American Standard 2633.1, 2257.001, 3353, 2634.001, 3351 User Manual

...

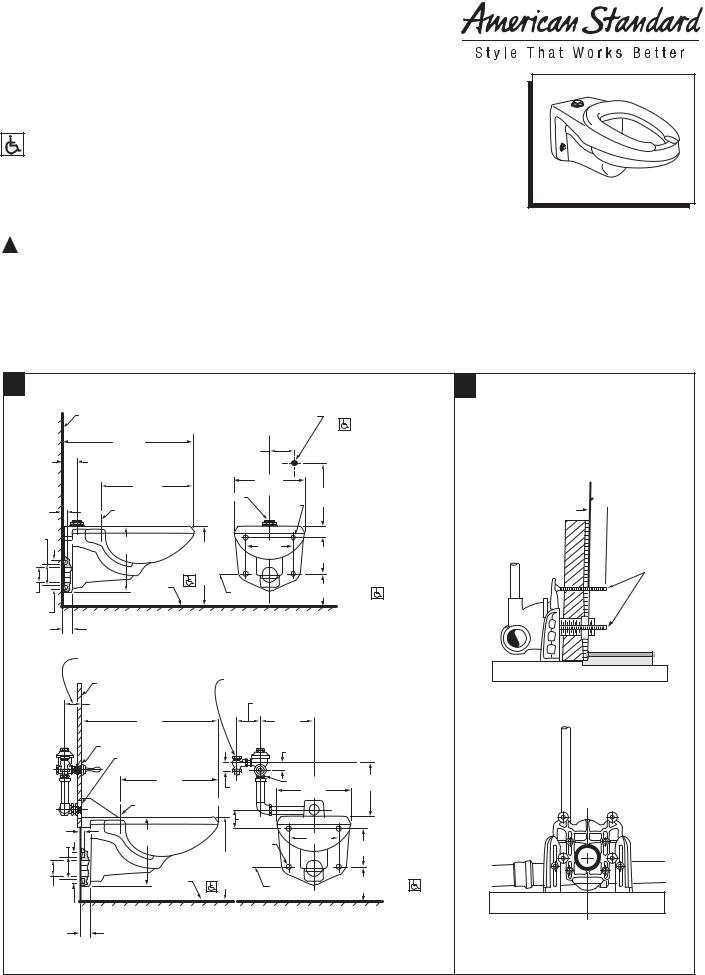

INSTALLATION INSTRUCTIONS

AFWALL FLUSH VALVE

WALL-MOUNTED TOILETS

Model 3351, 3352, 3353, 3354, 2257.001, 2633.100, 2634.001

Meets the American Disabilities Act Guidelines and ANSI A117.1

Requirements for the Physically Challenged

Thank you for selecting American Standard – the benchmark of fine quality for over 100 years. To ensure thisproduct is installed properly, please read these instructions carefully before you begin. (Certain installations may require professional help.) Also be sure your installation conforms to local codes.

! CAUTION: PRODUCT IS FRAGILE. TWO PEOPLE ARE RECOMMENDED FOR

HANDLING TO AVOID BREAKAGE AND POSSIBLE INJURY!

NOTE: For proper operation product requires a minimum of 30 psi working line pressure

