American Standard 6068.26X, 6068.22X, 6067.22X, 6065.22X, 6067.26X User Manual

...

Installation Instructions

SELECTRONIC™ |

MODEL NUMBERS |

|

|

|

|

||

PROXIMITY TOILET |

6065.22X |

6065.26X |

|

6067.22X |

6067.26X |

|

|

CONCEALED FLUSH VALVE |

|

|

|

6068.22X |

6068.26X |

|

|

1.28 & 1.6 GPF

Certified to comply with ASME A112.19.2M

© 2010 AS America, Inc.

M968550 REV. 1.5

Concealed Flushometer

for 1-1/2" Top or Back Spud Bowls

CLOG RESISTANT

• Self-cleaning piston valve prevents clogging and reduces maintenance.

ONE SENSOR FITS ALL

•Only 1 sensor for entire Selectronic™ line of faucets, urinals, and flush valves.

•Range can be adjusted manually or with optional remote control.

•Sensor Features Low Battery Indicator.

NOTE TO INSTALLER: Please give this manual to the customer after installation.

To learn more about American Standard Faucets visit our website at: www.americanstandard-us.com or U.S. customer's e-mail us at: faucetsupport@americanstandard.com

For Parts, Service, Warranty or other Assistance,

please call 1-800-442-1902 (In Canada: 1-800-387-0369)

(InTorontoArea onlly::1--905--3061093))

Thank you for selecting American-Standard...the benchmark of fine quality for over 100 years. To ensure that your installation proceeds smoothly--please read these instructions carefully before you begin.

UNPACKING |

All American Standard Products Are Water Tested At Our Factory. |

Some Residual Water May Remain In The Valve During Shipping. |

|

|

|

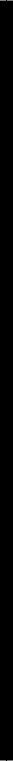

1. Remove the Flush Valve items from the carton. The illustration below shows all items after they have been removed from the carton. Some items may be packaged partially assembled to other items.

1. Flush Valve Assembly |

5. Sweat Solder Adapter |

7c. Vacuum Breaker Flush Connection |

|

2. Electrical Box |

6. Manual Override Hoses |

(Top Spud) |

|

8a. AC Power Supply [Model# 6067] |

|||

3. Cover Plate with Sensor |

7a. Vacuum Breaker Flush Connection |

||

8b. DC Power Supply |

|||

|

|||

4. Supply Stop |

(Wall-Mount Back Spud) |

||

8c. 10’ Extension Wire for Multi-AC |

|||

|

7b. Vacuum Breaker Flush Connection |

||

|

9. Installation Instructions |

||

|

(Floor-Mount Back Spud) |

CARE INSTRUCTIONS FOR CHROME PLATED ITEMS:

DO: SIMPLY RINSE THE PRODUCT CLEAN WITH CLEAR WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: DO NOT CLEAN THE PRODUCT WITH SOAPS, ACID, POLISH, ABRASIVES, HARSH CLEANERS, OR A CLOTH WITH A COARSE SURFACE.

6

6

2

T O P

3

4

5

1

7b

DO NOT REMOVE PROTECTIVE FILM FROM SENSOR EYE UNTIL INSTALLATION IS COMPLETE.

|

Instructions |

SELECTRONIC™ |

MODEL NUMBERS |

|

|

PROXIMITY TOILET |

6065.22X |

6065.26X |

|

|

|

6067.22X |

6067.26X |

|

|

|

CONCEALED FLUSH VALVE |

6068.22X |

6068.26X |

|

|

1.28 & 1.6 GPF |

|

|

9 |

Installation |

M968550 REV. 1.5 |

|

|

|

|

|

|

|

|

|

Concealed Flushometer |

|

|

|

|

for 1-1/2" Top or Back Spud Bowls |

|

|

|

|

CLOG RESISTANT |

|

|

|

|

• Self-cleaning piston valve prevents clogging and reduces maintenance. |

||

|

|

ONE SENSOR FITS ALL |

|

|

|

|

• Only 1 sensor for entire Selectronic™ line of faucets, urinals, and |

||

|

|

flush valves. |

|

|

|

|

• Range can be adjusted manually or with optional remote control. |

||

|

|

Certified to comply with ASME A112.19.2M • Sensor Features Low Battery Indicator. |

