A.O. Smith GPSH, GPCR User Manual

RESIDENTIAL GAS WATER HEATERS

OWNER'S MANUAL

Thank you for buying this energy efficient water heater from A.O. Smith Water Products Company. We appreciate your confidence in our products.

You should thoroughly read this manual before installation and/or operation of this water heater. Please pay particular attention to the important safety and operating instructions as well as the WARNINGS and CAUTIONS.

Power Vented Gas Models

GPSH/GPCR with Hot Surface Ignition

TABLE OF CONTENTS

|

PAGE |

GET TO KNOW YOUR WATER HEATER |

2 |

GENERAL SAFETY INFORMATION |

3 |

INSTALLATION |

4-12 |

OPERATION & LIGHTING INSTRUCTIONS |

12-15 |

MAINTENANCE |

15-16 |

TROUBLESHOOTING |

17-18 |

WARRANTY |

19 |

|

|

CAUTION

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ THOROUGHLY BEFORE INSTALLING AND USING THIS APPLIANCE.

A DIVISION OFA.O. SMITH CORPORATION

MCBEE, SOUTH CAROLINA

www.hotwater.com

KEEP THIS MANUAL IN THE POCKET ON THE HEATER FOR FUTURE REFERENCE WHENEVER MAINTENANCE ADJUSTMENT OR SERVICE IS REQUIRED.

PRINTED IN U.S.A. 0605 |

1 |

PART NO. 185171-001 |

|

|

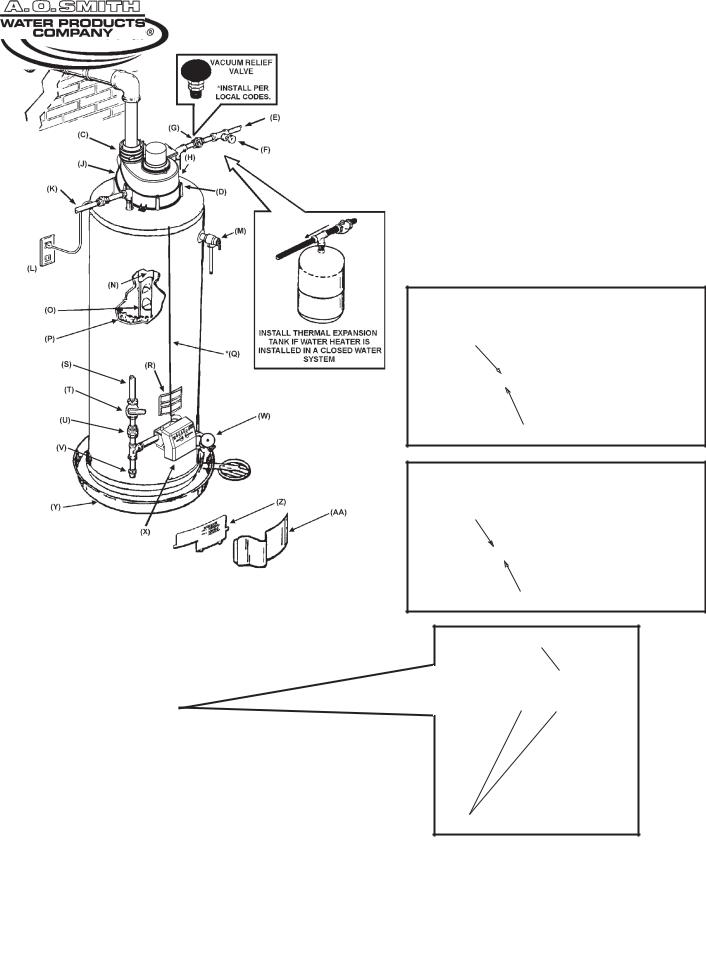

GET TO KNOW YOUR WATER HEATER

REPLACEMENT PARTS AND DELIMING PRODUCTS

Replacement parts and recommended delimer may be ordered through authorized servicers or distributors. Refer to the Yellow Pages for where to call. When ordering parts, provide complete model and serial numbers (see rating plate), quantity and name of part desired (as listed in Figure 1). Standard hardware items may be purchased locally.