RECOMMENDED TOOLS AND MATERIALS

Closet Carrier Support |

Regular Screwdriver |

Sealant |

Carpenters Level |

Putty Knife |

Adjustable Wrench |

Tape Measure |

Flush Valve |

1 |

Pictures may not exactly define contour of china |

|

||||||||

|

|

|||||||||

|

|

FINISHED WALL |

1" N.P.T. OR C.W.T. SUPPLY |

|

|

When installed, |

||||

|

|

|

AS REQUIRED TO FLUSH VALVE |

|

|

|||||

|

|

660mm |

|

|

|

|

|

|

top of seat is |

|

|

|

|

C/L |

|

|

|

17" to 19" |

|||

|

|

(26") |

|

|

|

|

||||

|

|

121mm |

|

|

|

|

(432mm to 483mm) |

|||

|

|

73mm |

(4-3/4") |

|

|

|

|

|||

|

|

|

|

|

|

from the finished |

||||

|

|

|

|

|

|

|

|

|||

|

|

(2-7/8") |

|

|

|

|

|

|

||

|

|

|

356mm |

|

|

|

floor. |

|

||

|

|

470mm |

|

|

|

|

|

|||

|

|

|

(14") |

|

|

|

|

|

||

|

|

(18-1/2") |

|

292mm |

|

|

|

|

||

|

|

1-1/2" SPUD |

(4) 22mm |

|

|

|

|

|||

|

|

C/L OF SEAT POST |

(11-1/2") |

|

|

|

|

|||

|

19mm |

|

|

(7/8") |

|

|

|

|

||

|

HOLES 140 mm |

|

|

|

|

|

|

|

||

|

|

|

HOLES |

|

|

|

|

|

||

|

(3/4") |

(5-1/2") CENTER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

83mm |

330mm |

381mm |

229mm |

|

|

|

|

|

|

|

(3-1/4") |

(13") |

191mm |

|

|

|

|

|||

|

(9) |

|

|

|

|

|||||

|

|

|

(15") |

(7-1/2") |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

432mm |

|

|

|

|

|

|

|

|

|

FINISHED |

(17") |

|

|

133mm |

|

|

|

|

62mm |

C/L OF |

|

|

or |

184mm |

|

||||

FLOOR |

|

|

|

|||||||

(2-1/8") |

OUTLET |

|

(5-1/4") |

(7-1/4") |

|

|||||

|

|

|

|

|||||||

|

142mm |

|

|

|

|

|

|

|

|

|

|

(5-1/4") |

32mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1-1/4") |

|

|

|

|

|

|

|

|

|

|

FOR WALLS UP TO 1" IN THICKNESS FOR EACH INCH |

|

|

|

|

|

|

|

|

|

|

ADDITIONAL THICKNESS OF WALL ADD 25mm (1) TO |

|

|

|

|

|

|

|

|

|

|

MEASUREMENT SHOWN |

|

|

|

|

|

|

|

|

|

|

FINISHED WALL |

1" C.W.T. OR N.P.T. SUPPLY |

|

|

|

|

|||

|

|

AS REQ'D NOT FURNISHED |

|

|

|

|

||||

|

|

95mm |

|

121mm |

|

|

|

|

|

|

|

|

(3-3/4") |

|

(4-3/4") |

|

|

|

|

|

|

|

|

660mm |

|

|

254mm |

|

|

|

|

|

|

|

(26") |

|

|

(10") |

|

|

|

|

|

|

|

38mm (1-1/2") DIA. HOLE IN WALL |

|

38mm |

|

|

|

|

||

|

|

76mm(3") DIA. HOLE IN WALL |

|

(1-1/2") C/L |

|

|

|

|

||

|

|

FOR 1-1/2" SPUD |

|

|

|

|

|

|

|

|

|

|

470mm |

41mm |

|

VACUUM BREAKER |

298mm |

|

|||

|

|

(18-1/2") |

|

(11-3/4") |

|

|||||

|

|

|

|

356mm |

|

|

|

|||

|

|

(1-5/8") |

|

|

|

|

|

|||

|

|

|

|

|

(14") |

|

|

|

|

|

|

|

C/L OF SEAT POST HOLES |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

140mm(5-1/2") CENTERS |

|

|

|

|

|

|

|

|

|

|

|

89mm |

|

|

|

|

|

|

|

|

(3/4") |

|

(3-1/2") |

|

|

|

|

|

|

|

|

330mm |

|

|

|

|

|

|

|

|

|

|

19mm |

(4) 22mm (7/8") |

|

229mm |

|

|

|

|

||

|

(13") |

|

|

|

|

|

||||

|

83mm |

|

|

|

191mm |

|

||||

|

DIA. HOLES |

|

(9") |

|

|

|

||||

|

|

|

|

|

|

|||||

|

(3-1/4") |

|

381mm |

|

|

|

|

|

(7-1/2") |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(15") |

|

|

|

|

|

|

|

|

|

|

or |

|

|

|

|

|

|

|

|

|

FINISHED |

432mm |

|

|

|

|

|

133mm |

184mm |

|

62mm 1/8")-(2 133mm |

FLOOR |

(17") |

|

C/L OF |

|

|

|

(5-1/4") or |

(7-1/4") |

|

1/4")-(5 |

|

|

OUTLET |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32mm |

|

|

|

|

|

|

|

|

|

|

(1-1/4") |

|

|

|

|

|

|

|

|

Refer to instructions supplied with wall carrier for proper installation of 4-bolt support system wall cavity requirements and rough-in information for waste outlet piping.

2 FIXTURE MOUNTING

Fixture studs should project 1-7/8" (48mm) from face of finished wall.

FINISHED  WALL

WALL

1-7/8" (48mm)

1-7/8" (48mm)

(4) STUDS

Side View

Front View

P r o d u c t n a m e s l i s t e d h e r e i n a r e t r a d e m a r k s o f A S A m e r i c a , I n c . |

7301115-100 Rev. C |

© A S A m e r i c a , I n c . 2 0 1 0 |

S A V E F O R F U T U R E U S E

Loading...

Loading...