Aprilia RX 50 User Manual 1996

1

ONLY FOR THE CATALYTIC VERSION

USE ONLY UNLEADED PETROL IN CONFORMITY WITH THE DIN 51607 STANDARD, MIN. O.N. 95

(N.O.R.M.) AND 85 (N.O.M.M.) AND HIGH PERFORMANCE SYNTHETIC OIL FOR 2 STROKE ENGINES.

THE USE OF FUELS AND LUBRICANTS DIFFERENT FROM THOSE INDICATED CAUSES SEVERE

FUNCTIONAL INCONVENIENCES TO THE VEHICLE AND THE VOIDING OF THE

aprilia

GUARANTEE.

ONLY FOR THE CATALYTIC VERSION

To have the catalytic converter functioning correctly for long periods and to reduce possible

problems regarding the contamination of the thermal unit and of the exhaust, it is necessary to

avoid covering long distances with the engine running at constantly low rpm.

It is sufficient to alternate these periods with periods in which the engine runs at relatively high rpm,

even if only for a few seconds, but rather frequently.

What has been stated above assumes particular importance for the cold starting of the engine: in this

case, in order to reach a rpm regime sufficient to enable the “priming” of the catalytic reaction, you just

need to make sure that the temperature of the thermal unit has reached at least 50°C, which generally

occurs a few seconds after starting the engine.

a

2

CATALYTIC SILENCER

The catalytic version of the RX50 is fitted with a silencer with metal catalytic converter of the “platinum-

rhodium bivalent” type. This device provides for the oxidation of the CO (carbon monoxide) and of the

HC (unburned hydrocarbons) contained in the exhaust gases, changing them into carbon dioxide and

steam, respectively. Due to the catalytic reaction, the high temperature reached by the exhaust gases

results in the burning of the oil particles, thus keeping the silencer clean and eliminating the exhaust

fumes.

Avoid parking the catalytic vehicle near dry brush wood or in places easily accessible to chil-

dren, as the catalytic silencer becomes extremely hot during use; be very careful and avoid any

kind of contact before it has completely cooled down.

a

3

First edition: february 1996

Reprint: september 1996, march 1997, april 1998

Produced and printed by:

Studio Tecno Public

Viale del Progresso - 37038 Soave (VR) - Italy

Tel. +39 - 045 76 11 911

Fax +39 - 045 76 12 241

www.stp.it

E-mail: customer@stp.it

On behalf of:

aprilia s.p.a.

via G. Galilei, 1 - 30033 Noale (VE) - Italy

Tel. +39 - 041 58 29 111

Fax +39 - 041 44 10 54

www.aprilia.com

This manual contains all the main information and the

instructions required for normal use and maintenance

of your vehicle.

For controls and check-ups that cannot be carried out

easily with the standard equipment supplied, we ad-

vise you to consult our Dealers who can assure you

of quick and careful servicing.

To keep your

aprilia

vehicle always in perfect operat-

ing conditions, we advise you to insist on Original

Spares and to have repairs carried out only by

aprilia

Authorized Outlets and Official Dealers.

