A.O. Smith BTI 85 G, BTI 100 G User Manual

MODELS

BTI 85 G

BTI 100 G

INSTALLATION AND USER

INSTRUCTION

UNITED KINGDOM / IRELAND

HOT WATER STORAGE HEATERS

Read these installation instructions first before installing the appliance. Carefully read

the user instructions before igniting the appliance. Failure to follow these instructions

may lead to risk of explosion and/or fire and could cause material damage and/or bodily

harm. Installation and commisioning should be carried out by a qualified competent

installer. The type of gas and the value at which the appliance is set standard in the

factory are registered on the rating plate. The appliance may only be installed in a room if

this room meets the ventilation requirements.

A.O. SMITH ACCEPTS NO RESPONSIBILITY FOR WARRANTY, SERVICE AND/OR

PRODUCT LIABILITY IN CASE OF UNAUTHORISED ALTERATIONS, PRODUCT

MODIFICATIONS OR REPAIR.

2

CONTENTS PAGE

1. GENERAL

1.1 Description...................................................................................................... 4

1.2 Technical safety equipment ............................................................................ 6

1.2.1 Gas control valve ............................................................................................ 6

1.2.2 Control panel................................................................................................... 6

1.2.3 Operation of the storage water heater ........................................................... 7

1.2.4 Combustion products discharge safety device ............................................. 7

1.3 Technical information ...................................................................................... 8

1.3.1 Dimensions ..................................................................................................... 8

1.3.2 Technical data ............................................................................................... 10

2. FOR THE INSTALLER

2.1 Installation instructions.................................................................................. 12

2.1.1 Installation ..................................................................................................... 12

2.1.2 Water circulation system .............................................................................. 13

2.1.3 Gas connection ............................................................................................. 15

2.1.4 Flue system .................................................................................................. 15

2.1.5 Flue down draught safety device ................................................................. 15

2.1.6 Electrical connection ..................................................................................... 15

2.2 Commissioning .............................................................................................. 16

2.2.1 Filling the water heater ................................................................................. 16

2.2.2 Putting in to operation.................................................................................... 16

2.2.3 Shut down .................................................................................................... 16

2.3 Removing and replacing the control panel front cover.................................. 17

2.4 Setting the gas pressure .............................................................................. 17

2.5 Removing and replacing the inner door......................................................... 18

2.6 Temperature regulation ................................................................................. 18

2.7 Converting to another type of gas ................................................................ 19

2.8 Maintenance ................................................................................................. 19

2.8.1 Magenesium anode ....................................................................................... 19

2.8.2 Cleaning ........................................................................................................ 20

2.8.3 Decalcification...............................................................................................20

2.8.4 Spare parts ................................................................................................... 20

2.9 Inlet combination............................................................................................ 20

2.10 Gas smell ...................................................................................................... 20

2.11 Condensation................................................................................................ 20

3. FOR THE USER

3.1 Commisioning ................................................................................................ 21

3.1.1 Filling the water heater ................................................................................. 21

3.1.2 Putting into operation..................................................................................... 21

3.1.3 Use ............................................................................................................... 21

