.00 Hz 26.00–400.0 Hz 42

54-SKBND Skip Frequency Hysteresis Band 1.00 Hz 0.20–20.00 Hz 42

55-SK1 Skip Frequency 1 0.00 Hz 0.00–400.0 Hz 42

56-SK2 Skip Frequency 2 0.00 Hz 0.00–400.0 Hz 42

57-SK3 Skip Frequency 3 0.00 Hz 0.00–400.0 Hz 42

59-MVOLT Rated Motor Voltage 230/400 V 185–240 V;

5B-MSAT Motor Saturation Level 47% 15–80% 42

61-LTLF Load Torque Limit Forward 150% 10–150% 42

DESCRIPTION FACTORY

SETTING

52-BOOST

RANGE PAGE CUSTOMER

of line voltage

03-IRAT

of

(1)

Hz

(2)

0–11

(2)

0–19

(2)

0–7

0–15% 40

370–480 V

36

36

55 Read-only

36/55

38/55

39/56

42

SETTING

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

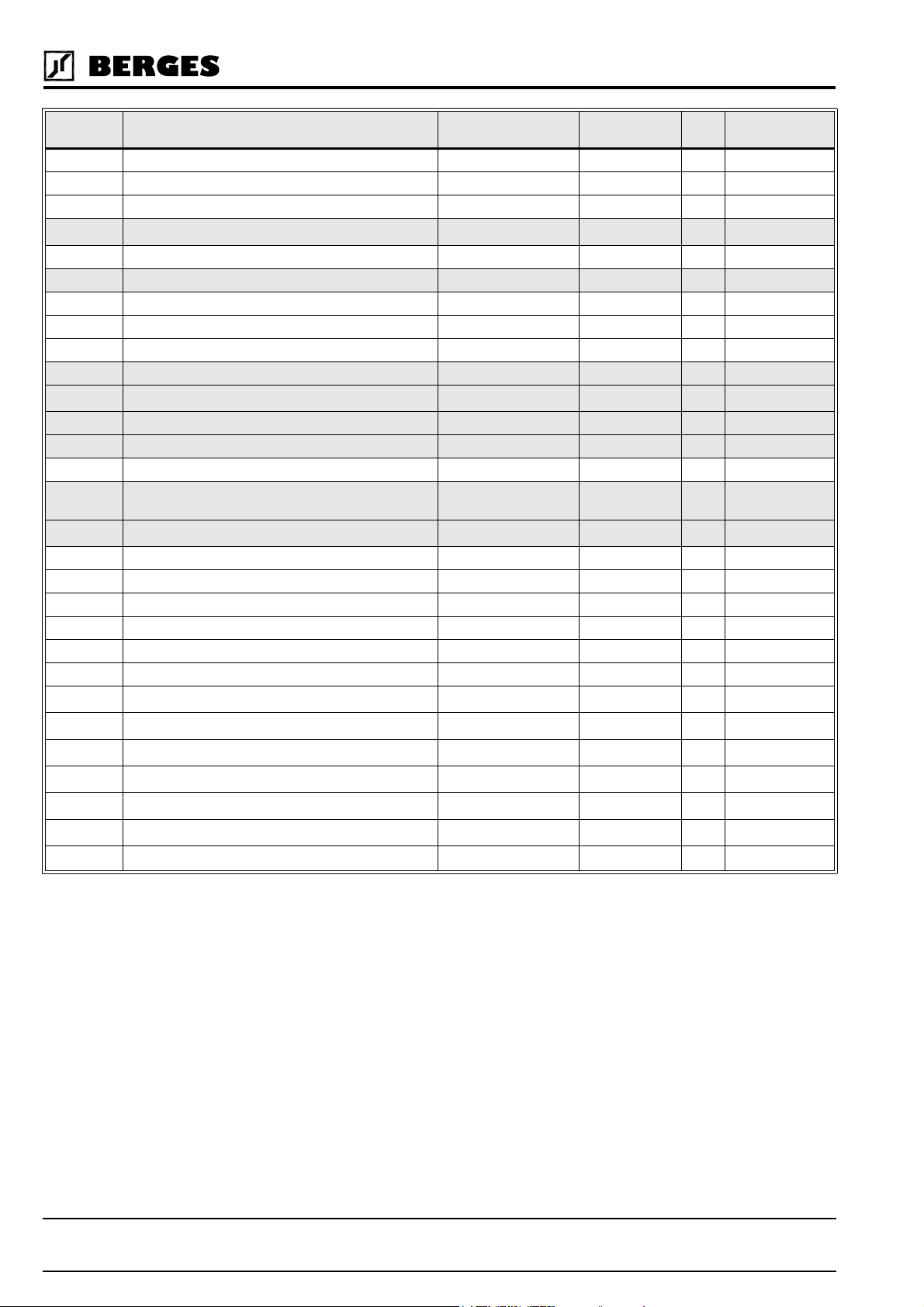

PARA-

METER

62-LTLR Load Torque Limit Reverse 150% 10–150% 42

63-RTLF Regenerative Torque Limit Forward 80% 10–110% 42

64-RTLR Regenerative Torque Limit Reverse 80% 10–110% 42

65-SLIP Slip Compensation 0.00%

66-STAB Current Stability Adjustment 3 0–4 43

67-TOL Timed Overload Trip Point 0% 0–100% 43

68-NRST Trip Restart Number 0 0–8 44

69-DRST Restart Delay Time 0.00 s 0.00–60.00 s 44

6A-TOLC Timed Overload Characteristic 0 0–7 45

70-MCAL Analog Meter Output Calibration MET1 Set for10 VDC 0–255 45

71-METER Analog Meter Output Selector MET1 1

72-ST1 Open Collector Output 1 7 0–10 46

75-STR Auxiliary Relay Output 1 0–10 46

77-MOL Motor Overload Input 2 0–3 47

78-MCAL2 Analog Meter Output Calibration MET2 0–20 mA or 4–20 mA;

79-MET2 Analog Meter Output Selector MET2 3

81-PRGNO Special Program/PI Control Characteristics 0 0–9999 48/56

82-START Start Options 1 0–11 48

83-PWM PWM Carrier Frequency Selector 1 0–5 49

84-DISP Display Option Setting 0 0–3000 49

87-ACODE Security Access Code 0 0–999 50

97-RVLVL2 Software Revision Level 2 0.00–12.75 50 Read-only

A1-FCORR Frequency Correction

A6-ERROR2 Final Error

A7-ERROR1 Initial Error

A8-SIPART Integral Sum

B3-KP Proportional Gain

B4-KI Integral Gain

B5-KIN VIN1 Scaling

DESCRIPTION FACTORY

SETTING

set for 20 mA

RANGE PAGE CUSTOMER

(2)

0.00–12.00%

(2)

0–5

0–255 47

(2)

0–15

(1)

0.00–400.0 Hz

(1)

–

(1)

–

(1)

–

(1)

0–255

(1)

0–255

(1)

0–255

43/56

45/56

47/56

55

55 Read-only

55 Read-only

55 Read-only

55

55

55

SETTING

NOTES:

Level 1 Parameters shown shaded.

(1) Additional parameters that are only available when using the PI controller and when

81-PRGNO

the

parameter is set to a value between 80 and 95 (see page 56). See

chapter 6, from page 51 on, for further information about the PI controller.

(2) Extended parameters when using the PI controller. For further information about the

PI controller, see chapter 6, as from page 51.

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Table of Contents

Page

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Explanation of Symbols and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety and Operating Instructions for Drive Converters. . . . . . . . . . . . . . . . . . . . . . 3

1.3 Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Model Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 General Drive Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