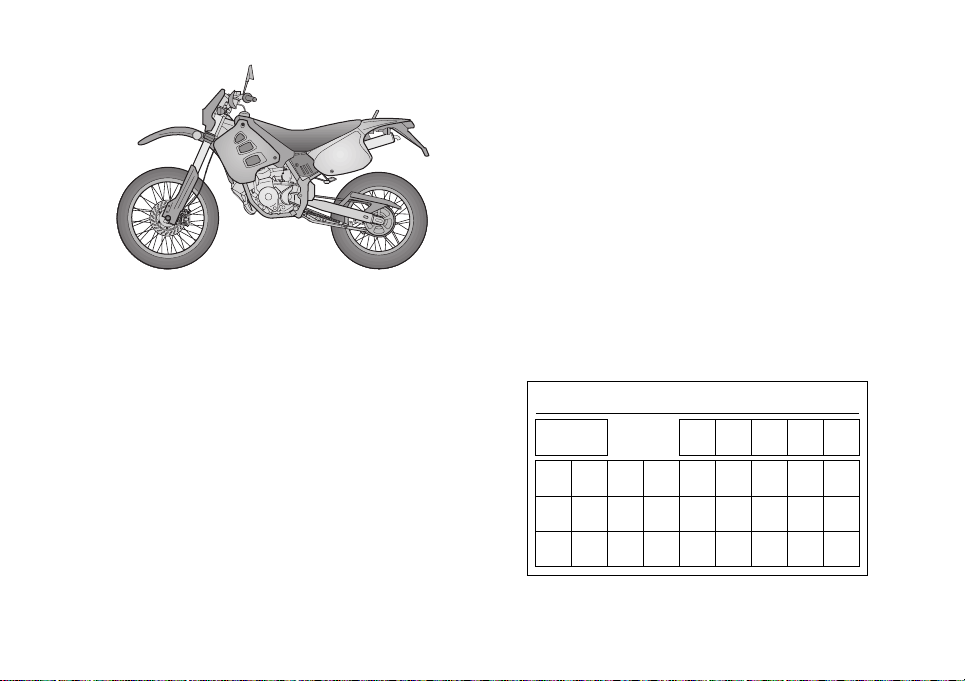

When ordering spare parts from the Dealers, always

quote the spares code which is stamped on a sticker

placed under the saddle.

It is a good idea to make a note of the identification

code in the space provided in this manual, so that

you will always have a record of it even if the identifi-

cation sticker comes off.

All information is purely indicative and may be sub-

ject to variation without notice.

aprilia

CODICE RICAMBI spare parts code number

N˚

I.M.

ABCDE

IUKAPSFB D F E

GR NL CH DK J SGP PL IL ROK

MAL RCH BM USA AUS

4

Carefully observe the instructions preceded by the

following warning signs:

Safety norms and regulations to protect

the driver and other people from severe

injuries or grave risks

.

Caution norms and suggestions to avoid

damaging the vehicle and/or hurting your-

self or other people

.

Indications to make the operations easier.

Technical information

.

CONTENTS

Pag.

Technical features ....................................................5

Identification data.....................................................8

Arrangement of the controls.....................................9

Instructions for use.................................................12

Maintenance...........................................................15

Electrical system ....................................................35

Cleaning.................................................................40

Long inactivity ........................................................40

Periodic maintenance chart....................................41

Lubricant chart .......................................................42

Importers................................................................43

Wiring diagram.......................................................45

_

automatic light switching version

(Automatic Switch-on Device)

2

catalytic version

I

Italy version

£

Denmark version

U

United Kingdom version

J

Japan version

A

Austria version

S

Singapore version

P

Portugal version

V

Poland version

"

Finland version

%

Israel version

B

Belgium version

K

South Korea version

D

Germany version

M

Malaysia version

F

France version

R

Chile version

E

Spain version

Q

Bermuda version

G

Greece version

-

United States

of America version

O

Holland version

C

Switzerland version

^

Australia version

a

b

c

5

TECHNICAL FEATURES

MOTOR

Model..................................................................AM6

Type......................................2 stroke single-cylinder

with lamellar inlet

Cooling..........................Liquid with forced circulation

Lubrication .................................................. Separate

Bore / stroke...................................40,3 mm / 39 mm

Displacement ............................................ 49,75 cmC

Compression ratio.............................................12 : 1

KICK START

To pedal (Kick-starter)

CLUTCH

Light alloy multiple disc oil bath

GEARS

Frontal clutch 6 speed unit

TRANSMISSION

Primary ........................................ Helical teeth gears

Ratio 3,55 (Z=20/71)

Secondary.........chain 1/2"x3,16" = Roller Ø7,75 mm

Ratio: 4,25 (Z=12/51)

CARBURETTOR

Model .................................................. Dell’Orto SHA

Diffuser...................................................Ø 12-14 mm

AIR FILTER

Sponge

IGNITION

Type........................................................... electronic

Spark advance reference...............................1,5 mm

correspondent to 20° before T.D.C.

Spark plug............................................NGK BR8 ES

FUEL

Running-in (500 km) .........................unleaded petrol

according to the DIN 51607 standard

min. O.N. 95 (N.O.R.M.)

and 85 (N.O.M.M.)

Aferwords:.........................................unleaded petrol

according to the DIN 51607

min. O.N. 95 (N.O.R.M.)

and 85 (N.O.M.M.)

