Ariston Unvented Hot Water Storage Cylinders User Manual

www.tradeplumbing.co.uk Call Sales On 08708034288

Unvented Hot

Water Storage

Cylinders

Instructions for Installation, Servicing and Use

LEAVE THESE INSTRUCTIONS WITH THE END-USER

www.tradeplumbing.co.uk Call Sales On 08708034288

Country of destination: GB/IE

www.tradeplumbing.co.uk Call Sales On 08708034288 |

||

TABLE OF CONTENTS |

1. |

GENERAL INFORMATION |

|

1.1 |

DELIVERY |

|

2. |

INSTALLATION |

|

2.1 |

WATER REGULATIONS |

|

2.2 |

BUILDING REGULATIONS |

|

2.3 |

HOW THE APPLIANCE WORKS |

|

2.4 |

OVERALL DIMENSIONS |

|

2.5 |

COLD WATER SUPPLY |

|

2.6 |

SITING AND FIXING |

|

2.7 |

CONNECTION OF MAINS WATER SUPPLY |

|

2.8 |

COLD WATER COMBINATION VALVE |

|

2.9 |

CONNECTION TO SERVICES |

|

2.10 |

SECONDARY RETURN |

|

2.11 |

DISCHARGE PIPEWORK |

|

2.12 |

ELECTRICAL DIAGRAMS |

|

3. |

COMMISSIONING |

|

4. |

MAINTENANCE |

|

4.1 |

PROTECH ANTI-CORROSION SYSTEM |

|

4.2 |

THERMAL CUT-OUT(S) |

|

4.3 |

IMMERSION HEATER(S) |

|

4.4 |

UNVENTED CONTROLS |

|

4.5 |

THERMOSTATS |

|

4.6 |

MAINTENANCE |

|

5. |

FAULT FINDING |

|

6. |

TECHNICAL INFORMATION |

www.tradeplumbing.co.uk Call Sales On 08708034288

2

www.tradeplumbing.co.uk Call Sales On 08708034288 |

|||

1. |

GENERAL |

This manual is an integral and essential part of the product. It should be kept |

|

with the appliance so that it can be consulted by the user and our authorised |

|||

|

INFORMATION |

||

|

personnel. |

||

|

|

Please read carefully the instructions and notices about the appliance |

|

|

|

contained in this manual, as they provide important information regarding the |

|

|

|

safe installation, use and maintenance of the cylinder. |

|

|

|

Failure to do so may invalidate the guarantee. |

|

1.2 |

DELIVERY |

The Ariston range is available in the following options: |

|

|

|

The Wall-hung ProTech range (50, 75, 100 litre models), which are supplied |

|

|

|

as follows; |

|

One box containing;

1)The cylinder with factory fitted temperature & pressure relief valve, immersion heater and thermostat with thermal cut-out.

One box containing;

1)Unvented control pack (expansion vessel, 2 piece cold water combination valve and tundish), instructions for installation, servicing and use and the Benchmark Log Book).

The Contract ProTech floor-standing range (100, 125, 150, 200 and 300 litre models), which are supplied as follows;

One box containing;

1) The cylinder with factory fitted temperature & pressure relief valve.

One box containing;

1)Unvented control pack (expansion vessel, 2 piece cold water combination valve and tundish), motorised valve (indirect only). Immersion heater(s) and thermostat(s) with thermal cut-out(s), cylinder thermostat with thermal cut-out (indirect only), feet (x3), instructions for installation, servicing and use and the Benchmark Log Book.

The High Capacity ProTech floor-standing range (500 litre models), which are supplied as follows;

One box containing;

1) The cylinder with factory fitted temperature & pressure relief valve.

1)Unvented control pack (expansion vessel, 2 piece cold water combination valve and tundish), motorised valve (indirect only). Immersion heater(s) and thermostat(s) with thermal cut-out(s), cylinder thermostat with thermal cut-out (indirect only), feet (x 3), instructions for installation, servicing and use and the Benchmark Log Book.

The Classico and Primo floor-standing ranges (125, 150, 200 and 300 litre models).

Are supplied with the following;

One box containing;

1) The cylinder with factory fitted temperature & pressure relief valve.