(A) |

Vent Pipe - Exhaust |

(O) |

Flue Baffle Assembly** |

(B) |

Vent Terminal |

(P) |

Insulation |

(C) |

Vent Adapter-Rubber Boot |

(Q) |

Control Harness |

(D) |

Blower Assembly |

(R) |

Rating Plate |

(E) |

Cold Water Inlet |

(S) |

Gas Supply |

(F) |

Inlet Water Shut-off Valve |

(T) |

Manual Gas Shut-off Valve |

(G) |

Union |

(U) |

Ground Joint Union |

(H) |

Inlet Dip Tube |

(V) |

Dirt Leg (Sediment Trap) |

(J) |

Anode** |

(W) |

Drain Valve |

(K) |

Hot Water Outlet |

(X) |

Gas Valve - Thermostat |

(L) |

Oulet Receptacle (115 VAC) |

(Y) |

Drain Pan |

(M) |

Temperature-Pressure |

(Z) |

Inner Door |

|

Relief Valve |

(AA) Outer Door |

|

(N) |

Flue |

(BB) HSI Burner Assembly |

|

**Located Under Blower Assembly

NATURAL HOT SURFACE IGNITER & MAIN BURNER

HOT

SURFACE

IGNITOR

SENSOR

PROPANE HOT SURFACE IGNITER & MAIN BURNER

HOT

SURFACE

IGNITOR

SENSOR

TEMPERATURE INDICATORS

*CAUTION: 115VAC IN CONTROL HARNESS AND INSIDE OUTER DOOR

GAS MODELS

WITH HOT SURFACE IGNITION

& - 2" OR 3" PVC VENT CAPABILITY

TEMPERATUREADJUSTMENT BUTTONS

FIGURE 1

2

GENERAL SAFETY INFORMATION

GENERAL SAFETY INFORMATION

EXTERNAL DAMAGE

Do not operate the water heater until it has been fully checked out by a qualified technician, if the water heater:

•Has been exposed to fire or damage.

•Displays evidence of sooting.

•Produces steam or unusually hot water.

If the water heater has been flooded it must be replaced.

CHEMICAL VAPOR CORROSION

WARNING

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN CHEMICAL VAPORS. SUCH CORROSION MAY RESULT IN FAILUREAND RISK OF ASPHYXIATION.

Spray can propellants, cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium chloride (water softener salt), waxes, and process chemicals are typical compounds which are potentially corrosive.

Do not store products of this sort near the heater. Also, air which is brought in contact with the heater should not contain any of these chemicals. If necessary, uncontaminated air should be obtained from remote or outside sources. The limited warranty is voided when failure of water heater is due to a corrosive atmosphere. (Reference is made to the limited warranty for complete terms and conditions).

IMPROPER COMBUSTION

WARNING

WARNING

ATTIC AND/OR EXHAUST FANS OPERATING ON THE PREMISES WITH A WATER HEATER CAN RESULT IN CARBON MONOXIDE POISONING AND DEATH.

OPERATION OF THESE FANS CAN PRODUCE A NEGATIVE DRAFT IN THE AREA OF THE WATER HEATER PREVENTING THE PRODUCTS OF COMBUSTION FROM EXHAUSTING THROUGH THE VENT PIPE.

The venting of the water heater should be inspected by a qualified service technician at the time of installation and periodically thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND VENTILATION MUST BE PROVIDED FOR SAFE OPERATION.

LIQUID PETROLEUM MODELS

WARNING

WARNING

Water heaters for propane or liquefied petroleum gas (LPG) are different from natural gas models. A natural gas heater will not function safely on LP gas and no attempt should be made to convert a heater from natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive and heavier than air. It collects first in the low areas making its odor difficult to detect at nose level. If LP gas is present or even suspected, do not attempt to find the cause yourself. Go to a neighbor's house, leaving your doors open to ventilate the house,

then call your gas supplier or service agent. Keep area clear until a service call has been made.

At times you may not be able to smell an LP gas leak. One cause is odor fade, which is a loss of the chemical odorant that gives LP gas its distinctive smell. Another cause can be your physical condition, such as having a cold or a diminishing sense of smell with age. For these reasons, the use of a propane gas detector is recommended.

IF YOU EXPERIENCE AN OUT-OF-GAS SITUATION, DO NOT TRY TO RELIGHTAPPLIANCE YOURSELF. Ask your LP delivery person to relight pilots for you. Only trained LP professionals should conduct the required safety checks in accordance with industry standards.

