Behringer FBQ1000 User Manual [ru]

User Manual

FEEDBACK DESTROYER FBQ1000

Automatic and Ultra-Fast Feedback Destroyer/Parametric EQ

with 24 FBQ Filters

2 FEEDBACK DESTROYER FBQ1000 User Manual

Table of Contents

Thank you .......................................................................2

Important Safety Instructions ...................................... 3

Legal Disclaimer ............................................................. 3

Limited warranty ............................................................ 3

1. Introduction ............................................................... 4

2. Applications ............................................................... 5

3. A Few Quick Steps to EliminateFeedback .............. 6

4. Control Elements ....................................................... 6

5. FBQ1000 Architecture:

Presets, Filters, Operating Modes ................................ 7

6. Operating Modes of the FBQ1000 ............................ 8

7. Working with Presets ................................................8

8. Problems Do Have A Cause ... ................................. 10

9. MIDI Control ............................................................. 10

10. Installation ............................................................. 11

11. Appendix ................................................................12

12. Specications ......................................................... 15

Thank you

Thank you very much for expressing your condence in BEHRINGER products by

purchasing the FEEDBACK DESTROYER FBQ1000. With the FEEDBACK DESTROYER

you have acquired a highly useful device for the control of sound reinforcement

systems, which will enable you to focus your attention on what is essential:

your music. The fully featured FBQ1000 not only suppresses feedback but also

incorporates a wealth of additional functions in one single unit. Its 24 separate

lters can be edited in all parameters, and automatically detect and suppress

feedback frequencies. With its pro-level internal processing circuitry, the unit can

also be used as a high-end equalizer for stage and studio applications. The MIDI

interface allows for integrating the FBQ1000 into any MIDI system, and the open

system architecture enables you to update the system software whenever you

want. In short: the FBQ1000 will be your reliable “workhorse” over many years

tocome.

3 FEEDBACK DESTROYER FBQ1000 User Manual

9. Do not defeat the safety purpose of the polarized

TO BIND MUSICGROUP BY ANY EXPRESS OR IMPLIED

Important Safety Instructions

Terminals marked with this symbol carry

electrical current of su cient magnitude

to constitute risk of electric shock.

Use only high-quality professional speaker cables with

¼" TS or twist-locking plugs pre-installed. Allother

installation or modi cation should be performed only

by quali edpersonnel.

This symbol, wherever it appears,

alertsyou to the presence of uninsulated

dangerous voltage inside the

enclosure-voltage that may be su cient to constitute a

risk ofshock.

This symbol, wherever it appears,

alertsyou to important operating and

maintenance instructions in the

accompanying literature. Please read the manual.

Caution

To reduce the risk of electric shock, donot

remove the top cover (or the rear section).

No user serviceable parts inside. Refer servicing to

quali ed personnel.

Caution

To reduce the risk of re or electric shock,

do not expose this appliance to rain and

moisture. The apparatus shall not be exposed to dripping

or splashing liquids and no objects lled with liquids,

suchas vases, shall be placed on the apparatus.

Caution

These service instructions are for use

by quali ed ser vice personnel only.

Toreduce the risk of electric shock do not perform any

servicing other than that contained in the operation

instructions. Repairs have to be performed by quali ed

servicepersonnel.

or grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. Ifthe

provided plug does not t into your outlet, consult an

electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11. Use only attachments/accessories speci ed by

themanufacturer.

12. Use only with the

cart, stand, tripod, bracket,

or table speci ed by the

manufacturer, orsold with

the apparatus. When a cart

is used, use caution when

moving the cart/apparatus

combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or

when unused for long periods of time.

14. Refer all servicing to quali ed service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed

to rain or moisture, does not operate normally, or has

beendropped.

15. The apparatus shall be connected to a MAINS socket

outlet with a protective earthing connection.

16. Where the MAINS plug or an appliance coupler is

used as the disconnect device, the disconnect device shall

remain readily operable.