One box containing;

1)Unvented control pack (expansion vessel, 2 piece cold water combination valve and tundish), motorised valve (indirect only). Immersion heater(s) and thermostat(s) with thermal cut-out(s), cylinder thermostat with thermal cut-out (indirect only), feet (x3), instructions for installation, servicing and use and the Benchmark Log Book.

www.tradeplumbing.co.uk Call Sales On 08708034288

3

3

www.tradeplumbing.co.uk Call Sales On 08708034288

2.INSTALLATION

2.1WATER REGULATIONS

2.2BUILDING REGULATIONS

2.3HOW THE APPLIANCE

WORKS

These regulations (byelaws in Scotland) ensure a good supply of wholesome water, and that only approved materials, pipes and fittings are used to convey water.

These are a statutory document and take priority over all other regulations and recommendations. The installation of an unvented hot water storage cylinder is classified as a “Controlled Service” and Regulation G3 applies. To meet the requirements of the Regulation, installation of an unvented system should be undertaken by a “competent installer”.

All installations of unvented hot water storage systems having a capacity of more than 15 litres should be notified to the relevant Local Authority by means of building notice or by the submission of full plans. It is important to note that it is a criminal offense to install an unvented hot water storage system without notifying the Local Authority. The installation of the unvented cylinder and hot water system must comply with BS 6700 and the HSE Legionella Code of Practice.

The immersion heater(s) are controlled through a thermostat which senses the water temperature. The operating temperature can be pre-set by adjusting the spindle in the head of the thermostat. In addition to the thermostat there is a thermal cut-out incorporated if the thermostat fails and the water temperature rises too high. Once the cut-out operates it can only be re-set manually after the fault has been rectified.

Indirect models have dual thermal controls. In addition to the above there is a separate cylinder thermostat and thermal cut-out for controlling the indirect circuit. Again the thermal cut-out operates if the cylinder thermostat fails, by disconnecting the live feed (call for hot water) from the programmer.

Classico (STD/STI) models have magnesium anodes provided to prevent corrosion of the cylinder tank.

All High Capacity (STD/STI) 500 litre models, Wall-hung (ST) units and the Contract (STD/STI) Floor-standing models utilise the ProTech anti-corrosion system (electronic anode).

The factory fitted temperature & pressure relief valve at the top of the cylinder is a safety device to back-up the thermostat(s) and thermal cutout(s). It works by sensing an excess in water temperature or pressure and releasing the hot water into a discharge tundish and drain.

The cylinder will only work in the vertical position. The inlet pipe needs to deliver cold water to the bottom of the tank. When water is heated it expands. To accommodate this increase in volume an expansion vessel is provided. A cold water combination valve is also provided in two pieces, loose jointed for ease of installation. These comprise a combined line strainer/pressure reducing valve and core non-return valve/expansion relief valve.

The strainer prevents any debris entering the other controls. The pressure reducer ensures the correct operation of the expansion vessel, and prevents any damage to the control valves through too great a pressure.

The non-return valve ensures the water expansion is forced into the expansion vessel and prevents contamination of the mains cold water supply. The expansion relief valve will discharge expanded water to the discharge tundish if the expansion vessel fails.