|

|

|

|

© 2009 AS America, Inc. |

|

|

|

NOTE TO INSTALLER: Please give this manual to the customer after installation. |

|||

|

To learn more about American Standard Faucets visit our website at: www.americanstandard-us.com |

|||

|

or U.S. customer's e-mail us at: faucetsupport@americanstandard.com |

|

|

|

For Parts, Service, Warranty or other Assistance,

please call 1-800-442-1902 (In Canada: 1-800-387-0369)

(InTorontoArea onlly::1--905--3061093))

7a

7c

8a |

8b |

8c |

M968550 REV. 1.5

1

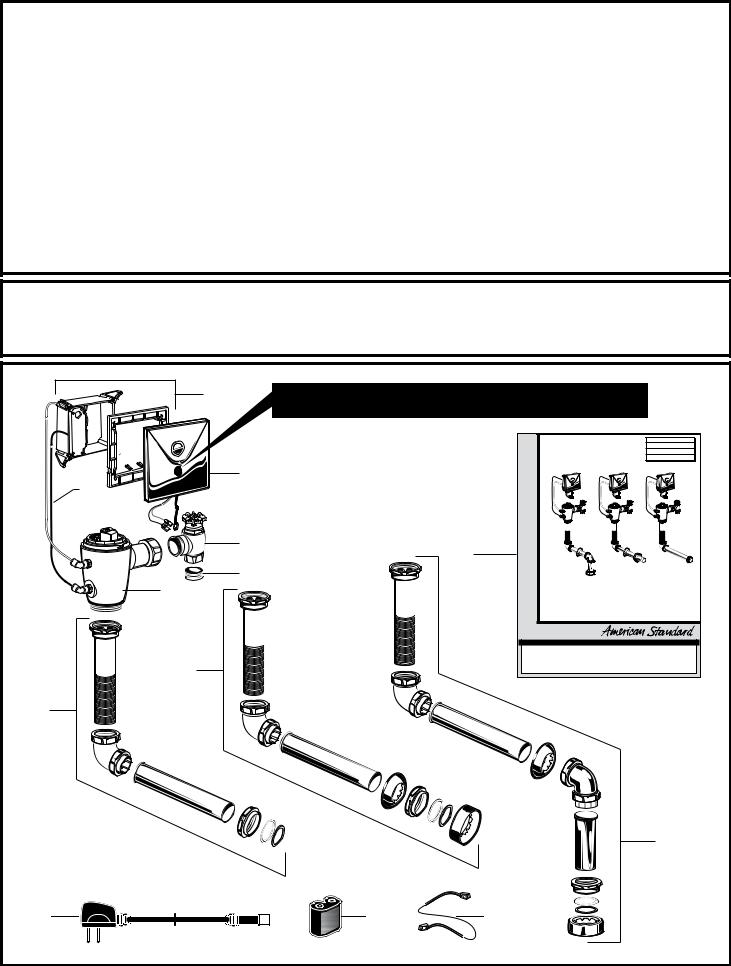

Fig. 1 |

GENERAL DESCRIPTION: |

Roughing-in Dimensions |

25mm (1) MAX. |

|

|

SELECTRONIC™ |

|

|

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

PROXIMITY TOILET |

|

||

|

|

|

FINISHED WALL |

MAXIMUM |

|

FLUSH VALVE |

|

|

|

|

160mm |

|

|

DETECTION ZONE |

Concealed Flushometer |

|

|||

|

|

TOP SPUD |

400mm-800mm |

|

|

||||

|

|

|

for 1-1/2" Spud Fixtures |

|

|||||

|

(6-1/4) |

|

TOILET |

(15-3/4 TO 31-1/2) |

|

||||

|

|

|

|

|

|

Exclusive, self cleaning piston-type flush |

|||

|

|

|

|

|

|

valve with proximity operation and manual |

|||

160mm |

|

|

|

127X127mm |

|

override. |

Operates on DC (batter y)or |

||

(6-1/4) |

OVERRIDE |

|

|

(5X5 CUTOUT |

|

AC power. Recommended operating |

|||

|

|

15˚ |

|

||||||

|

BUTTON |

|

FOR BOX) |

|

pressure 25psi (flowing) to 80 psi (static). |

||||

|

|

|

|

|

|||||

|

SENSOR |

|

|

|

|

Can install left or right-handed. Detection |

|||

|

|

|

|

|

|

Zone can also be adjusted manually, or |

|||

|

|

|

|

|

|

with optional remote control. |

|

||

406mm |

|

|

|