3.2 Fault overview ..............................................................................................22

4. WARRANTY..................................................................................................... 23

5. Appendix 1..................................................................................................... 25

3

1. GENERAL

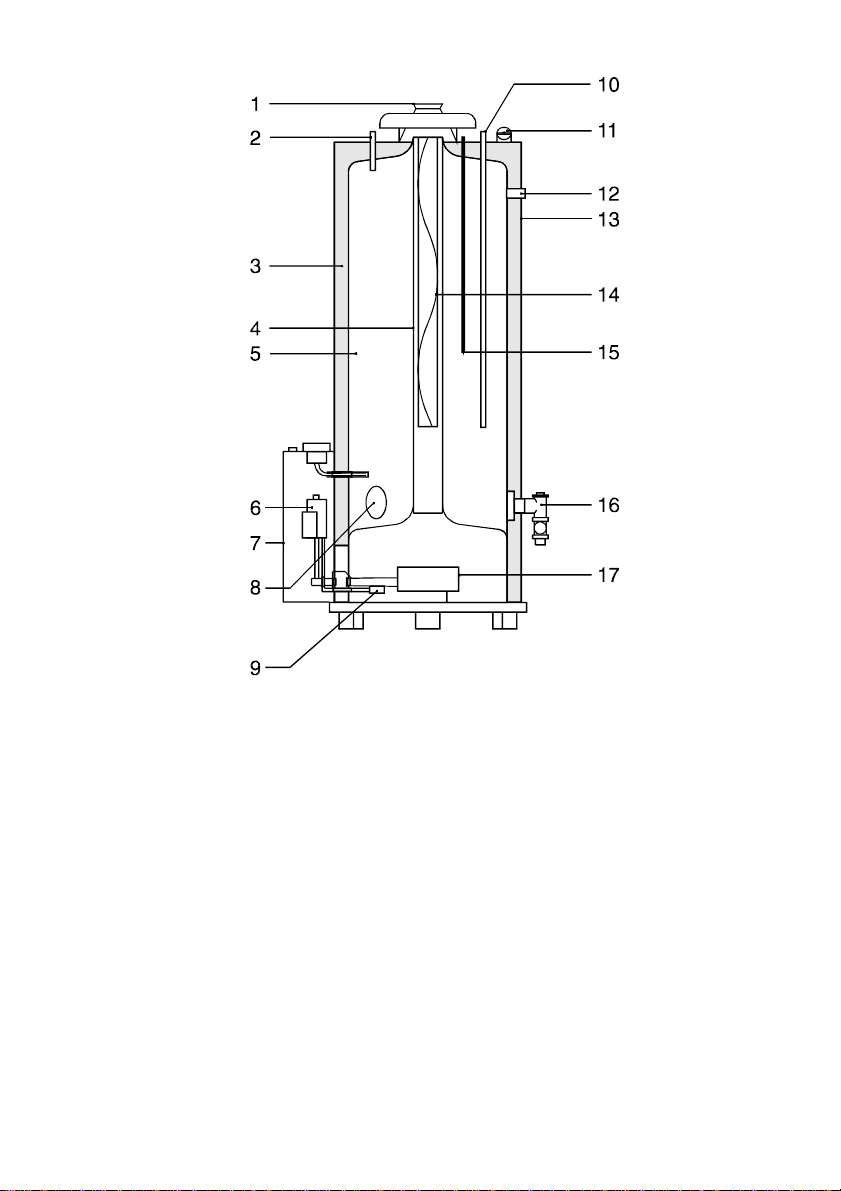

1.1 Description of the

appliance

Construction of the water heater is in

accordance with the European

standard for gas heated water storage

heaters for sanitary application (EN89).

The appliance thus meets the European

Directory for Gas Appliances and is

therefore entitled to carry the CEmarking. It is an open flued appliance

without ventilator and with a flue gas

down draught safeguard, a Thermal

Reflux Safeguard (TRS) (category

B

). The water heater is suitable for a

11BS

maximum working pressure of 8 bar.

The water heater tank is manufactured

from low carbon sheet steel and is

glasslined on the inside. In addition the

tank is fitted with a magenesium anode

as extra protection against corrosion. A

thick, CFC-free, PU insulation layer

covered in a steel jacket reduces

unnecessary heat loss. When the

appliance is filled with water it

continuously is under water pressure.

As hot water is drained from the tank,

cold water is added immediately. Four

flue baffles have been placed in the flue

tube to improve heat tranfer. The flue

gasses pass their heat on to the water

by means of radiation and convection.

The exhaust of the flue gasses is

realized by natural thermal draught (see

figur 1).

exceeding 25 mm. maximum length of

dead leg 3 metres.

Dead legs on a hot water installation are

undesireable. Where possible they

should be avoided. When the inclusion

on the system of a dead leg is

unavoidable the following restrictions

should be applied:

- for pipes not eceeding 19 mm. inside

diameter; maximum length of dead leg

permitted 12 metres;

- for pipes exceeding19 mm. but not

exceeding 25 mm. inside diameter;

maximum lenght of dead leg 7,5

metres;

- for pipes with an inside diameter

4

Figur 1 - Cross section of the heater

1) Draught diverter

2) Hot water outlet

3) Insulation

4) Flue tube

5) Glass lined tank

6) Gas valve and spark ignition

7) Control panel

8) Inspection cover plate

9) Intermittent pilot burner and

flame probe

10) Cold water inlet

11) Combustion products discharge

safety device

12) T&P valve connection

13) Outer casting

14) Flue baffle

15) Magnesium anode

16) Drain valve and secondary

return connection

17) Main burner

5

1.2 Technical safety

equipment

1.2.1 Gas control valve

The water heater is equipped with a

gas control wich regulates the flow of

gas to the burner. The gas block is

equipped with a safety valve, gas valve

and burner control (on a standard

natural gas setting). To ensure

improved ignition the gas control valve

opening mechanism is fitted with a

delay (softlite).