www.tradeplumbing.co.uk Call Sales On 08708034288

4

www.tradeplumbing.co.uk Call Sales On 08708034288 |

|||||||||||||||||||||||||||||||||||||||||||

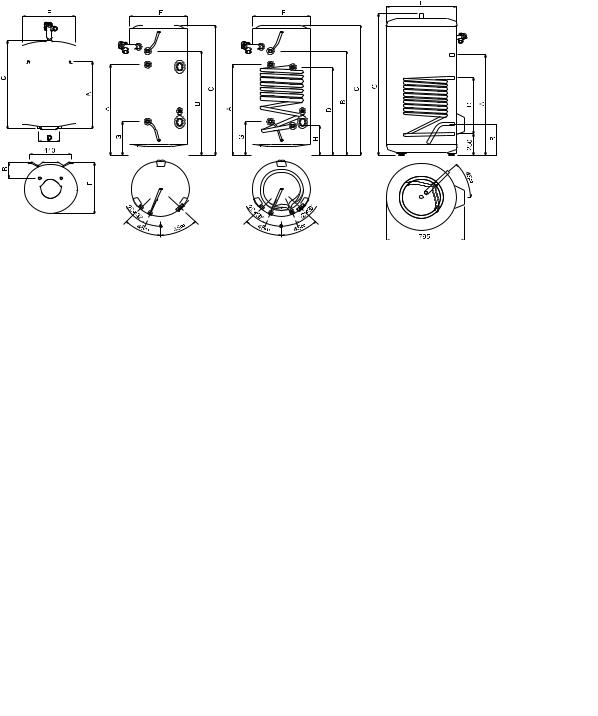

2.4 |

OVERALL DIMENSIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TABLE 1 |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

Model |

|

|

Storage |

Units Pipe Size |

Coil |

|

|

|

|

|

|

|

|

|

Dimensions in mm |

|

|

|

|

Weight |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Surface |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When Full |

|

|

|

|

|

|

|

|

Capacity |

|

|

Inlet Outlet |

m2 |

|

|

A |

|

B |

C |

|

D |

|

E |

F |

|

G |

H |

Kg |

||||||||||||||||

|

|

DIRECT RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Wall-hung |

|

|

|

|

50 l |

|

|

|

|

|

1/2” |

- |

|

410 |

120 |

|

580 |

|

160 |

|

475 |

460 |

|

|

|

77 |

|||||||||||||||

|

|

ST 50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||

|

|

ST 80 |

|

|

|

|

75 l |

|

|

|

|

|

3/4” |

- |

|

590 |

175 |

|

740 |

|

230 |

|

475 |

460 |

|

|

|

115 |

|||||||||||||||

|

|

ST 100 |

|

|

|

|

100 l |

|

|

|

|

|

3/4” |

- |

|

550 |

175 |

|

700 |

|

230 |

|

575 |

560 |

|

|

|

141 |

|||||||||||||||

|

|

Floor Standing |

|

|

|

|

100 l |

|

|

|

|

|

3/4” |

- |

|

530 |

650 |

|

890 |

|

- |

|

- |

505 |

|

265 |

225 |

129 |

|||||||||||||||

|

|

STD ProTech |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

STD / STD ProTech / ITD 125 |

|

|

|

|

125 l |

|

|

|

|

|

3/4” |

- |

|

700 |

805 |

|

1045 |

|

- |

|

- |

505 |

|

265 |

225 |

158/138* |

|||||||||||||||

|

|

STD / STD ProTech / ITD 150 |

|

|

|

|

150 l |

|

|

|

|

|

3/4” |

- |

|

840 |

965 |

|

1205 |

|

- |

|

- |

505 |

|

265 |

225 |

190/164* |

|||||||||||||||

|

|

STD / STD ProTech / ITD 210 |

|

|

|

|

200 l |

|

|

|

|

|

3/4” |

- |

|

990 |

1280 |

1525 |

|

- |

|

- |

505 |

|

265 |

225 |

245/220* |

||||||||||||||||

|

|

STD / STD ProTech / ITD 300 |

|

|

|

|

300 l |

3/4" |

|

|

|

|

- |

|

1215 |

1555 |

1790 |

|

- |

|

- |

560 |

|

275 |

255 |

385/331* |

|||||||||||||||||

|

|

500 STD ProTech |

|

|

|

|

495 l |

|

|

|

|

|

1” |

- |

|

1390 |

335 |

|

1870 |

|

- |

|

- |

714 |

|

|

|

630 |

|||||||||||||||

|

|

INDIRECT RANGE |

|

|

|

|

125 l |

|

|

|

|

|

3/4” |

0.75 |

|

700 |

805 |

|

1045 |

|

675 |

|

- |

505 |

|

265 |

225 |

166/143** |

|||||||||||||||

|

|

STI / STI ProTech / ITI 125 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||