EXPOSED BACK |

|

|

|

||

|

|

|

SPUD TOILET |

|

|

CONCEALED BACK |

|||

(16) |

SUPPLY |

|

|

432mm |

|

289 TO 403mm |

|

SPUD TOILET |

|

|

|

WALL THICKNESS |

|

|

|||||

|

DN 25mm |

|

|

(11-3/8 MIN. TO |

|

|

|

||

|

|

(17 MAX.) |

|

|

|

|

|||

|

(1) I.P.S. |

|

|

|

15-7/8 MAX.) |

|

|

TOP OF |

|

|

|

|

|

|

|

|

|||

|

-C-L- |

|

51mm (2) |

73 TO 111mm |

|

|

|

|

FIXTURE |

|

115mm-134mm |

|

|

|

|

|

|||

|

|

+ WALL THICKNESS |

|

|

|

|

|

||

|

(4-1/2 TO 5-1/4) |

|

(2-7/8 TO |

|

TOP OF |

292mm |

|

||

*-C-L- |

|

|

|

|

|||||

|

|

|

4-3/8) |

|

FIXTURE |

(11-1/2) MAX. |

|

||

152mm |

403 TO 441mm |

|

|

|

|

|

|

|

|

(6) MIN. |

73 TO 137mm |

|

|

19mm |

|

|

|||

(15-7/8) MIN. TO |

|

|

|

|

|||||

|

(17-3/8) MAX. |

(2-7/8)MIN. TO |

|

|

(3/4.) |

|

|

||

|

|

|

(5-3/8) MAX. |

|

|

|

|

|

|

|

|

51mm |

|

|

|

|

|

|

|

|

|

(2) |

|

|

|

|

|

|

|

|

|

|

127mm |

|

|

|

51mm |

19mm |

|

|

TOP SPUD |

|

|

|

|

(3/4.) |

|||

|

483mm |

(5) MAX. |

|

|

|

|

(2) |

||

|

TOILET |

|

|

*FOR LOCATION OF INLET |

|

||||

|

(19) MAX. |

51mm |

|

|

|

||||

|

|

|

SUPPLY ON BACK INLET |

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

(2) |

FIXTURES,REFER TO FIXTURE |

|

|

||

|

|

|

|

|

|

BEING INSTALLED |

|

|

|

|

|

|

71mm |

|

FOR CORRECT HEIGHT FROM |

|

|

||

|

|

|

|

|

FINISHED FLOOR |

|

|

||

*Note: The Critical Line (-C-L-) on Vacuum |

(2-3/4) DIA. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||

Breaker must typically be 6" (152mm) min. above fixture. Consult Codes for details.

