Alto-Shaam COMBITHERM 20.20ESG User Manual

COMBITHERM®

MODEL 20•20ESG DELUXE

CAPACITY OF FORTY (40) FULL-SIZE OR GN 1/1 PANS,

TWENTY (20) FULL-SIZE SHEET OR GN 2/1 PANS

ITEM NO. _______________________

20 20ESG

GAS COM BINATION OVEN/S TE AME R

• Fla sh-st eam gene rati on make s

conve ntiona l stea m genera tor obs olete :

— Elim ina tes stea m gener atin g boiler mainte nance

— Ends boiler hea ting ele ment burn-out

— Mai ntai ns stea m levels without a water rese rvoir

•Cook by internal product temperature or time with tempera ture variable steam, convection heat, or a combination of both to roast, steam, bake, or oven-fry in a single piece of equipment.

•Provi des inc rease d food qua lity and expand s menu options whi le increa sing prod uction effici enc y and speed by as much as 70-perc ent com pare d to conventi onal cooking met hods.

•EcoS mart™ technolo gy reduce s energy cos t by using less elec tric ity and water duri ng both norm al opera tion and the cle aning fun ction.

•Gold-n-Brown™ feature provides the operator with the abil ity to add additional product color.

•AutoClean™ feature simplifies the cleaning process to a single oven function.

•Sta nda rd and Del uxe cont rol offers a 2-speed fan, cool-d own feature, addit iona l moistu re injec tion, Delta -T cooking,

mul tip le langua ge dis play, and other con trol fea tures .

•Enha nced safety fea ture inc lude s autom ati c stea m venting imm edia tely before cooki ng time expires. PATENT #7,282,674

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

SHORT FORM SPECIFICATIONS: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

Provide Alto-Shaam Combitherm ® floor standing Model 20•20 ESG flash-steam combi oven/steamer |

designed with EcoSmart™ |

|

||||||||||||||||||

technology |

for reduced energy and water usage and include |

operational |

modes for steam, convection, and a combination of steam and |

|||||||||||||||||

convection |

heat. Standard features to include energy efficient forced-air |

power burner, patented |

heat exchange |

system, electronic |

||||||||||||||||

ignition, patented automatic steam venting; Gold-n-Brown™ |

browning |

function; |

and a self-adjusting, flush-mounted |

rotary door handle |

||||||||||||||||

with a steam venting safety |

stop. Control |

to include |

2-speed |

fan and cool-down |

function. Oven is to be constructed |

of 18 gauge stainless |

||||||||||||||

steel, include an attached spray hose with backflow |

preventer, and automatic cleaning function. |

The oven is to accommodate up to |

||||||||||||||||||

20 full-size |

sheet pans or 40 full-size hotel pans, include a removable door gasket for easy replacement, and standard |

right-hand door |

||||||||||||||||||

hinging. Includes roll-in pan cart with removable drip tray and cart handle. |

|

|

|

|

|

|

|

|

|

|||||||||||

STANDARD CONTROL: |

To include |

removable |

quick-connect |

internal |

product |

temperature |

probe in the oven interior. |

|

||||||||||||

DELUXE CONTROL: |

To include |

removable |

quick-connect |

internal |

product |

temperature |

probe in the oven interior |

|

|

|||||||||||

|

|

S-CONTROL: |

and programming capability |

with Rapid-Touch™ |

operational quick-keys. |

|

|

|

|

|||||||||||

|

|

To include |

removable |

quick-connect |

internal |

product |

temperature |

probe in the oven interior |

as an option. |

|||||||||||

|

MODELS: |

|

|

STANDAR D F EATURE S A ND ACCESSOR IES |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