UNDERTAKING OR REPRESENTATION. THIS MANUAL

IS COPYRIGHTED. NO PART OF THIS MANUAL MAY

BE REPRODUCED OR TRANSMITTED IN ANY FORM

OR BY ANY MEANS, ELECTRONIC OR MECHANICAL,

INCLUDING PHOTOCOPYING AND RECORDING OF ANY

KIND, FOR ANY PURPOSE, WITHOUT THE EXPRESS

WRITTEN PERMISSION OF MUSICGROUPIPLTD.

ALL RIGHTS RESERVED.

© 2013 MUSICGroupIPLtd.

Trident Chambers, Wickhams Cay, P.O. Box 146,

Road Town, Tortola, British Virgin Islands

LIMITED WARRANTY

For the applicable warranty terms and conditions

and additional information regarding MUSIC Group’s

Limited Warranty, please see complete details online at

www.music-group.com/warranty.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as

radiators, heat registers, stoves, or other apparatus

(including ampli ers) that produce heat.

LEGAL DISCLAIMER

TECHNICAL SPECIFICATIONS AND APPEARANCES

ARE SUBJECT TO CHANGE WITHOUT NOTICE AND

ACCURACY IS NOT GUARANTEED. BEHRINGER,

KLARKTEKNIK, MIDAS, BUGERA, AND TURBOSOUND

ARE PART OF THE MUSIC GROUP MUSICGROUP.COM.

ALL TRADEMARKS ARE THE PROPERTY OF THEIR

RESPECTIVE OWNERS. MUSICGROUP ACCEPTS NO

LIABILITY FOR ANY LOSS WHICH MAY BE SUFFERED

BY ANY PERSON WHO RELIES EITHER WHOLLY OR

IN PART UPON ANY DESCRIPTION, PHOTOGRAPH

OR STATEMENT CONTAINED HEREIN. COLORS AND

SPECIFICATIONS MAY VARY FROM ACTUAL PRODUCT.

MUSIC GROUP PRODUCTS ARE SOLD THROUGH

AUTHORIZED FULLFILLERS AND RESELLERS ONLY.

FULLFILLERSAND RESELLERS ARE NOT AGENTS OF

MUSICGROUP AND HAVE ABSOLUTELY NO AUTHORITY

4 FEEDBACK DESTROYER FBQ1000 User Manual

1. Introduction

1.1 The design concept

The philosophy behind BEHRINGER products guarantees a no-compromise

circuit design and employs the best choice of components. A 24-bit DSP is

used as the heart of the FEEDBACK DESTROYER, which belongs to the best

components available owing to its outstanding specications and excellent sonic

characteristics. What is more, high-quality 24-bit A/D and D/A converters ensure

the accurate processing of all signals. Additionally, the FEEDBACK DESTROYER

uses high-quality resistors and capacitors with very tight tolerances, high-grade

switches, and further selected components.

The FEEDBACK DESTROYER employs SMD technology (Surface Mounted Device).

These subminiature components known from aerospace technology allow for

an extreme packing density and improve the unit’s reliability even further.

Additionally, the FBQ1000 was manufactured in compliance with an ISO9000

certied management system.

1.2 Before you begin

Your FEEDBACK DESTROYER was carefully packed in the factory and

the packaging was designed to protect the unit from rough handling.

Nevertheless,werecommend that you carefully examine the packaging and its

contents for any signs of physical damage, which may have occurred in transit.

◊ If the unit is damaged, please do not return it to us, but notify your

dealer and the shipping company immediately, otherwise claims for

damage or replacement may not be granted. Shipping claims must be

made by the consignee.

The BEHRINGER FEEDBACK DESTROYER requires one standard 19" unit of

rack space. Please allow at least an additional 4" depth for the connectors on the

backpanel.

Be sure that there is enough space around the unit for cooling and please do not

place the FEEDBACK DESTROYER on high-temperature devices such as power

ampliers, etc. to avoid overheating.