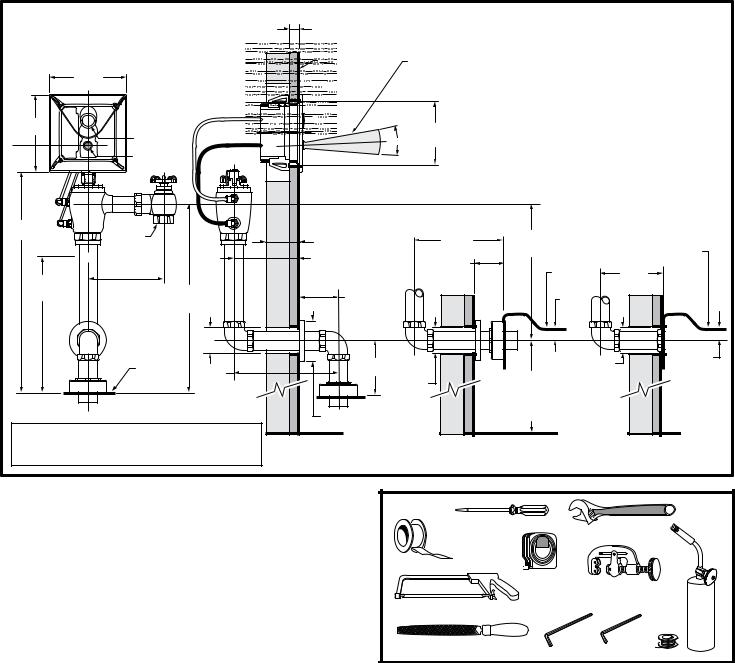

RECOMMENDED TOOLS; Fig. 2

1.Teflon Tape

2.Flat Blade Screwdriver

3.Adjustable Wrench

4.Tape Measure

5.Hacksaw

6.Tubing Cutter

7.File

8.For Sweat Connection; Solder and Torch

9.2.5mm Hex Wrench

10.1.5mm Hex Wrench

Fig. 2 |

|

|

|

|

1 |

2 |

|

|

3 |

|

4 |

|

|

|

|

|

10' |

|

|

|

|

|

|

|

|

|

|

|

6 |

|

5 |

|

|

8 |

|

7 |

|

9 |

10 |

PRIOR TO INSTALLATION |

• Flush all water lines prior to operation (See Step 4). Dirt |

|

Note: Prior to installing the Selectronic™Flush Valve |

|

|

and debris can cause flush valve to run continuously. |

|

|

the following items must be installed. |

|

|

|

|

|

1. Water Closet |

• With the exception of Supply Stop Inlet, DO NOT use pipe |

|

sealant or plumbing grease on any valve component or |

|

|

|

|

|

2. Drain line |

coupling! |

|

|

|

|

3. Water supply line |

• Protect the chrome or special finish on chrome plated |

|

items. |

|

|

|

DO NOT USE toothed tools on finished surfaces to install or |

|

IMPORTANT: |

service these valves. Also see “Care and Cleaning” section |

|

• All plumbing must be installed in accordance with |

of this manual. |

|

applicable codes and regulations. |

• This product contains mechanical and/or electrical |

|

|

|

|

• Water supply lines must be sized to provide an |

components that are subject to normal wear. These |

|

components should be checked on a regular basis and |

|

|

adequate volume of water for each fixture. |

|

|