Fuel tank capacity............................................... 9,5

l

Reserve (with mechanical operation)..................1,5l

Mixer oil tank capacity......................................... 1,3l

Reserve (with warning light on the dashboard)...0,5l

6

LUBRICATION

Gearbox and primary transmission 820 cmC of oil (*)

COOLING

Cooling circuit capacity .................................0,9 l (*)

(60% antifreeze + 40% water)

Minimum operating temperature.......................-17°C

FRAME

High-resistance one-beam structure, split over the

exhaust

REAR FORK

Made of rectangular-profile steel, mounted on anti-

friction bushings

SUSPENSIONS

Front....................................aprilia telehydraulic fork

with reversed rods

with advanced pin, rods Ø 35

stroke 250 mm

Rear ................................aprilia Progressive System

adjustable hydraulic mono-shock absorber

Rear wheel stroke.........................................260 mm

(*) see “LUBRICANT CHART”

BRAKES

Front........................................ disc brake Ø 230 mm

with hydraulic control

and floating caliper with two parallel pins

Rear ........................................ disc brake Ø 220 mm

with hydraulic control

and fixed caliper

with two opposing pins Ø 28 mm

TYRES

Front....................................90/90 x 21" Enduro type

inflation pressure: 1,6 bar

Rear ..................................110/80 x 18" Enduro type

inflation pressure: 1,8 bar

RIMS

Front.............................................................21 x 1,6"

Rear ...........................................................18 x 1,85"

DIMENSIONS

Max. length..................................................2060 mm

Wheelbase (slot center) ..............................1360 mm

Handlebars width ..........................................810 mm

Max. height..................................................1350 mm

Seat height....................................................890 mm

Footboard height...........................................355 mm

7

TYRE INFLATION PRESSURE

Maximum front and rear pressure: 2,5 bar

Low pressure can cause handling prob-

lems and the tendency to weave and in

extreme cases loss of control.

Moreover this will cause a great increase of roll-

ing friction.

The results are: high consumption of fuel and re-

duced maximum speed.

The disadvantage may cause a damage of the cover,

due to excessive local deformation.

Tyre pressure must be checked when the

tyres are at environment temperature,

that is, when the vehicle has not been moved in

the last 2 or 3 hours for more than 1 km.

Check the depth of the tyre tread often, if

it is worn below the allowable limit (2 -

3 mm.) change the tyre.

– The tyre should often be inspected for signs of

damage or cuts.

– Blowings or irregular wavings are showing in-

ternal damages, which request the prompt re-

placement of the tyre.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

Kind of drive

Driver only

Front Rear

Off-road 1,3 bar 1,4 bar

On mixed roads 1,5 bar 1,6 bar

On asphalt

paved roads

1,6 bar 1,8 bar

a

c

a

c

8

IDENTIFICATION DATA

It is a good rule to write down the frame and engine

numbers in the space provided in this manual.

The frame number can be used for the purchase of

spare parts.

Do not alter the identification numbers if

you do not want to incur severe penal and

administrative sanctions. In particular, the altera-

tion of the frame number results in the immediate

invalidity of the guarantee.

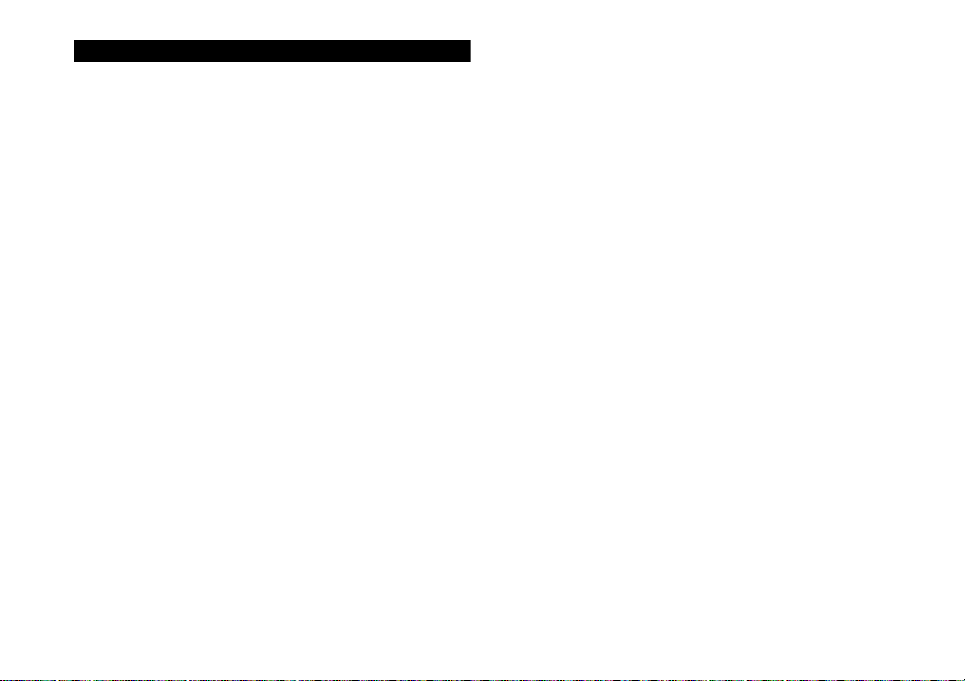

FRAME NUMBER (Fig. 1)

The frame number is stamped on the left side of the

steering head.