|

|

STI / STI ProTech / ITI 150 |

|

|

|

|

150 l |

|

|

|

|

|

3/4” |

0.9 |

|

840 |

965 |

|

1205 |

|

815 |

|

- |

505 |

|

265 |

225 |

201/171** |

|||||||||||||||

|

|

STI / STI ProTech / ITI 210 |

|

|

|

|

200 l |

|

|

|

|

|

3/4” |

0.9 |

|

990 |

1280 |

1525 |

|

815 |

|

- |

505 |

|

265 |

225 |

256/227** |

||||||||||||||||

|

|

STI / STI ProTech / ITI 300 |

|

|

|

|

300 l |

|

|

|

|

|

3/4” |

0.9 |

|

1215 |

1555 |

1790 |

|

815 |

|

- |

560 |

|

275 |

255 |

395/337** |

||||||||||||||||

|

|

500 STI ProTech |

|

|

|

|

495 l |

1" |

|

|

|

|

1.5 |

|

1390 |

335 |

|

1870 |

|

700 |

|

- |

714 |

|

|

|

641 |

||||||||||||||||

|

|

*ITD Models **ITI Models |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

ST ProTech |

STD/STD ProTech/ITD |

STI/STI ProTech/ITI |

|

|

|

500 STD ProTech |

|

|

||||||||||||||||||||||||||||||||

|

50-80-100 |

|

|

|

|

125-150-200-300 |

|

|

125-150-200-300 |

|

|

|

500 STI ProTech |

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

It is important to ensure that the cold water main is capable of supplying the increased demand which will be imposed on it. Hot and cold water are both drawn off the same source of supply. Remember, there will not be a storage tank to help compensate for variations in the demand on the system.

A minimum pressure of approximately 1.5 bar and 20 litres per minute is required for satisfactory operation. 85% of UK dwellings have a mains pressure above 2.0 bar.

NOTE: THE MAINS WATER SUPPLY MUST NOT EXCEED 16 BAR.

The cylinder should be left packed until it is time to install. When unpacking the appliance follow the guidelines within the packaging and take care not to damage the temperature and pressure relief valve.

The cylinder may be installed at any convenient position, as it is connected to the mains cold water supply, it is equally effective on any floor, however, consideration must be given to allow ease of access for maintenance purposes.

However, do not install the unit in premises which may be subject to freezing. Ensure that the floor load bearing strength is adequate to take the weight of the cylinder when full of water (see TABLE 1).

The ST50, ST80 and ST100 ProTech models are wall mounted. All other models are free standing. These are supplied with feet which are attached to the heater via self-tapping screws which are also supplied. All units must be installed in the VERTICAL POSITION.

For maintenance purposes leave at least 500 mm free space in front of the

www.tradeplumbing.unit,cofor.ukaccessCall. Sales On 08708034288

5

5

www.tradeplumbing.co.uk Call Sales On 08708034288 |

|

2.7 CONNECTION OF MAINS |

For floor standing models: |

WATER SUPPLY |

On the front of the unit there is a label to identify the connection ports. |

|

Please check this before making any connection to the unit. |

For units up to 300 litres it is recommended that all mains cold water supply pipe work is a minimum of 22mm, with the exception of model ST 50 ProTech where 15mm can be used. For 500 litre models the supply should be 28mm. An isolating valve should be installed between the cold water supply and the cylinder for servicing. ALL PIPEWORK MUST BE FLUSHED TO AVOID DAMAGE TO THE CONTROL VALVES.