replaced as needed to maintain the valve’s performance. |

|

|

|

|

|

|

|

|

|

M968550 REV. 1.5 |

|

2

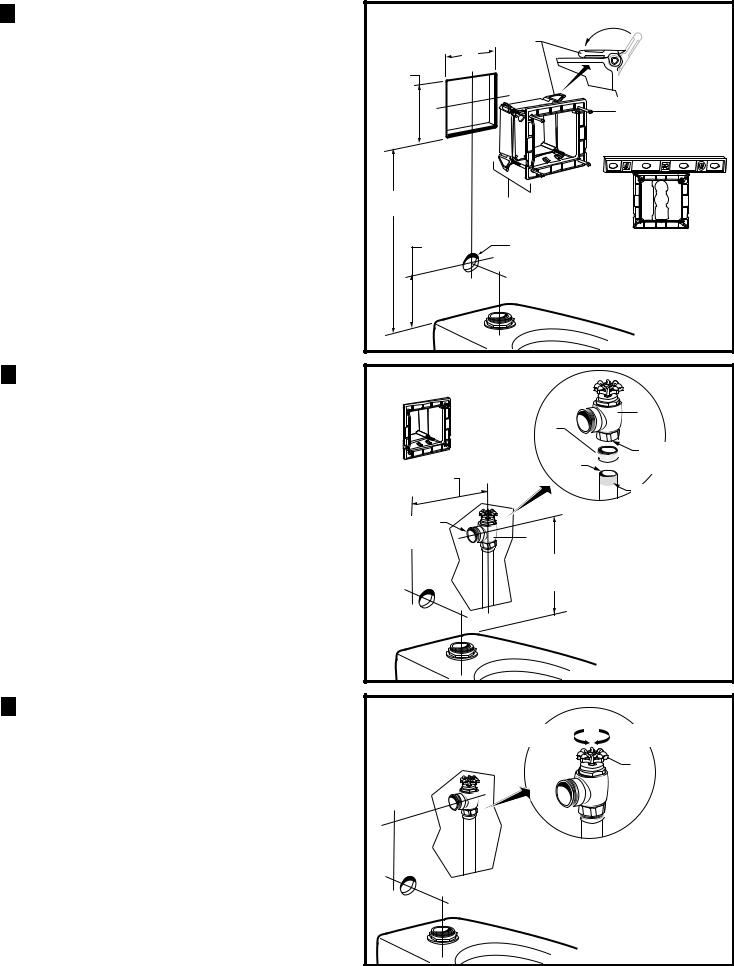

1 INSTALL ELECTRICAL BOX

ASSEMBLY; Fig. 3

1.Cut a 127x127mm (5"x 5") opening in finished wall for ELECTRICAL BOX (1) at the deminsion shown in Fig.3.

2.Rotate the 4 MOUNTING TABS (2) flat against the electrical box. Holding the MOUNTING TABS (2) in position install the ELECTRICAL BOX (1) into the opening. Make sure the MOUNTING TABS (2) are behind the wall.

3.Tighten the the 4 MOUNTING SCREWS (3) until the ELECTRICAL BOX (1) is almost secure in the wall. Before tighting fully rest a level at the top edge of the ELECTRICAL BOX (1) and make sure the box is level, then tighten fully. Fig. 3a.

4.*Cut a 2" hole for supply to fixture at deminsion shown.

2 INSTALL SWEAT SOLDER

ADAPTER; Fig. 4

CAUTION |

Turn water supplies off |

before beginning |

Note: Control stop inlet is 1" IPS. For optional sweat connection, install Sweat Solder Adapter (1) (Supplied) for 1" copper pipe supply line. Fig. 4.

1.Clean the end of the supply pipe. Push the threaded ADAPTER (1) on until it is seated against the internal stop. Sweat the ADAPTER (1) to the pipe.

2.From behind the wall install the CONTROL STOP (2) to the water supply line with the outlet positioned as required.

3.Support piping as required.

3 FLUSH OUT SUPPLY LINES; Fig. 5

1. Open SUPPLY STOP (1).

3.Turn on water supply to flush line of any debris or sediment.

4.Close SUPPLY STOP (1) and turn off water supply line.

Fig.3 (TOP SPUD FIXTURE ILLUSTRATED)