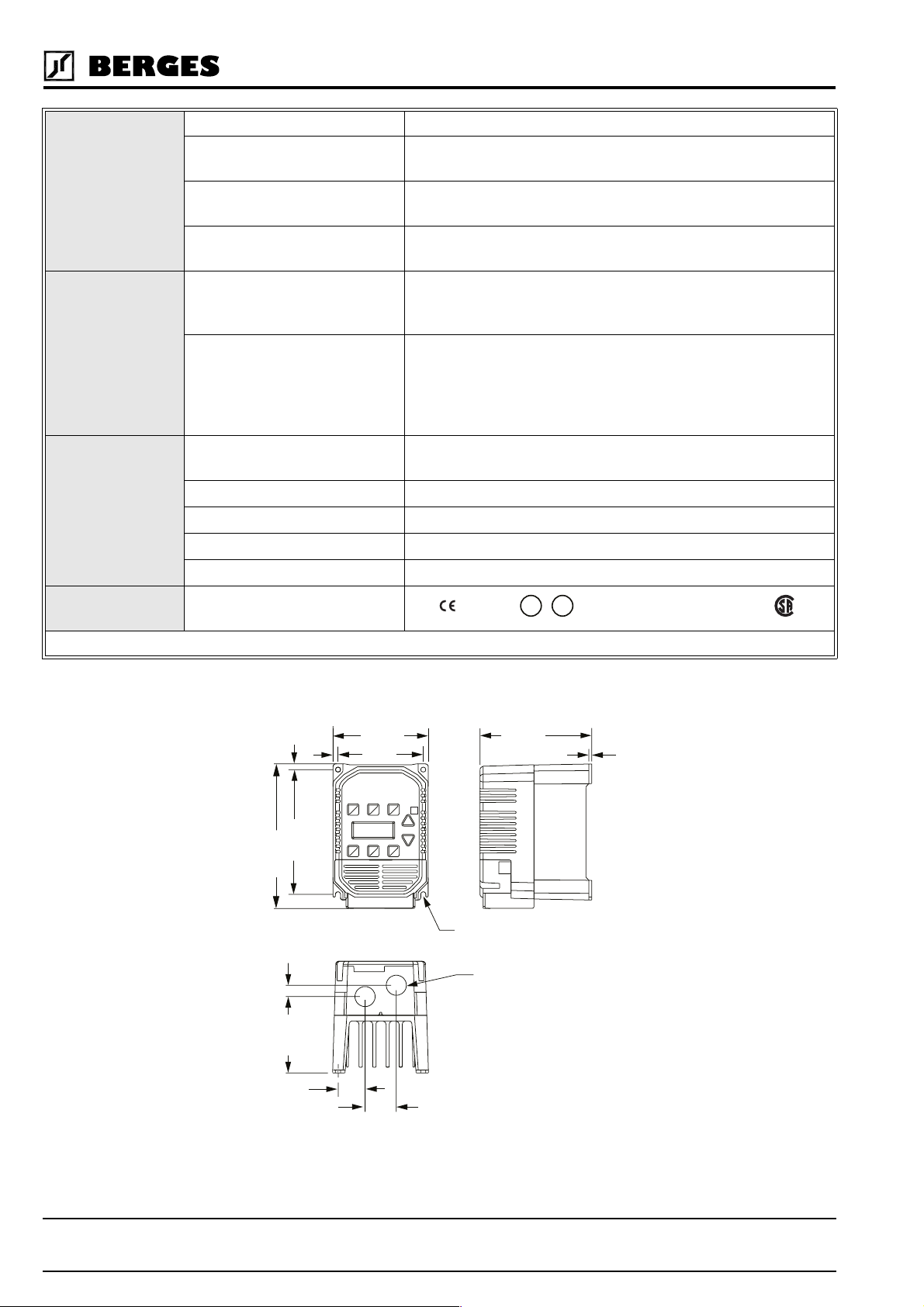

2.4 Dimensional Data (Size I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

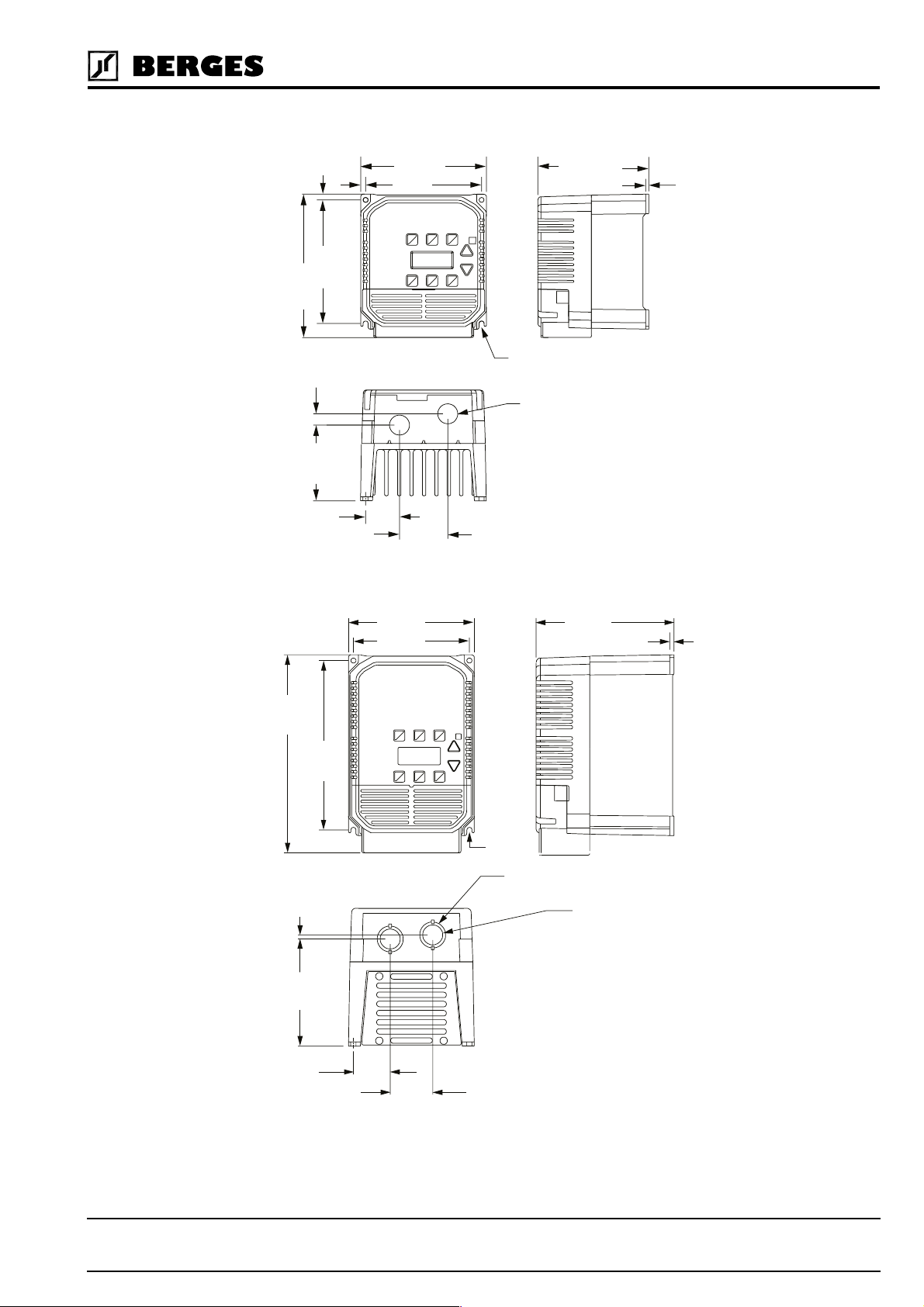

2.4.1 Dimensional Data (Size II). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.2 Dimensional Data (Size III) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

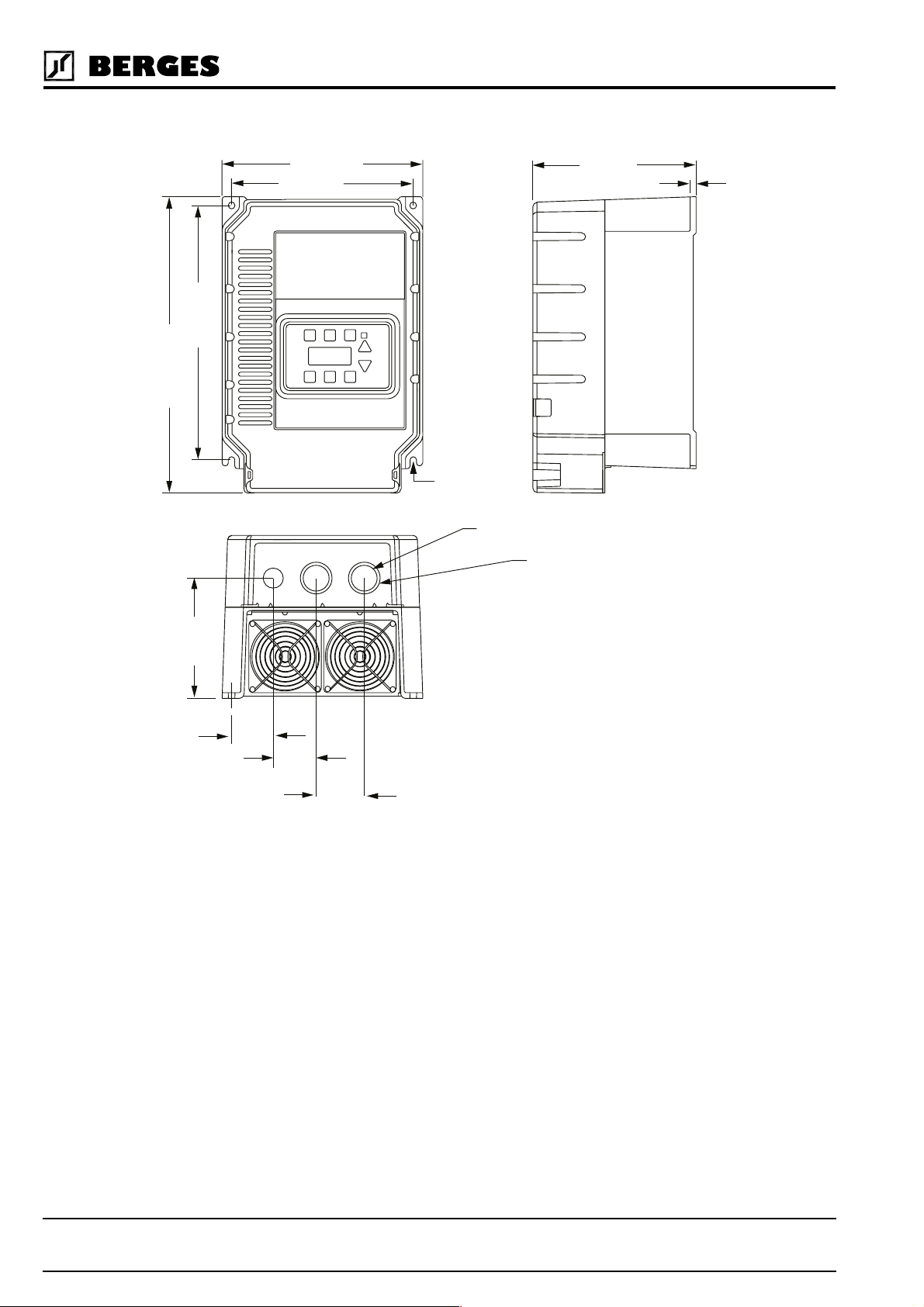

2.4.3 Dimensional Data (Size IV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 General Rules for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 EMC (Electromagnetic Compatibility) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3.1 Suggestion on how to solve the Problem of Radio Frequency Interference

Suppression of Frequency Converters to VDE 0875/EN 55011 . . . . . . . . . . . . . . 12

3.3.2 Mains Filters/Output Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.3 Filter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.4 Interference Suppression Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 EMC Ordinance (EMC Directive, 89/336 EEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Wiring Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.1 Applicable Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.2 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.3 Control Wiring/Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Mains Power Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6.1 Mains Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6.2 Line Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6.3 Using Mains Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6.4 Line Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.7 Motor Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.8 Reducing Current Surges and Voltage Transients. . . . . . . . . . . . . . . . . . . . . . . . . 23

3.9 Function and Use of Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.10 Terminal Access Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.11 Terminal Assignment (Mains supply 1 × 230 VAC, 0.37–4.0 kW) . . . . . . . . . . . . . 26

3.12 Terminal Assignment (Mains supply 3 × 400 VAC, 0.37–4.0 kW) . . . . . . . . . . . . . 26

3.13 Terminal Assignment (Mains supply 3 × 400 VAC, 5.5–15.0 kW) . . . . . . . . . . . . . 27

3.14 Remote Keypad/Program Memory Unit Connector (J22) . . . . . . . . . . . . . . . . . . . 27

3.15 Control Terminal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.16 J20 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

1

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Page

4 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 Digital Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.3 Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.4 Operation Mode (RUN and STOP Modes). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.5 Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.6 Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.7 Description of Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.8 Programming Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.9 Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5 Parameter Configuration and Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2 Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6 PI Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.2 Overview of PI Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.3 Reference and Feedback Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4 Calculating PI Controller Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.5 Parameters for PI Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7 Connection Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.1 AC Line and Motor Connections (Mains supply 1 × 230 VAC and 3 × 400 VAC) . 58

7.2 2-Wire Run/Stop Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.3 3-Wire Run/Stop Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.4 Auxiliary Relay Output and Digital Output ST1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5 MOL Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.6 Analog Speed Input Connections (VIN1/VIN2) . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.7 Optional Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.1 Special Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2 Fault Trip Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

8.3 Resetting a Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.4 Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.1 Parameter Code Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.2 Parameters Added or Amended when PI Control is Utilized . . . . . . . . . . . . . . . . . 67

9.3 Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

2

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

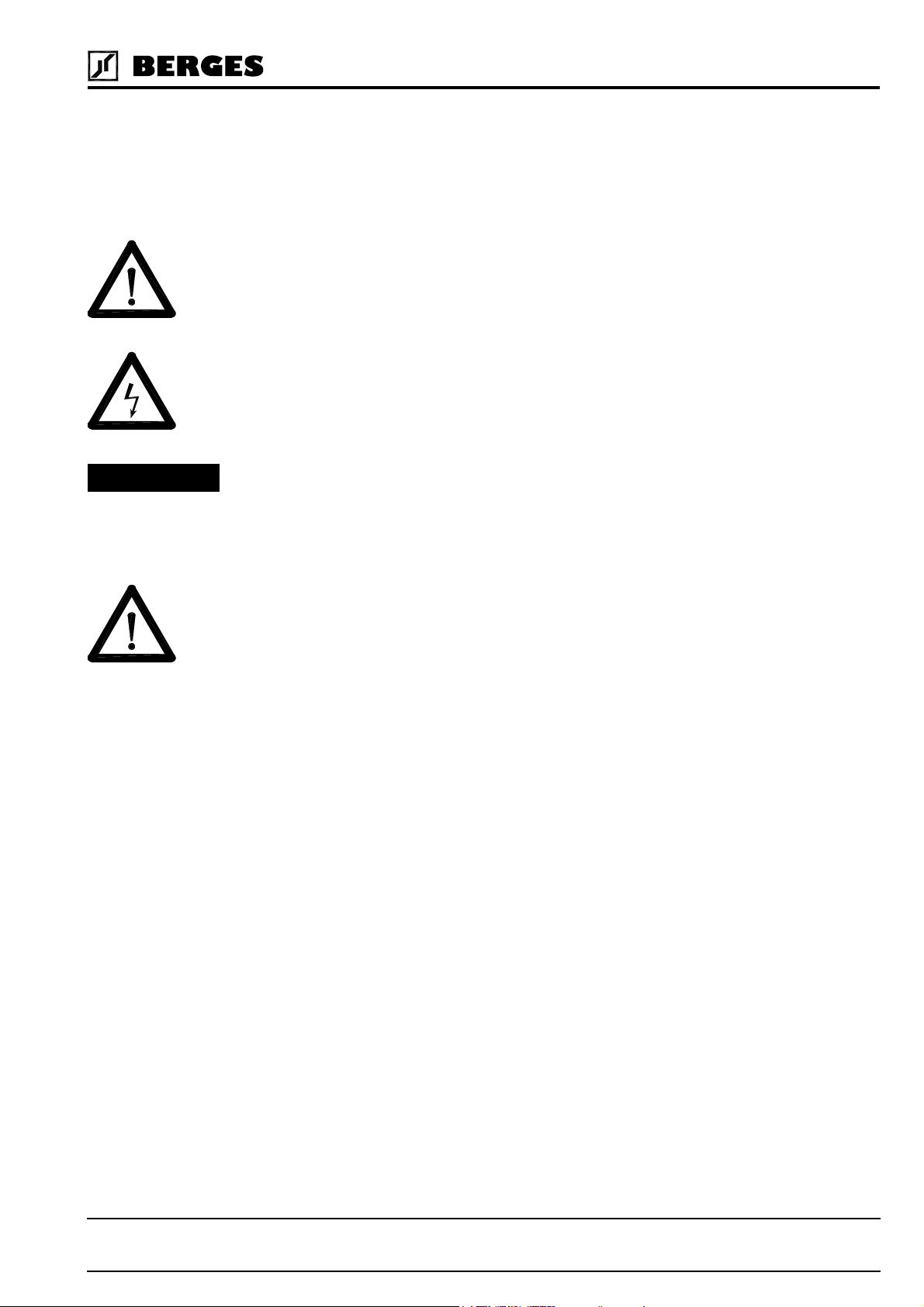

1 General Information

1.1 Explanation of Symbols and Notes

Work Safety Symbol

You will find this symbol next to all work safety notes in this operating manual if there is a

risk of injury or death for persons involved. Pay attention to these notes and observe particular caution in such cases. Also pass on all work safety instructions to other users.

Voltage Warning

This symbol is shown wherever particular caution is necessary owing to occurring or applied voltages (e.g. DC voltages up to 650 V) and where special precautionary measures

have to be taken. The inverter must always be isolated from the mains when working on it.

Caution Note

ATTENTION!

This note is shown in all parts of this operating manual to which particular attention must be

paid to ensure that the guidelines, specifications, notes and the correct sequence of work

will be obeyed and to prevent damage or destruction of the inverter and/or systems.

1.2 Safety and Operating Instructions for Drive Converters

1. General

In operation, drive converters, depending on their degree of protection, may have live,

unisolated, and possibly also moving or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of improper use, wrong installation

or maloperation, there is the danger of serious personal injury and damage to property.