◊ Before you connect your FEEDBACK DESTROYER to the mains,

please make sure that your local voltage matches the voltage required

by the unit:

The fuse holder on the female mains connector has 3 triangular markings, with

two of these triangles opposing each other. The FEEDBACK DESTROYER is set to the

operating voltage printed next to these markers and can be set to another voltage

by turning the fuse holder by 180°. CAUTION: This instruction does not apply to

export models exclusively designed, e.g. for 115-V operation!

Please use the enclosed power cord to connect the unit to the mains. The cord

complies with all applicable safety standards.

◊ Please note that all units must be grounded properly. For your own

safety, you should never remove any ground connectors from electrical

devices or power cords or render them inoperative.

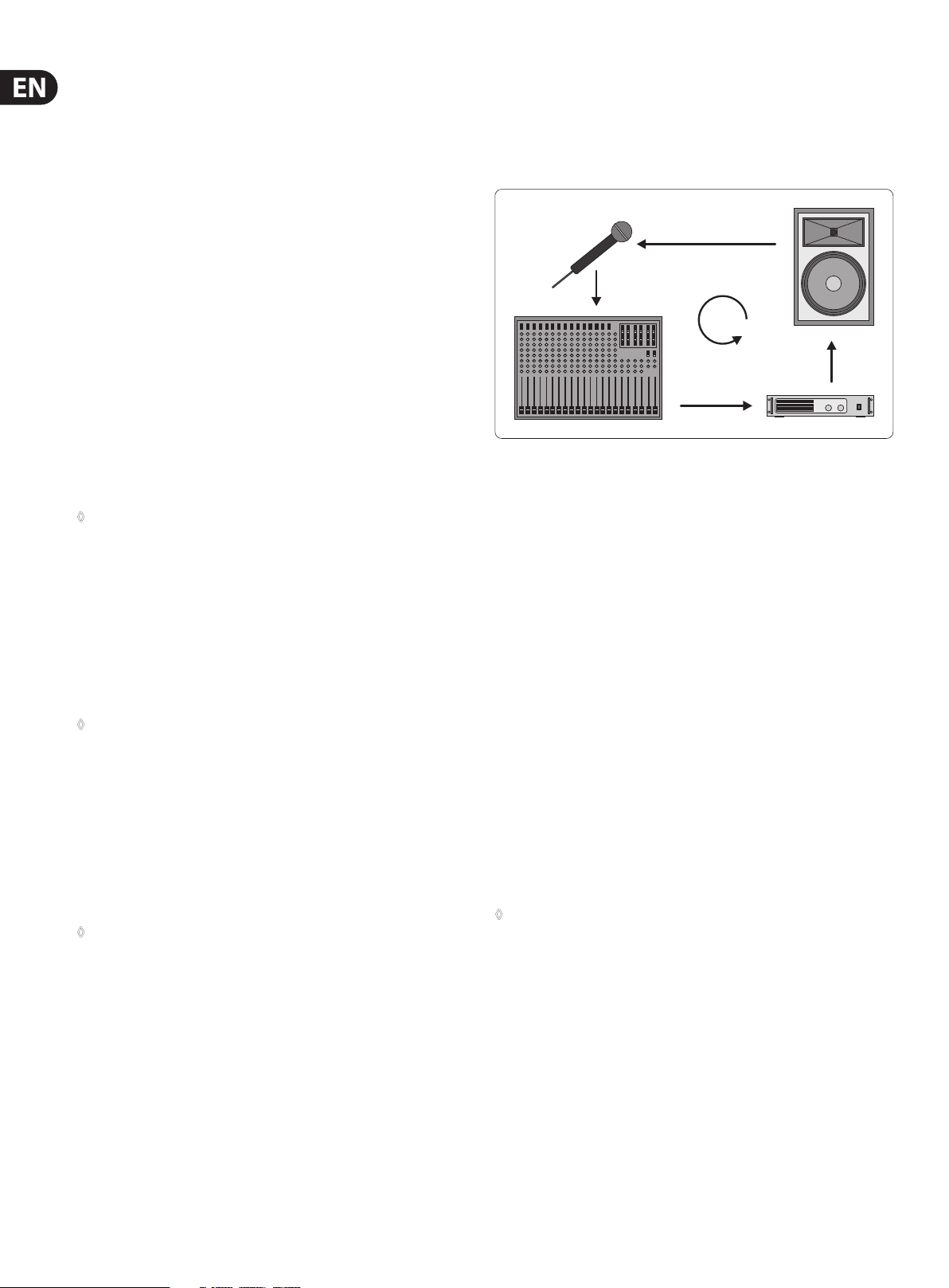

1.3 Background: How is feedback produced?

A feedback loop is produced when a microphone signal is reproduced by an

amplication system and is subsequently picked up again (with identical phase)

by the microphone. If this happens repeatedly, such a feedback loop can become

ever more persistent.

Fig. 1.1: How a feedback loo p is produced

1.3.1 Background: front of house mix (FOH)

There are two main sec tions in any sound reinforcement system, which are liable

to produce feedback: the rst section is the so-called front of house mix (FOH),

i.e. the “public address” mix, which is reproduced by one or several ampliers

plus several loudspeakers directed at the audience.

1.3.2 Background: monitor mix

The monitor mix, which is often derived from the same console, feeds one or

several stage-mount monitor speakers. Unlike FOH systems, stage monitors

are used to provide the individual musicians with a monitor signal, because it

is often dicult to hear oneself or each other on the stage, which can be due

to the high volume levels produced by the FOH systems, or to dierent volume

levels of the stage-mount instruments and ampliers. It is therefore not unusual

to give each musician his or her own monitor speaker, which is why there are

usually several monitor speakers placed along the stage. This is the only way to

provide each musician with a directed and focused monitor signal. In an ideal

situation, eachmonitor provides a specic mix, comprising e.g. vocals, drums and

