A.O. Smith HW 610 User Manual

MODELS HW 300, 399, 420, 520, 610, 670

GAS-FIRED COMMERCIAL COPPER BOILERS FOR

HYDRONIC HEATING AND HOT WATER SUPPLY

UP-FLOW MODELS

• INSTALLATION • OPERATION • MAINTENANCE • LIMITED WARRANTY

• INDOOR ONLY

WARNING: If the information in this manual

is not followed exactly, a re or explosion

may result causing property damage,

personal injury or death.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the re department.

— Installatio n a n d service mu s t be

pe rfo rme d by a qualified installer,

service agency or the gas supplier.

500 Tennessee Waltz Parkway

Ashland City, TN 37015

www.hotwater.com

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE

PRINTED 0210 317693-000

SAFE INSTALLATION, USE AND SERVICE

DANGER indicates an imminently

hazardous situation which, if not avoided,

will result in injury or death.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in injury or death.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, could result in

property damage.

WARNING

CAUTION

CAUTION

DANGER

The proper installation, use and servicing of this water heater is extremely important to your safety and the safety of others.

Many safety-related messages and instructions have been provided in this manual and on your own water heater to warn you and others

of a potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important that the

meaning of each safety message is understood by you and others who install, use, or service this water heater.

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message, and how

to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances known to

the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of potential exposure

to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive harm. This appliance

can cause low level exposure to some of the substances listed in the Act.

IMPORTANT DEFINITIONS

• Qualied Installer: A qualied installer must have ability equivalent to a licensed tradesman in the elds of plumbing,

air supply, venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas

Code or the Natural Gas and Propane Installation Code as it relates to the installation of gas red boilers. The qualied

installer must have a thorough understanding of this instruction manual.

• Service Agency: A service agency also must have ability equivalent to a licensed tradesman in the elds of plumbing,

air supply, venting and gas supply, including a thorough understanding of the requirements of the National Fuel Gas

Code as it relates to the installation of gas red boilers. The service agency must also have a thorough

understanding of this instruction manual, and be able to perform repairs strictly in accordance with the service guidelines

provided by the manufacturer.

• Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning

appliances within this application. The gas supplier typically has responsibility for the inspection and code approval of

gas piping up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers also

offer service and inspection of appliances within the building.

2

GENERAL SAFETY

3

TABLE OF CONTENTS

SAFE INSTALLATION, USE AND SERVICE.......................................................................................................................................................................... 2

GENERAL SAFETY................................................................................................................................................................................................................ 3

TABLE OF CONTENTS .......................................................................................................................................................................................................... 4

DIMENSIONS AND CAPACITY DATA .................................................................................................................................................................................... 5

INTRODUCTION .................................................................................................................................................................................................................... 7

Grounding Instructions ................................................................................................................................................................................................... 7

Correct Gas .................................................................................................................................................................................................................... 7

Precautions .................................................................................................................................................................................................................... 7

Liquid Petroleum Gas Models ........................................................................................................................................................................................ 7

High Altitude Installations ............................................................................................................................................................................................... 7

CONTROLS AND FUNCTION ................................................................................................................................................................................................ 8

High Limit ....................................................................................................................................................................................................................... 8

Intermittent Ignition Control Module ............................................................................................................................................................................... 8

Thermal Balancer ........................................................................................................................................................................................................... 9

Auto Reset High Limit Control ........................................................................................................................................................................................ 9

Safety Flow Switch ......................................................................................................................................................................................................... 9

Safety Relief Valves...................................................................................................................................................................................................... 10

Tank Temperature Control .............................................................................................................................................................................................11

Thermometers (not installed) ....................................................................................................................................................................................... 12

DRAIN VALVE ...................................................................................................................................................................................................................... 12

GENERAL ............................................................................................................................................................................................................................ 12

Required Ability ............................................................................................................................................................................................................ 12

Location ........................................................................................................................................................................................................................ 12

Air Requirements .......................................................................................................................................................................................................... 13

Chemical Vapor Corrosion............................................................................................................................................................................................ 13

Installation Clearances ................................................................................................................................................................................................. 14

Leveling ........................................................................................................................................................................................................................ 14

System Connections .................................................................................................................................................................................................... 14

VENTING ............................................................................................................................................................................................................................. 14

Venting the Boiler ......................................................................................................................................................................................................... 14

Venting Maintenance .................................................................................................................................................................................................... 16

Venting Sidewall ........................................................................................................................................................................................................... 16

Venting System ............................................................................................................................................................................................................ 16

Venting Tables .............................................................................................................................................................................................................. 17

SYSTEM INSTALLATIONS .................................................................................................................................................................................................. 18

Installations .................................................................................................................................................................................................................. 18

Conventional ........................................................................................................................................................................................................ 18

Linear Temp .......................................................................................................................................................................................................... 18

Water Supply Line ................................................................................................................................................................................................ 19

Expansion Tank .................................................................................................................................................................................................... 19

Vent Valves ........................................................................................................................................................................................................... 20

Manifold Headers ................................................................................................................................................................................................. 20

Cooling Piping ...................................................................................................................................................................................................... 20

Circulating Pump .................................................................................................................................................................................................. 20

Gas Connections .......................................................................................................................................................................................................... 20

Gas Supply Line Purging and Sizing ............................................................................................................................................................................ 21

Gas Pressure Regulators ............................................................................................................................................................................................. 22

WIRING ................................................................................................................................................................................................................................ 23

WIRING DIAGRAMS ....................................................................................................................................................................................................... 24-33

PIPING ............................................................................................................................................................................................................................34-39

OPERATION AND START-UP INSTRUCTIONS .................................................................................................................................................................. 39

Important ...................................................................................................................................................................................................................... 39

Filling the System ......................................................................................................................................................................................................... 39

Pilot Alignment and Main Burner .......................................................................................................................................................................................... 39

Lighting Instructions ................................................................................................................................................................................................ 43-44

Checking and Adjusting Input ....................................................................................................................................................................................... 41

Operating Sequence .................................................................................................................................................................................................... 42

REMOVAL OF EXISTING BOILER FROM A COMMON VENTING SYSTEM ..................................................................................................................... 45

GENERAL MAINTENANCE ................................................................................................................................................................................................. 45

Cleaning and Flushing Instructions ...................................................................................................................................................................................... 46

PRE TROUBLESHOOTING ................................................................................................................................................................................................. 46

TROUBLESHOOTING .................................................................................................................................................................................................... 47-54

LIMITED WARRANTY .......................................................................................................................................................................................................... 55

4

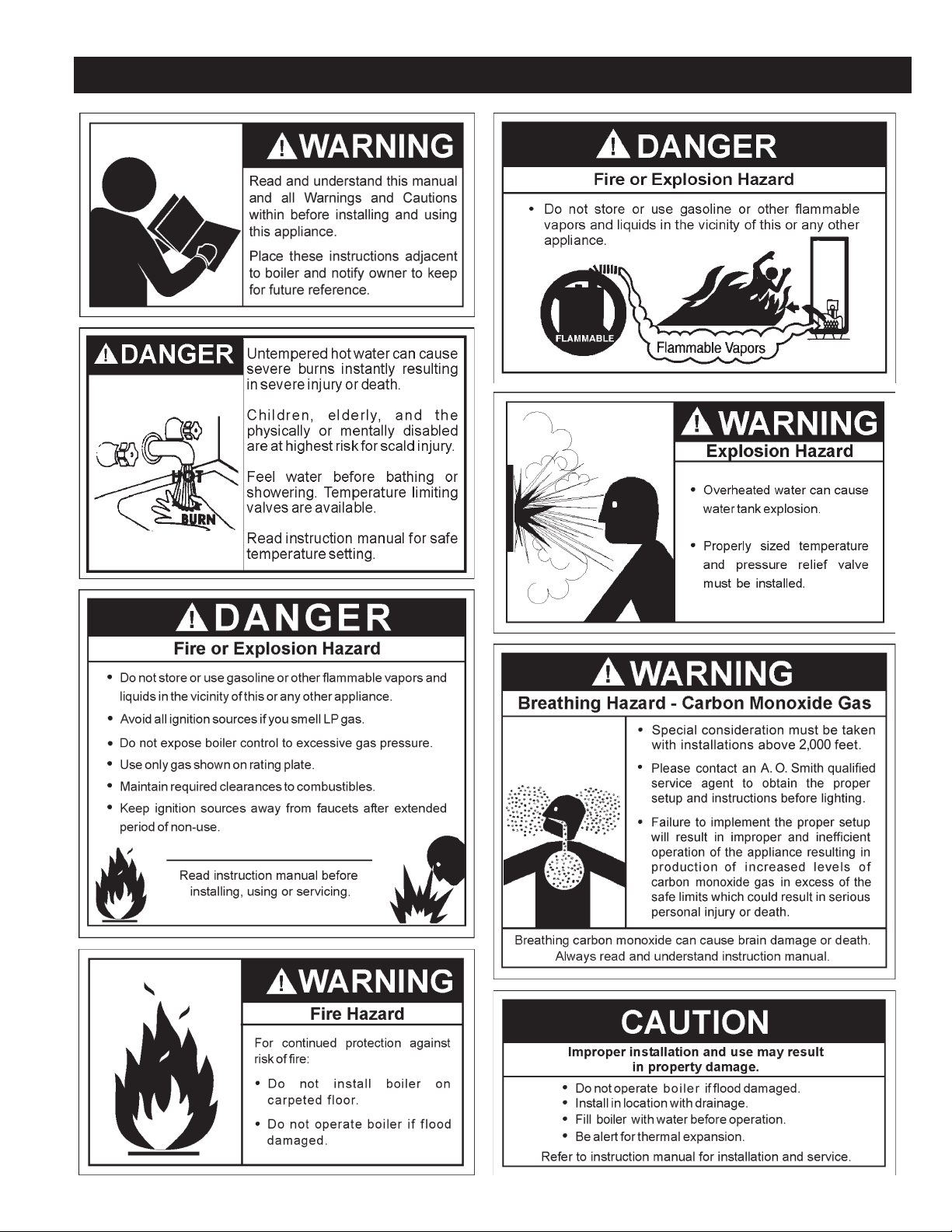

DIMENSIONS AND CAPACITY DATA

EXTRA OPENING

FOR THERMOMETER

AND RELIEF VALVE

HW-520, 610

AND HW--670

TABLE 1

MODELS

DIMENSIONS IN INCHES

A Overall height 65 (1651) 57-1/8 (1451) 57-1/8 (1451) 68-5/16 (1735) 67 (1702) 64-3/4 (1645)

B Height to Top of Jacket 43-1/4 (1099) 45-1/8 (1146) 45-1/8 (1146) 56-1/4 (1429) 56-1/4 (1429) 56-1/4 (1429)

