Baumer AFI4 User Manual [en, de, fr]

www.baumer.com

Operators Instruction: 11126179 00 Page 1 / 36

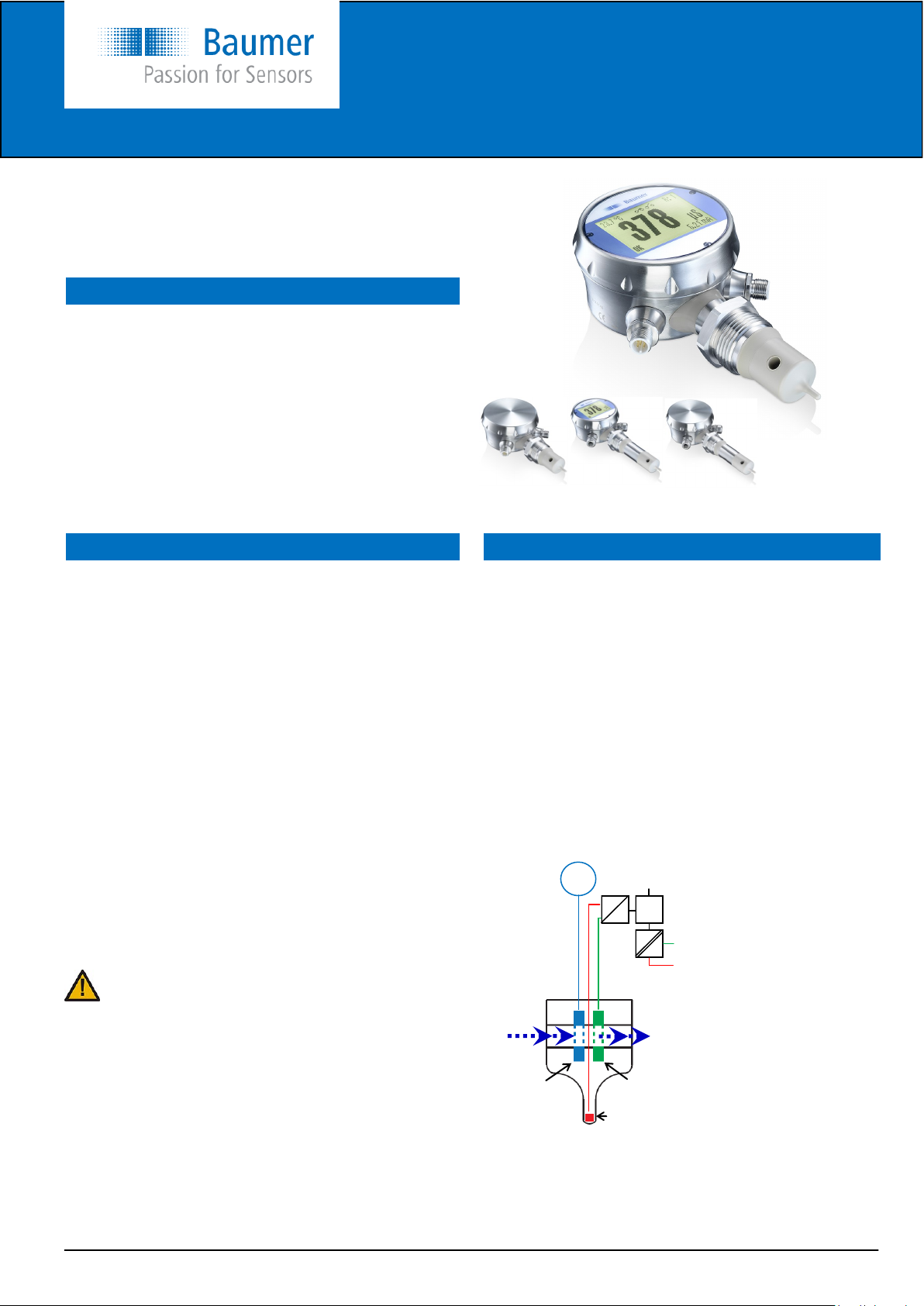

CombiLyz, AFI4

Operators Instruction

EN/2014-04-29 Design and specifications subject to change without notice

CombiLyz AFI4 conductivity transmitter is a compact sensor/transmitter,

based on inductive technology, which is designed and produced to meet

the requirements in hygienic and general industry where measuring of

medium range conductivity is used.

Description

Safety instruction

This instrument is built and tested according to the current EU-directives

and packed under technically safe conditions. In order to maintain these

conditions and to ensure safe operation, the user must follow the hints

and warnings given in this instruction.

During the installation the valid national rules have to be observed. Ig-

noring the warnings may lead to severe personal injury or substantial

damage of property.

The product must be operated by trained staff. Correct and safe opera-

tion of this equipment is dependent on proper transport, storage installa-

tion and operation.

All electrical wirings must conform to local standards. In order to prevent

stray electrical radiation, we recommend twisted and shielded input

cables and also to keep power supply cables separated from the input

cables. The connection must be made according to the connection dia-

grams.

Before switching on the power supply take care that other equipment is

not affected. Ensure that the power voltage, the conditions are the envi-

ronment comply with the specification of the device.

Before switching off the power supply voltage, check the possible effects

on other equipment and the processing system.

WARNING

The device is not approved for electrical installations in explosion proof

areas.

After mounting of the device - do check that the housing has a ground

potential.

The product contains no direct replaceable parts, except for the DFON

display. In case of malfunction the product must be sent to Baumer for

repair.

CombiLyz AFI4 consists of a conductivity sensor and a transmitter built

into one compact unit.

The output from the transmitter are two 4...20 mA, which is available for

both conductivity, concentration and temperature.

The display features more user selectable modes and user specified

“product labels” and warnings. Further there are two switch outputs for

alarms or control.

The background colour can be set in three colours, white, green or red

- steady or flashing, controlled by the alarm settings. The transmitter and

display can be programmed by either the touch screen on the display or

by the FlexProgrammer programming unit and software.