keyboards, foreach individual musician on the stage.

Unfortunately, it is anything but easy to nd perfect positions for the various

stage monitors, because the distance between speaker and microphone must be

kept very short, which in turn increases the risk of feedback.

◊ In contrast to FOH systems, it is common practice to create two or even

more dedicated monitor mixes, which also involves the use of several

monitor speakers. Again, this can lead to increased feedback.

As a standard, the BEHRINGER FEEDBACK DESTROYER is equipped with

electronically servo-balanced inputs and outputs. The circuit design features

automatic hum and noise reduction for balanced signals and thus allows for

trouble-free operation, even at high operating levels. Externally induced mains

hum, etc. will be eectively suppressed. The automatic servo-function recognizes

the presence of unbalanced connectors and adjusts the nominal level internally

to avoid level dierences between the input and output signals (6-dB correction).

The MIDI interfaces IN, OUT, and THRU are on standardized DIN connectors.

Dataare transmitted via potential-free opto couplers.

5 FEEDBACK DESTROYER FBQ1000 User Manual

2. Applications

The FBQ1000 is used exclusively to eliminate feedback in FOH and

monitormixes.

Before you go on, please note the following two remarks:

◊ The FEEDBACK DESTROYER is not intended to be connected directly

to the microphones! If this is unavoidable, then we recommend our

proven BEHRINGER SHARK FBQ100 instead, which is equipped with a

dedicated microphone preamplifier.

◊ No processing device can undo the mistakes made when placing the

microphones! So, when you set up your mics, use them according to

their directivity and feedback susceptibility (see chapter 8 “Problems

Do Have A Cause ...”).

2.1 Level setting

Take care to set levels properly on the FBQ1000, so as to successfully employ

the FEEDBACK DESTROYER to remove feedback. Use the LED LEVEL METER (1).

Makesure that the top Clip LEDs icker only rarely, but never light up all the time.

Low levels deteriorate the dynamics of the music signal, which results in a

poor, weak and noisy sound. On the other hand, excess levels overdriving the

converters in the FEEDBACK DESTROYER should also be avoided. Digitaldistortion

is (unlike its analog counterpart) very unpleasant to hear as it does not occur

gradually but abruptly.