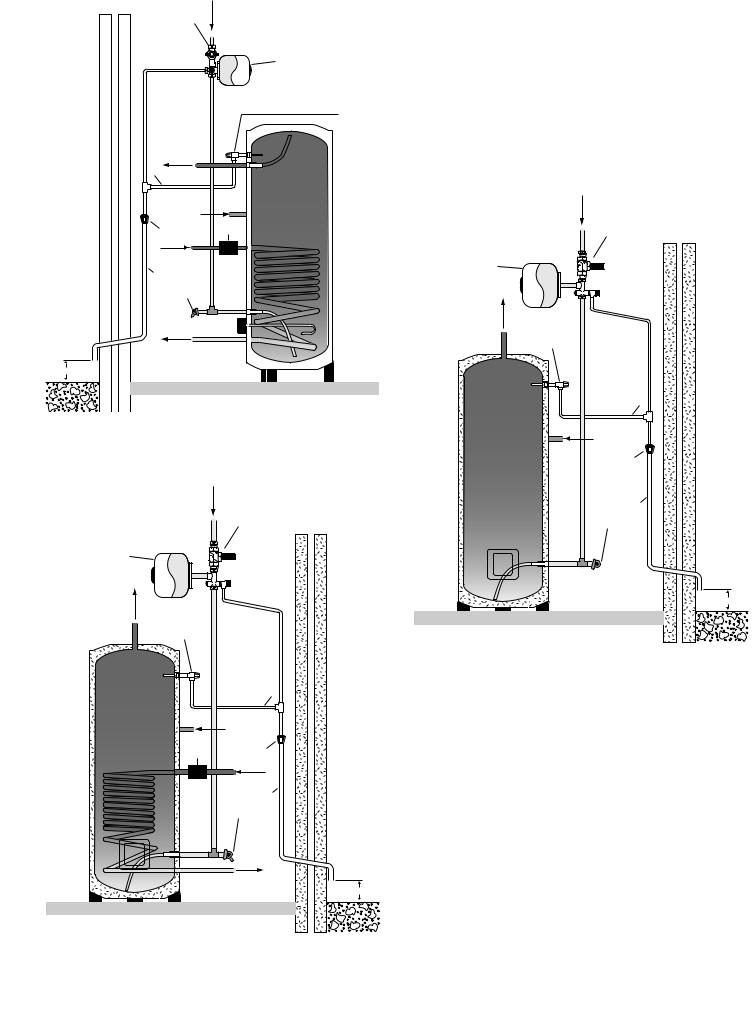

Please refer to FIGS. 2.1, 2.2, 2.3, 2.4, 2.5 for a suggested installation layout.