EXTENDED NON-USE PERIODS

WARNING

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER SYSTEM SERVED BY THIS HEATER THAT HAS NOT BEEN USED FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR MORE). HYDROGEN GAS IS EXTREMELY FLAMMABLE. To reduce the risk of injury under these conditions, it is recommended that the hot water faucet be opened for several minutes at the kitchen sink before using any electrical appliance connected to the hot water system. If hydrogen is present, there will probably be an unusual sound such as air escaping through the pipe as the water begins to flow. THERE SHOULD BE NO SMOKING OR OPEN FLAME NEAR THE FAUCET AT THE TIME IT IS OPEN.

INSULATION BLANKETS

Insulation blankets available to the general public for external use on gas water heaters are not approved for use on your water heater. The purpose of an insulation blanket is to reduce the standby heat loss encountered with storage tank heaters. Your water heater meets and exceeds the National Appliance Energy Conservation Act standards with respect to insulation and standby loss requirements, making an insulation blanket unnecessary.

WARNING

WARNING

Should you choose to apply an insulation blanket to this heater, you should follow these instructions (See Figure 1 for identification of components mentioned below). Failure to follow these instructions can restrict the air flow required for proper combustion, potentially resulting in fire, asphyxiation, serious personal injury or death.

•Do not cover the outer door, thermostat or temperature & pressure relief valve.

•Do not allow insulation to come within 2 inches of dilution air inlet on the blower to prevent blockage of the dilution air.

•Do not allow insulation to come within 2" of the floor to prevent blockage of combustion air flow to the burner.

•Do not cover the instruction manual. Keep it on the side of the water heater or nearby for future reference.

•Do obtain new warning and instruction labels for placement on the blanket directly over the existing labels.

•Do inspect the insulation blanket frequently to make certain it does not sag, thereby obstructing combustion air flow.

3

INSTALLATION

INSTALLATION

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR SUPPLY, VENTING AND GAS SUPPLY ARE REQUIRED.

GENERAL

The installation must conform to these instructions and the local code authority having jurisdiction. In the absence of local codes, the installation must comply with the current editions of the National Fuel Gas Code ANSI Z223.1/NFPA 54 and the National Electrical Code, NFPA 70. The former is available from the Canadian Standards Association, 8501 East Pleasant Valley Road, Cleveland, OH 44131, and both documents are available from the National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

GROUNDING

The water heater when installed must be grounded in accordance with local codes, or in the absence of local codes:

In the United States

The National Electric Code, ANSI/NFPA 70.

HIGH ALTITUDE INSTALLATION

WARNING

WARNING

STANDARD MODELS ARE FOR INSTALLATION UP TO 2,000 FEET (610m) ABOVE SEA LEVEL.

IF A STANDARD MODEL IS INSTALLED ABOVE 2,000 FEET (610m), INPUT RATING SHOULD BE REDUCED AT A RATE 4 PERCENT FOR EACH 1,000 FEET (305m) ABOVE SEA LEVEL WHICH REQUIRES REPLACEMENT OF THE BURNER ORIFICE IN ACCORDANCE WITH THE NATIONAL FUEL GAS CODE (ANSI Z223.1/NFPA 54).

FAILURE TO REPLACE THE STANDARD ORIFICE WITHA HIGH ALTITUDE ORIFICE WHEN INSTALLED ABOVE 2,000 FEET (610m) COULD RESULT IN IMPROPER AND INEFFICIENT OPERATION OF THE WATER HEATER, PRODUCING CARBON MONOXIDE GAS IN EXCESS OF SAFE LIMITS, WHICH COULD RESULT IN SERIOUS INJURY OR DEATH. CONTACT YOUR LOCAL GAS SUPPLIER FOR ANY SPECIFIC CHANGES WHICH MAY BE REQUIRED IN YOUR AREA.

LOCATION OF HEATER

The heater is design certified by the Canadian Standards Association for installation on combustible flooring in a closet having minimum clearances from combustible material of: 0" clearance from sides and rear, 5" from the front and 12" from the top. (Standard clearance.) If clearances stated on the heater differ from standard clearances, install water heater according to clearances stated on heater.

Adequate clearance for servicing this appliance should be considered before installation, such as changing the anodes, etc.

A minimum clearance of 5" must be allowed for access to replaceable parts such as the thermostats, drain valve and relief valve.

When installing the heater, consideration must be given to proper location. Location selected should be as close to the wall as practicable and as centralized with the water piping system as possible.