For further information, see documentation.

All operations serving transport, installation and commissioning as well as maintenance are

to be carried out by skilled technical personnel (Observe IEC 364 or CENELEC HD 384

or DIN VDE 0100 and IEC 664 or DIN/VDE 0110 and national accident prevention rules!).

For the purposes of these basic safety instructions, “skilled technical personnel” means persons who are familiar with the installation, mounting, commissioning and operation of the

product and have the qualifications needed for the performance of their functions.

We draw attention to the fact that no liability can be assumed for damage and malfunctions

resulting from failure to observe the operating manual.

Technical amendments of illustrations and data given in this operating manual are reserved

in the interest of improving the unit and its functions.

2. Intended Use

The application of the drive converter described in this operating manual exclusively serves

the purpose of continuously variable speed control of three-phase motors.

Drive converters are components designed for inclusion in electrical installations or machinery.

The drive converters are designed for installation in a switchgear cabinet and for permanent

connection.

The operator of the system is solely liable for damage resulting from improper use of the

drive converter.

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

3

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Only items expressly approved by BERGES (e.g. mains filter, choke, external braking choppers and braking resistors etc.) may be used as accessories.

The installer of the system is liable for any damage resulting from the use of accessories

that have not been approved expressly by BERGES. Please consult us in case of doubt.

In case of installation in machinery, commissioning of the drive converters (i.e. the starting

of normal operation) is prohibited until the machinery has been proved to conform to the

provisions of the directive 89/392/EEC (Machinery Safety Directive – MSD). Account is to

be taken of EN 60204.

Commissioning (i.e. the starting of normal operation) is admissible only where conformity

with the EMC directive (89/336/EEC) has been established.

The drive converters meet the requirements of the low-voltage directive 73/23/EEC. They

are subject to the harmonized standards of the series prEN 50178/DIN VDE 0160 in conjunction with EN 60439-1/DIN VDE 0660, part 500, and EN 60146/DIN VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken

from the rating plate and from the documentation and shall be strictly observed.

3. Transport, Storage

The instructions for transport, storage and proper use shall be complied with.

Damage established after delivery must be notified to the transport company immediately.

Where necessary, the supplier must also be notified before the damaged drive converter is

put into operation.

The climatic conditions shall be in conformity with prEN 50178.

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications

in the pertinent documentation.

The drive converters shall be protected against excessive strains. In particular, no components must be bent or isolating distances altered in the course of transportation or handling.

No contact shall be made with electronic components and contacts.

Drive converters contain electrostatic sensitive components which are liable to damage

through improper use. Electric components must not be mechanically damaged or destroyed (potential health risks).

5. Electrical Connection

When working on live drive converters, the applicable national accident prevention rules

(e.g. VBG 4) must be complied with.

The electrical installation shall be carried out in accordance with the relevant requirements

(e.g. cross-sectional areas of conductors, fusing, PE connection). For further information,

see documentation.

Instructions for the installation in accordance with EMC requirements, like screening, earthing, location of filters and wiring, are contained in the drive converter documentation. They

must always be complied with, also for drive converters bearing a CE marking. Observance

of the limit values required by EMC law is the responsibility of the manufacturer of the installation or machine.

4

6. Operation

The components of the power section and certain elements of the control section are connected to the voltage mains when the drive converter is connected to the mains voltage.

Touching these components involves mortal danger!

Always isolate the drive converter from the mains supply before performing any work on the

electrical or mechanical part of the system.

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Isolate the drive converter from the mains before removing the terminal cover or the housing (e.g. by removing or deactivating on-site fuses or by deactivating a master switch isolating all poles etc.).

After disconnection of the drive converters from the voltage supply, live appliance parts and

power terminals must not be touched immediately because of possibly energized capacitors. In this respect, the corresponding signs and markings on the drive converter must be

respected. After switching off the mains voltage, wait for at least 5 minutes before beginning work on or in the drive converter. Dangerous voltages are still present as long as the

“STATUS” lamp is still lit. In the event of malfunctions, the discharge time of 5 minutes may

be exceeded substantially.

The drive converter contains protective facilities that deactivate it in the event of malfunctions, whereby the motor is de-energized and comes to a standstill (so-called “coasting” of

the motor is possible depending on the rotating mass of the type of drive involved). Standstill of the motor can, however, also be produced by mechanical blockage. Voltage fluctuations, and particularly mains power failures, may also lead to deactivation. In certain

circumstances, the drive may start up automatically once the cause of the fault has been

remedied. As a result of this, certain systems may be damaged or destroyed and there may

be a risk for operators working on the system. Installations which include drive converters

shall be equipped with additional control and protective devices in accordance with the relevant applicable safety requirements, e.g. Act respecting technical equipment, accident

prevention rules etc. Changes to the drive converters by means of the operating software

are admissible.

1.3 Preface

The motor may be stopped during operation by disabling it or by deactivating the setpoint,

whereby the drive converter and motor may remain live. If inadvertent start-up of the mo-

tor must be excluded to protect operating personnel, electronic interlocking by disabling the motor or by deactivating the setpoint is inadequate. This is why the drive

converter must be isolated from the mains voltage.

During operation, all covers and doors shall be kept closed.

Measuring instruments must be connected and disconnected only in de-energized condi-

tion.

Unauthorized conversions or modifications on or in the drive converter and its components

and accessories will render all warranty claims void.

Please contact BERGES if conversions or modifications are necessary, particularly if elec-

trical components are involved.

7. Maintenance and Servicing

The manufacturer's documentation shall be followed.

KEEP SAFETY INSTRUCTIONS IN A SAFE PLACE!

Before you read on, please check whether technical changes are at-

tached in the annex to this operating manual!

The present manual contains the specifications, installation instructions, description of operation and troubleshooting procedures for ACP 3000 inverters. The information in this

manual must be known before installation of the inverter in order to guarantee fault-free installation and thus maximum performance.

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

5

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

2 Technical Data

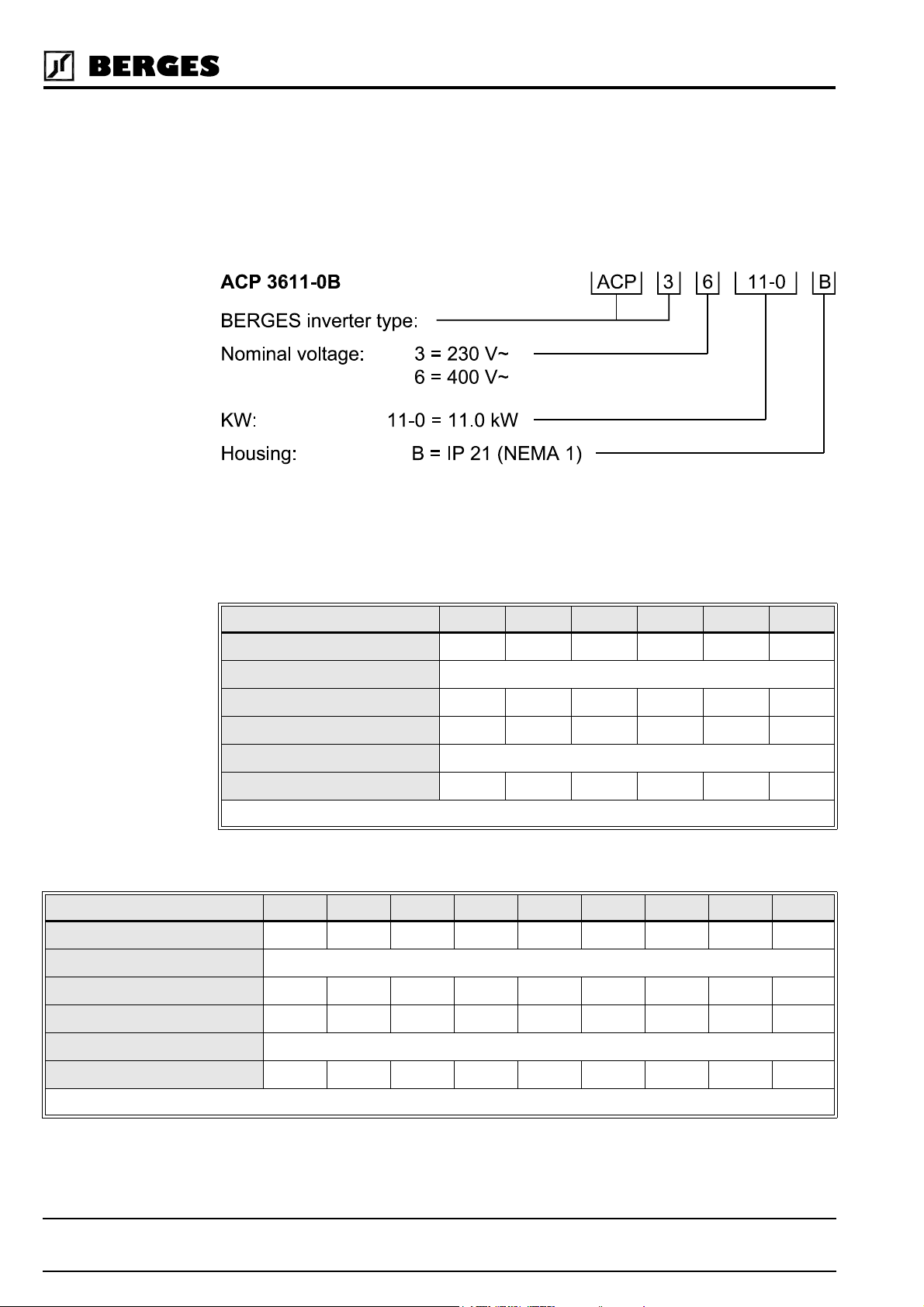

2.1 Model Identification Number

All ACP 3000 models bear a systematic identification number designating the rated input

voltage, the rated power and the housing type. This model number appears both on the

shipping carton label and the technical data label on the drive.

Example type marking

2.2 Power Specifications

Models with Supply Voltage 1 × 230 VAC

Model ACP 3300-3 3300-5 3300-7 3301-1 3301-5 3302-2

Kilowatt (kW) 0.37 kW 0.55 kW 0.75 kW 1.1 kW 1.5 kW 2.2 kW

Output Voltage Three Phase 3.5–230 VAC

Rated current 1.94 A 2.6 A 3.4 A 4.8 A 6.4 A 9.0 A

Maximum Output Current * 2.1 A 2.9 A 3.7 A 5.3 A 7.0 A 9.9 A

Input Volts (±10%) 208–230 V~

Maximum Input Current 3.1 A 4.7 A 6.4 A 9.4 A 12.7 A 18.6 A

Table 2.1

Models with Supply Voltage 3 × 400 VAC

Model ACP 3600-7 3601-5 3602-2 3603-0 3604-0 3605-5 3607-5 3611-0 3615-0

Kilowatt (kW) 0.75 kW 1.5 kW 2.2 kW 3.0 kW 4.0 kW 5.5 kW 7.5 kW 11.0 kW 15.0 kW

Output Voltage Three Phase 7.0–460 VAC

Rated current 1.95 A 3.7 A 5.2 A 6.8 A 9.2 A 13.0 A 18.0 A 24.0 A 30.0 A

Maximum Output Current * 2.1 A 4.1 A 5.7 A 7.5 A 10.1 A 14.3 A 19.8 A 26.4 A 33.0 A

Input Volts (±10%) 400–460 V~

Maximum Input Current 2.11 A 4.2 A 6.2 A 8.4 A 11.2 A 16.0 A 22.2 A 31.0 A 37.9 A

Table 2.2

6

* = Maximum inverter capacity. Value = 1.1 ×

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

03-IRAT

(see page 35).