The gas control block is suitable for

gasses from the first, second and third

gas family. The maximum inlet pressure

is 60 mbar.

The automatic incandescent ignition (hot

surface) ensures that the burner ignites

as soon as there is a demand for heat.

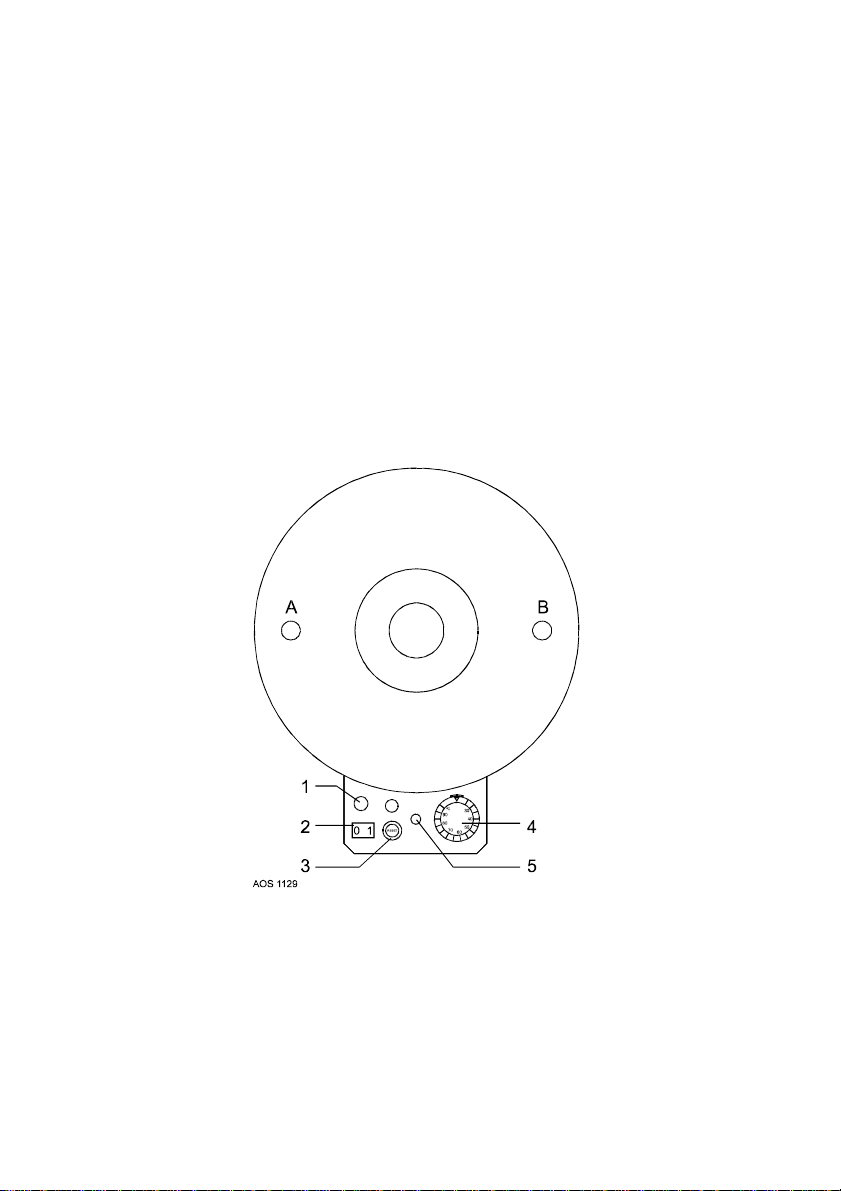

1.2.2 Control panel

Temperature control for the water

heater is housed in the control panel

(See figur 2). For safety purposes,

heaters are always fitted with two

thermostats: a control thermostat is

adjustable between 40 °C and 80 °C

and a safety thermostat 90 °C. The

control panel is fitted with an ON/OFF

switch (I/0). At setting ”I”, the gas

control is activated on the basis of heat

demand from the control thermostat. At

setting ”0” the heater is switched off.

Figur 2 - Top view of the heater

A) Hot water outlet

B) Cold water inlet

1) Electrical connection

2) ON/OFF switch

3) Ignition controller reset button

4) Control thermostat knob

5) Safety thermostat reset button

6

1.2.3 Operation of the storage

water heater.