AIR REQUIREMENTS

Dilution air temperature must be 100°F or less. In calculating the free area of a vent opening, the blocking effect of screens, louvers and grills should be considered. Screens shall not be of a mesh smaller than 1/4 inch square. If the free area is not known, the current edition of National Fuel Gas Code ANSI Z223.1/NFPA 54 recommends using figures of 20-25 percent free area for wood louvers or 60-75 percent for metal grills or louvers.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction, unconfined spaces may provide adequate air for combustion, ventilation, and dilution air for power venter.

If the unconfined space is within a building of tight construction (as defined in the most recent revision of the National Fuel Gas Code Handbook), air for combustion, ventilation, and venter dilution must be obtained from outdoors. The installation instructions for confined spaces must be followed.

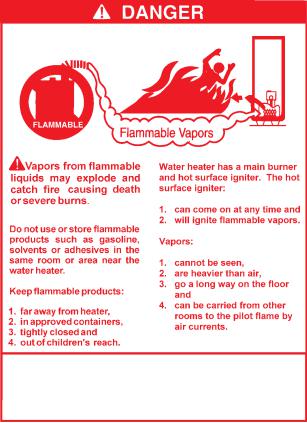

Installation: |

least 18” above the floor. |

Do not install water heater |

This will reduce, but not |

where flammable products |

eliminate, the risk of vapors |

will be stored or used |

being ignited by the main |

unless the main burner and |

burner or hot surface |

hot surface igniter are at |

igniter. |

CONFINED SPACE

When drawing combustion and dilution air from inside a conventionally constructed building to a confined space, such a space shall be provided with two permanent openings; ONE WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE WITHIN 12 INCHES OF THE ENCLOSURE BOTTOM. Each opening shall have a free area of one square inch per 1000 Btuh of the total input of all appliances in the enclosure, but not less than 100 square inches.

If the confined space is within a building of tight construction, air for combustion, ventilation and power venter dilution must be obtained from outdoors. When directly communicating with the outdoors or communicating through vertical ducts, two permanent openings, located in the above manner, shall be provided. Each opening shall have a free area of not less than one square inch per 4000 Btuh of the total input of all appliances in the enclosure. If horizontal ducts are used, each opening shall have a free area of not less than one square inch per 2000 Btuh of the total input of all appliances in the enclosure.

4

CAUTION

CAUTION

In cold climates provide protection against freeze-up.

THE HEATER SHOULD BE LOCATED IN AN AREA WHERE LEAKAGE OF THE TANK OR CONNECTIONS WILLNOT RESULT IN DAMAGE TO THE AREAADJACENT TO THE HEATER OR TO LOWER FLOORS OF THE STRUCTURE. When such locations cannot be avoided, a suitable drain pan should be installed under the heater, see fig. 1. The pan should have a minimum length and width of at least 2 inches greater than the diameter of the heater and should be piped to an adequate drain. Drain pans suitable for these heaters are available from your dealer.

Water heater life depends upon water quality, water pressure and the environment in which the water heater is installed. Water heaters are sometimes installed in locations where leakage may result in property damage, even with the use of a drain pan piped to a drain. However, unanticipated damage can be reduced or prevented by a leak detector or water shut-off device used in conjunction with a piped drain pan. These devices are available from some plumbing supply wholesalers and retailers, and detect and react to leakage in various ways:

•Sensors mounted in the drain pan that trigger an alarm or turn off the incoming water to the water heater when leakage is detected.

•Sensors mounted in the drain pan that turn off the water supply to the entire home when water is detected in the drain pan.

•Water supply shut-off devices that activate based on the water pressure differential between the cold water and hot water pipes connected to the water heater.

•Devices that will turn off the gas supply to a gas water heater while at the same time shutting off its water supply.

WARNING

WARNING

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A CARPETED FLOOR. A FIRE HAZARD MAY RESULT. Instead the water heater must be placed on a metal or wood panel extending beyond the full width and depth by at least 3 inches (76.2mm) in any direction. If the heater is installed in a carpeted alcove or closet, the entire floor shall be covered by the panel. Also, see DRAINING.

WARNING

WARNING

For California installation this water heater must be braced, anchored, or strapped to avoid falling or moving during an earthquake. See instructions for correct installation procedures. Instructions may be obtained from your local dealer, wholesaler, public utilities or California’s Office of the State Architect, 400 P Street, Sacramento, CA 95814.

WATER CONNECTIONS

Refer to figure 1 for typical installation. A suitable pipe thread sealant must be used to prevent leakage.