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

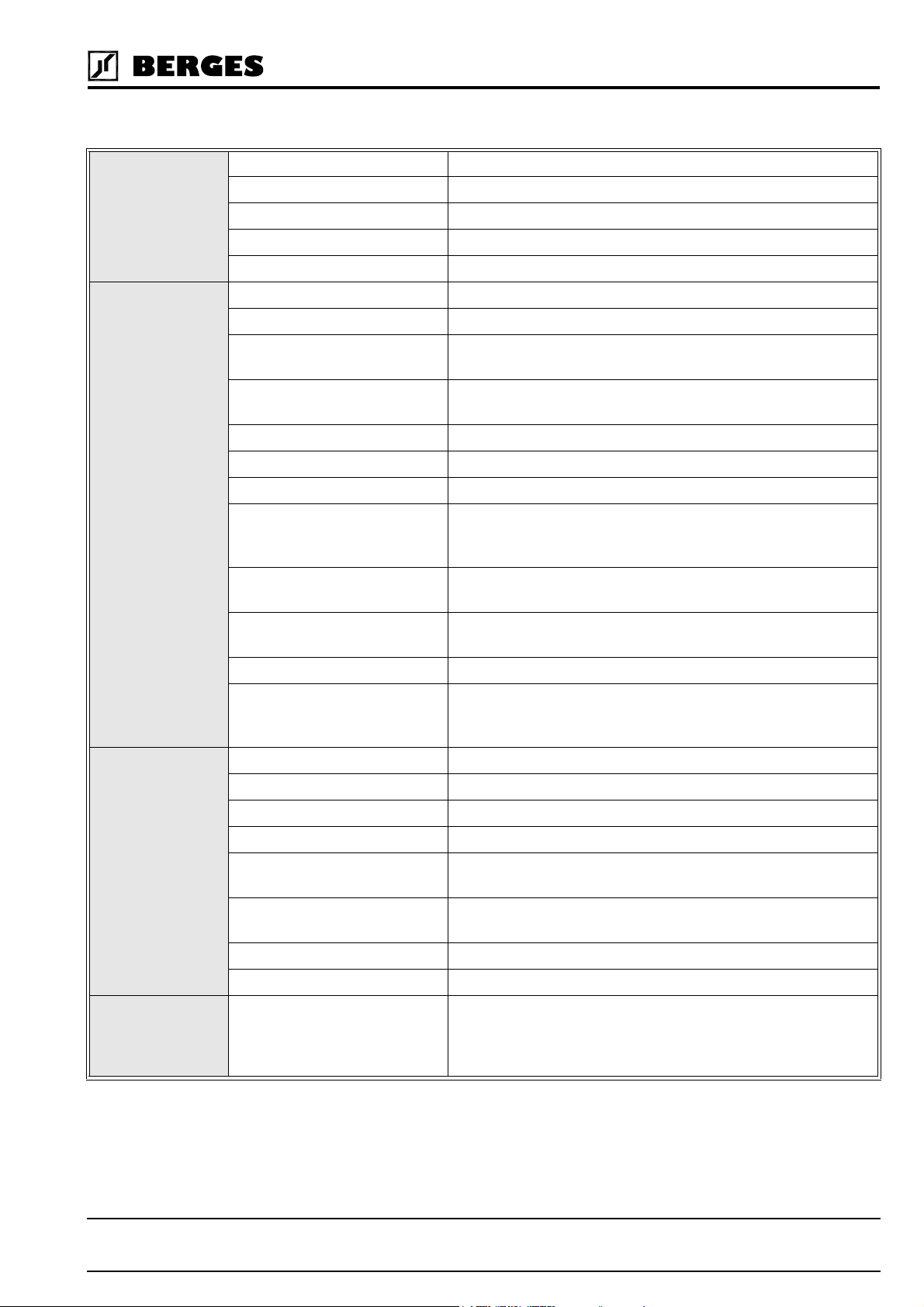

2.3 General Drive Specifications

Inverter

Power Ratings

Control

Specifications

Input Frequency 50/60 Hz (±2%)

Phase Imbalance (3 ∅ only) ±2%

Overload Capacity 150% for 60 seconds

Running Torque 100% at 3 Hz

Starting Torque Greater than 100%

Control System Sine-weighted voltage vector (PWM)

PWM Frequency 4–16 kHz (plus Autoselect feature)

Frequency Range 1.00–400.0 Hz programmable in 0.05 Hz increments

(0.1 Hz above 99.95 Hz)

Frequency resolution 0.05 Hz up 0.00 to 99.95 Hz,

0.1 Hz above 100.0 Hz

Minimum Frequency 0.00–400.0 Hz

Maximum Frequency 20.00–400.0 Hz

Preset Speeds Up to 8 available; programmable to maximum frequency

Frequency Command

Selections

Acceleration and Deceleration

Range

V/Hz Ratio 0.19–9.23 V/Hz (230 VAC models)

Torque Limit Automatic or fixed adjustment possible

0–5 VDC, 0–10 VDC, 0–20 mA, 4–20 mA, direct or inverted;

Digital Keypad; Program Memory Unit; Remote Keypad Unit;

external Potentiometer

Programmable 0.1 to 600 seconds to maximum frequency

(2 Each)

0.39–18.46 V/Hz (400 VAC models)

Protection

Features

Operating

Features

Dynamic Braking Up to 60% for 6 sec. with standard DB resistor; higher braking

power values can be achieved by means of an external braking

chopper (option)

Ground Fault Protected from damage

Short Circuit Protected from damage

Motor Overload Programmable inverse time overload trip

Torque Limit All four quadrants individually programmable

Overvoltage Short voltage peaks are bridged; an error is triggered if an ov-

ervoltage lasts for longer than 500 ms

Undervoltage Short voltage dips are bridged; a defined “Restart” is performed

if an undervoltage lasts for longer than 200 ms

Over Temperature Protected from damage, warning display

MOL Input Terminal Programmable for N.C. or N.O. contacts

Operating Controls 1. Keypad.

2. Remote keypad unit.

3. Terminal strip.

4. Program memory unit.

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

7

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

®

Operating

Features

LED Indicators Red and Green for operation and fault annunciation

Keypad Display 6 digit, backlit LCD with special annunciators

and unit symbols

Auxiliary Relay Programmable analog output;

programmable status signalling relay

Programming Levels Level 1 – Operator

Level 2 – Engineer

Inputs/Outputs Inputs 6 Digital: Pull-up or pull-down logic

2 Analog: VIN1 Current or voltage;

VIN2 Voltage only

Outputs 2 Digital: 1 Open collector (internal or external power supply)

up to 24 VDC;

1 Relay (Form C)

2 Analog: MET1 (0 to 10 VDC);

MET2 (0/4 to 20 mA DC)

Ambient

Conditions

Operating Temperature 0 °C to +40 °C (IP 21 models)

0 °C to +50 °C (with detached cover)

Storage temperature -20 °C to +60 °C

Humidity 90% RH or less, non-condensing

Vibration 0.6 G Maximum

Elevation 1000 Meters (3,300 Feet) without derating

UL-/CSA-

Agency Listings

Certifications

2.4 Dimensional Data (Size I)

6

137

159

12

U

Marked, UL/cUL listed, CSA-certified

U

C

®

®

L

L

Table 2.3

105

5

94

∅ 5.5

Size for devices:

123

3

∅ 22

I

84

30

ACP 3300-3 (230 V)

ACP 3300-5 (230 V)

ACP 3600-7 (400 V)

Weight: 1.4 kg

34

Operating manual 21.12.98

8

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

2.4.1 Dimensional Data (Size II)

6

5

137

159

12

84

38

140

129

2.4.2 Dimensional Data (Size III)

∅ 5.5

∅ 22

II

Size for devices:

ACP 3300-7 (230 V)

ACP 3301-1 (230 V)

ACP 3601-5 (400 V)

Weight: 1.9 kg

54

125

3

220

119

140

129

153

5

188

∅ 5.5

∅ 29

5

Size for devices:

∅ 22

III

ACP 3301-5 (230 V)

ACP 3302-2 (230 V)

ACP 3602-2 (400 V)

ACP 3603-0 (400 V)

ACP 3604-0 (400 V)

41

Weight: 3.45 kg

47

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

9

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

2.4.3 Dimensional Data (Size IV)

327

280

221

200

∅ 5.5

∅ 29

∅ 35

Size for devices:

IV

180

6

133

46

ACP 3605-5 (400 V)

ACP 3607-5 (400 V)

ACP 3611-0 (400 V)

ACP 3615-0 (400 V)

Weight: 8.6 kg

47

53

10

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3 Installation

3.1 Inspection

A. Upon receipt, unpack and carefully inspect for any damage sustained in transit (depres-

sion in the enclosure, damage to parts, missing parts).

B. Remove the cover (see page 25) and inspect the inverter for any apparent damage or

foreign objects. Ensure that all mounting hardware and terminal connection hardware is

properly seated, securely fastened, and undamaged.

C. Read the technical data label and ensure that the correct rated output and input voltage

for the application has been purchased.

D. If the inverter is to be stored for a long period of time, repack and store in a clean, dry

place, free from direct sunlight or corrosive fumes, and in a location where the ambient

temperature will not be less then -20 °C nor more than +60 °C.

3.2 General Rules for Installation

Improper installation of the inverter will greatly effect its life. Be sure to observe the following

points when selecting a mounting location. VIOLATING THE CONDITIONS LISTED BE-

LOW MAY VOID THE WARRANTY!

A. Mount the unit vertically and do not restrict the airflow to the heat sink fins on the back

of the controller. The fan and fins allow cooling of internal components. Any air restriction could greatly reduce the life of the inverter, as well as resulting in nuisance overtemperature trips.

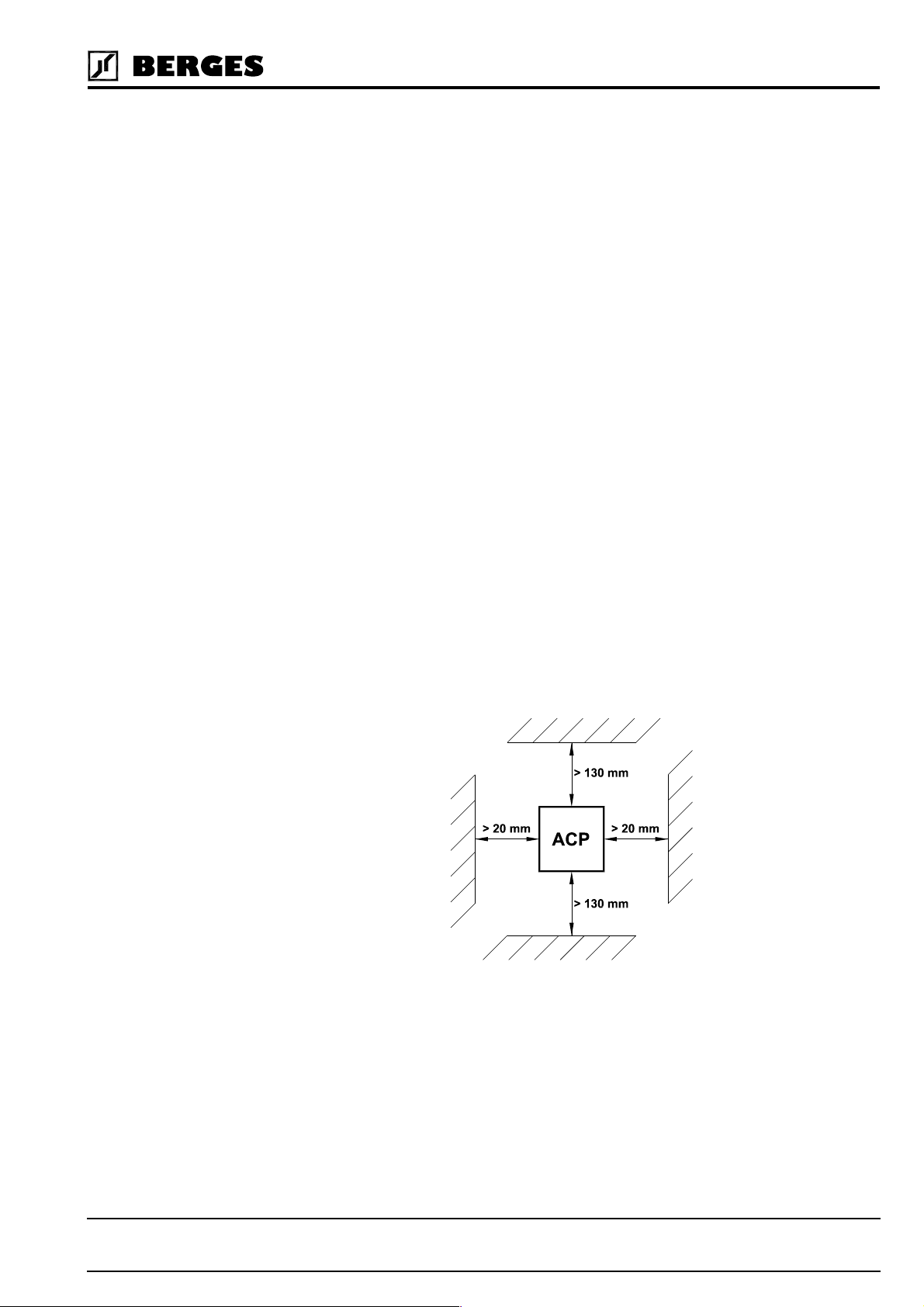

B. The ACP inverter generates heat, and therefore there must be a sufficient amount of

free space around the unit (see Figure 3.1). If the unit is accommodated in a housing

together with a different unit, the prescribed minimum distances must be observed so

that adequate ventilation can be ensured.

Figure 3.1

C. If the inverter has to be installed in a different position, external cooling is required for

full capacity utilization. In certain circumstances, the internal air circulation does not suffice when installing the unit in a control cabinet with a small volume. Therefore, when

installing the unit, you must ensure that a heat buildup is prevented.

D. Do not mount the ACP near heat generating equipment, or in direct sunlight. BERGES

inverters are generally designed so that they can be operated at ambient temperatures

of 0 °C to +50 °C (IP 00) or 0 °C to 40 °C (IP 21) and at a relative humidity of up to 90%.

The occurrence of condensate must be avoided!

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

11

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

E. Do not install the inverter in a place subjected to high temperature, high humidity, or ex-

cessive vibration (see Table 2.3, “Ambient Conditions”)

F. The units should never be installed in the proximity of corrosive or flammable gases,

conductive dust or large magnetic and electric fields.