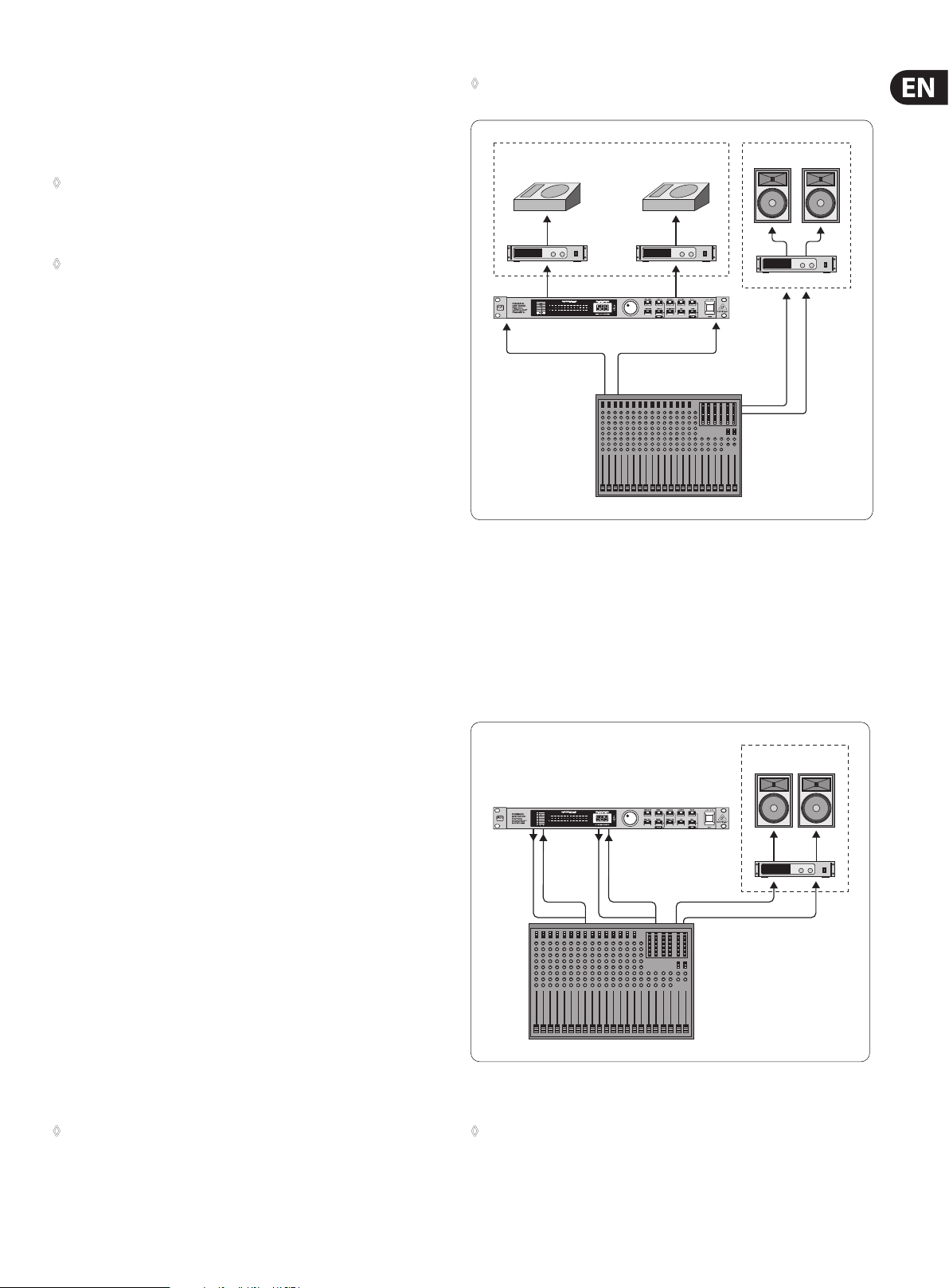

2.2 Using the FEEDBACK DESTROYER in the

monitor path

Your FBQ1000 is equipped with two channels. In Couple mode (see control

elements (8) and (9) ), these two channels are linked. But you can also

use them separately, for example, to protect two dedicated monitor paths

againstfeedback.