Frame n°

ENGINE NUMBER (Fig. 2)

The engine number is printed in the space provided

upper the pinion.

Engine n°

Fig. 1

Fig. 2

c

9

ARRANGEMENT OF THE CONTROLS

The control devices are positioned as indicated in fig-

ures 3 and 4, as follows:

Fig. 3

1) Clutch lever

2) Front brake lever

3) Twist grip

4) Rear brake pedal

5) Kick-starter

6) Gear pedal

Fig. 4

1) Turn indicator switch (c)

2) Horn push button (

f)

3) Dimmer light switch (

b - p) and low beam si-

gnalling push button (

b)

3a)

%

_

Dimmer light switch (

a - b) and high

beam signalling push button (

a)

4) Trip odometer control knob

5) Speedometer/odometer with trip counter

6) Mixer oil reserve warning light (

j)

7) Low beam warning light (

b)

7a) High beam warning light (

a)

%

_

8) Neutral indicator warning light (q)

9) Revolution counter (rpm)

10) Turn indicator warning light (

c)

11) Ignition switch / steering lock / light switch

(

s - m - n - o)

Remember: 1 mile = 1.6 km

1 km = 0.625 miles

c

Fig. 3

Fig. 4

10

IGNITION SWITCH / STEERING LOCK /

LIGHT SWITCH

The ignition switch has 4 click positions:

◆ First click clockwise = “n“ (start)

◆ Second click clockwise = “o“ (light on) (not provid-

ed in the

_

version).

◆ Central position = “m” (stop)

◆ Anticlockwise rotation = “s“ (steering lock)

AUTOMATIC

LIGHT SWITCHING VERSION

_

The vehicles provided with the Automatic Switch-on

Device can be immediately recognized, since the

lights come automatically on as soon as the engine is

started.

For this reason the light switch is replaced by a dim-

mer switch.

The lights can be switched off only by stopping the

engine.

For the versions with high beam, proceed as follows:

◆ Before starting the vehicle, make sure that the

dimmer switch is in position “

b” (front low beam).

STEERING LOCK

Never turn the key to the "s" position

while driving, in order to avoid losing

control of the vehicle.

OPERATION

To lock the steering turn the handlebars completely

to the left.

With the key on the "

m" position, press the key, re-

lease it and turn it to the "

s" position.

Remove the key.

Position Function Key removal

s

Steering

lock

The steering is

locked. It is neither

possible to start the

engine, nor to switch

on the lights.

It is possible to

remove the key.

m

Neither the engine,

nor the lights can be

switched on.

It is possible to

remove the key.

n

The engine can be

start.

It is neither possible

to switch the lights.

It isn't possible

to remove the

key.

o

The engine and the

lights can be

switched on.

It isn't possible

to remove the

key.