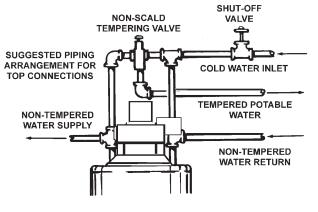

WATER (POTABLE) HEATING AND SPACE

HEATING

1.All piping components connected to this unit for space heating applications shall be suitable for use with potable water.

2.Toxic chemicals, such as those used for boiler treatment, shall NEVER be introduced into this system.

3.This unit may NEVER be connected to any existing heating system or component(s) previously used with a non-potable water heating appliance.

4.When the system requires water for space heating at temperatures higher than required for domestic water purposes, a tempering valve must be installed. Please refer to Figure 2 for suggested piping arrangement.

FIGURE2

CLOSED WATER SYSTEM

A closed system will exist if a back-flow preventer (check valve), or similar device is installed in the cold water line between the water heater and the street main (or well). Excessive pressure may develop due to the thermal expansion of heated water causing premature tank failure or intermittent relief valve operation. This type of failure is not covered by the limited warranty. An expansion tank may be necessary in the cold water supply to alleviate this situation, see fig. 1. Contact the local plumbing authority.

If the temperature and pressure relief valve on the appliance discharges periodically, this may be due to thermal expansion in a closed water supply system. Contact the water supplier or local plumbing inspector on how to correct the situation. Do not plug the temperature and pressure relief valve.

GAS CONNECTIONS

The minimum gas supply pressure is 5.0" W.C for natural gas (11.0" W.C. for propane).

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER THAN 14.0'' WATER COLUMN SUPPLY PRESSURE. EXPOSURE TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE DAMAGE TO THE CONTROL WHICH COULD RESULT IN FIRE OR EXPLOSION. If overpressure has occurred such as through improper testing of gas lines or emergency malfunction of the supply system, the control must be checked for safe operation. Make sure that the outside vents on the supply regulators and the safety vent valves are protected against blockage. These are parts of the gas supply system not the heater. Vent blockage may occur during ice storms.

IT IS IMPORTANT TO GUARD AGAINST CONTROL FOULING FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

All piping must comply with local codes and ordinances or with the National Fuel Gas Code (ANSI Z223.1/ NFPA-54) whichever applies. Copper and brass tubing and fittings (except tin lined copper tubing) shall not be used.

REFER TO FIG. 1 FOR CONNECTION DETAILS. BEFORE ATTACHING THE GAS LINE BE SURE THAT ALL GAS PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG) MUST BE INCORPORATED IN THE PIPING, FIG. 1. The dirt leg must be readily accessible. Install in accordance with recommendations of serving gas supplier. Refer to the current edition of National Fuel Gas Code, ANSI Z223.1/NFPA.

5

To prevent damage, care must be taken not to apply too much torque when attaching gas supply pipe to gas valve inlet. The thermostat inlet has a pad for use with back up wrench.

Apply joint compounds (pipe dope) sparingly and only to the male threads of pipe joints. Do not apply compound to the first two threads. Use compounds resistant to the action of liquefied petroleum gases. Do not use teflon tape on gas valve fittings.

DISCONNECT THE APPLIANCE AND ITS INDIVIDUAL SHUT OFF VALVE FROM THE GAS SUPPLY PIPING SYSTEM DURING ANY SUPPLY PRESSURE TESTING EXCEEDING 1/2 PSI (3.5 kPa). GAS SUPPLY LINE MUST BE CAPPED WHEN DISCONNECTED FROM THE HEATER. FOR TEST PRESSURES AT 1/2 PSI (3.5 kPa) OR LESS, THE APPLIANCE NEED NOT BE DISCONNECTED, BUT MUST BE ISOLATED FROM THE SUPPLY PRESSURE TEST BY CLOSING THE MAIN MANUAL GAS VALVE.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR GAS LEAKAGE. USE SOAPAND WATER SOLUTION OR OTHER MATERIAL ACCEPTABLE FOR THIS PURPOSE. DO NOT USE MATCHES, CANDLES, FLAME OR OTHER SOURCES OF IGNITION TO LOCATE GAS LEAKS.