• Roll-i n pan c art com plete ly interc hang eab le with QC-10 0 Quic kChil ler™ |

|||||||||||||

|

■ 20•20ES G: STANDAR D |

|

||||||||||||||||||

|

|

and 20•20 Com bim ate® compa nion holdi ng c abi net with : |

|

|

|

|||||||||||||||

|

■ 20•20ES G: DELUXE |

|

|

|

|

|||||||||||||||

|

|

Twenty (20) non-tilt pan support rails |

|

|

|

|

|

|

||||||||||||

|

■ 20•20ES G: S-CONTROL |

|

21-1/16" (535 mm) hor izont al wid th b etwe en rail s |

|

|

|

|

|||||||||||||

|

|

2-5/8" (65m m) vert ica l s paci ng b etwe en rail s |

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

Ten (10) s tainle ss stee l s helves |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

Removable dri p t ray and ca rt hand le |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

• Four (4) adjus tab le legs |

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

• One (1) h and -held show er with backflo w pr evente r PATENT PENDING |

|

|

|||||||||||

|

|

|

|

ANSI/NSF 4 |

|

• One (1) f lush-mount ed rota ry d oor l atc h w ith stea m venti ng position |

||||||||||||||

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

• Single -poi nt deta cha ble te mpera ture prob e |

(OPTIONAL ON S-CONTROL MODELS ) |

||||||||||||

|

|

|

|

|

W164 N9221 Water Street |

• P.O. Box 450 |

• |

Menomonee Falls, |

Wisconsin |

53052-0450 |

• |

U.S.A. |

||||||||

|

|

|

|

|

PHONE : |

262.251.3800 |

800.558.8744 |

U.S.A./CANADA |

FAX : |

|

262.251.7067 |

800.329.8744 |

U.S.A. ONLY |

|||||||

|

|

|

|

|

|

|

|

|

|

|

www.alto-shaam.com |

|

|

|

|

|

|

|||

PR INT ED IN U .S .A . |

D UE TO |

O N GOI N G P RODU C T IMP ROVE ME NT , SP E CI F IC ATI O NS AR E S UBJE CT TO C HAN GE WI THO U T NO TI C E . |

|

|

#475 - 1/08 |

|||||||||||||||

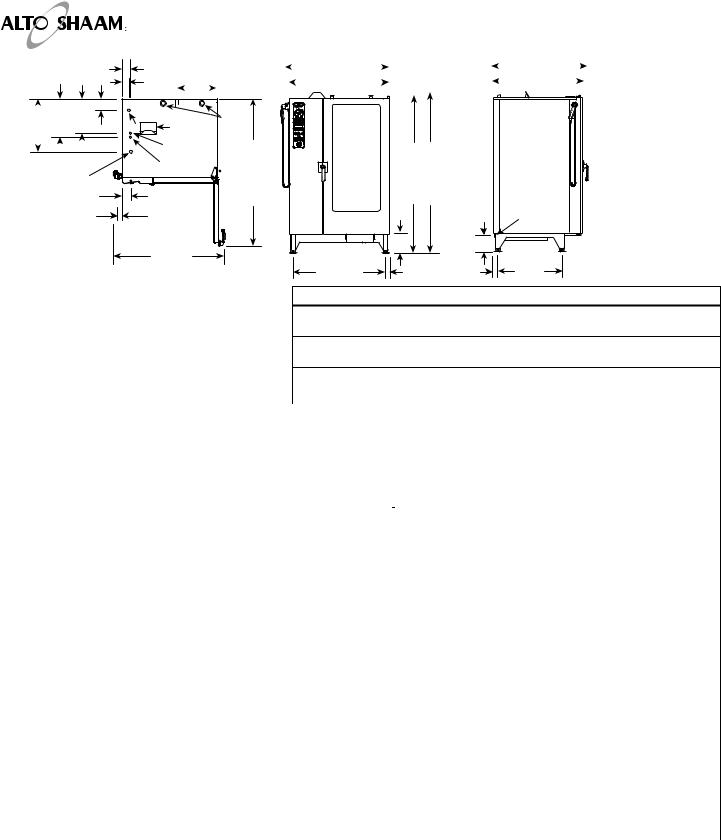

6" (151mm)

|

|

19-3/8" (491mm) |

17-3/8" (441mm) |

||

26-3/4" (678mm) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Gas Connection