a

11

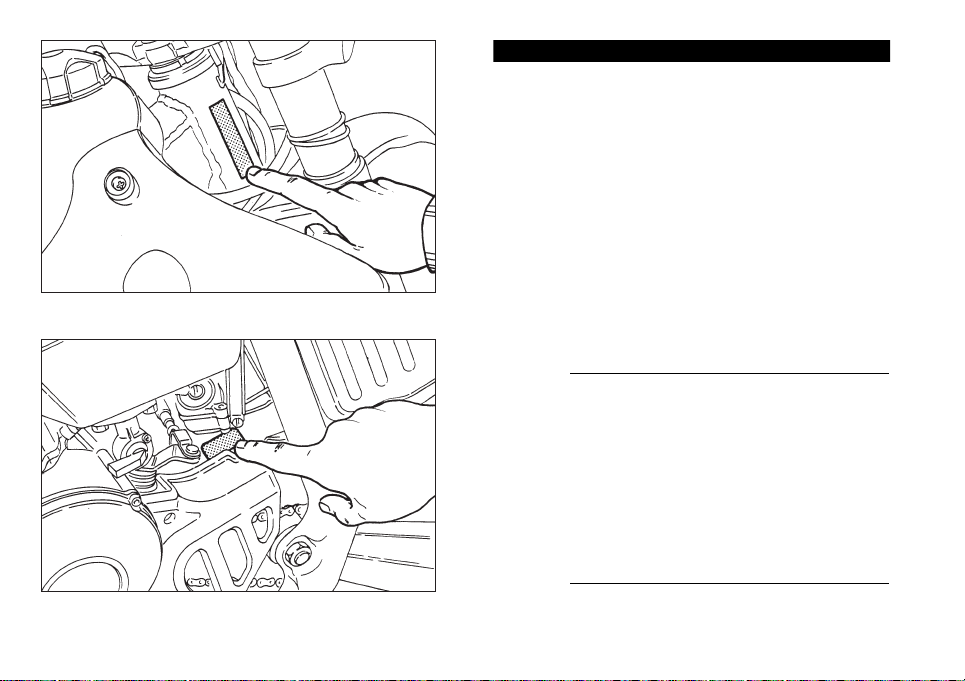

CRASH-HELMET LOCK (Fig. 5)

Using the ignition key it is possible to have access to

the crash-helmet lock positioned on the rear part of

the vehicle.

GLOVE / TOOL COMPARTMENT (Fig. 6)

It is positioned on the inner part of the left side of the

fairing.

Fig. 5

Fig. 6

12

INSTRUCTIONS FOR USE

◆ Before starting the vehicle for the first time, check

that the tyres are inflated to the correct pressure

(Front 1,6 bar - Rear 1,8 bar) and fill the fuel tank

with premium grade petrol (see “TECHNICAL DA-

TA”).

◆ Fill the mixer oil tank with oil (see “LUBRICANT

CHART”).

The motor must not be filled with petrol/

oil mixed at filling stations.

◆ Check the engine coolant level (see “COOLANT

CHECKING”).

◆ Make sure that there are no air bubbles in the mix-

er oil pipe (from the oil tank to the pump); if neces-

sary, bleed the pump by means of the appropriate

screw (see "SEPARATE LUBRICATION”).

RUNNING

In the initial period of use is very important for the fu-

ture performance of the engine.

We advise warming up the engine before starting off,

allowing it to turn over for a few minutes at a low

speed.

If possible, drive on hill roads and/or roads with many

bends, so that the engine, the suspensions and the

brakes undergo a more effective running-in.

After the first 500 km, have the vehicle checked with

the first service coupon by an aprilia Offical Deal-

er.

If there is no oil left in the mixer oil tank,

avoid using the vehicle so as not to cause

irreparable damage to the motor.

Then bleed the system (see “SEPARATE LUBRI-

FICATION”) after filling the tank with specific oil

(see “LUBRICANT CHART).

The disc and shoes of the front brake require a run-

ning-in period (about 500 km) before reaching opti-

mum performance conditions.

Remember: 1 mile = 1.6 km

1 km = 0.625 miles.

b

b

c

13

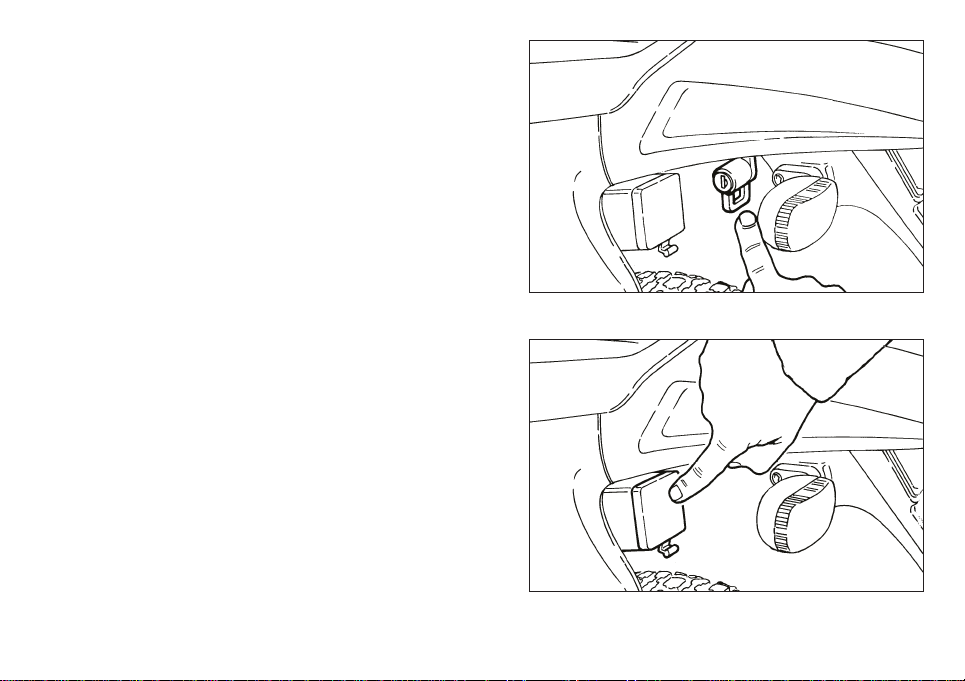

STARTING (Fig. 7-8)

◆ Open the fuel coock on the tank (Fig. 7).