C Floor to Center Line Water Inlet 36 (914) 38-3/4 (984) 38-3/4 (984) 46 (1168) 46 (1168) 46 (1168)

D Diameter of Jacket 25-1/4 (641) 27 (686) 27 (686) 27 (686) 27 (686) 27 (686)

E Floor to Center Line Water Outlet 12 (305) 12 (305) 12 (305) 12 (305) 12 (305) 12 (305)

F Draft Diverter Outlet Diameter 8 (203) 10 (254) 10 (254) 10 (254) 12 (305) 12 (305)

G Floor to Center Line Gas Inlet 16-1/2 (419) 16-3/4 (425) 16-3/4 (425) 18 (457) 18 (457) 18 (457)

H Overall Depth 29-5/8 (753) 31-1/2 (800) 31-1/2 (800) 36-1/2 (927) 36-1/2 (927) 36-1/2 (927)

J Support Height 9 (229) 9 (229) 9 (229) 9 (229) 9 (229) 9 (229)

K Width of Control String (approx.) 14 (356) 14 (356) 14 (356) 11 (279) 11 (279) 11 (279)

L Pipe Size of Water Inlet (NPT) 1-1/4 1-1/2 1-1/2 2 2 2

M Pipe Size of Water Outlet (NPT) 1-1/4 1-1/2 1-1/2 2 2 2

N Pipe Size of Gas Inlet (NPT) 3/4 1 1 1 1 1

P Control String Plus 1/2 Jacket Diameter (approx.) 26-5/8 (676) 27-1/2 (699) 27-1/2 (699) 24-1/2 (622) 24-1/2 (622) 24-1/2 (622)

S Horizontal Length between Water Inlet and Outlet 5-3/8 (137) 5-1/2 (140) 5-1/2 (140) 5-3/4 (146) 5-3/4 (146) 5-3/4 (146)

T Control String from Jacket 5 (127) 5 (127) 5 (127) 7 (178) 7 (178) 7 (178)

Approximate shipping weight lbs. (Kilograms) 240 (109) 291 (132) 291 (132) 361 (164) 361 (164) 361 (164)

NOTE: All dimensions in inches (millimeters) except pipe size which is NPT

HW-300 HW-399 HW-420 HW-520

PROPANE

HW-610/670

NATURAL

HW-610/670

5

TABLE 2, RECOVERY CAPACITIES

Input °F 20 40 50 60 70 80

Model

BTUH (kW) °C 11.1 22.2 27.7 33.3 38.8 44.4

HW 300 300,000 (88)

HW 399 399,000 (117)

HW 420 420,000 (123)

HW 520 520,000 (152)

HW 610 610,000 (179)

HW 670 660,000 (193)

GPH 1439 719 576 480 411 360

LPH 5448 2724 2179 1816 1556 1362

GPH 1914 957 765 638 547 478

LPH 7245 3623 2898 2415 2070 1811

GPH 2014 1007 806 671 576 504

LPH 7627 3813 3051 2542 2179 1907

GPH 2494 1247 998 831 713 624

LPH 9443 4721 3777 3148 2698 2361

GPH 2926 1463 1170 975 836 731

LPH 11077 5538 4431 3692 3165 2769

GPH 3165 1583 1266 1055 904 791

LPH 11985 5992 4794 3995 3424 2996

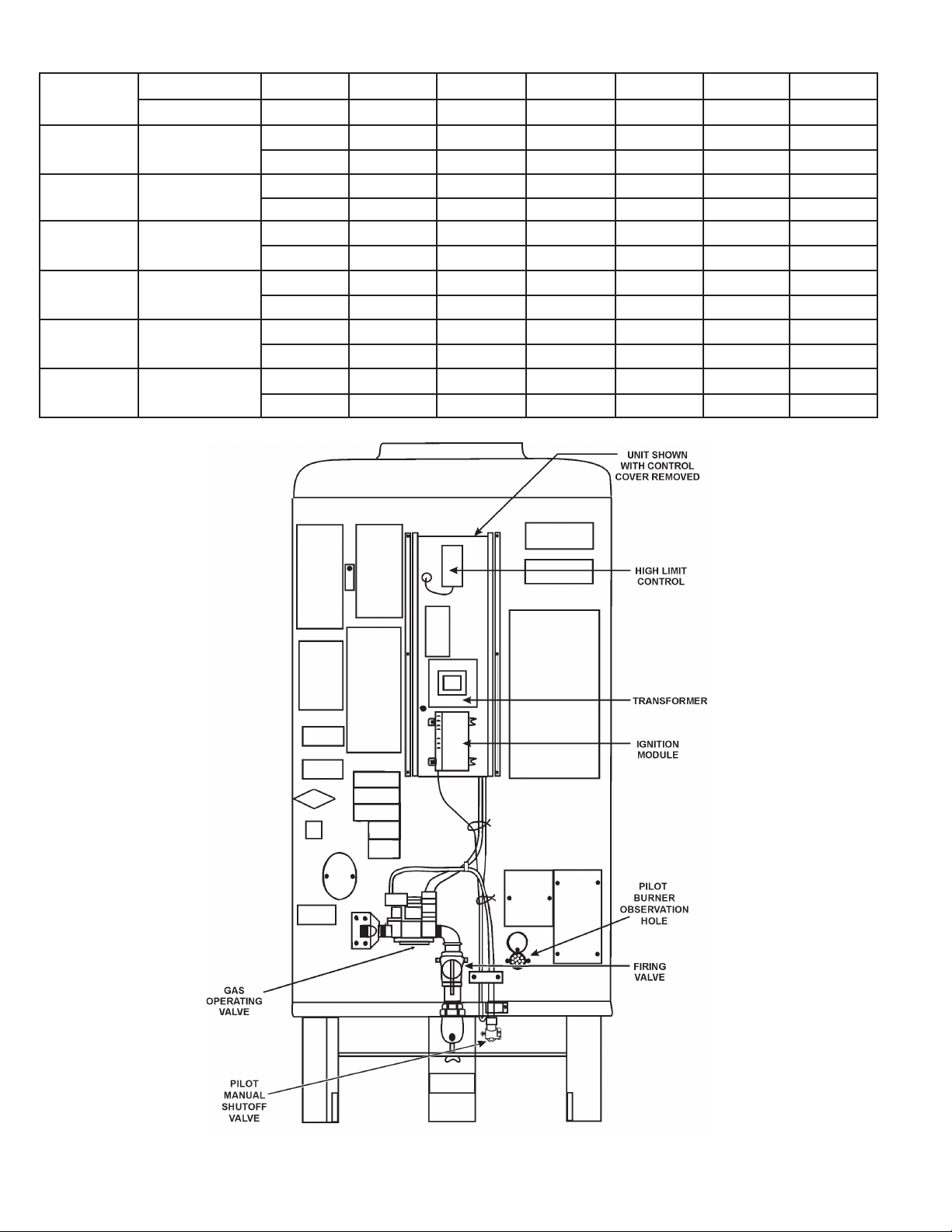

COMPONENT LOCATION

FIGURE 1.

6

INTRODUCTION

This design complies with the current edition of the ANSI Z21.13

low-pressure boiler standard.

Compliance under this standard implies that when the boiler

underwent test, the gas manifold and control assembly pro vided

on the boiler met safe lighting and other performance criteria.

Detailed installation diagrams are found in this manual. These

diagrams will serve to provide the installer a reference for the

materials and methods of piping necessary. It is essential that

all water, gas piping and wiring be installed as shown on the

diagrams. You should thoroughly read and understand this manual

before installation and/or operation of this boiler.

The factory warranty will be void if the boiler(s) have been

improperly installed or operated.

In addition to these instructions, the boiler(s) shall be installed

in accordance with those installation regulations in force in the

local area where the installation is to be made. These shall be

carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made.

In the absence of local codes, the installation must comply with the

current editions, as follows:

In the United States:

The National Fuel Gas Code, ANSI Z223.1/NFPA 54 and the

National Electric Code, NFPA 70.

In Canada:

Installation Code CAN/CSA B149.1 and Canadian Electrical Code,

CSA C22.1.

GROUNDING INSTRUCTIONS

IF THE BOILER HAS BEEN EXPOSED TO FLOODING, IT

MUST BE REPLACED.

LIQUEFIED PETROLEUM GAS MODELS

Boilers for propane or liquefied petroleum gas (LPG) are different

from natural gas models. A natural gas boiler will not function

safely on LP gas and no attempt should be made to convert a

boiler from natural gas to LP gas.

LP gas m ust be use d w i th g reat cau tion . I t is h ighl y

ex plo sive and h eavie r tha n air. It col lects f irs t in the low

ar eas m aki ng its odo r dif ficul t to det ect a t nose lev el.

If LP gas is prese nt or even sus pec ted, do not atte mpt

to fi nd the c aus e you rself . Lea ve the b uil ding, le avi ng

do ors open to ve nti late, t hen cal l your gas sup pli er o r

se rvi ce a gent. Kee p ar ea c lea r un til a se rvice cal l ha s

been made.

At ti mes you ma y not be ab le to smel l an LP gas leak.

On e c aus e is odor fad e, whic h i s a los s o f t he chemic al

od ora nt th at give s LP ga s its di stinc tiv e sme ll. An oth er

ca use can b e y our p hys ica l con dit ion, suc h a s hav ing

a c o ld o r d imin i shin g s ense o f smel l with a g e. F o r

the se r eas o ns, the u se o f a p rop a ne g as d etec tor i s

recommended.

IF YOU E XPE RIENC E AN OUT OF GAS S ITU ATION, D O

NO T T RY TO RELIGHT APP LIA NCES Y OUR SELF. Call

yo ur l oca l serv ice age nt. On ly t rained LP profe ssi ona ls

sh oul d co ndu ct t he r equ ired safety checks in accord anc e

with industry standards.

HIGH ALTITUDE INSTALLATIONS

This boiler must be grounded in accordance with the National Electrical

Code, Canadian Electrical Code and/or local codes. Correct wiring is

imperative for proper operation.

This boiler must be connected to a grounded metal, permanent

wiring system, or an equipment grounding conductor must be run

with the circuit conductors and connected to the equipment grounding

terminal or lead on the boiler.

CORRECT GAS

MAKE SURE THE GAS ON WHICH THE BOILER WILL

OPERATE IS THE SAME AS THAT SPECI FIED ON THE

BOILER RATING PLATE. DO NOT INSTALL THE BOILER IF

EQUIPPED FOR A DIFFERENT TYPE OF GAS — CONSULT

YOUR SUPPLIER.

PRECAUTIONS

IF THE UNIT IS EXPOSE D TO THE FOLLOWING, D O NO T

OPERATE UNTIL ALL CORRECTIVE S TE PS HAVE B EE N

MADE BY A QUALIFIED SERVICEMAN:

1. EXPOSURE TO FIRE.

2. IF DAMAGED.

3. FIRING WITHOUT WATER.

4. SOOTING.

Rated inputs are suitable up t o 2000 feet (61 0 m) elevation.