Normal operation

When there is a demand for heat a

waiting period of about 1 second

elapses before the built-in spark generator and pilot gas valve are switched

on. The ignition sparks ignite the pilot

burner and the resulting flame is

detected by the ionisation electrode.

Almost immediately after the pilot flame

is detected, sparking stops and the

main gas valve is openend. The main

burner is lit by the pilot flame. The unit

is now in operation. When the

temperature of the water in the unit

reaches the temperature that is set

with the thermostat, the thermostat

switches and disconnects the

electrical heat demand signal to the

burner controller. The gas valves are

then closed.

Ignition failure

If the flame is not established within

the safety period the automatic ignition

controller locks out. The safety period

is about 25 seconds. Lock-out is

indicated by the lamp in the RESETbutton on the control panel. The unit

has to be manually reset by pushing

the reset button. If the flame is lost

during normal run, the automatic

ignition controller repeats the start

sequence.

operation by pressing its reset button. If

this failure occurs frequently, this

indicates that the flue suffers from down

draught conditions. It is recommended

that a competent person carry out the

necessary remedial action.

Important

The combustion products

discharge safety device should

never be put out of operation. Reentry of flue gases to the building

could be harmful and cause

poisoning or death.

1.2.4 Combustion products

discharge safety device

The heater has been fitted with a

combustion products discharge safety

device. It is the function of the safety

device to prevent flue gases from the

water heater entering the room where

the water heater has been placed,

instead of passing through the flue to

outside atmosphere. The gas supply is

disconnected as soon as the device is

activated by hot gases flowing over

the sensor. After the cause of the reentry of flue gases has been traced

the device can be put back into

7

1.3 Technical information

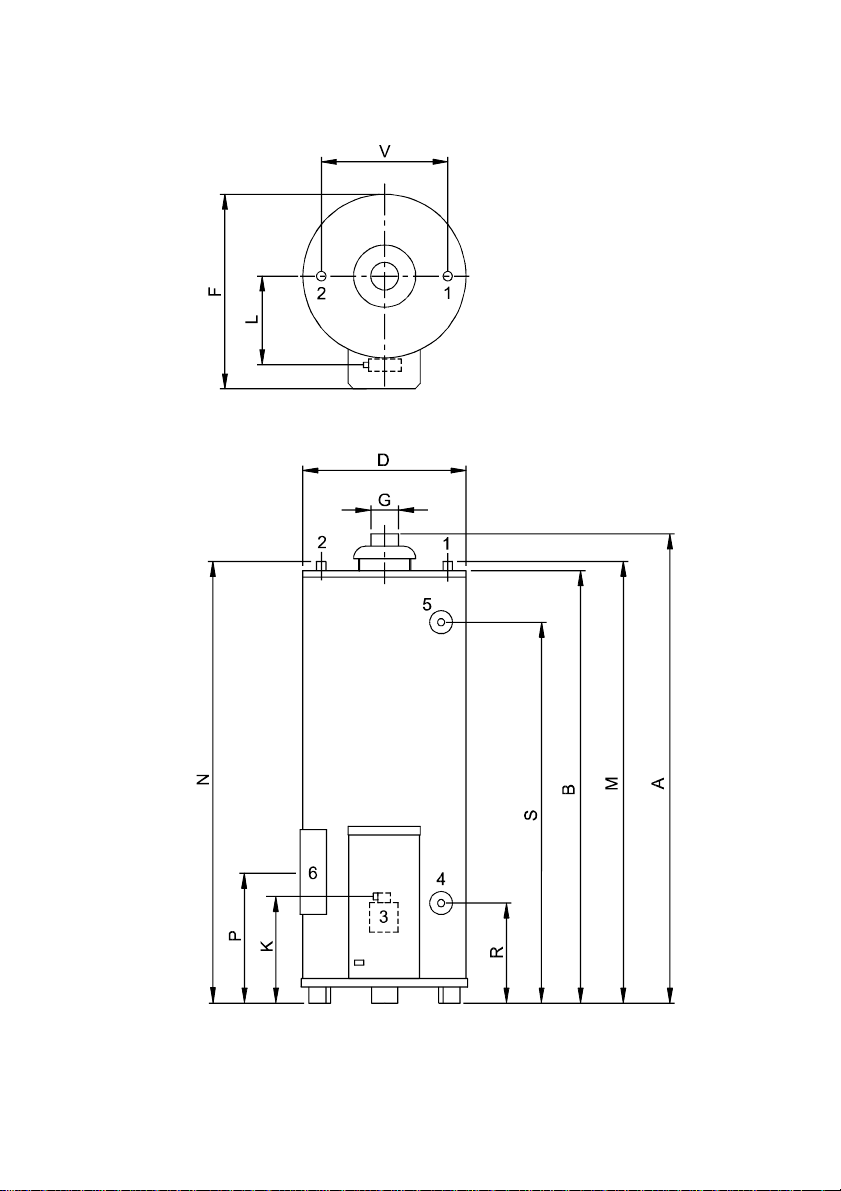

1.3.1 Dimensions

These water heaters are only suitable

for a flue tube with minimal the

announced diameter (dimension G).