G. Pay close attention during installation to ensuring that no objects (such as drilling swarf,

wire or anything else) fall into the unit. Otherwise, a device fault cannot be excluded,

even after longer periods of operation.

ATTENTION!

H. Do not use wire end ferrules for the control terminals. The terminals are designed

so that the wires can be inserted in the terminals after twisting the individual

wires.

I. Table 3.1 shows the watts generated by the inverter when at full current. The heat gen-

erated is dependent on the carrier frequency used. For carrier frequencies other than

those shown in Table 3.1, consult BERGES or use the worst-case scenario (16 kHz carrier).

HEAT GENERATED BY INVERTER (IN WATTS)

Inverter Model Number @ 4 kHz Carrier @ 16 kHz Carrier

3300-3 19 27

3300-5 37 42

3300-7 66 75

3301-1 66 75

3301-5 70 79

3302-2 129 154

3600-7 40 62

3601-5 67 99

3602-2 118 186

3603-0 184 281

3604-0 184 281

3605-5 280 640

3607-5 360 790

3611-0 470 1120

3615-0 610 1400

Table 3.1

3.3 EMC (Electromagnetic Compatibility)

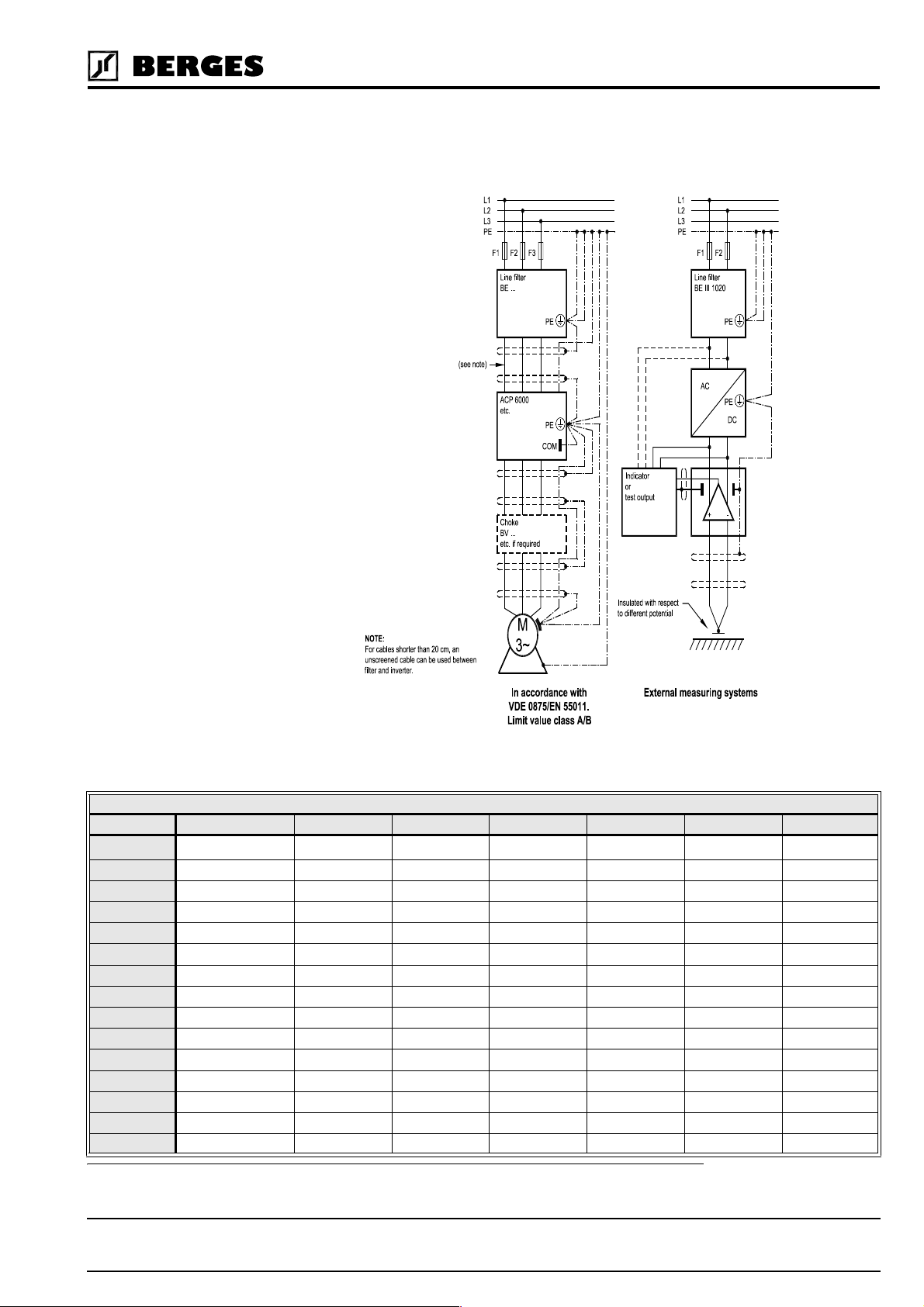

3.3.1 Suggestion on how to solve the Problem of Radio Frequency Interference

Suppression of Frequency Converters to VDE 0875/EN 55011

It is necessary to connect a mains filter type “BE/(xxx) xxxx” before every frequency converter. The size (xxx) depends on the rated current of the unit. A motor choke can be dispensed with.

HINT!

The motor choke type BV... may be necessary as from a cable length in excess of 20 m and

when operating several motors in parallel on one frequency converter output. This choke

attenuates the capacitive earth leakage currents and considerably reduces wire-borne interference voltages.

12

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

The converter and accessories must be wired in accordance with the following schematic.

To render the remaining interference voltage at the PE conductor potential ineffective for

“external measurement systems”, the following proposed circuit will achieve successful results if applied consistently.

3.3.2 Mains Filters/Output Chokes

ACP 3000

DEVICE TYPE MAINS FILTER ARTICLE NO. INPUT PHASES VOLTAGE (V) CURRENT (A) WEIGHT (kg) FOOTPRINT

ACP 3300-3 BE I 1005 32501739 1~ 250 5 0.60

ACP 3300-5 BE I 1005 32501739 1~ 250 5 0.60

ACP 3300-7 BE II 1010 32501740 1~ 250 10 0.70

ACP 3301-1 BE II 1010 32501740 1~ 250 10 0.70

ACP 3301-5 BE III 1020 32501741 1~ 250 20 1.05

ACP 3302-2 BE III 1020 32501741 1~ 250 20 1.05

ACP 3600-7 BE I 3003 32501742 3~ 380/480 3 0.75

ACP 3601-5 BE II 3005 32501743 3~ 380/480 5 0.80

ACP 3602-2 BE III 3012 32501744 3~ 380/480 12 1.15

ACP 3603-0 BE III 3012 32501744 3~ 380/480 12 1.15

ACP 3604-0 BE III 3012 32501744 3~ 380/480 12 1.15

ACP 3605-5 BE IV 3038 32501745 3~ 380/480 38 1.90

ACP 3607-5 BE IV 3038 32501745 3~ 380/480 38 1.90

ACP 3611-0 BE IV 3038 32501745 3~ 380/480 38 1.90

ACP 3615-0 BE IV 3038 32501745 3~ 380/480 38 1.90

(1) FOOTPRINT means that these filters have been prepared for the installation of an ACP converter on the filter (securing).

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

13

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

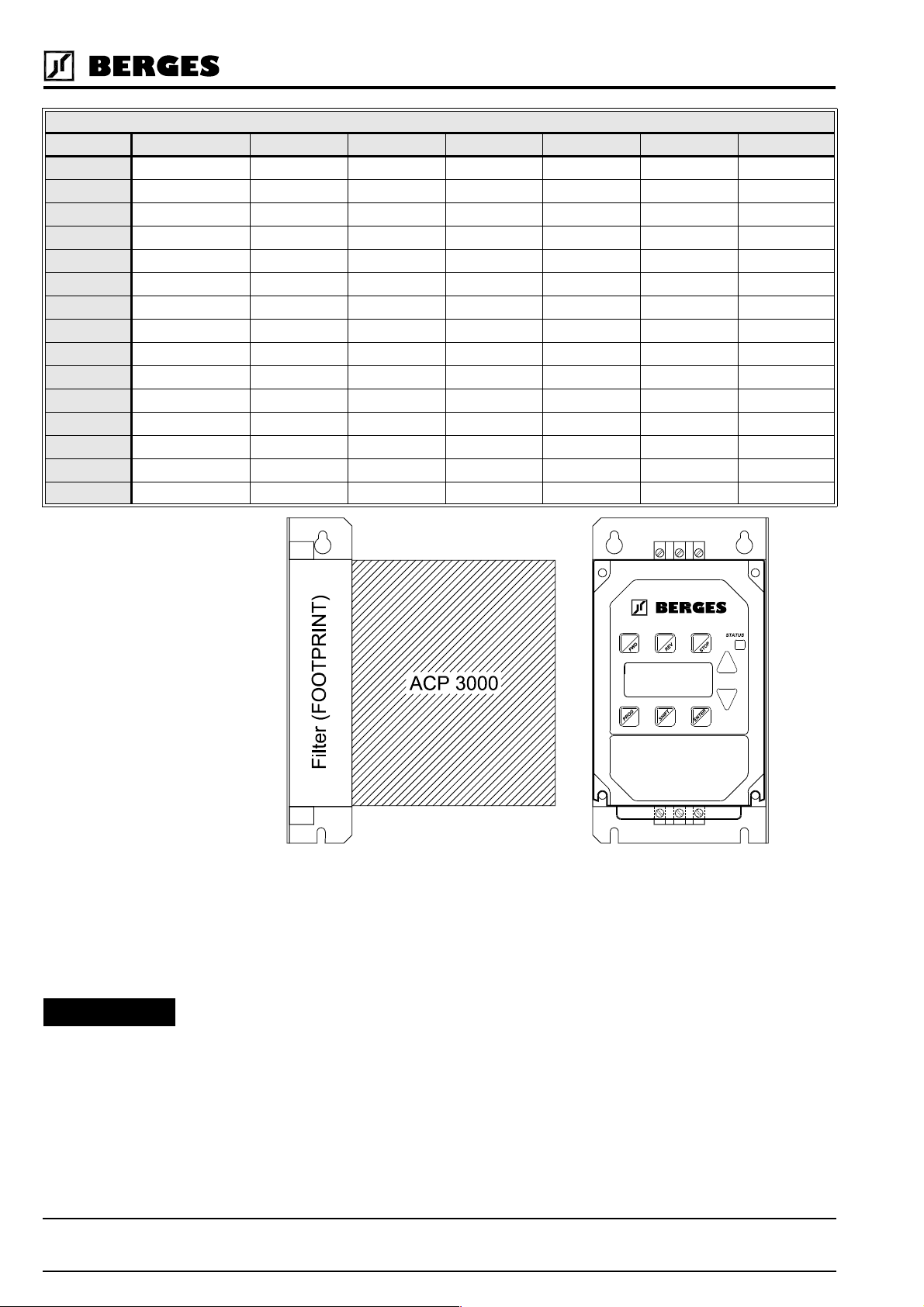

ACP 3000

DEVICE TYPE CHOKE ARTICLE NO. INPUT PHASES VOLTAGE (V) CURRENT (A) WEIGHT (kg) FOOTPRINT

ACP 3300-3 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3300-5 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3300-7 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3301-1 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3301-5 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3302-2 BV 20394/313 32501346 – 440 13 0.70 –

ACP 3600-7 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3601-5 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3602-2 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3603-0 BV 20394/307 32501345 – 440 7 0.25 –

ACP 3604-0 BV 20394/313 32501346 – 440 13 0.70 –

ACP 3605-5 BV 20394/313 32501346 – 440 13 0.70 –

ACP 3607-5 BV 20394/325 32501347 – 440 25 1.10 –

ACP 3611-0 BV 20394/325 32501347 – 440 25 1.10 –

ACP 3615-0 BV 20394/330 32501348 – 440 30 1.15 –

3.3.3 Filter Specifications

ATTENTION!

14

All BERGES line filters are provided in IP20 enclosures. They can operate over a temperature range of -10 to +50 °C (-23 to +122 °F). The filters can be mounted parallel or perpendicular to the control panel. The filter is supplied with the correct mounting hardware for

mounting the inverter on top of the filter enclosure (Footprint).

The mains filters and chokes must be installed and connected in conformity with the recommendations given in chapters 3.3.1 (page 12), 3.3.4 (page 15) and 3.6.3 (page 22).