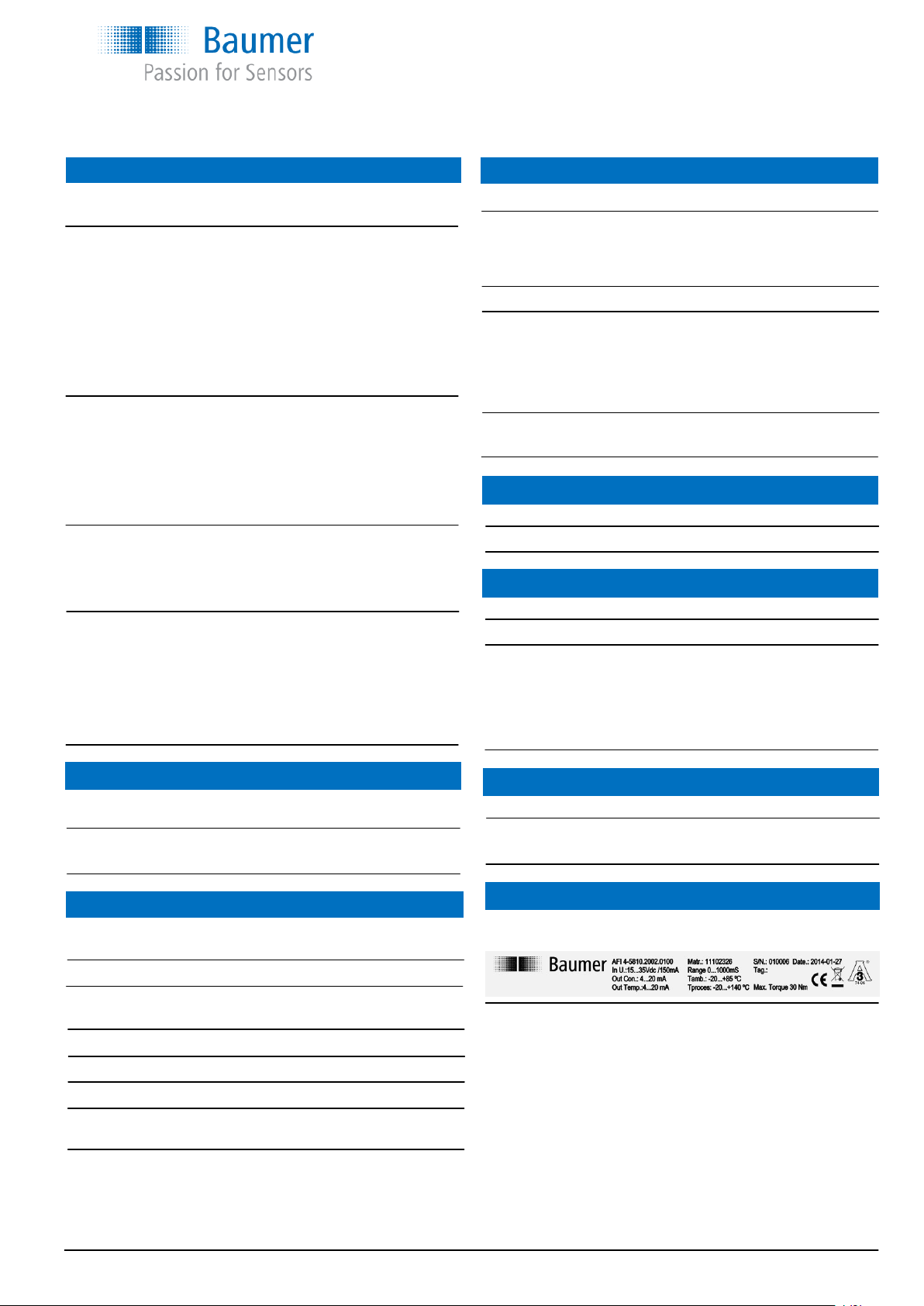

The measuring cell is a homogeneous sealed body all in PEEK.

Through the body is a hole, through which the media is flowing. Built-in

around the hole are two coils; a primary coil supplied with an AC volt-

age and a secondary coil, which picks up a small signal through the

media inducted voltage. The size of this voltage is dependent on the

conductivity of the media. This signal is handled and amplified in the

electronics to a linear analogue 4...20 mA output signal. Also built into

the body is a Pt100 sensor placed in the tip of the sensor. This is meas-

uring the media temperature to enable temperature compensation of

the conductivity signal, which is very temperature dependent. The

Pt100 sensor signal also features an analogue 4...20 mA output signal.

The coils and sensor are encapsulated in the PEEK sensor body, which

have a surface with surface roughness (Ra) <0,8 µm. It is therefore well

suited for use in hygienic processes or direct in concentrated acids or

alkalis.

Media

Primary coil Secondary coil

Pt100

~

CPU

D

A

VAC

Range setting

input R1 and R2

Conductivity/Concentration

4...20 mA output

4...20 mA output

Temperature

A

D

Working principle

English

English page 1...11

Deutsch Seite 12...22

Français page 23...33

www.baumer.com

Operators Instruction: 11126179 00 Page 2 / 36

Operators Instruction

Electrical specifications

Technical specifications

Housing FlexHousing, Ø80 mm

Material Stainless steel, AISI 304

Process connection G1A, rotating

(for other connections see adapters page 4)

Insertion length Standard 37 mm / 3A version 40,5 mm

Long version 83 mm / 3A version 87 mm

Material Not wetted Stainless steel AISI 304

Wetted parts 37… mm PEEK natura

83... mm PEEK narura+AISI 316L

Surface Wetted parts Ra <0,8 µm

Measuring range Conductivity 0...500 µS/cm … 0…1.0 S/cm

14 selectable ranges

Concentration 4 factory set medias/ranges

1 customer defined media/range

Temperature -30...150°C

Free programmable range

Accuracy Cond./conc. 0...500 µS/cm ≤1,5%

(sensor incl. transmitter) 0...1 / 0...500 mS/cm ≤1,0%

0...1 S/cm ≤1,5%

Temperature ≤0,4% selected range

Temperature compensation 0,0...5,0%/°C, free adjustable

Compensation range -20...150°C

Reference temperature 25°C (adjustable)

Response time Cond./conc. <2,0 seconds

Temperature, t

90

<15 seconds

Start up time without display ≤10 seconds

Start up time with display ≤15 seconds

General specifications

Media temperature -20...140°C

150°C up to 1 hour

Media pressure <10 bar (helium tested)

Ambient temperature Without display -40...85°C

With display -30...80°C

Isolation voltage 500 VAC

Protection class IEC 529 IP 67 / IP 69K

Humidity IEC 68.2.38 98% condensing

Vibrations IEC 60068.2.6 - test Fc

1,0 mm

(2-13,2 Hz)

0,7g

(13,2-100 Hz)

Power supply 15...35 VDC

Output Cond./Conc. 4...20 mA

4...20 mA + HART

®

(pending)

Temperature 4...20 mA

Relay 2 relays included in the display

Temperature drift ≤0,1%/°C

El. connection Left side M12, 5-pin

M16 or M20 cable gland

Right side M12, 5-pin

(4...20 mA output only)

M12, 8-pin

(4...20 mA + relay output)

M16 or M20 cable gland

Material Plastic

Stainless steel

Apply to EU directives 10/2011, 1935/2004, 2023/2006

FDA PEEK: CFR 21.177.2415

Approvals 3A approval 74-06

EHEDG (pending)

Compliance and approvals

Product marking

The marking on the product is made by laser engraving.

Below see example:

Contacts 2 × solid state relays

Voltage 60 V

p

Relay

Display

Type FSTN Graphically LCD

Measuring range -9999...99999

Digit height Max. 22 mm

Temperature drift ≤0,0001%/°C inside optimal range

-10...70°C

≤0,00015%/C outside optimal range

-30…-10 / 70...80°C

Mechanical data

Material Polycarbonate plastic

Protection class IP 10 on terminals

IP67/IP69K in FlexHousing

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 3 / 36

Operators Instruction

Set-up the AFI4

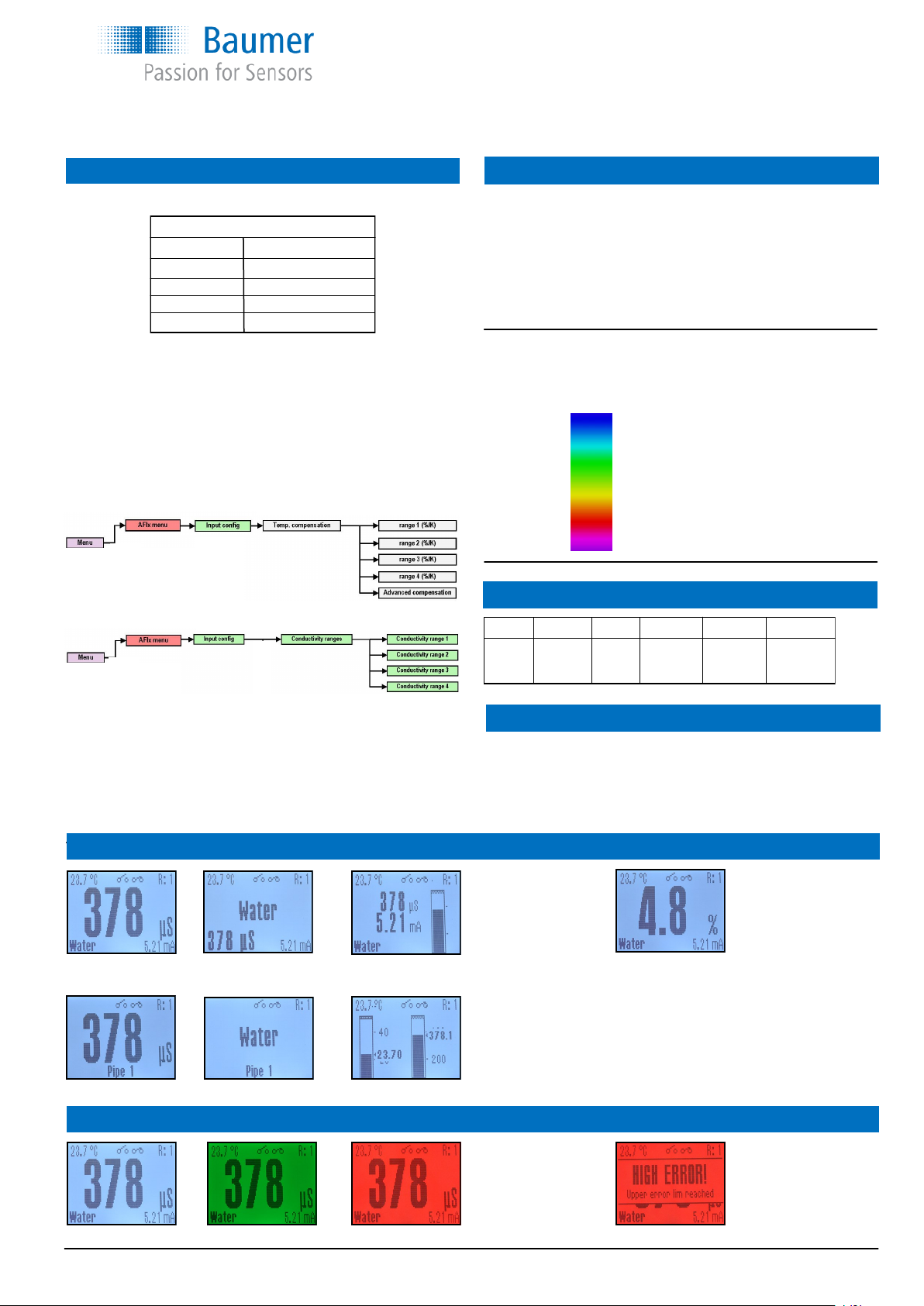

Typical temperature dependence

Media % change per °C

Acids 1,0 … 1,6

Bases 1,8 … 2,2

Salts 2,2 … 3,0

Neutral water 2,0

AFIx

range

Conductivity in different media:

Conductivity Media group Media

55 nS/cm Water Ultra-pure water

1 µS/cm Pure water

10 µS/cm Process water

100 µS/cm Food Drinking water

Beer

1 mS/cm Milk

Orange juice

10 mS/cm Apple juice

100 mS/cm Process Phosphoric acid

Hydrochloric acid

Conductivity ranges (selectable)

0…500 µS/cm

0...1 mS/cm 0...10 mS/cm 0...100 mS/cm 0...1 S/cm

0...2 mS/cm 0...20 mS/cm 0...200 mS/cm

0...3 mS/cm 0...30 mS/cm 0...300 mS/cm

0...5 mS/cm 0...50 mS/cm 0...500 mS/cm

Definition: 1.000 µS/cm = 1.0 mS/cm

1.000 mS/cm = 1.0 S/cm

Concentration ranges (selectable)

Range R1 R2 Range R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

To set the external input for range selection

White background Green background Red background Error message and red background

Selectable display views Conductivity Concentration

Visual alerts and colours

Value w. all values Media w. values Bar graph w. values Concentration value in %

same views available as for conductivity

Value w. TAG Media w. TAG Bar graph incl. temp.

NaOH (caustic soda) 0...15% by weight (0...90°C)

25...50% by weight (0...90°C)

HNO

3

(nitric acid) 0...25% by weight (0...80°C)

36...82% by weight (0...80°C)

1 × customer defined (30 point linearization)

Conductivity measurement is very temperature dependent.

The factory set-up is 2,0%/°C.

This means that the AFIx will automatically compensate with this fac-

tor. If the temperature dependence is known for the media this factor

must be set. However if the factor is unknown, it is recommended to

use an average from above table.

It is possible to adjust the temperature compensation factor from 0,0 …

5,0 %/°C.

Configure the temperature compensation by the touch screen:

Configure the range by the touch screen:

Configuration by the FlexProgram and FlexProgrammer please see

HELP in the FlexProgram.

Concentration output can also be selected by the touch screen or pro-

grammed by the FlexProgram.

Programming of the display colours, warnings and relays can be done

by the touch screen (see page 8 and 9) or by the FlexProgrammer.