Co nsu lt the factory for i nst all ation a t alt itu des ove r 200 0

feet (610 m).

7

HIGH ALTITUDE INSTALLATIONS

IN CANADA

Acceptance of these models for use at altitudes above 2000 feet

(600 m) is based on eld test of the individual installation by the

provincial/state authority having jurisdiction.

IN THE U.S.A.

WARNING

INSTALLATIONS ABOVE 2000 FEET REQUIRE REPLACEMENT

OF THE BURNER ORIFICES IN ACCORDANCE WITH THE

CURRENT EDITION OF THE NATIONAL FUEL GAS CODE

(ANSI Z223.1). FAILURE TO REPLACE THE ORIFICES WILL

RESULT IN IMPROPER AND INEFFICIENT OPERATION OF THE

APPLIANCE RESULTING IN THE PRODUCTION OF INCREASED

LEVELS OF CARBON MONOXIDE GAS IN EXCESS OF SAFE

LIMITS WHICH COULD RESULT IN SERIOUS PERSONAL

INJURY OR DEATH.

For specic orice requirements, please refer to the appropriate

section of the National Fuel Gas Code ANSI Z223.1.

You should contact your gas supplier for any specic changes which

may be required in your area.

Ratings specified by manufacturers for most boilers apply for

elevations up to 2000 feet (600 m). For elevations above 2000 feet

(600 m) ratings must be reduced by a rate of 4% for each 1000 feet

(300 m) above sea level.

Example: If a boiler is rated at 610,000 Btu/hr. at sea level, to operate

the boiler at 5000 feet (1500 m) it must be derated by 20% (4% x 5)

to a new rating of 488,000 Btu/hr.

A. O. Smith does build some models specically for high altitude

service. Please check the rating plate before making changes.

The input reduction is primarily achieved by reducing the size

of the main burner orifices. To do this, the main burner orifices

re qui re repl aceme nt with orific es size d for the pa rticu lar

installation elevation. When ordering, be sure to state the model

number and the altitude of the location where the boiler is being

installed.

Upon field deration of the boiler, adjustment to the gas pressure

regulator is required. See CHECKING AND ADJUSTING

THE INPUT in this manual for inlet and manifold pressure

requirements. Also, due to the input rating reduction required at

high altitudes, the output rating of the appliance is also reduced

and should be compensated for in the sizing of the equipment

for applications.

CONTROLS AND FUNCTION

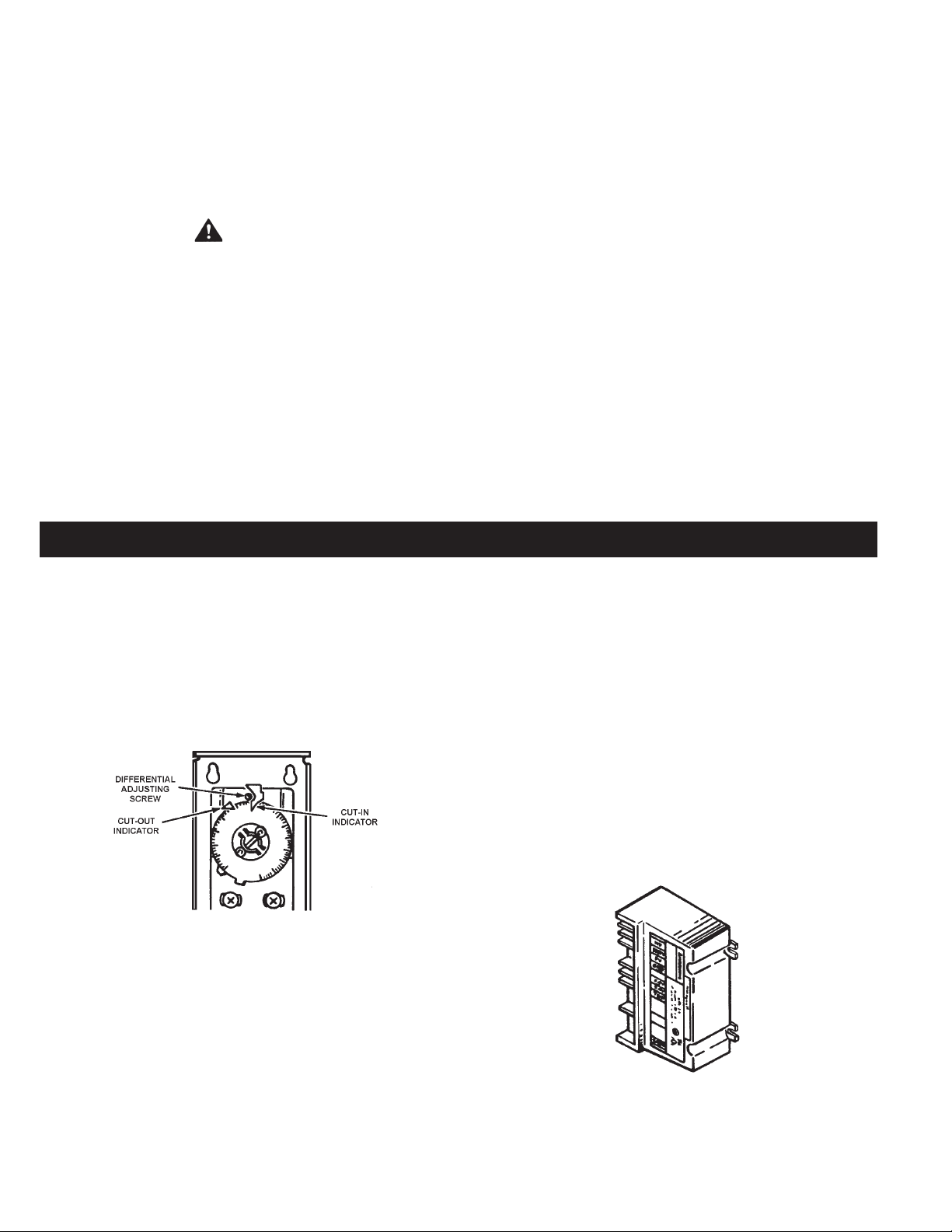

AUTO RESET HIGH LIMIT

Th e hig h l im it is a safety devic e w ired in s eries wit h t he

ignition system. Set the high limit control to approximately 10

ab ove the maxi mum d esigned system temper at ure. If th e

boi ler out let wa ter te mpe r atu re shou l d exc e ed the hig h

limit setting, the main gas valve will close but the circulator

will continue to operate. Maximum adjustable setting is 115

(239°F) cut-out with a 3

0

C (50F) to 250C (450F) adjustable

differential, see Figure 2.

FIGURE 2.

INTERMITTENT IGNITION CONTROL MODULE

The Honeywell S-8600 control module contains the electronic

components of the system and also serves as a control wiring system

for the controls mounted on the heater. The control module performs

the following functions:

0

F

0

C

3. Opens the pilot valve.

4. Discontinues ignition spark when the pilot flame is established.

The S-8600 control used on propane gas models provides

safety lockout if the pilot fails to ignite within the pilot flame

estab lishing period. The S-8600 control used on natural

gas models continues trial for ignition until pilot flame

is established.

5. After proof of pilot ame, opens then main valve.

6. On a power loss, shuts the heater down. When power is restored

it will begin a new ignition cycle.

7. On a loss of ame, shuts off main gas and starts trial for pilot ignition.

PLEASE SEE TROUBLESHOOTING SECTION FOR MORE

INFORMATION.

1. Checks for safe-start by sensing for a false ame condition on

start-up.

2. Generates a potential of 15,000 volts for spark ignition of the

pilot burner.

S-8600 INTERMITTENT IGNITION

CONTROL MODULE (IID)

FIGURE 3.

8

THERMAL BALANCER

Figure 4 shows the internal wiring of the thermal balancer. The

device may be tested after disconnecting the four leads from their

respective terminals on the unit.

1. Apply a test light to the yellow and red leads.

• The lamp should light as the contact in this circuit is normally

closed when the resistor is cool.

2. Apply a light to the black and yellow leads.

• The lamp should not light as the contact in this circuit is normally

open when the resistor is cool.

3. Remove the test light.

4. Apply 120 volts to the white and red leads which power the 1900

ohm resistor. After a warming period the contacts of the thermal

balancer should operate.

5. Remove the test light.

6. Apply the test light as described in steps 1 and 2.

While the resistor is still warm the lamp indications should be the

opposite as described previously.

FIGURE 4.

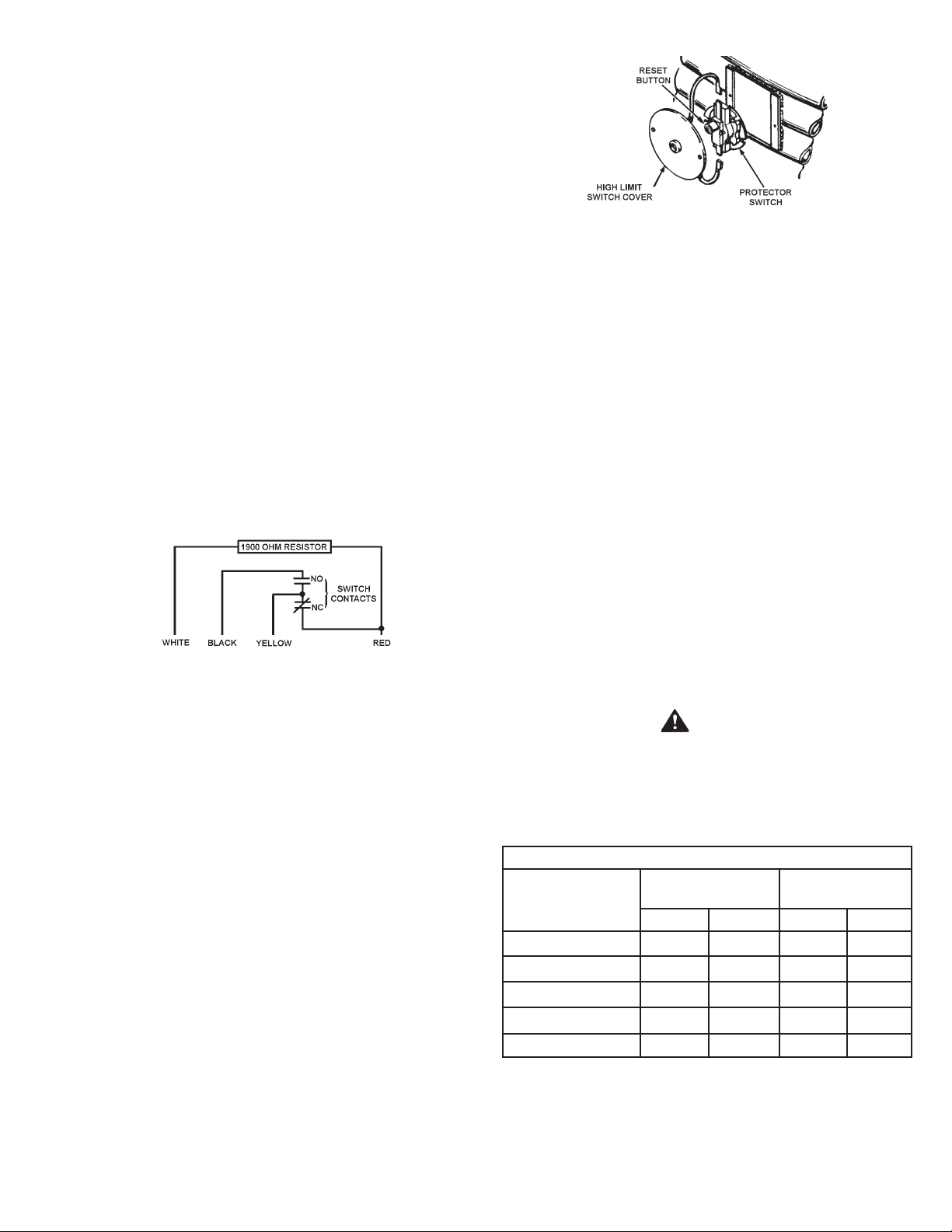

HIGH LIMIT SWITCH

FIGURE 5.