◆ Insert the ignition key and turn to “n” position.

◆ If the starting takes place with cold engine, push

the choke lever upwards (Fig. 8).

◆ Place gears in neutral position, (neutral indicator

warning light “

q” comes on) or pull on clutch lever.

◆ Act on the kick starter with your right foot, releas-

ing it immediately.

If the mixer oil reserve warning light "

j"

comes on during the normal running of

the engine, this means that the mixer oil

reserve is being used; in this case, provide for

topping up.

Do not continue to press the kickstart le-

ver or attempt to use it while the engine

is running.

a

b

Fig. 7

Fig. 8

14

◆Once you have started the engine, wait for a few

seconds, then twist the throttle, turn the accelera-

tor handle firmly as far as it will go, thus automati-

cally disconnecting the starter (a metallic click will

be heard).

◆When the engine is warm it should be started with-

out using the choke.

The engine must not remain turned on

with the battery or the voltage regulator

disconnected; this would cause irrepara-

ble damage to the electrical system.

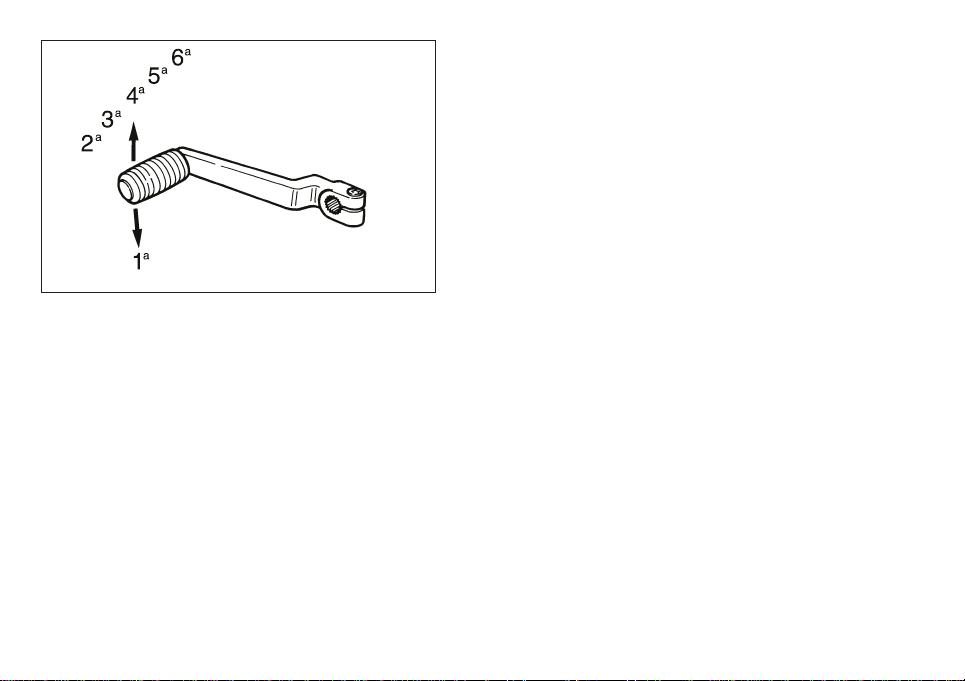

MOVING OFF (Fig. 9)

After warming up the engine:

◆Pull in the clutch lever.

◆Engage 1st gear (gear pedal downwards).

The neutral indicator warning light “

q” go out.

◆ Then gradually release the clutch and turn the

throttle at the same time.

CHANGING GEAR (Fig. 9)

Release the throttle, pull the clutch lever in and lift the

gear lever upwards to change to the higher gears.

Vice versa, push downwards when changing to a

lower gear.

Before riding the motor cycle we advise

you to get to know the controls and all

their functions as explained in this manu-

al. Contact your aprilia Offical Dealer if there is

anything you do not understand.

Fig. 9

b

a

Loading...

Loading...