ST PROTECH 50-80-100

PRESSURE + TEMPERATURE

RELIEF VALVE

COLD

MAINS-IN 15/22mm

15mm

EXPANSION

VESSEL

COMBINATION

VALVE

HOT SUPPLY 15/22mm

EXPANSION

RELIEF

PIPE

TUNDISH

STD PROTECH 100

STD/STD PROTECH/ITD 125-150-210-300 DIRECT

22mm |

|

|

|

|

COLD |

|

|

MAINS-IN |

|

COMBINATION |

22mm |

|

|

|

|

VALVE |

|

MAX. 100mm |

|

EXPANSION |

|

|

VESSEL |

|

|

PRESSURE + TEMPERATURE |

|

|

RELIEF VALVE |

FIG. 2.1 |

|

|

|

HOT SUPPLY |

|

|

22mm |

|

|

EXPANSION RELIEF |

|

|

PIPE |

|

|

SECONDARY |

|

|

RETURN |

|

|

TUNDISH |

|

|

22mm |

|

|

DRAIN |

|

MAX. 100mm

www.tradeplumbing.co.uk Call Sales On 08708034288FIG. 2.2

6

www.tradeplumbing.co.uk Call Sales On 08708034288

STI/STI PROTECH/ITI 125-150-210-300 INDIRECT

|

COLD |

|

|

MAINS-IN |

|

COMBINATION |

22mm |

|

|

|

|

VALVE |

|

|

|

EXPANSION |

|

|

VESSEL |

|

|

PRESSURE + TEMPERATURE |

|

|

RELIEF VALVE |

|

HOT SUPPLY |

|

|

22mm |

|

500 STD PROTECH |

EXPANSION RELIEF |

|

|

|

|

|

PIPE |

|

|

|

|

COLD |

SECONDARY |

|

MAINS-IN |

|

28mm |

|

RETURN |

|

|

ZONE |

|

|

|

|

|

TUNDISH |

VALVE |

COMBINATION |

|

|

|

|

|

VALVE |

FLOW |

|

|

|

|

EXPANSION |

22mm |

|

VESSEL |

|

|

|

DRAIN |

|

|

|

|

HOT SUPPLY |

|

|

28mm |

|

|

PRESSURE + |

|

|

TEMPERATURE |

RETURN |

|

RELIEF VALVE |

|

|

|

MAX. 100mm |

|

|

|

|

EXPANSION RELIEF |

|

FIG. 2.3 |

PIPE |

|

|

|

|

|

SECONDARY |

|

|

RETURN |

500 STI PROTECH |

TUNDISH |

|

COLD |

|

|

MAINS-IN |

|

|

28mm |

|

22mm |

|

COMBINATION |

DRAIN |

|

VALVE |

|

EXPANSION |

|

|

VESSEL |

|

|

HOT SUPPLY |

|

|

28mm |

|

|

PRESSURE + |

|

|

TEMPERATURE |

|

|

RELIEF VALVE |

|

|

|

EXPANSION RELIEF |

|

|

PIPE |

|

|

SECONDARY |

|

|

RETURN |

|

ZONE |

TUNDISH |

|

VALVE |

|

|

|

|

|

|

FLOW |

|

|

22mm |

|

|

DRAIN |

|

|

RETURN |

|

|

MAX. 100mm |

|

MAX. 100mm

FIG. 2.4

www.tradeplumbing.coFIG..uk2.5 Call Sales On 08708034288

7

7

www.tradeplumbing.co.uk Call Sales On 08708034288 |

|

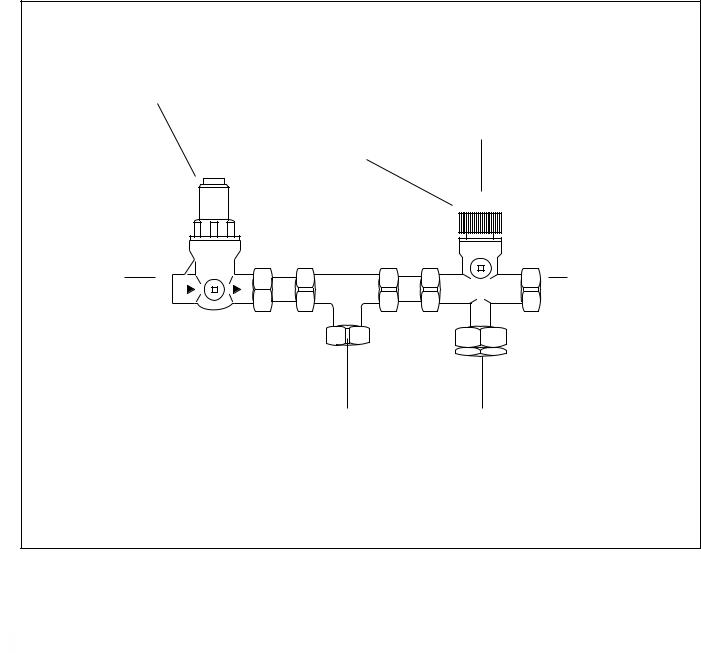

2.8 COLD WATER |

The cold water combination valve can be connected either close by |

COMBINATION VALVE |

the unit or alternatively it may be installed in a remote position from |

|

the unit as there is no requirement to site it in close proximity to the |

|

cylinder. This allows a flexible and convenient installation. However, it |

|

is important to note allowances for the discharge pipe work from the |

|

expansion relief valve must be accounted for. |

A balancing port is supplied on the 22mm valves (for units above 50 litres) and 28mm valves (for 500 litres units) allowing balanced cold water supply to the rest of the building giving constant results for mixer and shower valves. If the facility is not needed a plug is supplied. Refer to FIG. 2.7 and FIG. 2.8

Although this facility is not built into the 15mm valve (supplied with model ST50), a tee piece may be inserted between the two components giving the same result. Refer to FIG. 2.6

NOTE!

THERE SHOULD BE NO OTHER VALVES FITTED BETWEEN THE CYLINDER AND

THE EXANSION VALVE.

SERVICEABLE 1/2” PRESSURE

REDUCING CARTRIDGE AND

LINE STRAINER

EXPANSION RELIEF

VALVE (SET AT 6 BAR)

NON-RETURN

VALVE (WITHIN HOUSING)

15mm |

15mm |

COLD |

TO CYLINDER |

MAINS IN |

|

TEE PIECE |

3/4” B.S.P. CONNECTIONS |

FOR BALANCED |

FOR EXPANSION VESSEL |

COLD WATER |

|

TAKE OFF |

|

(NOT SUPPLIED) |

|

FIG. 2.6 For Model ST 50

www.tradeplumbing.co.uk Call Sales On 08708034288

8

Loading...

Loading...