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 4 / 36

Operators Instruction

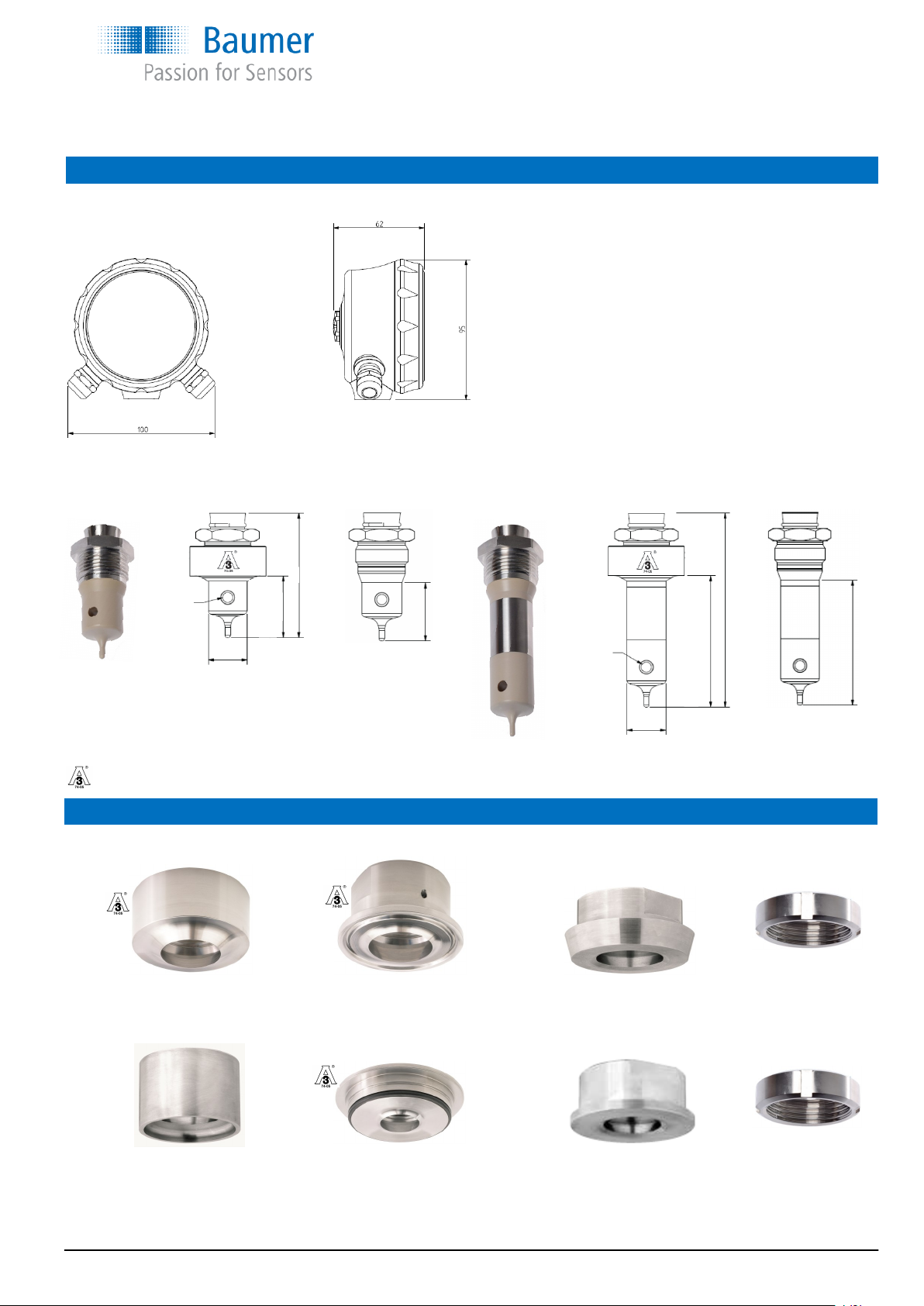

Dimensions

Welding connection Clamp connection Screwed connections Union nut

Short version 3A versions Standard Long version 3A versions Standard

40,5 mm 37 mm 87 mm 83 mm

G1” mounting adapters

DN 40...50 PM052-1 Variline, type N VAM053 SMS 1145 DN 38 SAM-038-1 SNF038

DN 65...150 PM052-2 SMS 1145 DN 51 SAM-051-1 SNF051

More adapters are available, e.g. with standard industrial thread. Please see data sheet for Accessories.

For tank

For tube

PM053 ISO 2852 DN38 CAM050-505 DIN 11851 DN 32 MAM050-032 MNF032

ISO 2852 DN51 CAM050-640 DIN 11851 DN 40 MAM050-040 MNF040

DIN 11851 DN 50 MAM050-050 MNF050

The two above sensors are 3A approved when mounted in one of below 3A approved G1” mounting adapters

Front view Bottom connection

Ø6,6

Ø25,5

87

128

83

37

Ø6,6

Ø25,5

40,5

82

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 5 / 36

Operators Instruction

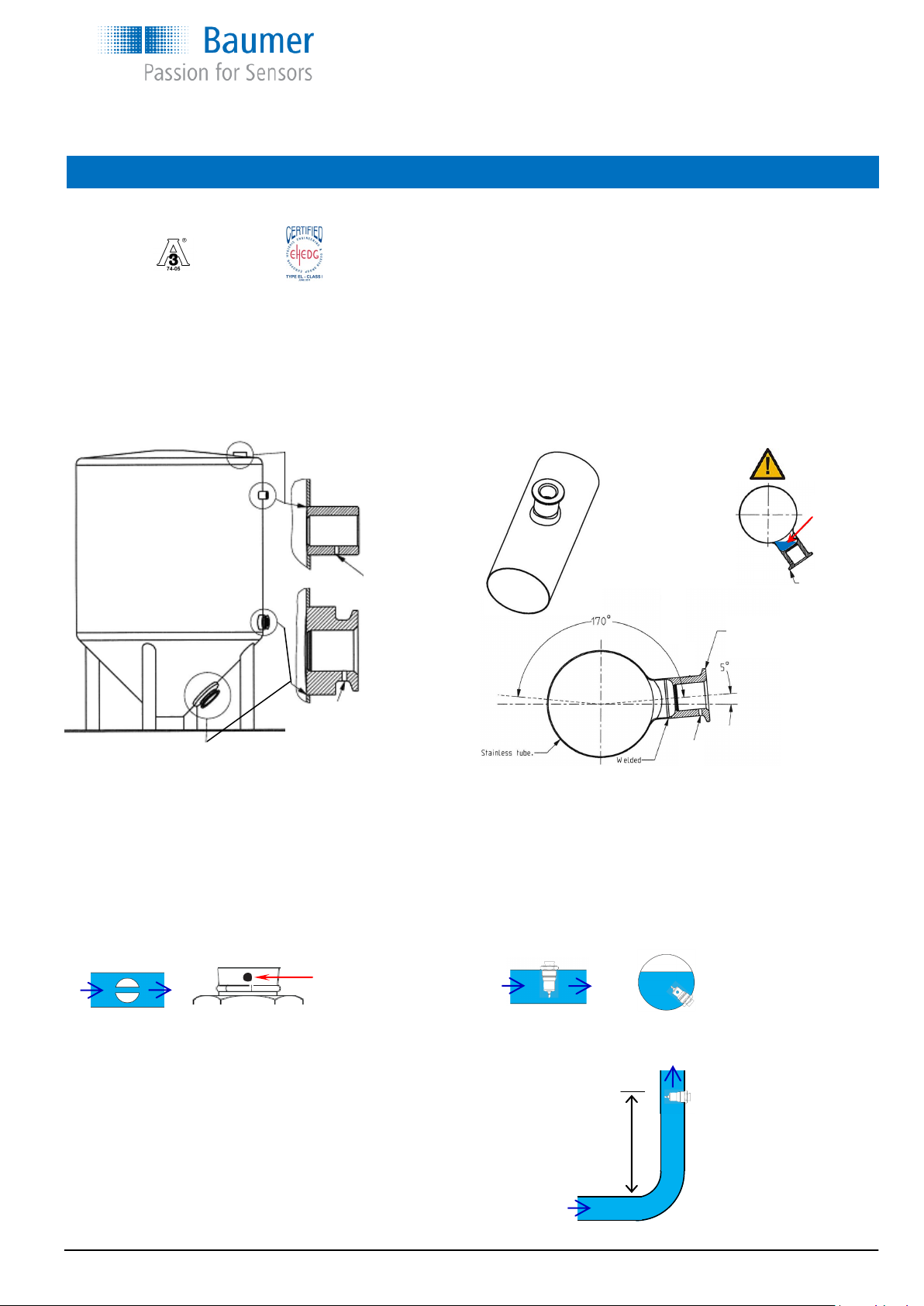

Installation of 3A approved and EHEDG certified products:

1) Use only a 3A approved counter part

2) The inspection hole should be visible and drained

3) Mount the adapter in a self drained position/angle

4) Level the inner surface of the pipe with the counter part.

After installation

Check the leak tightness of the sleeve.

Check the tightness of glands or M12 plugs.

Check the tightness of the cover

Mounting

Example

with PM060-2

Example with

PM023 or PM053

Example

with PM060-1

Leakage indication hole

must be places downwards

Fitted

incorrect

Cannot be

drained

WARNING

5) The 3A mark or the arrow shall be placed upwards

6) Welding should be grinded to Ra= 0.8

7) Tighten the swirling nipple on the AFIx 20...25 Nm

8) Installed with correct torque the electrical connection

will point downwards

≥1 meter

The sensor must be fully submersed in the media.

To avoid turbulence problems the sensor is recommended to mount in

a distance of >1 meter from a bend.

The hole through the sensor must be in the flow direction

The marks on the

connection must

point in flow direction

There must be some bi-directional flow through the hole to ensure a

homogeneous media - i.e. correct measurement. There must be no

air-bubbles in the hole.