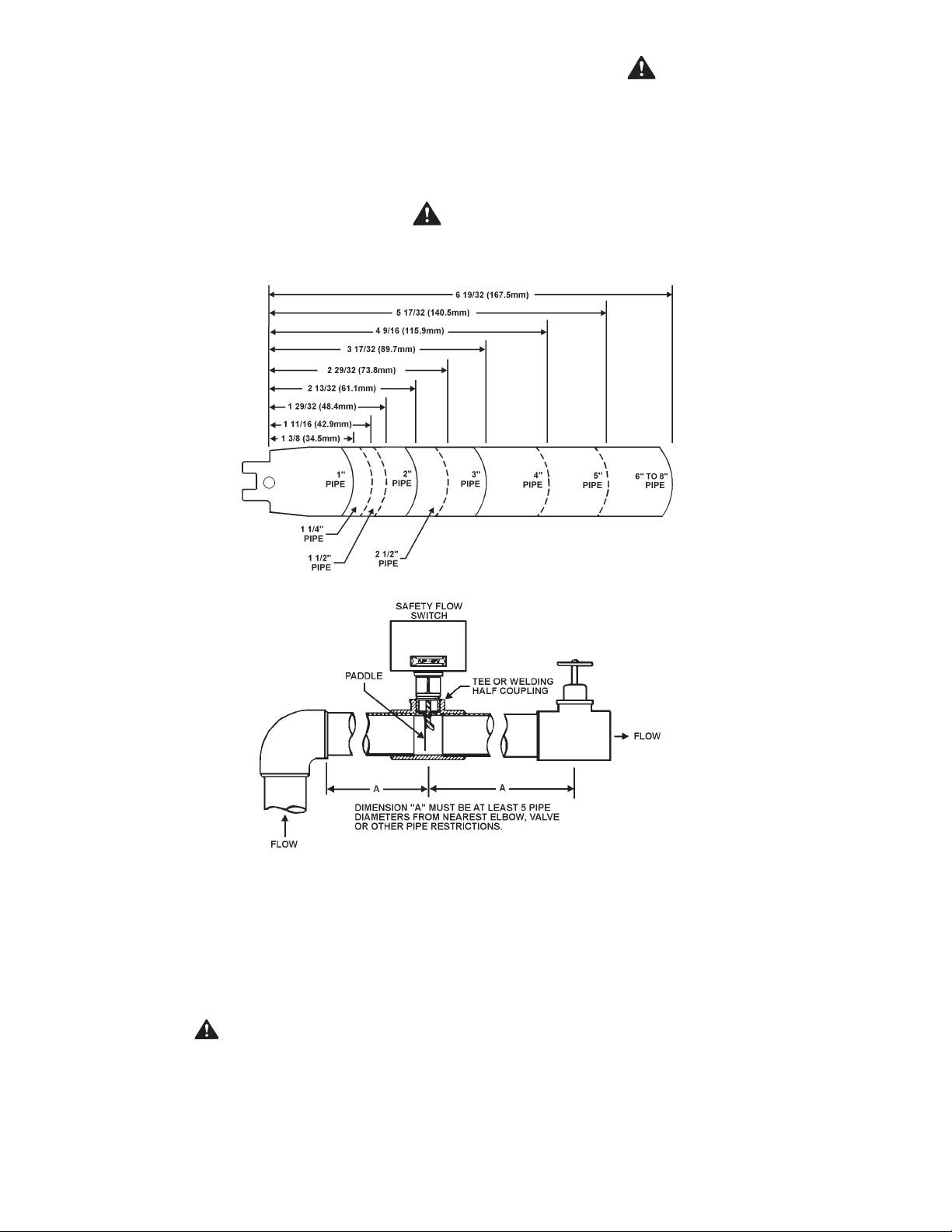

SAFETY FLOW SWITCH

The safety ow switch is a safety device which must be installed at

the water outlet of the unit to prevent main burner operation in the

event of inadequate water ow through the unit.

An accessory package containing a safety ow switch is available

for this application.

This switch may be mounted in a horizontal pipe line or a vertical

pipe line with upward water ow. Do not install the switch where the

water ow is downward.

For proper performance mount the switch in a section of pipe where

there is a straight run of at least 5 pipe diameters on each side of the ow

switch (i.e. do not locate adjacent to valves, elbows, orices, etc.).

The ow switch shall be mounted in a standard 1-1/2" x 1-1/2" x 1"

tee for a 1-1/2" pipe application. For larger pipe sizes use a reducing

tee in order to keep the switch as close to the pipe as possible. Install

the ow switch in the branch (top) opening of the reducing tee and

provide adequate paddle length in the ow stream. For example in

a 2" pipe installation use a 2" x 2" x 1" reducing tee. For 2", or 3"

pipe use paddle segments as supplied. For other pipe sizes (i.e.

1-1/4", 1-1/2" and 2-1/2") trim the paddle to the proper pipe size, see

Figure 6 on page 10. If a standard tee is used, install a face or hex

bushing in the top opening. The paddle must be adjusted or trimmed

to the size of the pipe in which it will be installed.

MANUAL RESET HIGH LIMIT

This boiler is equipped with a manual reset high limit switch,

located under the small cover on the side of the jacket, see

Fi gur e 5. T his devi ce p rov ide s posi tiv e s hut dow n of the

boiler in the event of boiler or system malfunction. Should the

surface temperatu re of the copper t ubing hea t exc ha nger

rea ch 25 0 °F (12 0°C), th e h i gh li mit sw itc h will ac tiv ate ,

the gas valve will c lose, the pilot and main burners will be

extinguished. If the high limi t switch should shut of f unit, check

the following conditions:

• No water in boiler.

• Restricted water flow through the boiler.

• Improper wiring (boiler firing without circulator

operating).

• Pump failure.

After correcting failure condition remove the protector switch cover

and push the reset button. The high limit switch may be reset after

the coil surface cools to 6°F (3.3°C) below the trip setting.

CAUTION

Any part of the paddle must not touch the pipe or any restrictions in

the pipe. Screw the ow switch in position so the at of the paddle

is at right angles to the ow. The arrow on the side case must point

in the direction of the ow.

TABLE 3 - SAFETY FLOW SWITCH

Minimum Pipe Rate

Model Number

Contacts Closed

(Flow)

Contacts Open

(No Flow)

GPM LPM GPM LPM

HW-300 5.8 22.0 3.7 14.0

HW-399 7.5 28.4 5.0 18.9

HW-420 7.5 28.4 5.0 18.9

HW-520 13.7 51.9 9.5 36.0

HW-610/670 13.7 51.9 9.5 36.0

The safety ow switch may be eld adjusted to obtain higher

minimum ow rates than those shown in table 3.

9

To adjust the ow rate setting:

1. Remove the ow switch cover.

2. For higher ow rate - turn the range adjusting screw clockwise.

CAUTION

The switch is factory set at approximately the minimum ow rate, see

Table 3 on page 9. It must not be set lower than the factory setting as

this may result in the switch failing to return at 'no ow' condition.

3. For lowe r flow rat e - tur n the rang e adjus tin g sc rew

counterclockwise.

CAUTION

Paddle must be trimmed at the dotted arc. It must not touch the pipe or have any restriction when installed.

4. Replace ow switch cover. Where units are installed in multiples,

each boiler must be individually protected by a safety ow switch.

FIGURE 6.

SAFETY RELIEF VALVES

Your local code authority may have other specic relief valve

requirements not covered below.

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE OR TEMPERATURE INTO THE STEAM

RANGE WHICH MAY CAUSE SCALDING AT FIXTURES, TANK

EXPLOSION, SYSTEM OR BOILER DAMAGE.

TO AVOID SCALDING OR WATER DAMAGE A DRAIN LINE MUST

BE CONNECTED TO A RELIEF VALVE TO DIRECT DISCHARGE

TO A SAFE LOCATION. A DRAIN LINE MUST NOT BE REDUCED

FROM THE SIZE OF THE VALVE OUTLET AND IT MUST NOT

CONTAIN ANY VALVES BETWEEN THE BOILER AND THE

RELIEF VALVE OR THE RELIEF VALVE AND THE DRAIN EXIT.

IN ADDITION, THERE SHOULD NOT BE ANY RESTRICTIONS

IN A DRAIN LINE NOR SHOULD IT BE ROUTED THROUGH

AREAS WHERE FREEZING CONDITIONS MIGHT OCCUR. DO

NOT THREAD OR CAP THE DRAIN LINE EXIT. RESTRICTING

OR BLOCKING A DRAIN LINE WILL DEFEAT THE PURPOSE OF

THE RELIEF VALVE AND MAY CREATE AN UNSAFE CONDITION.

INSTALL A DRAIN LINE WITH A DOWNWARD SLOPE SUCH THAT

IT NATURALLY DRAINS ITSELF.

If any safety relief valve is replaced, the replacement valve must comply

with the current editions of the ASME Boiler and Pressure Vessel

10

Code, Section IV or CSA B51, as applicable. Select a relief valve with

a discharge NOT less than the boiler input, and a pressure rating NOT

exceeding the working pressure of any component in the system.

A. O. Smith supplies a 125 psi relief valve for hot water supply systems

and 50 psi relief valve for space heating application.

An ASME rated temperature and pressure relief valve must be installed

on each and every water storage tank in a hot water supply system.