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

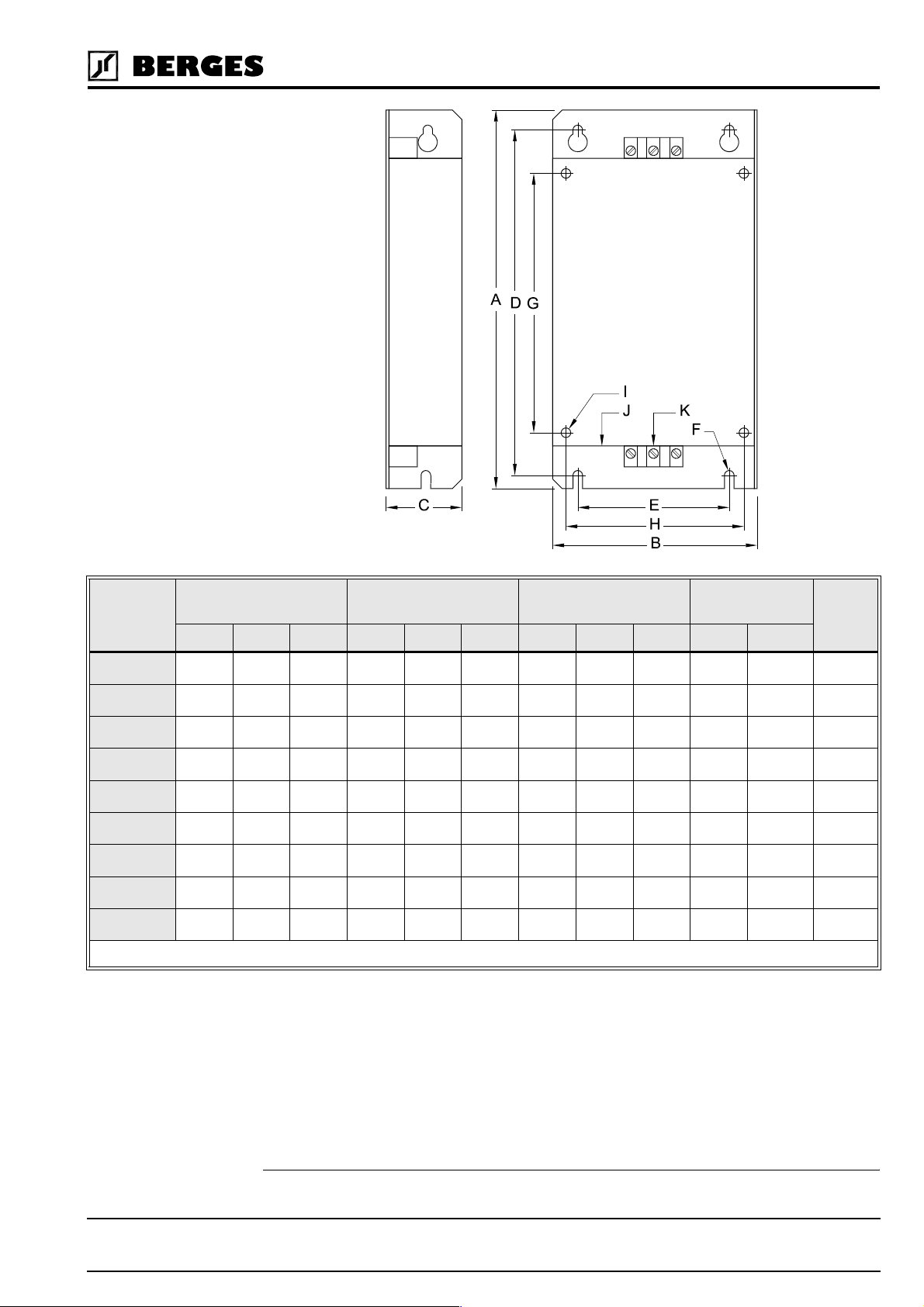

TYPE OUTER DIMENSIONS SECURING SECURING ON THE

CONNECTIONS FOOT-

INVERTER

A B C D E F G H I J (PE) K

BE I 1005 200 108 40 183 80 M5 137 94 M5 M4

BE II 1010 200 145 40 183 110 M5 137 129 M5 M4

BE III 1020 250 145 45 235 110 M5 188 129 M5 M4

BE I 3003 200 108 40 183 80 M5 137 94 M5 M4

BE II 3005 200 145 40 183 110 M5 137 129 M5 M4

BE III 3012 250 145 45 235 110 M5 188 129 M5 M5

BE IV 3038 360 222 50 342 160 M6 280 200 M6 M5

BE V 3012 360 222 50 342 160 M6 280 200 M6 M5

BE VI 3040 496 232 50 478 180 M6 419 200 M6 M5

Table 3.2

NOTE: Dimensions in mm.

(1)

3.3.4 Interference Suppression Measures

2,5 mm

2,5 mm

2,5 mm

2,5 mm

2,5 mm

2,5 mm

16 mm

16 mm

16 mm

PRINT

2(1)

2(1)

2(1)

2(1)

2(1)

2(1)

2(1)

2(1)

2(1)

Electrical/electronic devices are capable of influencing or disturbing each other through

connecting cables or other metallic connections. “Electromagnetic compatibility” consists of

the factors “interference resistance” and “interference emission”. Correct installation of

the inverter in conjunction with any possible local interference suppression measures has a crucial effect on minimizing or suppressing mutual interference.

(1) FOOTPRINT means that these filters have been prepared for the installation of an ACP converter on the filter (securing).

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

15

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

The scope of noise suppression measures depends on the limit value class, the local situation and the application.

The following notes refer to a mains power supply that is not “contaminated” by high frequency interference. Other measures may be necessary to reduce or suppress interference

if the mains voltage is “contaminated”. No generally valid recommendations can be given

in such cases. Please consult BERGES if all recommended interference suppression

measures should not produce the desired result.

Basically, it is not the cross section of the conductor that is important for radio-frequency

interference suppression but the surface area. Since the high-frequency interference does

not flow through the entire cross section but mainly on the outer surface of the conductor

(skin effect), braided copper tapes of corresponding cross section should be used.

All conductive housing parts must be interconnected using corresponding lines. Minimum

cross sections are prescribed for a fault case at 50 Hz (referred to the range of the safety

regulations) which must be observed under all circumstances.

The inverter and all other components used for interference suppression (especially also

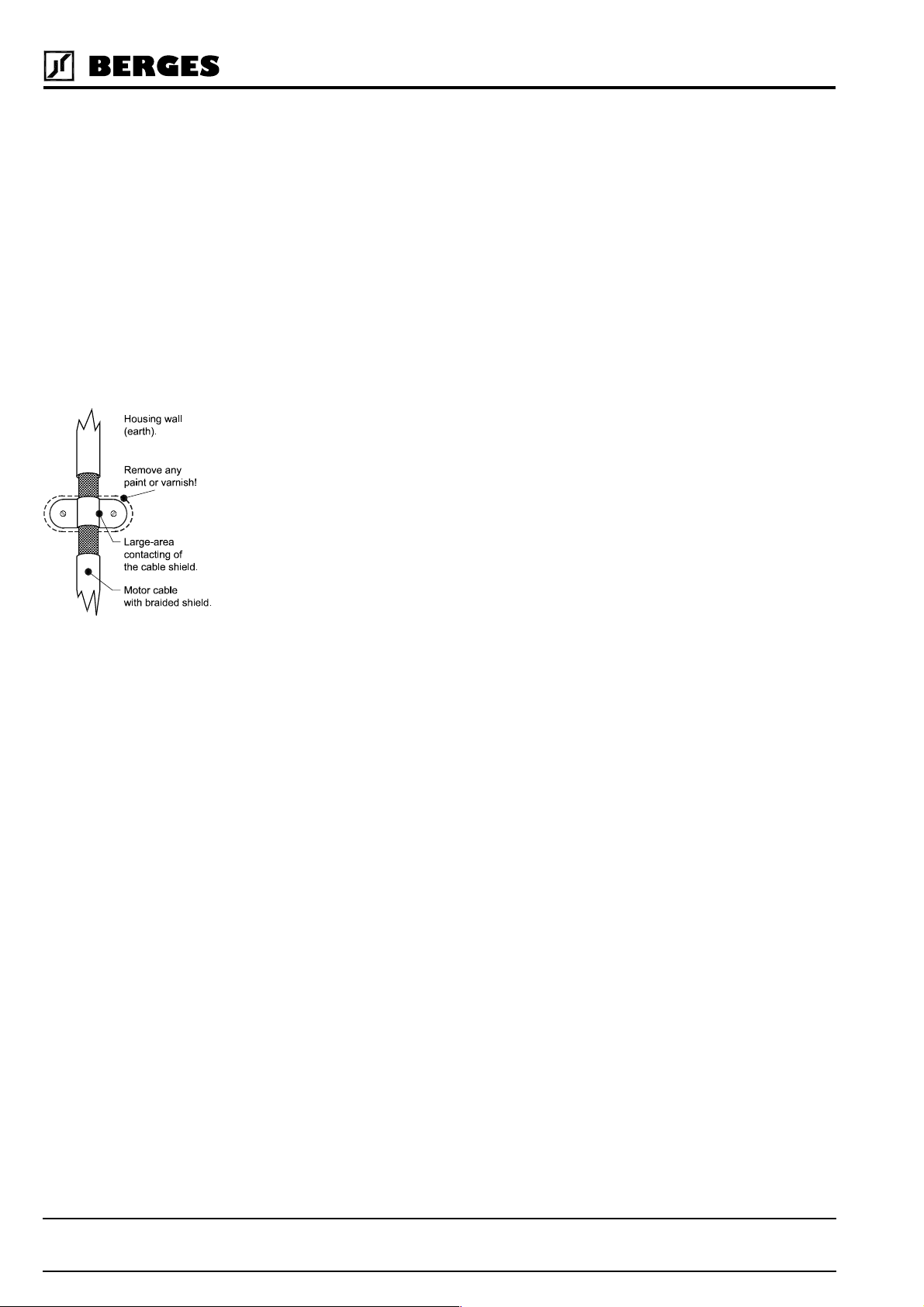

the shield of the motor cable) should be contacted over as large an area as possible when

connected to metal (control panels, switchgear cabinets and similar) (skin effect). Remove

the paint at the respective areas to ensure good contacting over a large area!

A central earthing point should be used for interference suppression (e.g. equipotential

bonding strip or centrally at an interference suppression filter). The earthing lines are routed

to the respective terminals radially from this point. Conductor loops of the earthing lines

are impermissible and can lead to unnecessary interference.

The shield cross section must not be reduced when the shield is connected to continuing

lines. This would give rise to RF resistance at a cross section reduction, and the resulting

RF energy would consequently not be discharged but radiated. Shields – particularly

shields of control lines – must not be contacted via pin contacts of plug connectors. In these

cases, the metallic hand guard of the plug connector should be used for large-area connection of the shield.

Use a shielded motor cable (earthed over a large area at both sides). The shield should be

routed uninterrupted from the PE terminal of the inverter to the PE terminal of the motor.

If a shielded motor line cannot be used, the unshielded motor line should be laid in a metal

duct. The metal duct must be uninterrupted and adequately earthed. The following points

are prescribed if radio interference suppression is to be realized in accordance with EN

55011, EN 55014 and EN 50081-1:

• Preceding the unit by a mains filter or a mains filter and a output choke (mains filter and

output choke not included in the scope of delivery).

• Laying the motor cable in a shielded configuration.

• Laying the control cable in a shielded configuration.

• Observe general RFI suppression measures (refer to the chapters 3.3.1 and 3.3.4).

Lay motor, mains power and signal cables as far away from each other as possible and separately.

If a mains filter is used, the smallest possible spatial distance from the frequency inverter

must be selected so that both units can be connected by short connection leads.

If an output choke is used (option), it must be fitted in the direct vicinity of the inverter and

connected to the inverter via screened cables earthed at both ends.

16

Shielded signal cables should be laid at a minimum distance of 10 cm from power cables

running parallel. A separate earthed metal cable duct is advisable for such signal cables. If

signal cables intercept with a power cable, they should do so at an angle of 90°.

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Control lines longer than 1 m must be laid with a shield and earthed at one side on the frequency inverter. The screen is earthed via terminal “CM” in the case of pull-up logic and

pull-down logic (see “Connection Diagrams”, chapters 7.1 to 7.7). If cables have lengths in

excess of 10 m, use a 0–20 mA control signal because of the possibility of parasitics. The

inverter can be switched over to this mode of operation. See parameter

5.2, page 38).

Other loads connected to the mains may produce voltage spikes that may interfere with

functioning of the inverter or may even damage it. Chokes or mains filters can be used on

the mains side to protect the inverter against voltage spikes (resulting from switching large

loads to the mains). Such chokes and filters are available as accessories.

If inverters are operated in switchgear devices or in their close proximity (e.g. in one common control cabinet) in connection with the same power mains, we recommend the following precautionary measures to suppress interference in the switchgear:

• Wire the coils of contactors, switchgear devices and relay combinations with “RC elements” or with free-wheel diodes.

• Use shielded cables for external control and measuring cables.

• Lay disturbing cables (e.g. power and contactor control circuits) separately and at a distance from the control cables.

3.4 EMC Ordinance (EMC Directive, 89/336 EEC)

24-FSEL

(chapter

HINT!