(Bottom)

GA S COM BI NATION OVEN/ST |

EAMER 20 20ESG |

||||||||||||||||||||||||||

4-3/8" (110mm) |

20-1/4" |

|

|

|

|

49-13/16" (1264mm) |

|

|

|

|

|

|

|

|

|

|

45-3/16" (1148mm) |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

3-9/16" |

|

|

|

(514mm) |

|

|

|

|

47-13/16" (1214mm) |

|

|

|

|

|

|

|

|

|

|

|

42-9/16" (1080mm) |

|

|

|

|

|

|

|

|

|

Water Drain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

(89mm) |

|

|

|

(Side Back) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical Connection |

Steam |

|

|

|

Vents |

|

|

|

|

(Bottom) |

|

|

|

|

Gas Exhaust (Top) |

(Top) |

|

|

|

Untreated Water |

13/16"-73 (1874mm) |

(226mm)15/16"-8 1/4"-75(1911mm) 5/8"-76(1946mm) |

(195mm)11/16"-7 |

(Bottom) |

2" (50mm) |

||||

Intake (Bottom) |

|

|

|

|

Treated Water |

|

|

|

|

Intake (Bottom) |

|

|

|

|

4-5/8" (116mm) |

|

|

Water Drain |

|

|

|

|

||

55-7/16" |

|

|

|

|

(1407mm) |

|

|

2-3/16" |

30-1/2" |

|

44" (1118mm) |

2" (49mm) |

(56mm) |

(775mm) |

|

DIME NS IONS : H x W x D |

|

||

|

EXTERIOR: |

|

|

|

|

76-5/8" x 49-13 /16 " x 4 5-3/16" |

(1946mm x 1 264mm x 1148mm ) |

||

|

EXTERIOR WITH RETRACTABLE DOOR: |

|

||

|

76-5/8" x 53-13 /16 " x 4 5-3/16" |

(1337mm x 1 366mm x 1148mm ) |

||

|

INTERIOR: |

|

|

|

|

54-15/16" x 25-1 /4" x 33-7 /8" |

(1395mm x 640 mm x 86 0mm) |

||

CLEARANCE |

REQUIREMENTS |

|

|

|

|

|

|

CONNECTED ENERGY LOAD : 190,000 Btu/ hr |

|

||||||

|

|

|

|

|

|

GAS RE QUI REME NT S |

|

|

|||||||

LEF T: 6" ( 152mm) |

PLUS SERVICE ACCESS : 18" (457mm) |

RECOM MENDED |

|

HOOK-UP : |

3/4" NPT |

||||||||||

|

20" (508mm) |

FROM HE AT PR OD UC IN G EQUIP MEN T |

|

MINIMUM CONNECTED PRESSUR E: |

5.5" W.C. (Natural Ga s) |

||||||||||

RI GH T: 4" ( 102mm) |

|

TO P: 20" ( 508mm) FOR AIR MOVEMENT |

MAXIMUM CONNECTED PRESSURE: |

9" W.C. (Propane) |

|||||||||||

|

14" W.C. |

||||||||||||||

BA CK : 4" ( 102mm) |

BO TTOM : 5- 1/ 8" |

(13 0mm) FOR LEGS |

GAS TYPE MUST BE SPECIFIED ON ORDER. |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

WAT ER Q UALI TY M IN IM UM S TA ND AR DS |

|

|||

WATER |

RE QUIREMENTS |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

USING A WATER SUPPLY NOT MEETING ALTO-SHAAM'S |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

TWO (2) COLD WATER INLETS - DRINKING QUALITY |

MINIMUM WATER QUALITY STANDARDS WILL VOID THIS |

|

|||||||||||||

ONE (1) TREATED WATER INLET: |

3/4" NPT |

|

|

|

WARRANTY. It is the responsibility of the purchaser to ensure |

|

|||||||||

ONE (1) UNTREATED WATER INLET: |

3/4" NPT |

|

|

|

that incoming water supply is compliant with the specifications |

|

|||||||||

2.8 to 6.2 bar |

listed through adequate treatment measures. Installation of the |

|

|||||||||||||

LINE PRESSURE: |

|

|

30 to 90 psi |

CombiGuard™ Water Filtration System is recommended, but this |

|

||||||||||

WATER DRAIN: |

1-1/2" |

FERNCO CONNECTION WITH AIR GAP |

system may not address all water quality issues present. |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