The storage tank temperature and pressure (T & P) relief valve must

comply with the applicable contruction provisions of the Standard

for Relief valves and Automatic Gas Shutoff Devices for Hot Water

Supply Systems, Z21.22 - CSA 4.4. The T & P valve must be of the

automatic reset type and not embody a single-use type of fusible

plug, cartridge or linkage.

The T & P relief valve should have a maximum temperature rating

of 100°C (210°F), a pressure rating NOT exceeding the lowest

rated working pressure of any system component, and a discharge

capacity exceeding the total input of the water boilers supplying

water to the storage tank.

Locate the T & P relief valve (a) in the top of the storage tank or (b)

in the side of the tank on centerline within upper 6 inches from the

top of the tank. See Figures 28 to 33, Pages 34 to 38. Tapping shall

be threaded in accordance with the latest version of the Standard for

Pipe Threads, General Purpose (inch), ANSI/ASME B.120.1.

TANK TEMPERATURE CONTROL

The water temperature in the storage tank is controlled by the Tank

Temperature Control. The sensing element is mounted inside the

hot water storage tank.

DANGER

HOT WATER TEMPERATURES REQUIRED FOR AUTOMATIC

DISHWASHER AND LAUNDRY USE CAN CAUSE SCALD BURNS

RESULTING IN SERIOUS PERSONAL INJURY AND/OR DEATH.

THE TEMPERATURE AT WHICH INJURY OCCURS VARIES

WITH THE PERSON’S AGE AND TIME OF EXPOSURE. THE

SLOWER RESPONSE TIME OF CHILDREN, AGED OR DISABLED

PERSONS INCREASES THE HAZARDS TO THEM. NEVER ALLOW

SMALL CHILDREN TO USE A HOT WATER TAP, OR TO DRAW

THEIR OWN BATH WATER. NEVER LEAVE A CHILD OR DISABLED

PERSON UNATTENDED IN A BATHTUB OR SHOWER.

Mark location with a class III Label. See ANSI Z21.10.1, Part 1,

Marking, See CAN/CSA B149.

The tank temperature control is adjustable from 100°F (37.7°C) to

220°F (104.4°C). It is recommended that lower water temperatures

be used to avoid the risk of scalding. It is further recommended, in all

cases, that the water temperature be set for the lowest temperature

which satises the user’s hot water needs. This will also provide the

most energy efcient operation of the water heater and minimize

scale formation.

THE WATER HEATER SHOULD BE LOCATED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO SET

TEMPERATURES. SETTING THE WATER TEMPERATURE AT

120°F (49°C) WILL REDUCE THE RISK OF SCALDS. Some states or

provinces require settings at specic lower temperatures. Below you

will nd listed the approximate time-to-burn relationship for normal

adult skin. Valves for reducing point-of-use temperature by mixing

cold and hot water are available. Also available are inexpensive

devices that attach to faucets to limit hot water temperatures. Contact

a licensed plumber or the local plumbing authority.

11

Water Temperature

OVER: 170°F (77°C)

160°F (71°C)

150°F (65°C)

140°F (60°C)

130°F (54°C)

120°F (49°C)

USE ANTI-SCALD VALVE(S) in the hot water system to reduce

the risks of scalds at points of use such as lavatories, sinks

and bathing facilities.

A change in water temperature in the storage tank lower than

the Tank Temperature Control setting will c ause the sensor to

close its contacts and consequently energize the boiler.

If the Tank Temperature Control is out of calibration, replace it

with a new one; do not attempt to fix this control.

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN O FF THE MANUAL G AS CONTROL

VALVE TO THE APPLIANCE.

Time to Produce 2nd & 3rd

Degree Burns on Adult Skin

Nearly Instantaneous

About 1/2 second

About 1-1/2 seconds

Less than 5 seconds

About 30 seconds

More than 5 minutes

WARNING

THERMOMETERS

Thermometers should be obtained and field installed as shown

in the installation diagrams.

The rmom e ter s are ins tall e d in th e sys tem a s a mea n s

of de t e ctin g a p ossi b l e limi n g condi t i on in t h e boile r.

An incr ease of 5°F (3°C ) ov er the norma l te m per a tur e

rise t h r o u g h t h e boiler i s a n i n d i c a t i o n t h a t l i m e i s

p r e sen t . T he t e r m " t emp e rat u r e r ise " d es ign a t es

the diff ere nce be twe en the boil er inle t and ou tle t wate r

temperature.

An inc rease of 5°F (3°C) above the rec orded temperature

rise may signi f y a li ming con diti o n in the coil s or he at

e x c ha n ge r . R e fe r t o C L E A NI N G A N D F L US H IN G

section of this manual for deliming instructions.

Rec o r d temperature rise at i n i t i a l st a r t - up f o r future

reference.

DRAIN VALVE (Not Supplied)

A drain valve must be obtained and installed on each boiler

and tank for draining purposes, see installation diagrams in

this manual.

GENERAL

REQUIRED ABILITY

Installation or service of this boiler requires ability equivalent to that

of a licensed tradesman in the eld involved. Plumbing, air supply,

venting, gas supply and electrical work are required.

LOCATION

When installing the boiler, consideration must be given to proper

location. Location selected should be as close to the stack or chimney

as practicable with adequate air supply and as centralized with the

piping system as possible. This location should also be such that the

gas ignition system components are protected from water (dripping,

spraying, etc.) during appliance operation and service (circulator

replacement, control replacement, etc.).

THE BOILER MUST NOT BE INSTALLED ON CARPETING.

THE BOILER SHOULD NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

LOCATE IT NEAR A FLOOR DRAIN. THE BOILER SHOULD BE

LOCATED IN AN AREA WHERE LEAKAGE FROM THE BOILER OR

CONNECTIONS WILL NOT RESULT IN DAMAGE TO THE ADJACENT

AREA OR TO LOWER FLOORS OF THE STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A METAL

DRAIN PAN SHOULD BE INSTALLED UNDER THE BOILER. Such

pans should be fabricated with sides at least 60mm (2-1/2") deep,

with length and width at least 50mm (2") greater than the diameter

of the boiler and must be piped to an adequate drain. The pan must

not restrict combustion air ow.

WARNING

KEEPING BOILER AREA CLEAR AND FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS AND

LIQUIDS.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS BOILERS IN ROOMS OR AREAS WHERE GASOLINE,

OTHER FLAMMABLE LIQUIDS OR ENGINE DRIVEN EQUIPMENT

OR VEHICLES ARE STORED, OPERATED OR REPAIRED.

FLAMMABLE VAPORS ARE HEAVY AND TRAVEL ALONG THE

FLOOR AND MAY BE IGNITED BY THE IGNITER OR MAIN BURNER

FLAMES CAUSING FIRE OR EXPLOSION. SOME LOCAL CODES

12

PERMIT OPERATION OF GAS APPLIANCES IF INSTALLED

18 INCHES OR MORE ABOVE THE FLOOR. THIS MAY

REDUCE THE RISK IF LOCATION IN SUCH AN AREA CANNOT

BE AVOIDED.

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE BOILER.

OPEN CONTAINERS OF FLAMMABLE MATERIAL MUST

NOT BE STORED OR USED IN THE SAME ROO M WITH

THE BOILER.

A hot water boiler installed above radiation level or as required

by the authority having jurisdiction, must be provided with a low

water cutoff device at the time of boiler installation.

AIR REQUIREMENTS

Provisions for combustion and ventilation air in accordance

w i t h t h e c u r ren t e d iti o n o f t h e N a ti ona l F u el G as

C o d e , A NS I Z 2 2 3. 1, C A N / CS A B 1 4 9 .1 , I n st alla t i o n

C o d e s , o r a p p l i c a b l e p r o v i s i o n s o f t h e l o c a l

building codes.

Provisions for vent, bleed and gas relief lines (when applicable).

Keep appliance area free of combustible or ammable liquids.

If the confined space is within a building of tight construction,

air for combustion, ventilation, and draft hood dilution must be

obtained from outdoors. When directly communicating with the

outdoors or communicating with the outdoors through vertical

ducts, two permanent openings, located in the above manner,

shall be provided. Each opening shall have a free area of not

less than one square inch per 4000 Btuh of the total input of

all appliances in the enclosure. If horizontal ducts are used,

each o pe ni ng shall h ave a free area of not less tha n one

square inch per 2000 Btuh of the total input of all appliances

in the enclosure.

(b) Canadian Installations

Ventilation of the space occupied by the b oiler(s) shall be

provided by an opening for ventilation air at the highest practical

point communicating with outdoors. The total cross-sectional

area shall be at least 10% of the area of the combustion air

opening but in no case shall the cross-sectional area be less

than 10 square inches (6500 mm

2

).

In additional to the above, there shall be permanent air supply

opening(s) having a cross-sectional area of not less than 1

square inch per 7,000 BTUH (310 mm

2

/KW) up to and including

1,000,000 BTUH plus 1 square inch per 14,000 BTU in excess

of 1,000,000 BTUH. This opening(s) shall be located at, or

ducted to, a point neither more than 18" (450 mm) nor less

than 6 inches (150 mm) above the floor level.

Do not obstruct the ow of combustion or ventilating air.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN AIR CONTAMINATION THAT

MAY BE HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN

WILL RESULT IN A YELLOW, LUMINOUS BURNER FLAME,

CAUSING CARBONING OR SOOTING OF THE COMBUSTION

CHAMBER, BURNERS AND FLUE TUBES AND CREATES A

RISK OF ASPHYXIATION.

Unconned Space

In buildings of conventional frame, brick or stone construction,

unconned spaces may provide adequate air for combustion, and

draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.) air for combustion,

ventilation, and draft hood dilut io n must be obt ained from

outdoors or spaces freely communicating with the outdoors. The

installation instructions for confined spaces in tightly constructed

buildings must be followed to ensure adequate air supply.

Conned Space

(a) U. S. Installations

When drawing combustion and dilution air from inside a conventionally

constructed building to a conned space, such a space shall be

provided with two permanent openings, ONE WITHIN 12 INCHES

OF THE ENCLOSURE TOP AND ONE WITHIN 12 INCHES OF THE

ENCLOSURE BOTTOM. Each opening shall have a free area of at

least one square inch per 1000 Btuh of the total input of all appliances

in the enclosure, but not less than 100 square inches.

Where power vented equipment is used in the same room as the

boiler, sufcient air openings must be supplied.

UNDERSIZED OPENINGS MAY RESULT IN INSUFFICIENT AIR

FOR COMBUSTION.

WHERE AN EXHAUST FAN IS INSTALLED IN THE SAME ROOM

WITH A BOILER, SUFFICIENT OPENINGS FOR AIR MUST BE

PROVIDED IN THE WALLS.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT WITH AN INCREASED

RISK O F ASPHYXIATION.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION O F T H E FLUE W AY S A N D VENT SYSTEM

MAY OCCUR IF AIR FOR COMBUSTION CONTAINS

C E R TA I N C H E M I C A L V A P O R S W H I C H B R E A K

DOWN IN TO A C I D S AT HIGH T E M P E R AT U R E . SUCH

CORROSION M AY R E S U LT I N FA I L U R E A N D R I SK OF

ASPHYXIATION.