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 6 / 36

Operators Instruction

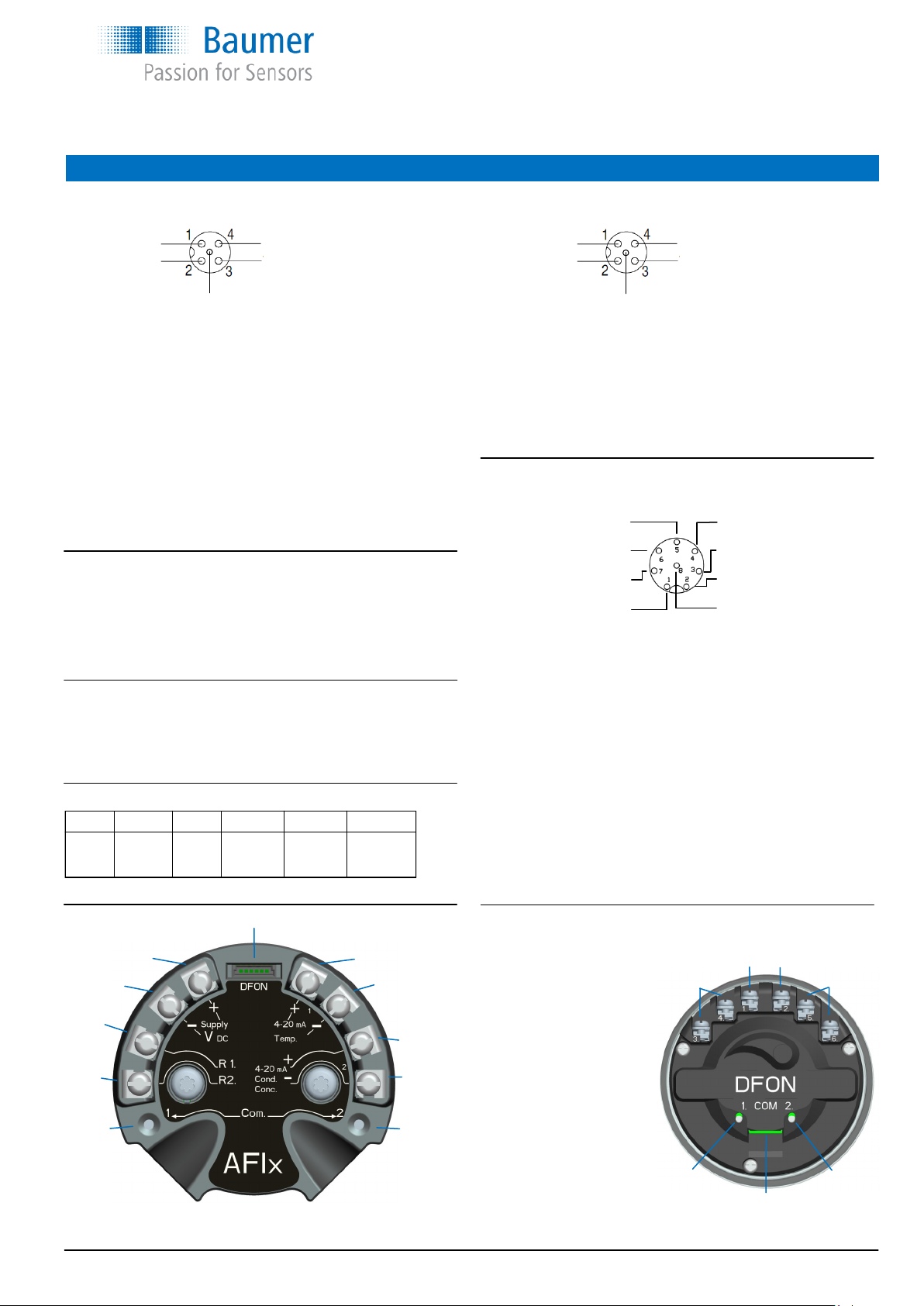

Electrical connection

Left side M12, 5-pin connector

1: Brown Supply (+) (15...35 vdc)

2: White Cond. (-) (4...20 mA)

3: Blue Supply (-) (15...35 vdc)

4: Black Cond. (+) (4...20 mA)

5: NC Not connected

Cond. (+) - 4

15...35 vdc (-) - 3

5 NC

1 - 15...35 vdc (+)

2 - Cond. (-)

Left side electrical connection (Front view) Right side electrical connection (Front view)

°C (+) - 4

R2 - 3

5 NC

1 - R1

2 - °C (-)

Right side M12, 5-pin connector

1: Brown R1 (external input)

2: White Temp. (-) (4...20 mA)

3: Blue R2 (external input)

4: Black Temp. (+) (4...20 mA)

5: NC Not connected

4 - Relay 2

3 - Relay 2

2 - Temp (+) (4...20 mA)

8 - R2 (external input)

Right side M12, 8-pin connector

1: White R1 (external input)

2: Brown Temp. (+) (4...20 mA)

3: Green Relay 2

4: Yellow Relay 2

5: Grey Relay 1

6: Light red Relay 1

7: Blue Temp. (-) (4...20 mA)

8: Red R2 (external input)

Right side electrical connection with relay output

Electrical connection on the display with relay output

1: Not connected

2: Not connected

3: Green Relay 2

4: Yellow Relay 2

5: Grey Relay 1

6: Light red Relay 1

(3 + 5 can be connected

common)

UnitCom Ribbon cable

to transmitter

To connect the

FlexProgrammer

COM 1 Red clip

COM 2 Black clip

DFON (UnitCom)

Supply + Temp. +

Supply - Temp. -

R1

Cond. +

R2 Cond. -

Com 1 Com 2

N.C. N.C.

Relay 2 Relay 1

Com 1 Com 2

UnitCom

Note:

If a M12 5-pin connector for left and right side is selected the

AFI4 is direct compatible with the old Baumer ISL conductivity

transmitter.

To connect the FlexProgrammer to the transmitter

Com 1 Red clip

Com 2 Black clip

The data entered to the transmitter will automatically be uploaded to

the DFON display via the ribbon cable (UnitCom)

To connect the FlexProgrammer to the DFON display

Com 1 Red clip

Com 2 Black clip

For setting the colour changes, error messages, relay set-points etc.

To set the external input for range selection

Relay 1 - 5

Relay 1 - 6

Temp. (-) (4...20 mA) - 7

R1 (external input) - 1

Range R1 R2 Range R1 R2

1 N.C. N.C. 3 N.C. 24 VDC

2 24 VDC N.C. 4 24 VDC 24 VDC

English

CombiLyz, AFI4

Note:

For ranges below 10 mS/cm a shielded cable must be used.