RELIEF VALVE (P)-FIG. 1

A NEW TEMPERATURE AND PRESSURE RELIEF VALVE COMPLYING WITH THE STANDARD FOR RELIEF VALVES AND AUTOMATIC GAS SHUT OFF DEVICES FOR HOT WATER SUPPLY SYSTEMS, ANSI Z21.22 (CURRENT EDITION) MUST BE INSTALLED IN THE HEATER IN THE MARKED OPENING PROVIDED. THE VALVE MUST BE OF A SIZE (INPUT RATING) THAT WILL BE ADEQUATE FOR YOUR SIZE HEATER.

Check the metal tag on the relief valve and compare it to the heater’s rating plate. The pressure rating of relief valve must not exceed the working pressure shown on the rating plate of the heater. In addition the hourly Btu rated temperature steam discharge capacity of the relief valve shall not be less than the input rating of the heater. NO VALVE IS TO BE PLACED BETWEEN THE RELIEF VALVE AND TANK. DO NOT PLUG THE RELIEF VALVE.

The drain line connected to this valve must not contain a reducing coupling or other restriction and must terminate near a suitable drain to prevent water damage during valve operation. The discharge line shall be installed in a manner to allow complete drainage of both the valve and line. DO NOT THREAD, PLUG OR CAP THE END OF THE DRAIN LINE.

VENTING

WARNING

WARNING

NEVER OPERATE THE HEATER UNLESS IT IS VENTED TO THE OUTDOORS AND HAS ADEQUATE AIR SUPPLY TO AVOID RISKS OF IMPROPER OPERATION, FIRE, EXPLOSION OR ASPHYXIATION.

Make sure the flue baffle and flue restrictor ring are properly aligned and inserted on top of the flue. This can be checked through the dilution air inlet of the blower.

VENT PIPE TERMINATION

NOTE: Before installing power venter determine place of vent pipe termination. See figure 3 on page 7.

IMPORTANT

The vent system must terminate so that proper clearances are maintained as cited in local codes or the current edition of the National Fuel Gas Code, ANSI Z223.1/NFPA54, 7.3.4e and 7.8a,b, as follows:

1.The exit terminals of a mechanical vent system shall be not less than 7 feet above grade when located adjacent to public walkways. (Figure. 3)

2.A venting system shall terminate at least 3 feet above any forced air inlet located within 10 feet. (Figure 3)

3.The venting system shall terminate at least 4 feet below, 4 feet horizontally from or, 1 foot above any door, window or gravity air inlet into any building.

The manufacturer also recommends that the vent termination should not be installed closer than 3 feet from an inside corner of an L shaped structure and not be less than 1 foot above grade.

The vent shall terminate a minimum of 12'' above expected snowfall level to prevent blockage of vent termination.

4.In cold climates, it is recommended that vent termination not be mounted directly above or within 3 feet horizontally from an oil tank vent or gas meter to avoid potential freeze-up from condensation.

Plan the vent system layout so that proper clearances are maintained from plumbing and wiring.

Vent pipes serving power vented appliances are classified by building codes as “vent connectors”. Required clearances from combustible materials must be provided in accordance with information in this manual under LOCATION OF HEATER and VENT TERMINAL INSTALLATIONS, and with the National Fuel

Gas Code and local codes.

IMPORTANT

Plan the layout of the vent system from the vent termination to the appliance considering all of the 90 degree and 45 degree elbows plus the number of feet of pipe that would be needed to install the total vent system. Make sure to include the 90 degree elbow if required at the blower. Review the tables on page 9 to make sure that the vent system is within the allowed vent configuration. Multiple fittings, 90 or 45 degree, installed in close proximity to each other could result in intermittent lockouts or prevent the unit from firing. Plan the layout to locate the fittings as far apart as possible.

CAUTION

CAUTION

Termination of the vent system with a device other than the 2", 22.50 degree schedule 40 elbow (supplied with the unit) or a 3", 45 degree schedule 40 elbow (supplied locally) could affect the system performance and result in a safety hazard. If the 3" elbow is used for the vent terminal, then the screens (supplied with this unit) for those elbows must be used and installed according to the provided instructions.

VENT TERMINAL INSTALLATION

1.After the point of termination has been determined, use the cover plate as a template to mark the hole for the vent pipe to insert through the wall. BEWARE OF CONCEALED WIRING AND PIPING INSIDE OF WALL.

2.If the Vent Terminal is being installed on the outside of a finished wall, it may be easier to mark both the inside and outside wall. Align the holes by drilling a hole through the center of the template from the inside through to the outside. The template can now be positioned on the outside wall using the drilled hole as a centering point for the template.

6

Loading...

Loading...