Water boiler corrosion and component failure can be caused

by the heating and breakdown of airborne chemical vapors.

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium

and sodium chloride, waxes, and process chemicals are typical

compounds which are corrosive. These materials are corrosive

at very low concentration levels with little or no odor to reveal

their presence. Products of this sort must not be stored near

the boiler. Also, air which is brought in contact with the water

boiler should not contain any of these chemicals. If necessary,

uncontaminated air should be obtained from remote or outside

sources.

13

INSTALLATION CLEARANCES

These boilers are approved for installation on combustible ooring

in an alcove with minimum clearance to combustibles of:

TABLE 4

HW

300

TOP 28" (711.2) 32" (812.8) 24" (609.6) 24" (609.6) 24" (609.6)

SIDES 6" (152.4) 6" (152.4) 24" (609.6) 24" (609.6) 24" (609.6)

HW

399

HW

420

HW

520HW610 & 670

Sufcient area should be provided at the front and rear of the unit

for proper servicing. Clearances of 24 inches (609.4mm) in the

rear and 48 inches (1,219mm) in the front are required by code.

In a utility room installation, the door shall be wide enough to allow

the boiler to enter or to permit the replacement of another appliance

such as a water heater.

LEVELING

Each unit should be checked after installation to be certain that it is level.

If the unit is not level, insert metal shims under the legs of the unit

to correct this condition.

REAR 6" (152.4) 6" (152.4) 24" (609.6) 24" (609.6) 24" (609.6)

VENT 6" (152.4) 6" (152.4) 6" (152.4) 6" (152.4) 6" (152.4)

Two inch (50.8mm) clearance is allowable from combustible

construction for hot water pipes.

SYSTEM CONNECTIONS

The system installatio n must conform to these instructions

and to the requirements of the local code authority having

jurisdiction. Good practice requires that all heavy piping be

supported.

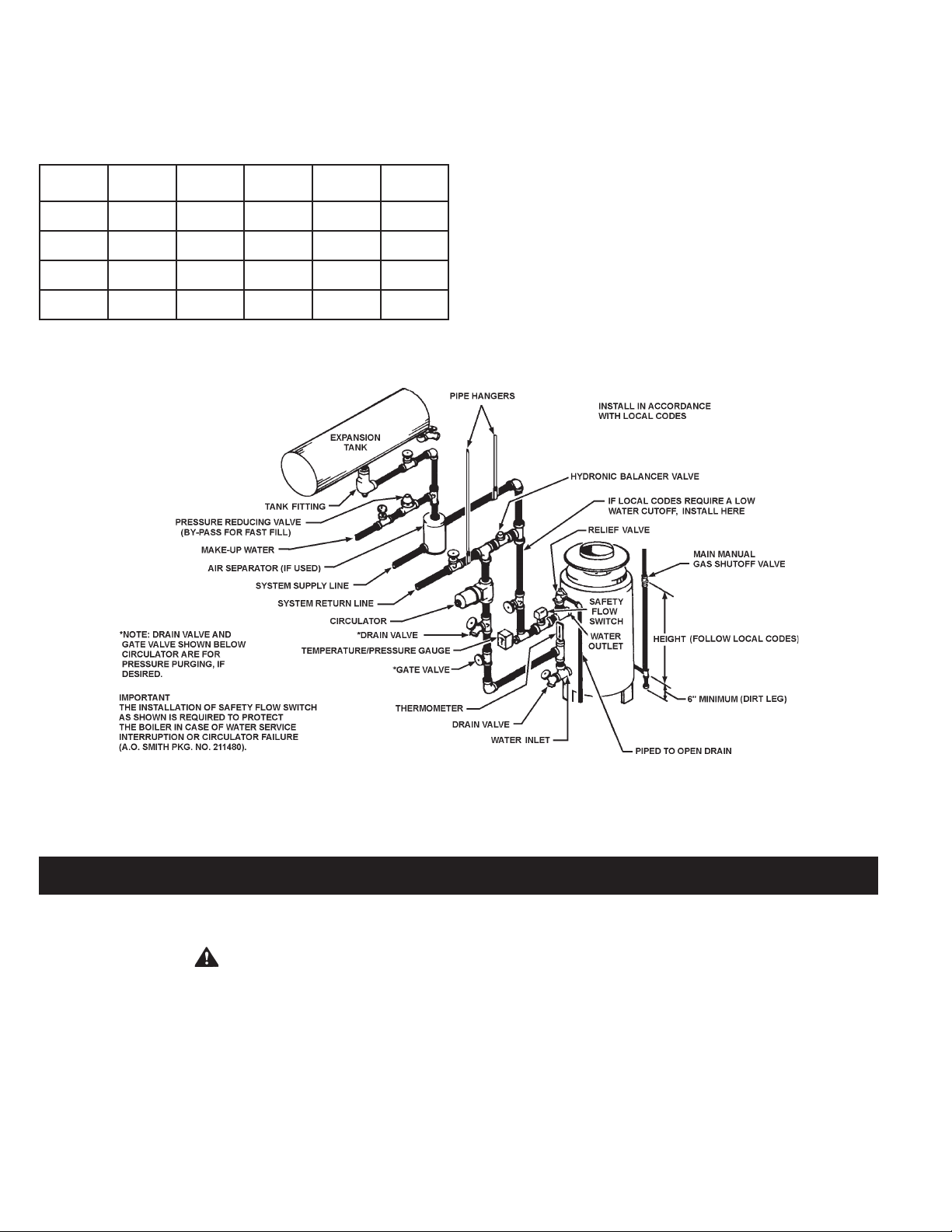

A TYPICAL BOILER INSTALLATION

FIGURE 7.

VENTING

VENTING THE BOILER - STANDARD VENTING

WARNING

THE INS T RUCT I ONS IN THIS SE CTIO N ON VEN TING

TH E BOILER M UST BE FOLLOWED TO AVOI D CHOK ED

COM B UST ION OR RECI RCU L AT ION OF FLUE GA SES .

SUCH CONDITIONS CAUSE SOOTING OR RISKS OF FIRE

AND ASPHYXIATION.

TYPE B VENTING MAY BE USED WITH THESE BOILERS. ALL

LOCAL UTILITY REGULATIONS ON VENTING SHOULD BE

FOLLOWED.

For boilers for connection to gas vents or chimneys, vent sizing,

installation and termination shall be in accordance with the

current edition of the National Fuel Gas Code, ANSI Z223.1, or

CAN/CSA B149.1, Installation Codes, or applicable provisions

of the local building codes.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

The minimum distance from adjacent public walkways, adjacent

buildings, openable windows and building openings shall not be

less than those values specif ied in the National Fuel Gas Code,

ANSI Z223.1 and/or CAN/CSA B149.1, Installation Codes;

Stack or chimney must be a minimum height of 12 " (305mm)

above the annual snow fall to prevent blockage.

14

Building materials must not come in contact with combustion

products from stack or chimney, due to the degradating properties

of ue products.

Vent connectors serving appliances vented by natural draft shall not

be connected into any portion of mechanical draft systems operating

under positive pressure.

Flue products must have a minimum clearance of 4 feet (1.22m)

horizontally from, and in no case above or below, unless a 4-foot

(1.22m) horizontal distance is maintained, from electric meters, gas

meters, regulators and relief equipment.

CAN/CSA B149.1, Installation Code species a 6 foot horizontal

vent terminal clearance to gas and electric meters and relief devices

(this clearance is specied as 4 feet in the U.S. under the National

Fuel Gas Code, ANSI/Z223.1). Therefore instruction, which species

compliance with the 4 foot clearance, as applies in the U.S. only, and the

CAN/CSA B149.1 Installation Code applies in Canada.

1. DRAFT HOOD

The draft hood furnished with this boiler must be installed without

alteration. Provision must be made if the boiler is installed in conned

space or a small boiler room to accommodate draft hood spillage and

avoid risks described above. The upper air opening called for in the

AIR REQUIREMENTS section of this manual is for this purpose.

2. VENT CONNECTION

Size and install proper size vent pipe. Do not reduce pipe size to

less than that of the draft hood outlet.

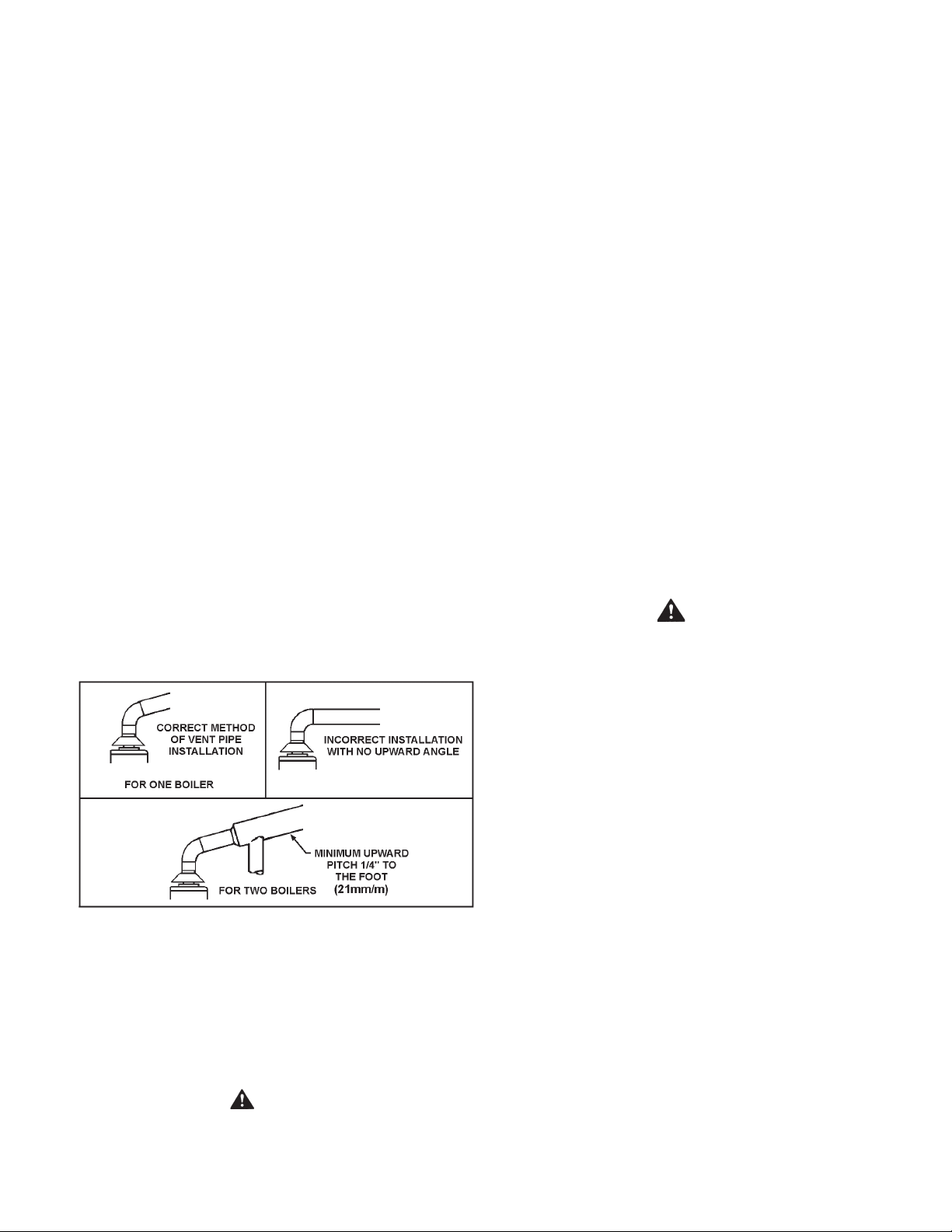

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet or 1 meter), noncombustible hanger s and /or slip joints suitable for the weight

and design of the materials employed to prevent sagging and

to maintain a minimum upward slope of 1/4" (21mm/m) per foot

from the boiler to the vent terminals, see Figure 8. Dampers or

other obstructions must not be installed in the vent. Be sure

that the vent pipe does not extend beyond t he inside wall of

the chimney.