The frequency inverters were tested in the form of a practical test set-up in a switchgear

cabinet (in accordance with our interference suppression measures in these operating instructions: “EMC (electromagnetic compatibility)”. The limit values of the standards below

were fulfilled under these conditions:

EMA (Electromagnetic Emission)

EN 50081-1 Basic specification “Emitted interference” (Limit value class A)

or

EN 50081-2 Basic specification “Emitted interference” (Limit value class B)

EN 55011 Emitted interference

EMB (Electromagnetic Interference)

EN 50082-2 Basic specification “Interference immunity”

EN 50140 Electromagnetic fields

EN 60801 Static discharge (ESD)

IEC 801-4 Burst on mains lead/data line

At least the following conditions must be fulfilled for compliance with

the limit values of the aforementioned standards:

• Installation of a mains filter or a mains filter and a motor choke (mains filter and motor

choke are not included in the scope of delivery).

• Laying the motor cable in a shielded configuration.

• Laying the control cable in a shielded configuration.

• Observe general RFI suppression measures (refer to the chapters 3.3.1 and 3.3.4).

As the aforementioned interference resistance tests are based on standardised mains conditions, in extreme cases it may happen that the function of the inverter will be lost (minimum operating quality). This malfunction can generally be remedied by a RESET of the

inverter. Refer to the chapter entitled “Resetting a Fault” and “Fault Codes” on page 63.

Detailed information and technical data relating to adapted mains filters and chokes can be

found in the chapters 3.3.2, “Mains Filters/Output Chokes” and 3.3.3, “Filter Specifications”.

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

17

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3.5 Wiring Practices

3.5.1 Applicable Codes

Pay conscientious attention to ensuring that the installation wiring is installed at least in conformity with the NEC standards. Where local codes exceed these requirements, they must

be followed.

All models are listed by the Underwriters Laboratories, Inc. (UL) and are certified by the Canadian Underwriters Laboratories (cUL) and therefore conform to the requirements of NEC

and CEC. Installations that are to meet the requirements of UL and cUL must be realised

in conformity with the UL and cUL specifications. Refer to the corresponding electrical data

on the rating plates of the ACP 3000 unit and the motor.

3.5.2 Power Wiring

Power wiring are those wires which are connected during installation to the power circuit

terminals, L1, N, L2, L3, M1, M2, and M3. Power wiring must be selected as follows:

1. Use only VDE, UL or cUL recognized wire.

2. Wire voltage rating must be a minimum of 300 V for 230 VAC systems, and 600 V for

400 VAC systems.

ATTENTION!

3.5.3 Control Wiring/Interface

ATTENTION!

3. The core cross section and the associated fuse are given in the tables in chapter 3.6.2,

page 22. The wires must consist of copper and be designed for insulation temperatures

of 60 °C or 75 °C.

4. Grounding must be in accordance with VDE, NEC and CEC.

NOTES:

Never connect input AC power to the motor output terminals M1, M2 and M3 or dam-

age to the drive will result.

The output voltage of variable-frequency controllers contains high-frequency components

that might cause disturbances in other installations. Therefore, avoid laying control cables

and mains input cables in the same cable duct or conduit together with the output cables

from the converter to the motor (see also chapter 3.3.4, “Interference Suppression Measures”).

All interfaces or control inputs and outputs possess only basic insulation by the

mains and must be incorporated in a further protective measure.

Use a dummy plug as additional protection if interface J22 is not allocated.

This is wiring connected to the control terminal strip (20 terminals). It must be selected as

follows:

1. Shielded wire is recommended to prevent electrical noise interference from causing improper operation or nuisance tripping. Only connect the screen on one end to the “CM”

terminal on the converter’s control terminal strip (see also chapter 3.3.4, “Interference

Suppression Measures”).

18

2. Use only VDE, UL or cUL recognized wire.

3. Wire voltage rating must be a minimum of 300 V for 230 VAC systems, and 600 V for

400 VAC systems. This is Class 1 wire.

4. Never run the control wiring in the same conduit or raceway with power wiring.

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

5. Do not use wire end ferrules for the control terminals. The terminals are designed

so that the wires can be inserted in the terminals after twisting the individual

wires.

3.6 Mains Power Connection

The frequency inverters are designed for installation in a switchgear cabinet and for

permanent connection.

To guarantee lasting operating safety and reliability, the inverter must be connected expertly in accordance with the valid electrical standards. Attention must be paid to good insulation from earth potential on the power terminals.

An AC system with a nominal voltage of 230 V (50/60 Hz) must be connected to mains terminals L1, N and PE or a three-phase system with a nominal voltage of 400 V (50/60 Hz)

to terminals L1, L2, L3 and PE (pay attention to rating plate). The neutral point must be

earthed (TN-C system).

Ensure a voltage balanced to earth or phase to phase when feeding in the mains power

through an isolating transformer (star point must be earthed).

Frequency inverters must not be connected via a residual-current-

operated circuit-breaker as the sole protective measure!

The single exception below permits connection of a frequency inverter via a residual-current-operated circuit-breaker as the sole protective measure:

• Installation of a residual-current-operated circuit-breaker of the newest design for fre-

quency inverters up to 4 kVA (input voltage 1 × 230 V) with MOBILE connection.

This residual current-operated circuit breaker must be suitable for alternating and pulsating DC leakage current. Residual-current-operated circuit-breakers of this type bear

the symbol .

Reliable tripping of the residual-current-operated circuit-breaker is not ensured in

the case of frequency inverters up to 4 kVA (input voltage 3 × 400 V) with MOBILE

connection; an additional protective measure must be used for this reason. Also see

the diagram below.

In the case of frequency inverters with PERMANENT connection (input voltage 1 ×

230 V and 3 × 400 V), another protective measure must always be used in addition to

the residual-current-operated protective device. Also see the diagram below.

The protective function of the residual-current-operated circuit-breaker is no longer ensured

due to leakage currents from interference suppression capacitors in the inverter and DC

components in the fault current. All devices connected to this residual-current-operated circuit-breaker (and persons touching them) are no longer protected in the event of a fault.

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

19

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Flow diagram of the requirements relating to the combination of frequency inverter

and residual-current-operated protective device

The inverter will be destroyed if the mains feeder is confused with the motor cable.

The DC link capacitors must be reformed if the inverter you wish to connect has been out

of operation for more than a year. To do this, connect the inverter to voltage for approx. 30

minutes. The inverter should not be loaded by connected motors during forming.

3.6.1 Mains Conditions

Permissible fluctuation of the mains voltage amounts to around ±10% of the rated

voltage. If the mains voltage should exceed or fall below these limits, the inverter will

be deactivated automatically as the result of the undervoltage or overvoltage.

When applying the inverter to line voltages other than the factory default values (230 VAC

or 460 VAC), be sure to set parameter

Adaptation to rated line voltages outside the permissible range is possible by means of autotransformers. Calculation according to the formula below is recommend:

U

P

T

P

D

NOTE:

Exercise caution when using the ACP 3000 under the conditions of a low-voltage network.

An inverter from the ACP 3000 series is fully functional when connected to an alternating

current of 370 V, for example. However, the maximum output voltage is limited to 370 VAC.

If the motor is rated for a mains voltage of 400 VAC, this can lead to higher motor currents

and overheating of the motor. It must be ensured that the connected mains voltage cor-

responds to the rated voltage of the motor.

PD 1

=

U2I2× 3×=

------ -–

U

59-MVOLT

P

2

1

= Equivalent two-winding kVA rating (kVA)

T

P

= Continuous output (kVA)

D

= Rated line voltage (V)

U

1

U

= Rated voltage, frequency inverter (V)

2

= Input current (A) as per table 2.1 and 2.2

I

2

to the proper value. Refer to page 42.

20

If other than 50 Hz output can be tolerated, proper volts/hertz can be programmed into the

inverter by the

53-FKNEE

and

32-FMAX

parameters. If you are unsure about this feature,

consult section 5.2 or BERGES.

Phase voltage imbalance of the input AC source can cause unbalanced currents and ex-

cessive heat in the input rectifier diodes and in the DC bus capacitors of the ACP. Phase

imbalance is calculated by the following method:

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Assume:

The voltage from L1 to L2 = L

The voltage from L2 to L3 = L

The voltage from L3 to L1 = L

The average line voltage = L

LaLbL

L

avg

++

------------------------------ -

c

3

a

b

c

avg

395 400 405++

------------------------------------------ 400== =

3

ATTENTION!

3.6.2 Line Protection

Determine the absolute value of the difference between each of the line voltages (La, L

and Lc) and L

the results of this calculation to be L

Phase Imbalance

. (Subtract the two values and disregard the sign of the result.) Consider

avg

, Lba, and Lca.

aa

++

L

aaLbaLca

--------------------------------------- -

()

2 L

avg

100%×

505++

----------------------

2 400×

100%× 1.25%===

Example: Measured phase voltages of 395, 400, and 405 would result in a calculated

phase imbalance of 1.25%.

If the resulting phase imbalance exceeds 2%, consult your local power company or plant

maintenance personnel and ask them to investigate this problem and recommend methods

of correcting this condition.

Phase imbalance can also cause damage to motors running direct on line. A 2% imbalance

requires a 5% derating factor on the motor, 3% imbalance requires a 10% derating. 4% requires an 18% derating.

NEVER USE POWER-FACTOR IMPROVEMENT CAPACITORS ON THE ACP MOTOR

TERMINALS, M1, M2, AND M3, OR DAMAGE TO THE INVERTER'S SEMICONDUCTORS WILL RESULT!

It is necessary to provide either a circuit breaker or a fused disconnect switch on the input

AC line in accordance with all applicable electrical codes. The following rules should be

used to select the correct size of the input line fuses or circuit breaker.

b

A. Sizing

The ACP inverter is able to withstand a 150% overload for 60 seconds. Minimum voltage

rating for the protection device should be 250 VAC for models 3300-3 to 3302-2, and 600

VAC for models 3600-7 to 3615-0.

B. Fuse Type

To guarantee a maximum protection of the inverter fuses should be used for current Limitation. These fuses should have a breaking capacity of 200,000 A

shows the recommended values in amps for all ACP-inverters.

ATTENTION!

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

For 230/400 V mains supplies we recommend time-lag type NEOZED-fuses.

. The following tables

eff

21

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

SUPPLY VOLTAGE 1 × 230 VAC

Type 3300-3 3300-5 3300-7 3301-1 3301-5 3302-2

Inverter power (kW) 0.37 0.55 0.75 1.1 1.5 2.2

Rated current, fuse (A) 4 6 6 10 10 16

Cable cross section, mains lead (mm2)

Cable cross section, motor lead (mm2)

Type 3600-7 3601-5 3602-2 3603-0 3604-0 3605-5 3607-5 3611-0 3615-0

Inverter power (kW) 0.75 1.5 2.2 3.0 4.0 5.5 7.5 11.0 15.0

Rated current, fuse (A) 2 4 6 6 10 16 16 25 32

Cable cross section, mains lead (mm2)

Cable cross section, motor lead (mm2)

For mains supplies with rated voltage exceeding 415 V the semi-lag fuses type “Bussmann

FRS-R” are recommended. The typical disconnection times are 150–250 sec. for 2 times

the overcurrent and 180–1500 msec. for 10 times the overcurrent.

1.5 1.5 1.5 1.5 1.5 2.5

1.5 1.5 1.5 1.5 1.5 1.5

SUPPLY VOLTAGE 3 × 400 VAC

1.5 1.5 1.5 1.5 1.5 2.5 2.5 4 6

1.5 1.5 1.5 1.5 1.5 1.5 2.5 4 6

3.6.3 Using Mains Filters

Special protective measures must be observed when using mains filters:

Owing to the leakage current involved (>3.5 mA), attention must be paid to EN 50178 when

using BERGES mains filters. One of the following protective measures must be taken:

ATTENTION!

• The mains filter must be connected separately by laying a second cable that is electrically parallel with the PE conductor; this conductor must meet the requirements of IEC

364-5-543 on its own.

2

• The PE conductor must have a cross section of at least 10 mm

diagrams).

• The PE conductor must be monitored by a facility that isolates the inverter from the

mains in the event of a fault (PE conductor monitoring).

The inverter must always be connected permanently (EN 50178) when using mains

filters (leakage current >3.5 mA).

Mains filter connection with a second

parallel PE conductor

Mains filter connection with at least

2

10 mm

PE conductor cross section

(refer to the following

22

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3.6.4 Line Starting

ACP 3000 is designed to provide controlled starting and stopping of AC motors by use of

the keypad or external contacts connected to the control terminal strip. The drive may also

be started by using a maintained contact (2-wire operation). To prevent accidental starting

of the motor, the inverter has linestart-lockout as a standard feature. This provision can be

defeated by programming

The inverter may be started once every two (2) minutes in this mode.

3.7 Motor Connection

Connect the motor cable to the “M1, M2, M3” and “PE” terminals.

The inverter will be deactivated if shorted to the motor terminals.

82-START

(see page 48).

ATTENTION!

The output of the drive will always be three phase. Do not connect single-phase motors to the inverter output terminals M1, M2 or M3.

Never use power factor correction capacitors on the motor terminals M1, M2 and M3,

or damage to the semi-conductors will result.

We recommend PTC evaluation using commercially available devices to achieve effective

protection of the motor.

If interrupting contacts (e.g. contactors or motor protection switches etc.) have to be installed between the motor and inverter, the circuit must be configured so as to ensure that

the “Enable” signal (terminals V+ and FWD/REV by pull-up logic, terminals CM and FWD/

REV by pull-down logic) is deactivated before separation of the inverter/motor connection.