127mm |

2 |

|

(5) |

|

|

127mm |

|

|

(5) |

|

|

|

T O P |

3 |

Fig. 3a

T O P

406mm |

1 |

(16 REF.) |

|

127mm |

*FOR HOLE LOCATION OF |

(5 MAX.) |

SUPPLY ON BACK INLET |

|

FIXTURES, REFER TO FIXTURE |

|

BEING INSTALLED FOR CORRECT |

|

HEIGHT FROM FINISHED FLOOR |

Fig. 4

T O P |

|

2 |

|

1 |

|

|

FILE |

CONTROL STOP |

|

DN 25mm |

|

|

EDGES |

|

|

(1" I.P.S.) |

|

115mm-134mm |

|

|

|

|

|

(4-1/2 TO 5-1/4) |

|

CLEAN & SOLDER |

|

|

|

|

|

TO ADAPTER (1) |

CONTROL |

2 |

|

STOP |

|

|

OUTLET |

|

|

|

403 TO 441mm |

|

|

(15-7/8 MIN. TO |

|

|

17-3/8 MAX.) |

|

Fig. 5

COUNTER-CLOCKWISE |

CLOCKWISE CLOSES |

OPENS CONTROL STOP |

CONTROL STOP |

|

1 |

M968550 REV. 1.5

3

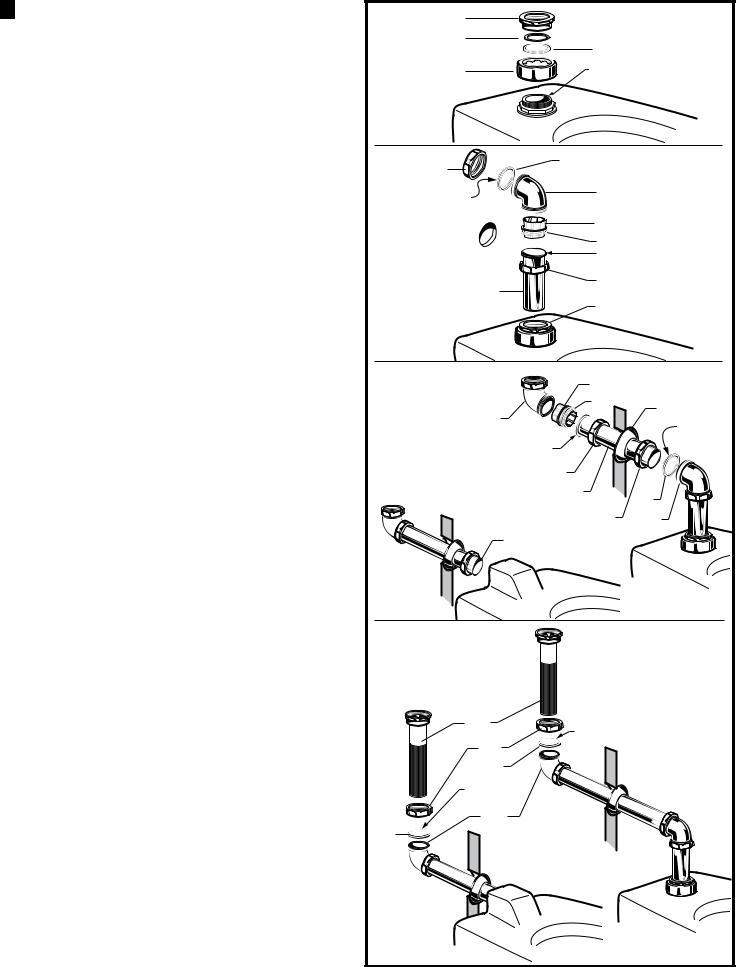

44 INSTALL VACUUM BREAKER AND

FLUSH CONNECTIONS; Fig. 6

1.Place the SPUD FLANGE (1) over the spud on the Fixture. Fig. 6.

2.Thread SPUD COUPLING NUT (2) onto Spud. Make sure SEAL WASHER (4) and FRICTION WASHER (3) are installed. Do not tighten fully. Fig. 6.

3. Remove the COUPLING NUTS (6, 6a) from the CHROME ELBOW (5). Make sure you have a TAPERED RUBBER WASHER (7), PLASTIC SUPPORT (8) and SQUARE SEAL WASHER (9). Fig. 6a.