3. CONNECTING BOILER TO A COMMON VENT

Do not connect the boiler to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by many local

building codes as is the practice of venting gas red equipment to

the duct work of ventilation systems.

Where a separate vent connection is not available and the vent pipe

from the boiler must be connected to a common vent with oil burning

equipment, the vent pipe should enter the common vent or chimney

at a point ABOVE the ue pipe from the oil red unit.

Where two or more appliances vent into a common vent connector

or manifold, the area of the common vent or vent connector should

at least equal the area of the largest vent connector plus 50% of the

areas of the additional draft hood outlets.

When removing a boiler from a system with a common vent, use

the following steps:

Be sure the other appliances connected to the common vent are

not in operation.

Seal any unused openings in the common venting system.

Visually inspect the venting system for proper size and horizontal pitch

and determine there is no blockage or restriction, leakage, corrosion

and other deciencies which could cause an unsafe condition.

WARNING

Ensure sufcient supply and ventilation air. Under no circumstances

should the equipment room where the boiler is installed ever be under

negative pressure. Insufcient air supply can interfere with combustion

and ventilation of this boiler resulting in unsafe conditions.

VENT PIPE INSTALLATION

FIGURE 8.

Where a continuous or intermittent back draft is found to exist the

cause must be determined and corrected. A special vent cap may

be required. If the back draft cannot be corrected by the normal

methods or if a suitable draft cannot be obtained, a blower type

ue gas exhauster may be employed to ensure proper venting and

correct combustion if permitted by local codes.

WARNING

FAIL URE TO CORRECT BACK DRAFTS WILL CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

Insofar as is practical, close all building doors and windows and

all doors between the space in which the appliances remaining

connected to the common venting system are located and other

spaces of the building. Turn on clothes dryers and any appliance not

connected to the common venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they will operate

at maximum speed. Close replace dampers.

Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will operate

continuously.

Test for spillage at the draft hood relief opening after ve minutes of

main burner operation. Use the ame of a match or candle.

After it has been determined that each appliance remaining connected

to the common venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, replace dampers and

any other gas burning appliance to their previous conditions of use.

Any improper operation of the common venting system should be

corrected so the installation conforms with the current edition of

CAN/CSA B149.1 (current edition). When resizing any portion of

the common venting system, the common venting system should

be resized to approach the minimum size as determined using the

appropriate tables in CAN/CSA B149.1.

15

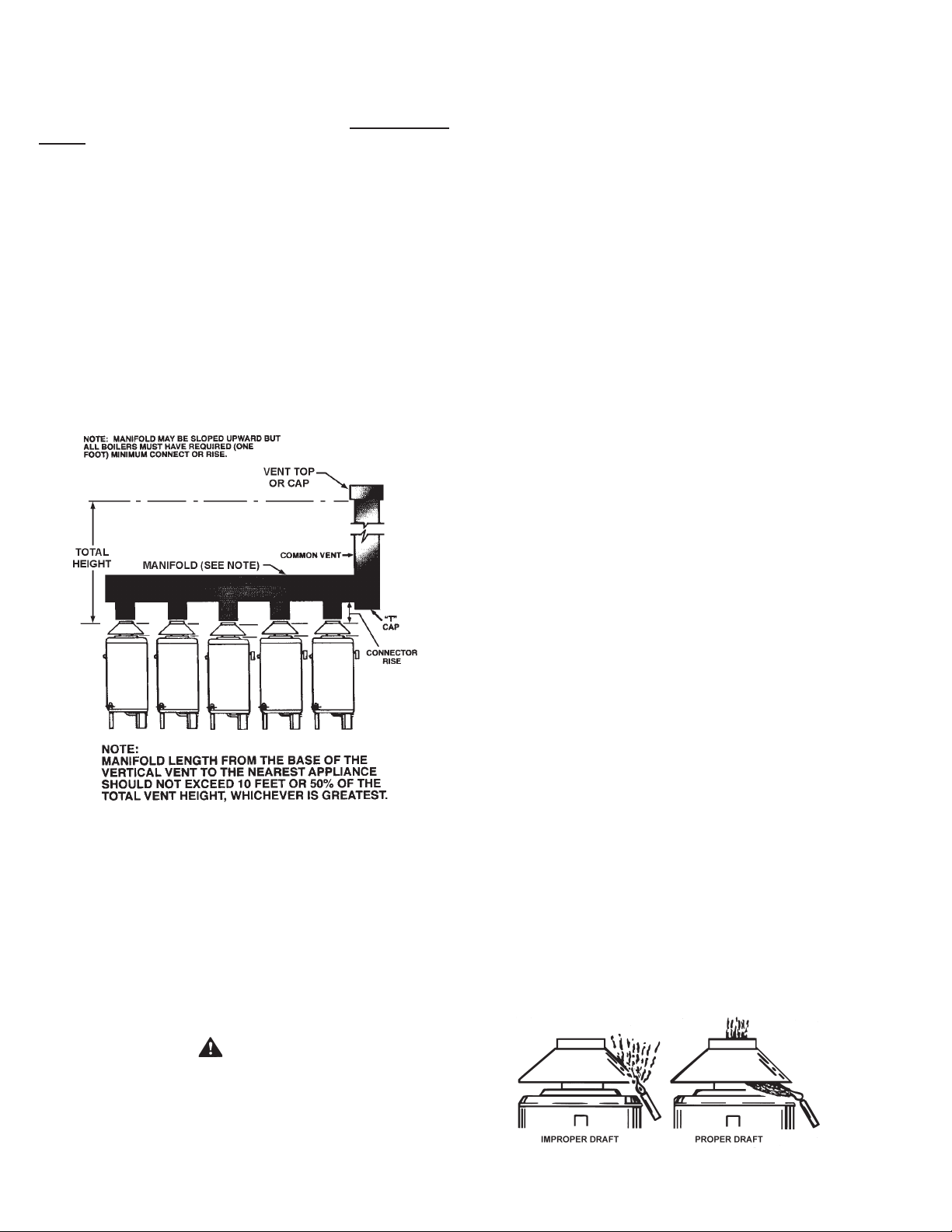

4. MULTIPLE VENT TABLE

Table 5 on page 17 has been compiled to show the material

sizes in a Type B doublewall combined vent system. Refer to

CAN/CSA B149 .1 (current edition), or the ASHRAE 1983 Equipment

Volume for further information.

A combined vent system is one in which two or more boilers at one

level are attached to a common vent.

In order to use table 5, the connector rise and total vent height must

be known. Connector rise is vertical distance from the draft hood outlet

to the point where the manifold connection is made. Total vent height

is the least vertical distance from a draft hood outlet to the top of the

vent. Local codes or utility requirements often govern termination

height. ULC listed doublewall gas vents, up through 24" (610mm)

diameter, can be installed in heated and unheated areas and can

pass through oors, ceilings, partitions, walls and roofs, provided

the required one inch clearance is observed. These vents should be

installed in accordance with CAN/CSA B149.1 (current edition).

EXAMPLE SHOWING USE OF THE HW-610 COMBINED VENT

SIZING TABLE

1. Turn off the electrical power (main manual gas shutoff and pilot

valves, if applicable).

Allow boiler parts and vent to cool before disassembly.

2. Remove the boiler draft diverter and vent pipe running to the chimney.

• Check parts and chimney for obstructions and clean as necessary.

3. Remove burner from boiler and other metal parts as required to

clean and vacuum the heat exchanger and combustion coils.

• Refer to parts list supplied with this manual for disassembly aid.

4. Reinstall the parts removed in steps 2 and 3.

• Be sure the vent pipe has a minimum upward pitch of one quarter

inch per foot of length (21mm/m) and is sealed as necessary.

5. Restore electrical power and gas supply to boiler.

• Place boiler in operation by following the lighting instructions

in this manual.

• Check for gas leaks and proper boiler and vent operation.

VENTING - SIDEWALL (OPTIONAL) POWER VENT SYSTEM

If you are installing the optional Power Vent Kit, refer to your

HW Power Vent Kit Installation Instructions for proper wiring

and installation procedures. Contact your local A. O. Smith

representative for details.

FIGURE 9.

VENTING MAINTENANCE - STANDARD VENTING

It is recommended that the heating surfaces and vent piping of

the appliance be checked every six months for dust, deterioration

and carbon deposits. Remove all soot or other obstructions from

chimney and ue which will retard free draft. Replace any damaged

or deteriorated parts of the venting system.

VENTING SYSTEM

HAVE VENTING SYSTEM CHECKED EVERY SIX MONTHS FOR

OBSTRUCTIONS AND/OR DETERIORATION IN VENT PIPING.

A. Insofar as is practical, close all doors, windows and air inlets to

the building. Turn on all exhaust fans (range hood, bathroom

exhaust, etc.) so they will operate at their maximum speed.

Close replace dampers.

B. After allowing appliance to operate for ve minutes, test for

spillage at the draft hood relief opening.