www.baumer.com

Operators Instruction: 11126179 00 Page 7 / 36

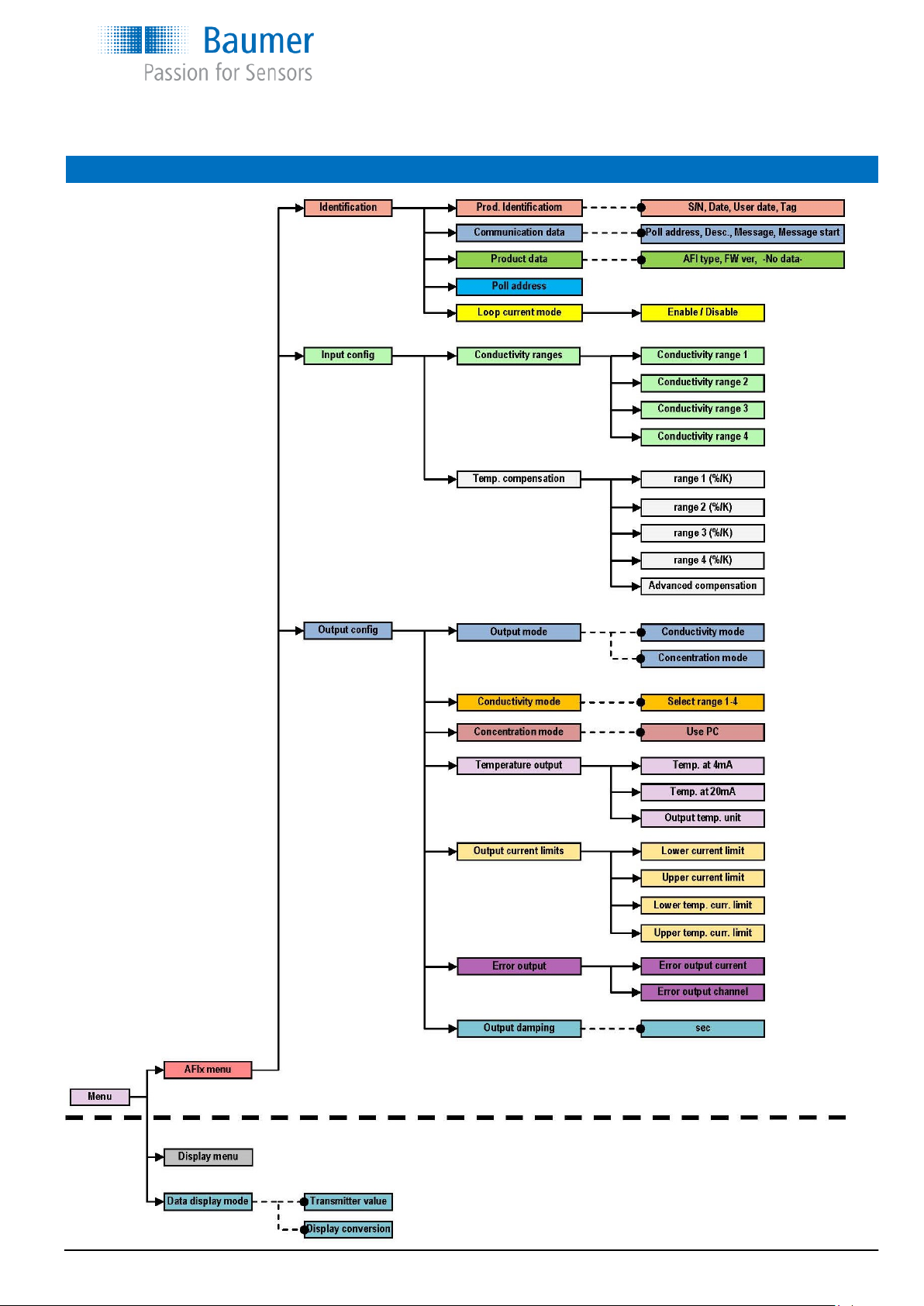

Programming the CombiLyz AFIx with touch screen on DFON display

Operators Instruction

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 8 / 36

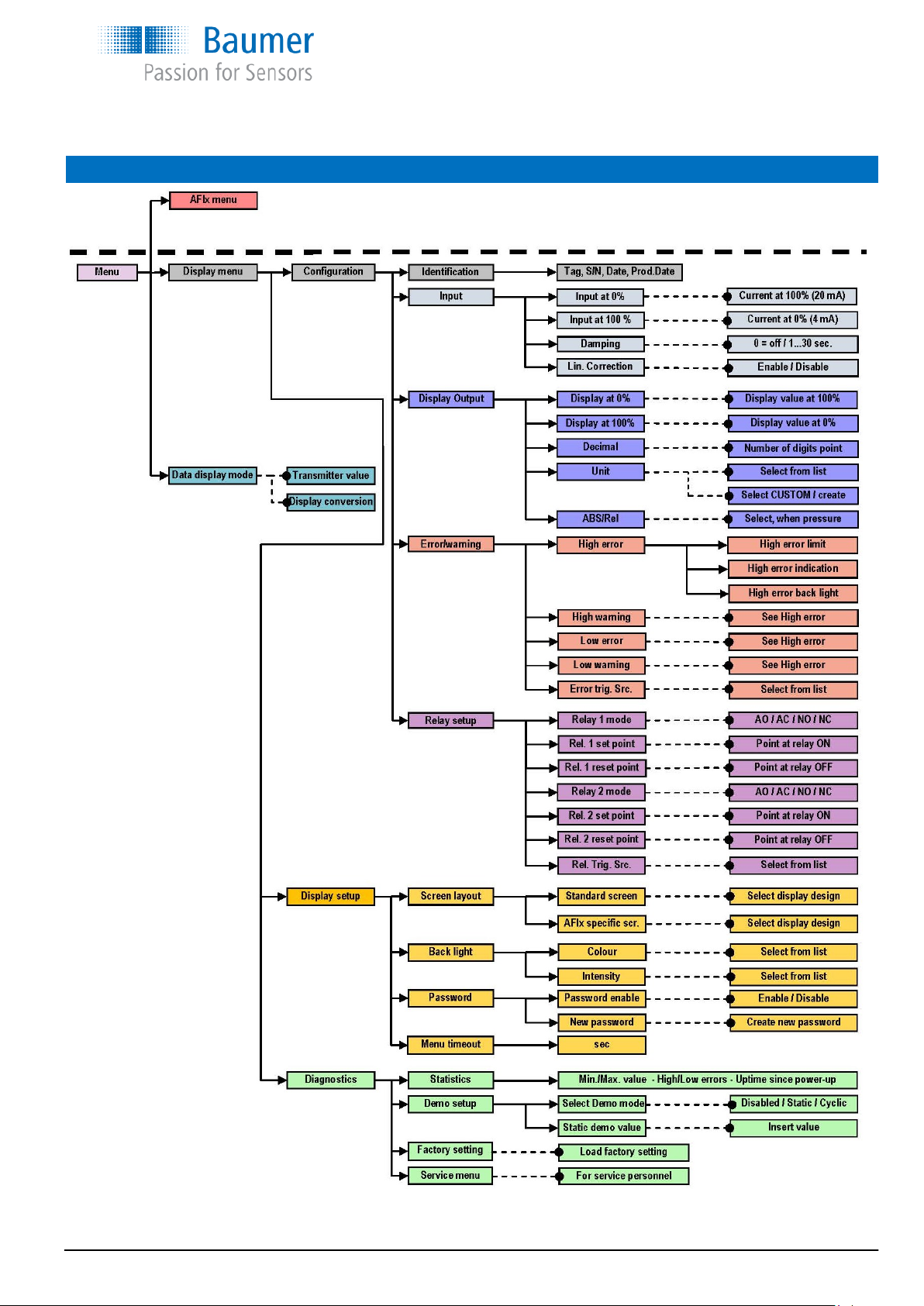

Programming the touch screen on DFON display on CombiLyz AFIx

Operators Instruction

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 9 / 36

Operators Instruction

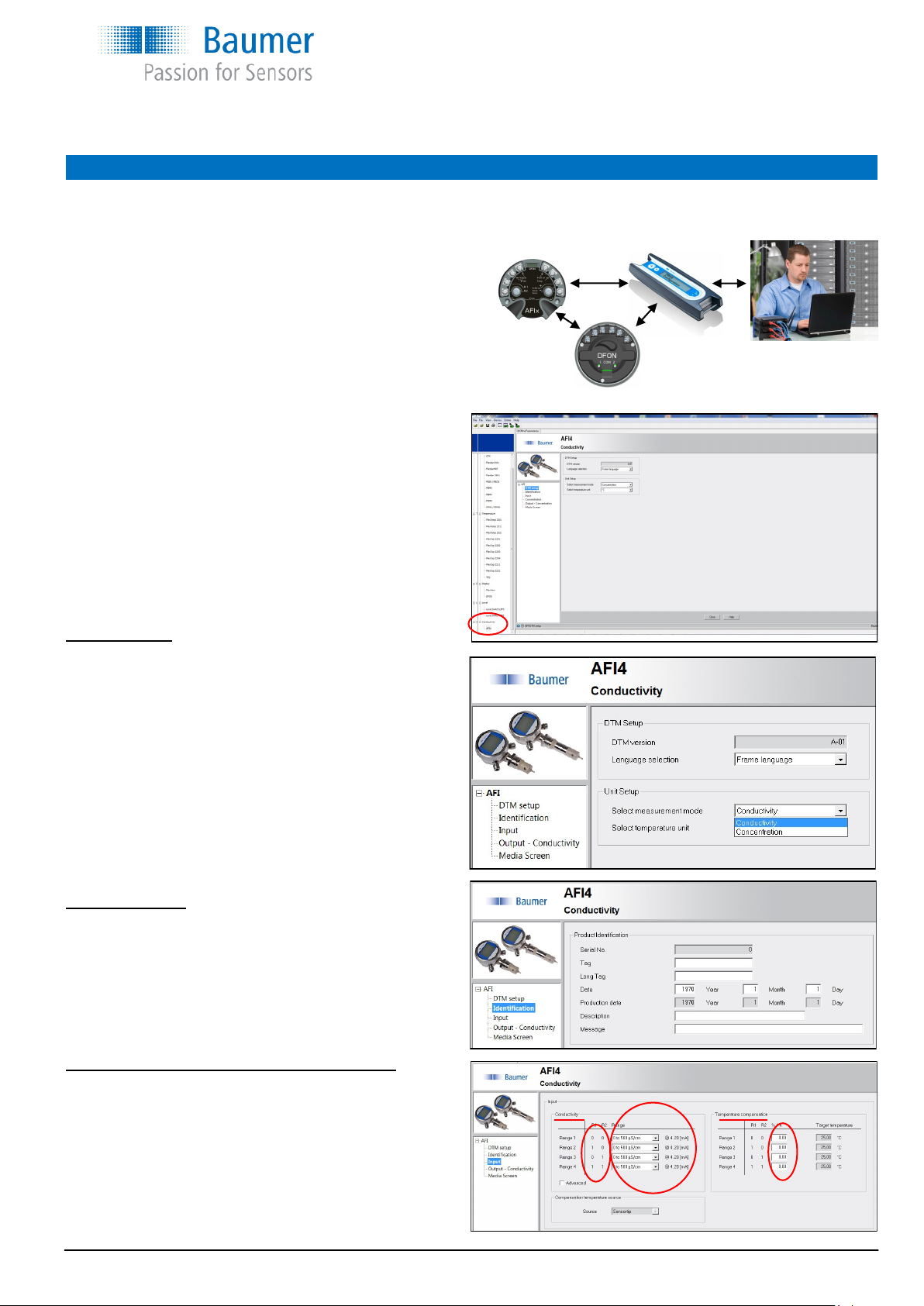

Programming the AFI4 with the FlexProgram

Open the FlexProgram

Select AFIx in the bottom and this screen will appear

Screen DTM setup

It is recommended to select

- “Frame language”

Select measurement mode:

- Conductivity or Concentration

Temperature unit °C or °F can also be selected.

Screen Identification

Enter TAG number Tag: 8 characters

Long tag: 30 characters

Date of 1

st

use (year/month/date)

Description (16 characters)

Message (32 characters)

Screen Input (when conductivity is selected in DTM setup)

Setting for the 4 conductivity ranges. Selectable from drop