4.Install the SQUARE SEAL WASHER (9) onto the PLASTIC SUPPORT (8) if not already installed. Insert the PLASTIC SUPPORT (8) into the DOWN TUBE (10). Slide the COUPLING NUT (6) onto the DOWN TUBE (10). Connect the COUPLING NUT (6) to the CHROME ELBOW (5) and tighten fully. Insert the DOWN TUBE (10) with CHROME ELBOW (5) into the SPUD COUPLING NUT (2) and push it down. Do not tighten fully. Fig. 6a. Note: If center line of ELBOW

(5) cannot be adjusted to line up with hole in wall, then cut the DOWN TUBE (10) as required.

5.Measure and cut the HORIZONTAL TUBE (11) to length required. Important: Make sure that there is a minimum of 1-1/4" for engagement with elbow when making your measurement. Fig. 6b.

6.Remove the COUPLING NUT (14) from BRASS ELBOW (12) and slide it onto the HORIZONTAL TUBE (11). Install the SQUARE SEAL WASHER (13) onto the PLASTIC SUPPORT (15) if not already installed. Insert the PLASTIC SUPPORT (15) into the HORIZONTAL TUBE (11). Connect the COUPLING NUT (14) to the BRASS ELBOW (12) and tighten fully.

Fig. 6b.

7.From behind the wall install the ELBOW AND TUBE ASSEMBLY (12, 11) through the hole in the wall. Install WALL ESCUTCHEON (16) onto HORIZONTAL TUBE (11). Assemble the COUPLING NUT (6a) and TAPERED RUBBER WASHER (7) in the CHROME ELBOW (5) onto the HORIZONTAL TUBE (11). Push the HORIZONTAL TUBE (11) into the CHROME ELBOW (5). Tighten COUPLING NUT (6a) but not fully. Fig. 6b.

8.For back spud installations: Follow steps #1 and #2 to install the spud coupling kit. Push the HORIZONTAL TUBE (11) into the spud connection on the back of the fixture. Do not tighten fully. If spud coupling kit is not required install HORIZONTAL TUBE (11) into back spud on fixture and hand tighten. Fig. 6b.

9.All installations: If required cut scored VACUUM BREAKER PIPE (17) to fit, leave a minimum of 1-1/4" (32mm) of pipe to ensure engagement with compression coupling. Assemble the COUPLING NUT (18) and TAPERED RUBBER WASHER (19) in the BRASS ELBOW (12) onto the VACUUM BREAKER PIPE (17). Install VACUUM BREAKER PIPE (17) into BRASS ELBOW (12) and hand tighten COUPLING NUT (18). Fig. 6c.

Note: If cutting VACUUM BREAKER PIPE (16) to size, note that Critical Line (C/L) on Vacuum Breaker must typically be 6" (152mm) above fixture.

Consult Code for details.

Fig. 6 |

2 |

|

|

|

3 |

4 |

|

|

|

|

|

|

1 |

1-1/2" TOP SPUD |

|

|

|

|

|

Fig. 6a |

6a |

7 |

|

|

|

||

|

|

|

|

TAPERED SIDE |

5 |

|

|

|

|

8 |

|

|

|

9 |

|

|

|

FLANGE END UP |

|

|

10 |

6 |

|

|

2 |

|

|

|

|

|

|

Fig. 6b |

|

15 |

TOP SPUD |

|

|

INSTALLATION |

|

|

12 |

13 |

16 |

|

|

||

|

|

TAPERED |

|

|

|

|

|

|

|

|

SIDE |

|

FLANGE END |

|

|

|

BACK SPUD |

14 |

|

|

11 |

|

|

|

INSTALLATION |

7 |

|

|

6a |

||

|

11 |

5 |

|

|

|

|

|

Fig. 6c |

|

|

|

BACK SPUD |

TOP SPUD |

||

INSTALLATION |

INSTALLATION |

||

|

17 |

TAPERED SIDE UP |

|

|

|

||

|

18 |

|

|

|

19 |

|

|

|

TAPERED |

|

|

|

SIDE UP |

|

|

19 |

12 |

|

|

|

|

|

|

4 |

|

|

M968550 REV. 1.5 |

|

|

|

|

Loading...

Loading...