C. “CHECKING THE DRAFT. Operate vent connected gas utilization

equipment for several minutes and check to see that the combustion

products are going up the chimney or gas vent properly by passing

a lighted match or taper around the edge of the relief opening of

the draft hood. If the chimney or gas vent is drawing properly, the

match ame will be drawn into the draft hood. If not, the combustion

products will tend to extinguish this ame. IF THE COMBUSTION

PRODUCTS ARE ESCAPING FROM THE RELIEF OPENING OF

THE DRAFT HOOD, DO NOT OPERATE THE EQUIPMENT UNTIL

PROPER ADJUSTMENT OR REPAIRS ARE MADE TO PROVIDE

ADEQUATE DRAFT THROUGH THE CHIMNEY OR GAS VENT.”

D. Next, turn on all other fuel burning appliances within the same

room so they will operate at their full input.

Qualied servicers should follow this procedure when the boiler’s

external heating surfaces and vent pipe need cleaning.

CAUTION

DO NOT USE A NYLON BRUSH OR OTHER STATIC CREATING

MATERIAL TO CLEAN DUST AND CARBON DEPOSITS FROM

HEATING SURFACES AND VENT.

SUCH DEPOSITS ARE FLAMMABLE AND MAY BE IGNITED BY

STATIC ELECTRICITY. USE A METAL BRUSH TO MINIMIZE THE

DANGER OF EXPLOSION.

Repeat step C above, checking the draft on each appliance.

FIGURE 10.

16

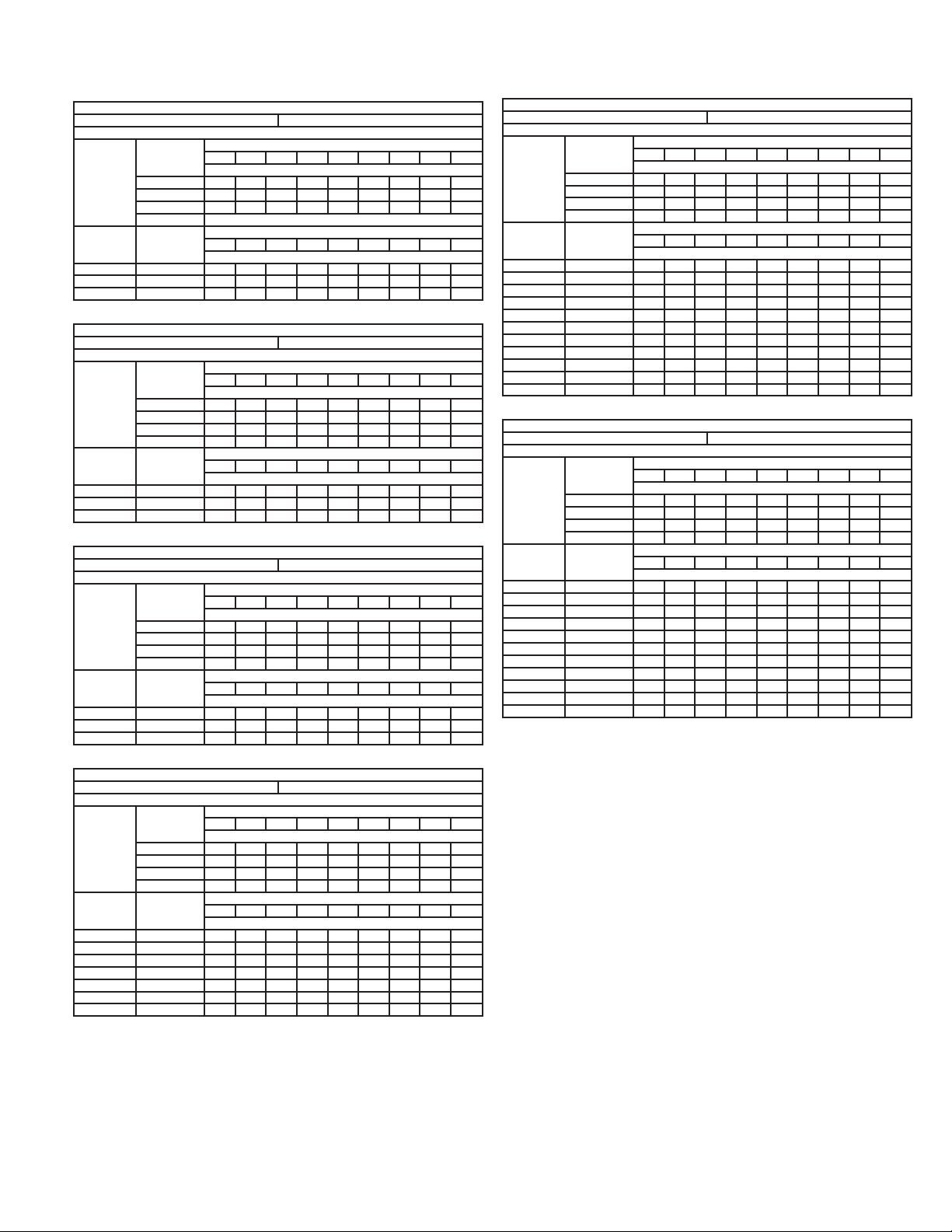

TABLE 5, COMBINED VENT SIZING TABLES

Input: 300,000 Btuh Draft Hood Outlet 8"

Connector

Rise in Feet

1 10 10 10 10 10 10 10 10 10

2 10 10 10 10 10 10 10 10 10

3 10 10 10 10 10 10 10 10 10

Number

if Units

Combined

2 600 14 12 12 12 10 10 10 10 10

3 900 16 14 14 14 12 12 12 12 12

4 1200 18 16 16 14 14 14 14 12 12

Number

if Units

Combined

2 798 14 14 14 12 12 12 12 12 12

3 1197 18 16 16 14 14 14 14 14 12

4 1596 20 20 18 16 16 16 14 14 14

Number

if Units

Combined

2 840 14 14 14 12 12 12 12 12 12

3 1260 18 16 16 14 14 14 14 14 12

4 1680 20 20 18 16 16 16 14 14 14

4 or more

Total Input

Btuh x 1000

Input: 399,000 Btuh Draft Hood Outlet 10"

Connector

Rise in Feet

1 12 12 12 12 12 12 12 12 12

2 12 12 12 10 10 10 10 10 10

3 12 10 10 10 10 10 10 10 10

4 or more 10 10 10 10 10 10 10 10 10

Total Input

Btuh x 1000

Input: 420,000 Btuh Draft Hood Outlet 10"

Connector

Rise in Feet

1 12 12 12 12 12 12 12 12 12

2 12 12 12 10 10 10 10 10 10

3 12 10 10 10 10 10 10 10 10

4 or more 10 10 10 10 10 10 10 10 10

Total Input

Btuh x 1000

MODEL HW-300 BOILER

Required Connector or Smoke Pipe Diameter

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

MODEL HW-399 BOILER

Required Connector or Smoke Pipe Diameter

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

MODEL HW-420 BOILER

Required Connector or Smoke Pipe Diameter

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Connector Diameter (in Inches)

Manifold and Common Vent Diameter (in Inches)

Connector Diameter (in Inches)

Manifold and Common Vent Diameter (in Inches)

Connector Diameter (in Inches)

Manifold and Common Vent Diameter (in Inches)

Input: 610,000 Btuh Draft Hood Outlet 12"

Connector

Rise in Feet

1 16 14 14 14 14 14 14 14 14

2 14 14 14 14 14 12 12 12 12

3 14 14 12 12 12 12 12 12 12

Number

if Units

Combined

2 1220 18 18 16 16 14 14 14 14 14

3 1830 22 20 20 18 18 16 16 16 14

4 2440 26 24 22 20 20 18 18 18 16

5 3050 28 26 26 24 22 22 20 20 18

6 3660 32 28 28 26 24 24 22 22 20

7 4270 34 32 30 28 26 24 24 22 22

8 4880 36 34 32 30 28 26 26 24 24

9 5490 38 36 34 30 30 28 28 26 24

10 6100 40 38 36 32 30 30 28 26 26

11 6710 42 38 38 34 32 30 28 28 26

12 7320 44 42 38 36 34 32 32 30 28

Number

if Units

Combined

2 1220 18 18 16 16 14 14 14 14 14

3 1830 22 20 20 18 18 16 16 16 14

4 2440 26 24 22 20 20 18 18 18 16

5 3050 28 26 26 24 22 22 20 20 18

6 3660 32 28 28 26 24 24 22 22 20

7 4270 34 32 30 28 26 24 24 22 22

8 4880 36 34 32 30 28 26 26 24 24

9 5490 38 36 34 30 30 28 28 26 24

10 6100 40 38 36 32 30 30 28 26 26

11 6710 42 38 38 34 32 30 28 28 26

12 7320 46 44 40 38 36 34 34 32 30

4 or more 12 12 12 12 12 12 12 12 12

Total Input

Btuh x 1000

Input: 660,000 or 670,000 Btuh Draft Hood Outlet 12"

Connector

Rise in Feet

1 16 14 14 14 14 14 14 14 14

2 14 14 14 14 14 12 12 12 12

3 14 14 12 12 12 12 12 12 12

4 or more 12 12 12 12 12 12 12 12 12

Total Input

Btuh x 1000

MODEL HW-610 BOILER

Required Connector or Smoke Pipe Diameter

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

MODEL HW-670 BOILER

Required Connector or Smoke Pipe Diameter

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Connector Diameter (in Inches)

Manifold and Common Vent Diameter (in Inches)

Connector Diameter (in Inches)

Manifold and Common Vent Diameter (in Inches)

Input: 520,000 Btuh Draft Hood Outlet 10"

Connector

Rise in Feet

1 14 14 14 12 12 12 12 12 12

2 12 12 12 12 12 12 12 12 12

3 12 12 12 12 10 10 10 10 10

Number

if Units

Combined

2 1040 16 16 14 14 14 14 12 12 12

3 1560 20 18 18 16 16 14 14 14 14

4 2080 22 22 20 18 18 18 16 16 14

5 2600 26 24 22 20 20 18 18 18 18

6 3120 28 26 24 22 22 20 20 18 18

7 3640 30 28 26 24 24 22 22 20 20

8 4160 32 30 28 26 24 24 22 22 20

4 or more 12 12 12 12 10 10 10 10 10

Total Input

Btuh x 1000

MODEL HW-520 BOILER

Required Connector or Smoke Pipe Diameter

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Total Vent Height (Measured in Feet Above Draft Hood)

10 15 20 30 40 50 60 80 100

Connector Diameter (in Inches)

Manifold and Common Vent Diameter (in Inches)

Known: (5) model HW-610 boilers. (See illustration).

Connector rise - 2' (Note 1' is minimum). Total vent

height 30'.

Problem: Determine diameter of connector, manifold and

common vent.

Procedure: Enter the top of the HW-610 table (total vent height)

at 30' and the side at 2' (connector rise). A 14"

connector diameter is indicated for each connector

rise.

To determine the manifold and common vent size, enter table on this

page (total vent height) at 30 and the side at 5 boilers. A manifold

diameter of 24" (610 mm) is indicated.

17

Loading...

Loading...