down menu with 14 defined ranges.

Factory setting will be

0...200 mS/cm

0… 20 mS/cm

0… 2 mS/cm

0…500 µS/cm

How to connect the external input R1 and R2 is defined

in front of the ranges. (0=Not Connected / 1=24VDC)

All settings can be individually programmed with the Baumer FlexProgram and programming unit FlexProgrammer 9701. All parameters, such as

conductivity range, concentration and output type, diagnostics, data logging, tag no., damping etc. can be configured using the FlexProgrammer

9701.

Integrated HELP-menus will give full instruction.

The programming entered to the AFIx transmitter will automatically

be uploaded to the DFON display through the UnitCom ribbon cable,

if Transmitter Value is selected in the programme or by the touch screen.

If Display Conversion is selected the DFON display can be programmed

individually, e.g. with other engineering units or ranges.

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 10 / 36

Operators Instruction

Programming the AFI4 with the FlexProgram

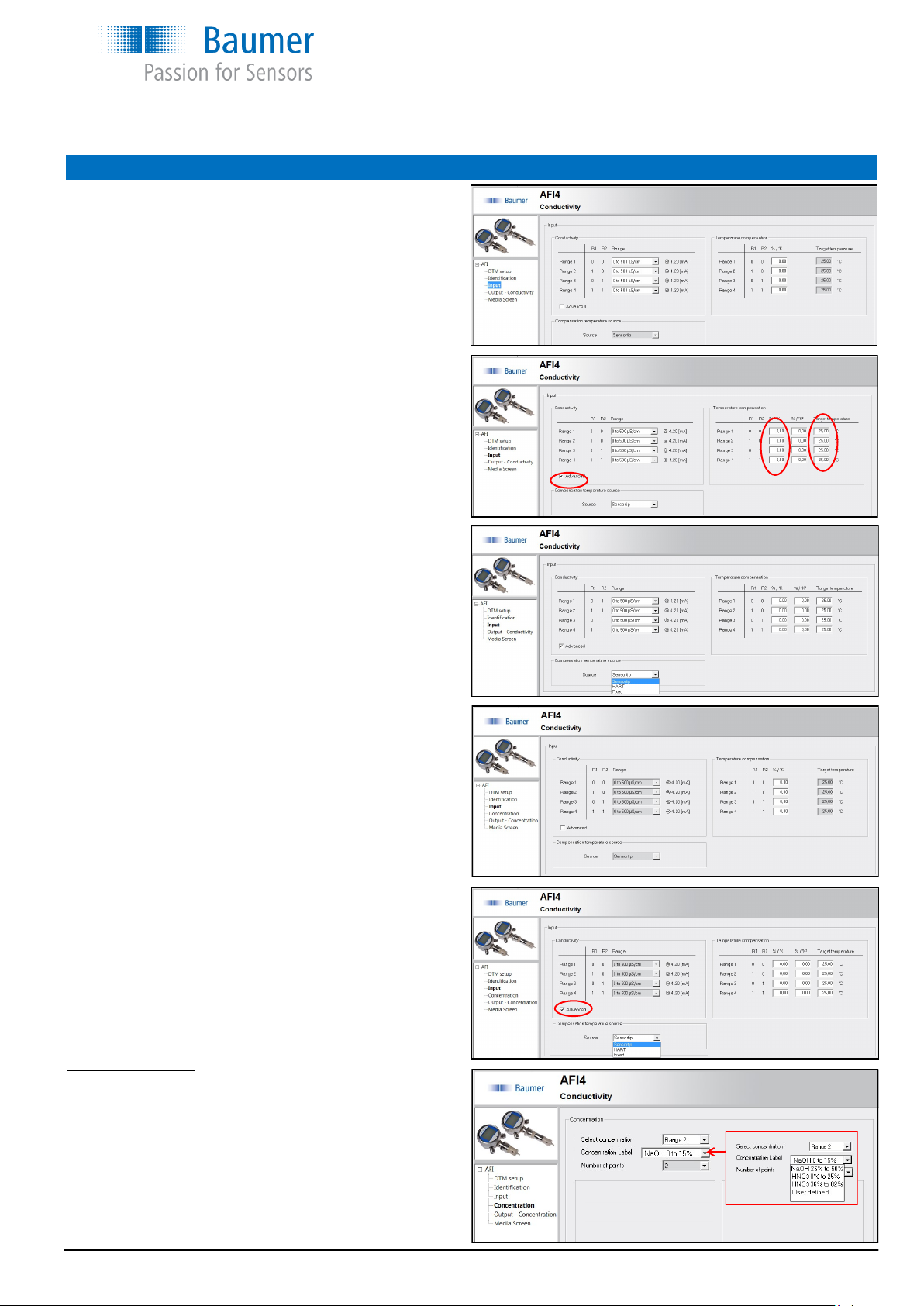

Setting of Temperature compensation for each range.