Contaminant |

Inlet Water Requirements(untreated water) |

|

||

INS TALL ATION REQUIREMENTS |

|

|

|

|

Free Chlorine |

Less than 0.1 ppm (mg/L) |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

Hardness |

Less than 3 gpg (52 ppm) |

|

||

Oven must be installed lev el. Hoo d i nst allat ion. Wate r s upply |

|||||||||||||||

Chloride |

Less than 30 ppm (mg/L) |

|

|||||||||||||

shut-off valve and back-f low p reven ter. Al ternate burn |

er ori fice |

pH |

7.0 to 8.5 |

|

|

||||||||||

is requ ired for in stallatio n sites at elevat ion s of 3,000 fe |

et (9 14m) |

Alkalinity |

Less than 50 ppm (mg/L) |

|

|||||||||||

Silica |

Less than 12 ppm (mg/L) |

|

|||||||||||||

abov e s ea level. |

|

|

|

|

|

|

|

|

Total Dissolved |

Less than 60 ppm |

|

||||

|

|

|

|

|

|

|

|

|

|

|

Solids (tds) |

|

|||

EL ECTRICA |

L |

|

|

|

|

|

|

|

|

|

|

|

|

||

VOLTAGE |

|

PHASE |

|

CYCLE/HZ |

|

AWG |

|

AMPS |

kW |

||||||

110 - 120 |

|

1 |

|

50/60 |

|

2 Wire plus ground, AWG 10 |

22.0 |

2.64 |

|

||||||

|

|

|

|

OTHER VOLTAGE S AVAILABLE : Range 200 — 415V — 1 or 3 ph, 50 or 60 Hz |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

WEIGHT |

|

|

|

|

|

|

CA PA CIT Y |

|

|

|

|

|

|||

NET |

838 lb EST . |

(380 kg) EST . |

|

|

FULL-SIZE PANS: |

20" x 12" x 2-1/2" |

Forty (40) |

|

|||||||

|

|

|

|

GN 1/1: |

530 x 325 x 65mm |

Forty (40) |

|

||||||||

SHI P |

1325 lb EST. |

(60 1 kg ) EST. |

|

|

|

|

GN 2/1: |

650 x 530 x 65mm |

Twenty (20) |

|

|||||

|

FULL-SIZE SHEET PANS:* |

18" x 26" x 1" |

Twenty (20) |

|

|||||||||||

CRATE |

|

82" X 56" X 50" EST. |

|

|

|

ON WIRE SHELVES ONLY |

|

|

|

|

|||||

|

|

|

|

|

|

|

480 l b ( 218 kg) MAXI MU M |

|

|

||||||

DIMENSIO NS: |

(2083 x 1422 x 1270m m) |

|

|

|

|

|

|

|

|||||||

|

|

|

|

VO LUM E MAX IM UM: 30 0 |

QU ARTS (380 LITE RS ) |

|

|||||||||

|

|

|

|

|

|

|

*ADD IT IONAL |

WIRE |

SHELVES RE QUIR ED FOR MAXIM UM CAPAC ITY |

|

|

||||

#4 75 - 1/0 8 |

|

DUE T O ON G OIN G PR ODU CT |

IMPR OVE ME NT , |

SP ECI F I C AT I ONS AR E SU B JECT T O CH ANGE WI TH O UT NOT IC E . |

www.alto-shaam.com |

||||||||||

Loading...

Loading...