Monitor mixes are realized either via the pre-fader Aux Sends on an FOH console,

or via a (usually stage-mount) monitor mixer. When using an additional monitor

mixer on the stage, you need a so-called splitter to route the single microphone

signals both to the FOH console and to the monitor mixer. When using the FOH

console for the monitor mix, the stage microphones are connected directly to the

console (if necessary, via a so-called stage box).

◊ If possible, all monitor paths should be set pre-fader, as this leaves the

monitor mix unaf fected from any changes made to the FOH mix.

Monitor System

Monitor 1

Power Amp

Output 1

Input 1

Pre-Fader

Aux Send 1

Fig. 2.1: Using the FBQ1000 in th e monitor sends

Monitor 2

(Mono)

Output 2

Input 2

Pre-Fader

Aux Send 2

P.A. System

Master

Out

2.3 Using the FEEDBACK DESTROYER

in the FOH mix

Since you want to make sure that deliberately produced feedback signals, such as

“guitar feedback”, are not eliminated, you should tr y inserting the FBQ1000 into

those channels that are susceptible to feedback. For example, you could process

a vocal microphone that is liable to produce feedback by connecting the FBQ1000

to the insert points of the respective channel.

P.A. System

In both cases, separate monitor mixes are created for the musicians, which can

then be provided from the console outputs (usually via the Aux Send outputs).

Owing to its 2-channel design, your FEEDBACK DESTROYER allows you to protect

two monitor paths against feedback. To do so, connect the pre-fader Aux Send

outputs on your console to the inputs of the FBQ1000 (as shown in g.2.1).

Then,connect the inputs of the monitor power amps to the outputs of the

FEEDBACK DESTROYER (see g. 2.1).

As already mentioned, monitor paths are particularly susceptible to feedback.

When vocal microphones are not installed in a xed position, things become even

worse, so it really makes sense to protect the monitor paths against feedback.

Another positive side eect of using the FBQ1000 in the monitor path is the fact

that you can raise the volume levels considerably.

As you can see, your FBQ1000 is a perfect tool to protect two independent

monitor paths. But why is that so important? Because “monitoring” is a complex

task. Usually, each monitor path is used for an independent mix comprising a

variety of signal sources. This is the only way to ensure that each performer on

the stage can hear exactly what he or she wants.

◊ Owing to its 2-channel design, the FBQ1000 is the perfect tool for

application in two separate monitor paths. However, if you need to

protect four monitors against feedback, we recommend that you use a

second FBQ1000.

Outp. 1 Inp. 1

Outp. 2

Channel

Insert

Fig. 2.2: Using the FBQ1000 for specic mics (connecting the FEEDBACK DESTROYER in either channel

or sub-group inserts)

Inp. 2

Channel

Insert

Master Out

◊ When processing a microphone signal with the FBQ1000 and a

compressor inserted into the same channel insert point, the FEEDBACK

DESTROYER should always be used pre-compressor: in this way,

the signal is taken at the insert jack, passes the FBQ1000, then the

compressor, and is finally routed back to the insert jack.

6 FEEDBACK DESTROYER FBQ1000 User Manual

Ideally, your mixer has sub-groups with dedicated insert points to connect

the FBQ1000! Route all channels that are susceptible to feedback (e.g. all vocal

mics) to one sub-group. While the other signals (e.g. line level signals, low-level

instrumental mics) pass unaected, all critical microphone channels are

monitored by the FBQ1000.

If your mixer has no sub-group inserts, we recommend that you connect the

FBQ1000 as follows: connect the sub-group output to one input on the FBQ1000,

and the corresponding output to a free line input of a mixing console channel

or one of the Aux Return inputs on the console. As long as ENGINE L and ENGINE

R are not linked, you would even have the second channel of your FEEDBACK

DESTROYER free for other applications (e.g. channel inserts).