A relay switching time of approx. 30 ms suffices.

In the case of special motors, the corresponding Volt/Hz values can be programmed on the

inverter by means of the parameters

contact BERGES or refer to chapters 5.2 and 9.1.

53-FKNEE

3.8 Reducing Current Surges and Voltage Transients

Voltage spikes caused by coils (inductors operated on the same mains as the inverter) can

lead to malfunctions of the inverter. In cases of this kind, the affected windings of contactors

and relays operated on the 230 VAC mains must be damped by fuses in the form of an RC

series circuit:

• Main Circuit Contactors and Solenoids: C = 0.2 MFD, 500 VDC; R = 500 W, 5 Watts.

• Auxiliary Control Circuit Relays: C = 0.1 MFD, 500 VDC; R = 200 W, 2 Watts.

and

32-FMAX

. In cases of doubt, please

Connection Diagram for AC and DC Relay Coils and Solenoids:

Figure 3.2

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

23

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

Free-wheeling diodes must be used on contactors, relays and solenoid coils operated with

direct current. The diodes in question should be fast types with short recovery time. The

diode must be connected in blocking direction in parallel with the winding (see Figure 3.2).

The rated current and voltage of the diode can be calculated using the formulae below:

Diode Current Rating (A)

Diode Voltage Rating (V) Rated Voltage of Coil (V) 2×≥

≥

3.9 Function and Use of Terminals

Refer to section 7.1 to 7.7 – Connection Diagrams for power and control wiring examples.

A. Power Circuit Terminals

Power terminals are located on the power module of the ACP 3000 inverter. They are labelled L1, L2, and L3 for incoming three phase AC line power (L1 and N for incoming singlephase AC line power), and M1, M2, and M3 for the motor connections.

Two ground connections (GND) are provided on the end plate of 0.37 to 4.0 kW IP 21 models (see Figures 3.4 and 3.5), and along the power terminal strip of 5.5 to 15.0 kW IP 21

models (Figure 3.6). Ground connections can be made to the heat sink on chassis models.

The ground screws must be connected to earth ground in accordance with the NEC.

Coil Capacity (VA)

------------------------------------------------------------------

Rated Voltage of Coil (V)

5.5 to 15.0 kW inverters also have two terminals, B+ and B-, that provide access to the DC

bus rails for the addition of external dynamic braking kits, or extra bus capacitors for custom

applications.

B. Control Terminals

The control terminals are located on the bottom edge of the inverter's control board. See

Figures 3.4 to 3.6, page 26/27 and chapter 3.15. These terminals are available for use with

external devices.

The 20-pole control terminal strip of the units, 0.37–4.0 kW, is plugged in and can be removed in the upward direction to connect the control cables. To do this, place a flat screwdriver on the metal tabs of the cover securing element and carefully lever off the terminal

strip in the upward direction.

NOTE:

Control input signals must not exceed 24 VDC ±20% potential to ground.

Logic Input Levels:

LOGIC TYPE PULL-UP PULL-DOWN

Active 10–24 VDC 0–3 VDC

Inactive 0–3 VDC 10–24 VDC

The input logic is compatible with either 12 or 24 VDC logic. J20 selects active High or Low

control inputs.

24

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3.10 Terminal Access Cover Removal Hazard of electrical shock.

Disconnect power before working on this drive.

Dangerous voltages exist until the STATUS Indicator is off.

A. IP 21 Enclosures

IP 21 versions of the ACP 3000 inverter are designed to prevent accidental removal of the

terminal access cover. The cover mounting meets UL and NEC specifications for safety.

To remove the access cover from 0.37 to 4.0 kW inverters, loosen the two screws mounted

at the lower corners of the cover (see Figure 3.3). When replacing the cover, a snug fit only

is required. Do not torque the screws or damage to the cover may result.

To remove the access cover from 5.5 to 15.0 kW inverters, insert a small blade screwdriver

into the slots located on the lower left and right corners of the cover. Use a slight twisting

motion while lifting upward to loosen one side then the other, and then lift the cover off the

inverter. To replace, hook the cover onto the two retainers on top of the inverter base and

snap the cover into place.

Figure 3.3

Access Cover

Access Cover

Mounting Screw

(Not Shown)

Conduit Entry

Plate

Access Cover

Mounting Screws (2)

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

25

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3.11 Terminal Assignment (Mains supply 1 × 230 VAC, 0.37–4.0 kW)

CM

MET2

MET1

CM

VIN2

VIN1

REF

CM

FWD

REV

PS3

PS2

PS1

V+

V+

MOL

ST1

NO

RCM

NC

J20

L1

AC Line

L1, N

Motor

N

M1 M2 M3

Control

Terminals

J22

M1, M2, M3

Figure 3.4

(1)

3.12 Terminal Assignment (Mains supply 3 × 400 VAC, 0.37–4.0 kW)

V+

V+

CM

MET2

MET1

CM

VIN2

VIN1

REF

CM

FWD

REV

PS3

PS2

PS1

MOL

ST1

NO

RCM

NC

26

J20

L1

AC Line

L1, L2, L3

Motor

L2 L3

M1 M2 M3

Control

Terminals

J22

M1, M2, M3

Figure 3.5

(1) Power Terminals torque to 3.4 Nm max.

Control Terminals torque to 0.28 Nm max.

(1)

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3.13 Terminal Assignment (Mains supply 3 × 400 VAC, 5.5–15.0 kW)

J20

Control Terminals

CM

MET2

MET1

CM

VIN2

B- B+ GND GND L3 M1 M2 M3L1 L2

AC Line

L1, L2, L3

Figure 3.6

FWD

REV

CM

VIN1

REF

Motor

M1, M2, M3

(1)

PS3

PS2

PS1

J22

NO

MOL

V+

RCM

ST1

NC

V+

(1) Power Terminals torque to 3.4 Nm max.

Control Terminals torque to 0.28 Nm max.

3.14 Remote Keypad/Program Memory Unit Connector (J22)

Connector J22, located on the right side of the ACP 3000 micro-inverter, is used with either

the Remote Keypad Unit (XRK01) or Program Memory Unit (XPM01), both sold separately.

Both options are battery or AC line adapter powered and can be used with any ACP 3000

model to allow remote programming and control of the inverter. The Remote Keypad Unit

can be mounted on another enclosure up to 100 m from the inverter. Programmer options

allow storage of up to ten separate parameter sets.

3.15 Control Terminal Description

The ACP 3000 series micro-inverter has a 20 position control terminal block. Some functions are defined by the setting of jumper J20, while others are defined by programming.

Refer to section 7.1 to 7.7 and Figures 3.4 to 3.6.

DESCRIPTION OF TERMINALS

CM Circuit Common, isolated from ground.

MET1 Analog meter output 1. Provides a 0 to 10 VDC (1 mA maximum) signal proportional to output frequency,

load, or current through setting of

70-MCAL

(page 45). Output impedance is 475 Ω.

MET2 Analog meter output 2. Provides a 0 to 20 mA or 4–20 mA signal proportional to output frequency, load, or

current through setting of

79-MET2

(page 47). Output impedance is 10 Ω.

71-METER

. May be calibrated while inverter is running by programming

. May be calibrated while inverter is running by programming

78-MCAL2

21.12.98 Operating manual

04_GB ACP 3000 — 0.37–15.0

27

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

DESCRIPTION OF TERMINALS

VIN1 Analog speed input 1. Selectable through jumper J20 for 0–5 VDC, 0–10 VDC, or 0/4–20 mA DC. A 4 mA

offset is programmed by

selected, the reference value is the sum of the two analog inputs or, if

24-FSEL

. Only VIN1 is active with functions 0–4. If a function between 4 and 7

24-FSEL

has been programmed

accordingly (page 38), it is the difference between VIN1 and VIN2 (functions 8–11). Functions 12–15

switch between VIN1 and VIN2. VIN1/VIN2 changeover via PS3.

VIN2 Analog speed input 2. Selectable through jumper J20 for 0–5 VDC or 0–10 VDC. Only VIN1 is active with

functions 0–4. If a function between 4 and 7 selected, the reference value is the sum of the two analog inputs or, if

24-FSEL

has been programmed accordingly (page 38), it is the difference between VIN1 and

VIN2 (functions 8–11). Functions 12–15 switch between VIN1 and VIN2. VIN1/VIN2 changeover via PS3.

REF 5.2 VDC reference voltage, 3 mA maximum load. USE ONLY FOR A FREQUENCY CONTROL POTEN-

TIOMETER (5 kΩ recommend).

FWD Digital input for Forward operation. May be programmed for maintained (standard) or momentary contacts

21-MODE

by

. See page 36.

REV Digital input for Reverse operation. May be programmed for maintained (standard) or momentary contacts

by

21-MODE

. See page 36.

V+ Positive nominal 12 VDC voltage. Only for use with digital inputs (see pages 59 to 61). NO OTHER USE IS

ALLOWED.

MOL Motor Overload relay input. May be configured to generate a fault on opening or closing. May also be con-

PS1

PS2

PS3

figured to command a Coast-to-Stop on opening or closing. See page 47,

77-MOL

Digital inputs normally used for preset speed selection. Jumper J20 selects pull-up or pull-down logic (see

page 29). PS3 can be defined as a Run/Jog selector or VIN1/VIN2 switch by

as the ART selector by

41-RSEL

(see page 39), unless the PI Regulator is enabled and PS3 is used as an

.

21-MODE

(see page 36), or

ON/OFF switch. Eight preset speeds are available if all 3 inputs are used, and four are available if PS3 is

redefined via

21-MODE

or

41-RSEL

.

PS1 PS2 PS3 Effective Speed Reference

0 0 0 Basic speed setpoint (keypad or terminals)

100 33-F2

010 34-F3

110 35-F4

001 36-F5

101 37-F6

011 38-F7

111 32-FMAX

PS1 PS2 PS3 Effective Speed Reference

PS1

PS2

(1)

0 0 N/A Basic speed setpoint (keypad or terminals)

10N/A 33-F2

01N/A 34-F3

11N/A 35-F4

ST1 Digital output (open collector transistor). May be set to activate under one of ten conditions. See

72-ST1

(page 46). Maximal load: 24 VDC, 50 mA.

NO Normally open contact for the Auxiliary Relay. Will close when the relay is activated. Rating is 115/240 VAC

at 1 Ampere.

RCM Auxiliary relay common terminal. May release by appropriate adjustment at one of ten preset conditions.

See page 46,

75-STR

.

NC Normally closed contact for the Auxiliary Relay. Will open when the relay is activated. Rating is 115/240

VAC at 1 Ampere.

Table 3.3

28

(1) These settings will be utilized when PS3 is redefined via parameter

PS3 is used as an ON/OFF switch.

Operating manual 21.12.98

ACP 3000 — 0.37–15.0 04_GB

21-MODE

or

41-RSEL

, or when the PI Regulator is enabled and

Berges electronic • D–51709 Marienheide-Rodt • Tel. 02264/17-0 • Fax 02264/17126

3.16 J20 Configuration

Jumpers J20, on the bottom left edge of the control module (see Figures 3.4–3.6), enable

changeover of analog value specification and the switching logic of the digital control inputs.

It has seven (7) positions and two movable shorting jumpers. One jumper selects the analog speed reference used and the second jumper selects the active state (High or Low) of

the digital inputs. A pair of small needle nose pliers will prove useful for moving these jumpers. REMOVE AC POWER AND WAIT FOR ALL INDICATORS TO GO OUT BEFORE

CHANGING THIS JUMPERS.

JUMPER

SETTINGS

FUNCTION DESCRIPTION

VIN1: 0–10 VDC Terminal input VIN1:

This configures the drive to accept an external 0–10 VDC speed reference sig-

24-FSEL

nal.

VIN1: 0–20 mA

or 4–20 mA

VIN1: 0–5 VDC Terminal input VIN1:

VIN2: 0–10 VDC Terminal input VIN2:

VIN2: 0–5 VDC Terminal input VIN2:

Pull-Down Logic This configures the digital inputs for pull-down logic. That is, active when con-

Terminal input VIN1:

This configures the drive for either a 0–20 mA or a 4–20 mA input from an external source. 0–20 mA or 4–20 mA is selected by

250 kΩ.

(DEFAULT SETTING) This configures the drive for an external 0–5 VDC signal,

or a speed potentiometer powered from the REF terminal on the control terminal

24-FSEL

strip.

This configures the drive to accept an external 0–10 VDC speed reference signal.

24-FSEL

This configures the drive for an external 0–5 VDC signal, or a speed potentiometer powered from the REF terminal on the control terminal strip.

lects direct or inverse operation. Input impedance is 48 kΩ.

nected to terminal CM. Inputs are high, and are pulled low to activate.

selects direct or inverse operation. Input impedance is 95 kΩ.

24-FSEL

selects direct or inverse operation. Input impedance is 48 kΩ.

selects direct or inverse operation. Input impedance is 95 kΩ.

. Input impedance is

24-FSEL

se-

Pull-Up Logic (DEFAULT SETTING)