This will be factory set to 2%/°C as default.

If the box Advanced is ticked, it will be possible to enter an

other target temperature. This is as default set to 25°C, which is the

most common target temperature for most media. If another target

temperature is wanted, it can be entered.

NOTE:

This is not the specific media temperature, but the

“0-point” for the temperature compensation.

When the “Advanced” is ticked the “Compensation temperature

source” is accessible.

You can enter a value to the column %/K

2

you will create a unlinear

curve.

These fields are not necessary to change for standard measurement.

Be careful if changing the default values, as wrong values in those

fields may course wrong measurement.

It is possible to select from where the temperature measuring shall

come from

Sensor tip (built in Pt100)

HART (external input via HART)

Fixed (no temperature measurement)

Screen Input (when concentration is selected in DTM setup)

No settings in this screen will be available as standard.

When user defined concentration is selected in screen concentration,

it will be possible to adjust temperature concentration.

The default setting will be 2%/°C.

Advanced settings

Here only “Compensation temperature source” will be available.

Screen Concentration

There is 4 selectable medias, for which the calibration curves

is default entered from factory.

NaOH (caustic soda) 0...15% by weight

NaOH - 25...50% by weight

HNO

3

(Nitric acid) 0...25% by weight

HNO

3

36...82% by weight

For user defined, please see next page.

English

CombiLyz, AFI4

www.baumer.com

Operators Instruction: 11126179 00 Page 11 / 36

Operators Instruction

Programming the AFI4 with the FlexProgram

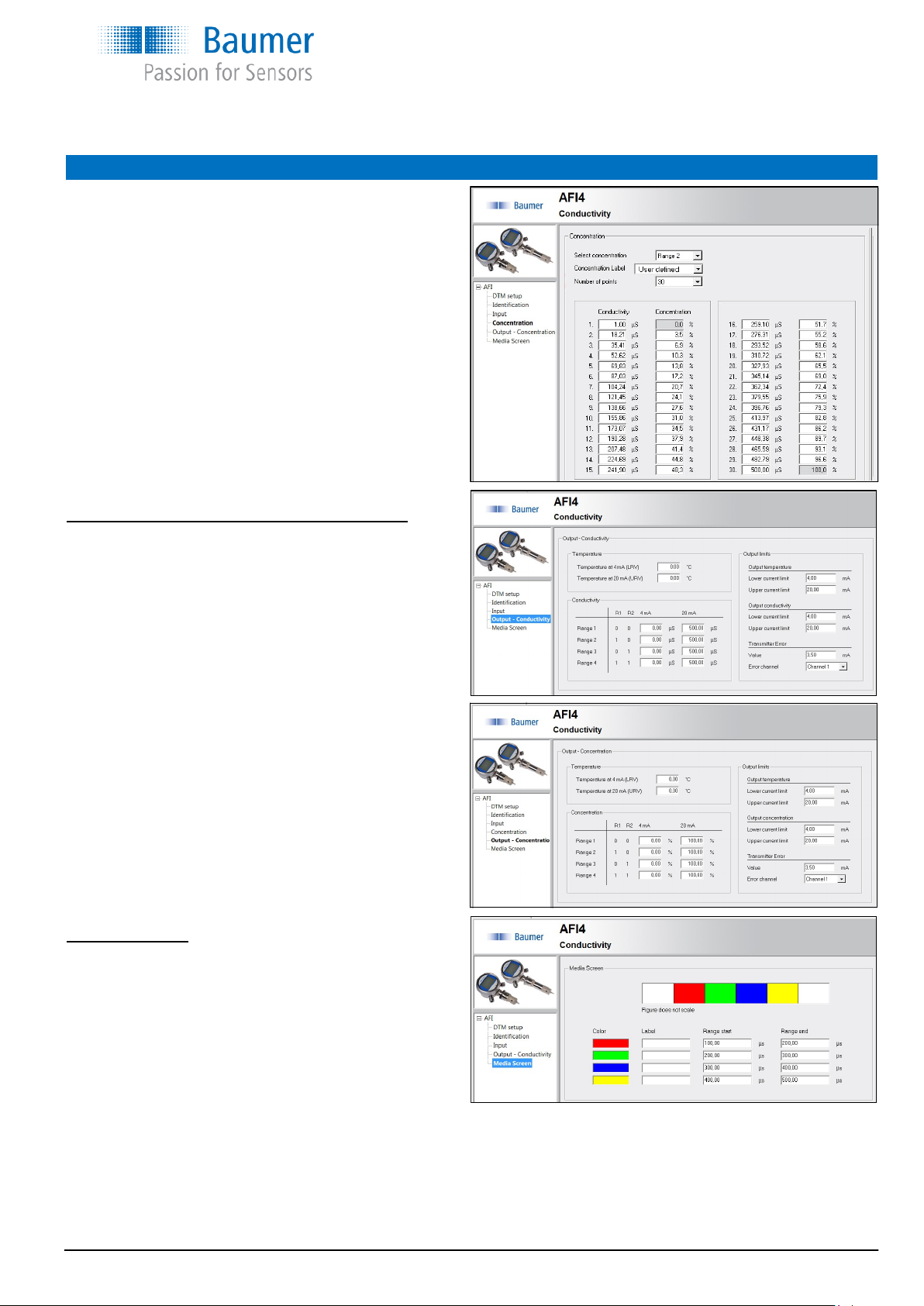

If user defined concentration is selected you may enter the number of

point (2...30 points) in which the media is to be calibrated.

Fill in conductivity in µS/cm and % for each point.

See example to the right.

Screen Output (when conductivity is selected in DTM setup)

Setting the temperature output range (4...20 mA)

Setting the conductivity µS/cm or mS/cm output 4 ranges (4...20 mA)

The ranges set under Input will appear, however can be overwritten if

wanted.

The transmitter error signal can be directed to either temperature out-

put or conductivity output or both outputs.

Screen Output

(when concentration is selected in DTM setup)

Setting the temperature output range (4...20 mA)

Setting the concentration % output 4 ranges (4...20 mA)

The ranges set under Input will appear, however can be overwritten if

wanted.

The transmitter error signal can be directed to either temperature out-

put or conductivity output or both outputs.

Screen Media screen

A product label can be entered in field “Label” e.g. Milk

and the values for the media entered in µS/cm in the two following

fields. Then the “Label” will appear on the display between the two

values (see media screens page 3)

(The colours is only informative, they will not appear on the display)

Example:

Water 600 µS/cm 700 µS/cm

Milk 4500 µS/cm 5500 µS/cm

CIP acid 9000 µS/cm 11000 µS/cm

CIP caustic 55000 µS/cm 65000 µS/cm

English

CombiLyz, AFI4

Loading...

Loading...