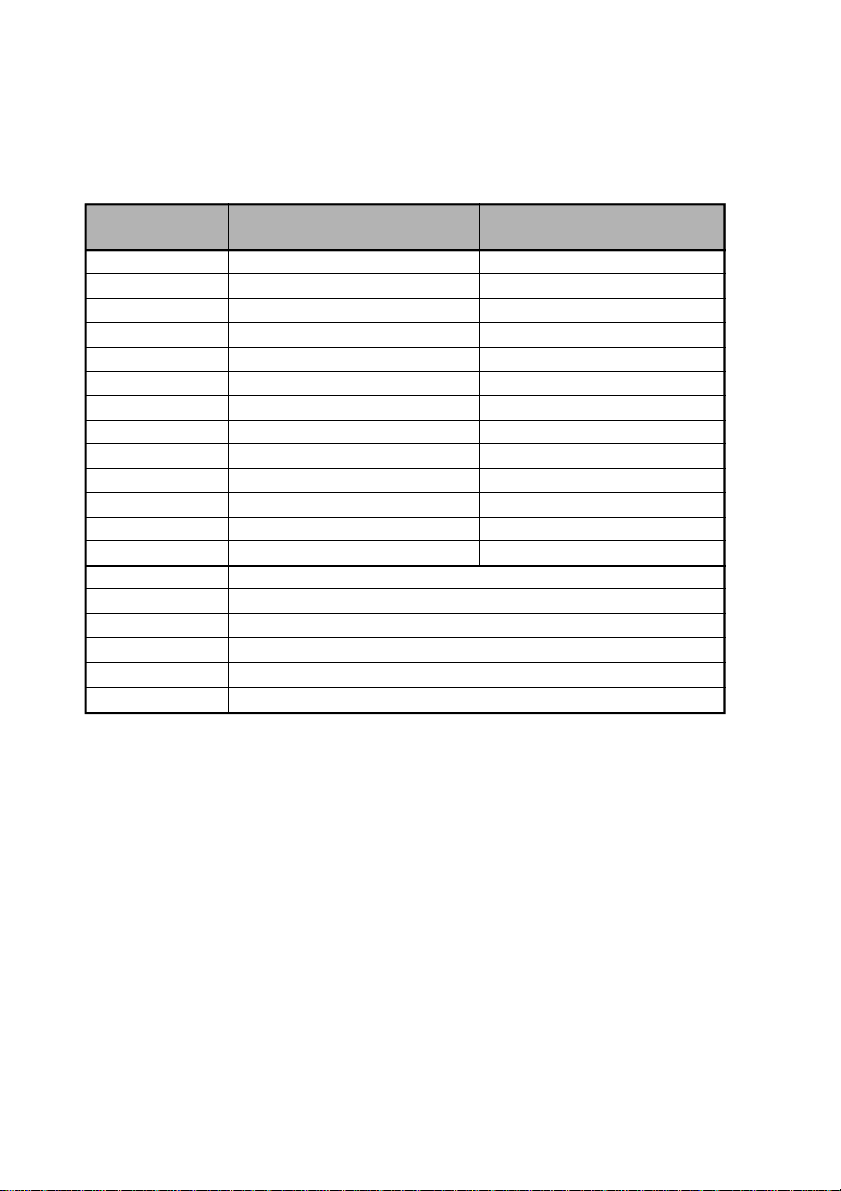

Dimensions BTI 85 BTI 100

A 1585 1780

B 1450 1640

D 645 675

F 770 775

G 130 130

K 340 340

L 355 370

M 1505 1685

N 1505 1685

P 210 210

R 285 285

S 1280 1460

V 410 410

1 Cold water inlet

2 Hot water outlet

3 Gas control

4 Drain valve

5 T&P relief valve tapping

6 Clean out

All dimensions are given in mm. (rounded off on 5mm). See figur 3.

8

Figur 3 - Dimensions

AOS 1092

9

Loading...

Loading...