2.4 Using the FEEDBACK DESTROYER

in a studio environment

With its highly exible conguration the FBQ1000 also delivers good results in a

professional studio or home recording environment, as it provides a maximum of

12 fully parametric equalizers per channel in Parametric EQ mode. Thus, you can

realize any application ranging from slight processing to the total manipulation

of music signals. For example, you can use the FBQ1000 as an equalizer for your

studio monitors or to enhance the EQs in your mixing console, as these are often

only semi-parametric.

3. A Few Quick Steps to

EliminateFeedback

Irrespective of whether you need the FBQ1000 to protect the FOH or the monitor

mix against feedback, the following procedure is always the same and should be

done before the concer t, so as to eliminate basic feedback problems right before

the show begins:

• Check the setting of the OPERATING LEVEL switch on the rear of the unit.

For most P.A. systems, this switch should be set to +4 dB. In doubt,

pleaseconsult the user’s manual of your mixing console. Always make sure

that the audio signal levels are set correctly (see control element (1))

• Switch on the unit, and use the JOG WHEEL (rotary control) to select preset1.

The preset table (see table 11.3) lists the various FBQ1000 presets available

• Using the FBQ1000 in the monitor path: Turn up the Aux Send or Mon.

controls in the rst mic channel, until the microphone starts to produce

feedback. If more than one monitor paths is being used, this procedure must

be done separately for each path. Repeat for each susceptible mic channel

• Using the FBQ1000 on channel/sub-group inserts: Deliberately induce

feedback by setting the channel/sub-group faders to 0 dB and raising the

gain controls for the individual microphones in turn

In either case, the FEEDBACK DESTROYER will suppress feedback as soon as it is

produced—the corresponding LED will stop ashing and stay lit. The various edit

options available are described in chapter 7. But don’t let us do the second step

before the rst:

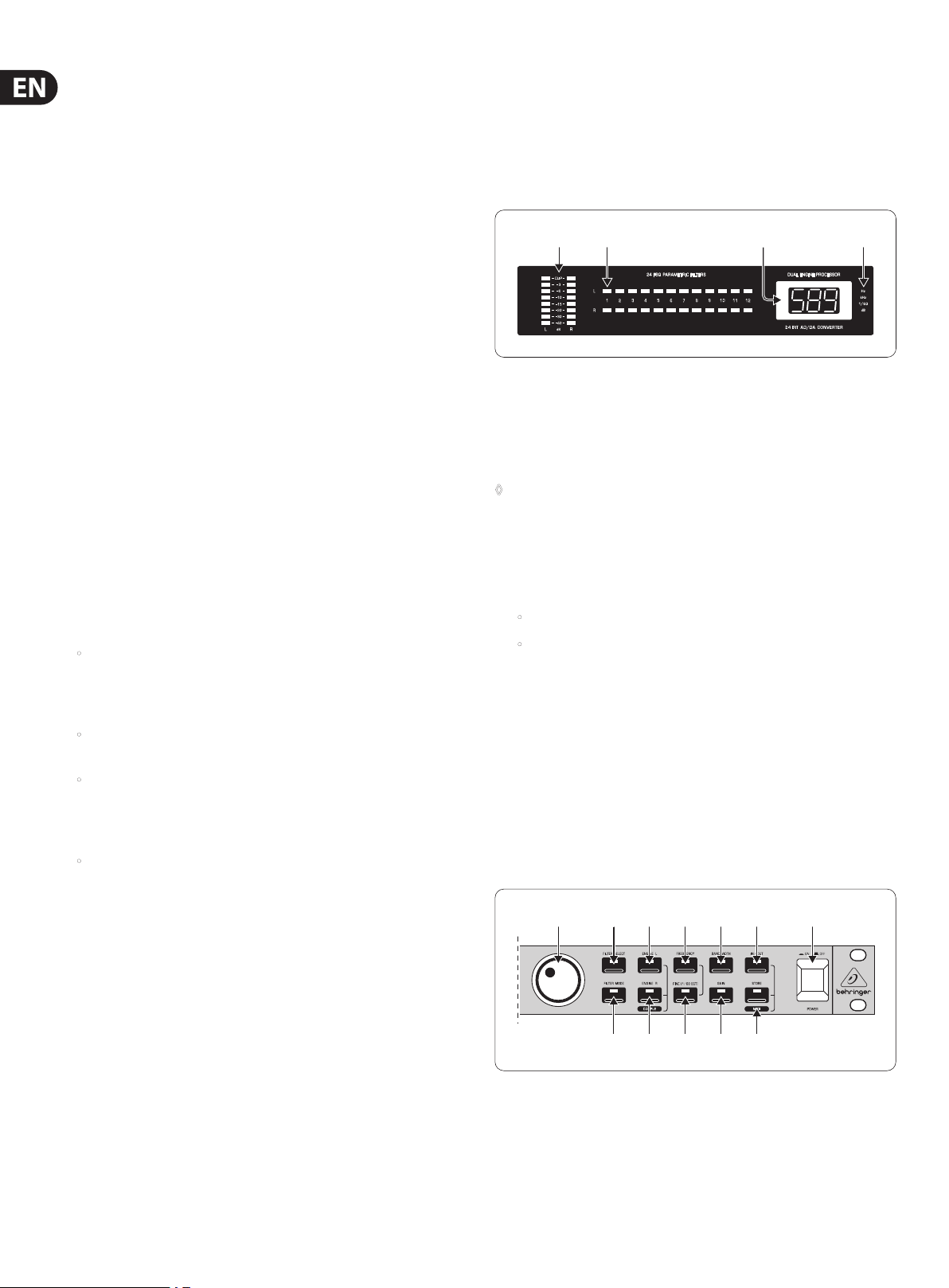

4. Control Elements

The BEHRINGER FEEDBACK DESTROYER is equipped with ten parameter keys,

one JOG WHEEL (rotary control) and a numeric LED DISPLAY. By means of an

8-segment LED meter, each of the two fully independent channels can be

monitored. Each of the 24 lters has one LED assigned to it, which informs about

the status of the lter.

(1) (2) (4)(3)

Fig. 4.1: Display sect ion of the FEEDBACK DEST ROYER

(1) The LED METER is used to monitor the output level. Each channel has eight

LEDs assigned to it. When the Clip LED lights up frequently, this warns you

of digital distortion. If the FBQ1000 is set to Total Bypass mode (see (14)),

thelevel meter reads the input level.

◊ Please always use appropriate level settings, as this is essential for

successful feedback elimination.

(2) The FBQ1000 features 24 lters, i.e. 12 lters per channel. These lters

can be monitored conveniently with the STATUS INDICATOR next to the

Display. 12LEDs inform you about the status of the lters on each channel

(left/right). Aconstantly lit LED signals the following conditions:

• A lter has been “set”, i.e. it is already suppressing feedback; or

• A lter is set to Parametric EQ mode (gain ≠ 0 dB)

Cyclically ashing LEDs signal that a lter is searching feedback frequencies

in Single-Shot or Auto mode (see chapters 5 and 6.3). Inactive lters (“OF”)

and lters in Parametric EQ mode (see 6.2), with a gain setting of 0 dB,

areindicated by unlit LEDs.

(3) The LED DISPLAY consists of a clearly visible, two-digit numeric

display. After power-up, it reads the number of the last preset used.

Additionally,theLED-DISPLAY shows the absolute values of the parameters

that are beingedited.

(4) The INDICATORS to the right of the DISPLAY (Hz, kHz, 1/60 and dB)

lightup when you edit the associated parameters in Edit mode. For example,

whenyou raise the level of a lter, the “dB” indicator lights up.

(5) (6)

(8) (10) (12) (14) (16)

(7) (9) (11) (13) (15)

Fig. 4.2: Func tion keys and Jog Wh eel

Loading...

Loading...