Page 1

MANUFACTURING

NUMBERS:

9700770

9700772

System Tested and Certified by NSF

International and WQA against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Nominal Particulate Reduction Class I

Standard No. 53: Health Effects

Cyst Reduction & Turbidity Reduction as

verified and substantiated by test data.

System Tested and Certified by WQA

against NSF/ANSI Standard 372

for lead-free compliance

P/N 1011114 Rev. H 12/13

VZN WATER

FILTRATION

VZN-421HC, VZN-441HC

Owner’s Manual

Page 2

VZN SERIES

TABLE OF CONTENTS

Owner Information ...............................................................2

General............................................................................... 2

Warranty Information .......................................................... 2

Service/Technical Assistance ............................................. 3

Important Safety Information ..............................................4

Specifications .......................................................................6

Dimensions......................................................................... 6

Electrical Ratings ............................................................... 6

Replacement Cartridges .................................................... 6

Electrical Cord & Plug Configurations ................................ 6

Performance Data Sheet ......................................................7

Filter Cartridge Capacities.................................................. 7

Performance Claims for Percent Reduction....................... 7

Operation ...............................................................................8

Overview ............................................................................ 8

Manual Flushing ................................................................. 8

Installation .............................................................................9

Unpacking .......................................................................... 9

Equipment Setup ................................................................ 9

Mounting the System ....................................................... 10

Drain Valve Connection .....................................................11

Rinse Valve Connection ................................................... 12

System Inlet Connection .................................................. 12

Filtered Water Permeate Outlet Connection .................... 12

Inlet Water Plumbing ........................................................ 12

Installing a Bypass ........................................................... 13

Starting the Controller ...................................................... 13

Rinsing the Ultra Filter Cartridge...................................... 13

Sanitizing the System and Lines ...................................... 14

Installing and Rinsing the Carbon Element ..................... 14

Maintenance ........................................................................15

Replacing the Ultra Filter Cartridge.................................. 15

Rinsing and Replacing the Carbon Element .................... 16

System Sanitization .......................................................... 16

Changing the Interval Setting ........................................... 17

Resetting the Timer Program ........................................... 17

Check Permeate Tank Air Pre-Charge ............................. 17

Troubleshooting .................................................................18

Replacement Parts .............................................................19

Limited Warranty ................................................................24

OWNER INFORMATION

General

The VZN system is an innovative filtration system that uses

proprietary multi-bore hollow fiber membranes as well as a

carbon element to provide the latest innovation in filtration

technology.

This manual provides the safety, installation, and

operating procedures for the VZN water filtration system. All

information contained in this manual should be read prior

to installing and operating the system. Your VZN system

is manufactured from the finest materials available and is

assembled to strict quality standards. This system has been

tested at the factory to ensure dependable trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty in this

manual.

If the system arrives damaged, contact the carrier immediately and file a damage claim with them. Save all packing

materials when filing a claim. Freight damage claims are the

responsibility of the purchaser and are not covered under

warranty.

The warranty does NOT extend to:

• Damages caused in shipment or damage as result of

improper use.

• Installation of electrical service.

• Normal maintenance as outlined in this manual.

• Malfunction resulting from improper maintenance.

• Damage from moisture leaking into electrical

components.

• Damage from tampering with, removal of, or changing

any preset control or safety device.

IMPORTANT! Keep these instructions for future reference. If the system changes

ownership, be sure this manual accompanies the equipment.

2

P/N 1011114 Rev. H 12/13

Page 3

OWNER INFORMATION (continued)

Service/Technical Assistance

If you experience any problems with the installation or operation of your system, contact A.J. Antunes & Co. at 1-630-784-

1000, or toll free in the United States at 1-800-253-2991.

Fill in the information in the next column and have it handy

when calling for assistance. The serial number is on the

specification plate located on the system.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

VZN SERIES

Suggested replacement period for the Ultra Filter Cartridge is

approximately 3 years.

For sales in the state of Iowa:

Seller: Date:

Buyer: Date:

IMPORTANT

A.J. Antunes and Company reserves the right to change specifications and product

design without notice. Such revisions do NOT entitle the buyer to corresponding

changes, improvements, additions, or replacements for previously purchased equipment.

P/N 1011114 Rev. H 12/13

3

Page 4

VZN SERIES

IMPORTANT SAFETY INFORMATION

In addition to the warnings and cautions in this manual, use

the following guidelines to safely operate the system:

• Read all instructions before using equipment.

• Install or locate the equipment only for its intended use

as described in this manual.

• Do NOT use corrosive chemicals in this equipment.

• Do NOT operate this equipment if it has a damaged

cord or plug; if it is not working properly, or if it has

been damaged or dropped.

• This equipment should be serviced by qualified personnel only. Contact A.J. Antunes & Co. for repair.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• This equipment should be supplied with only cold

water.

• For installations in Massachusetts, the Commonwealth

of Massachusetts Plumbing Code 248 CMR shall be

adhered to. The use of saddle valves are not permitted.

Please consult your local plumber.

The following warnings and cautions appear throughout this

manual and should be carefully observed.

• Unplug the power cord before performing any

service or maintenance on the unit.

• All electrical connections must be in accordance with

local electrical codes and any other applicable codes.

• WARNING ELECTRICAL SHOCK HAZARD. FAILURE

TO FOLLOW THESE INSTRUCTIONS COULD

RESULT IN SERIOUS INJURY OR DEATH.

- Do NOT modify the power supply cord plug. If it

does not fit the outlet, have a proper outlet installed

by a qualified electrician.

- Do NOT use an extension cord with this unit.

• If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent, or a similarly qualified person.

• This equipment is to be installed to comply with the

local plumbing code and any other applicable code.

• Water pressure must not exceed 100 psig (690 kPa).

To reduce water pressure, install a water pressure

regulator and set to suit the application.

• The trans membrane pressure (inlet pressure minus

the permeate water pressure) must not exceed 45 psi

(310 kPa).

• A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

• When installed on metallic plumbing, a properly sized

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this unit.

NOTE: If the inlet water pressure is less than 50 psig (345

kPa), it is recommended that a suitably-sized booster

system (outlet pressure 60 psig - 100 psig max (414 kPa 690 kPa max) be installed.

4

P/N 1011114 Rev. H 12/13

Page 5

IMPORTANT SAFETY INFORMATION (continued)

VZN SERIES

Protect from becoming dry

If the membrane dries out, irreversible damage to the Ultra

Filter membrane may result. Protect the filter from becoming

dry by keeping it wet and sealed at all times.

Protect from freezing

If the Ultra Filter membrane freezes during operation or storage, irreversible damage to the membrane and brittle cracking

of the cartridge or housing may result.

Protect from direct sunlight or other UV sources

Avoid long-term exposure to direct sunlight or other UV

sources. The Ultra Filter should be stored in a dark location.

Protect from high temperatures or abrupt variation in

temperature

The maximum operating temperature is 100°F (38°C). Avoid

abrupt variations in temperature. Any temperature variation

should be made slowly.

Protect from rough handling or dropping

Mechanical damage, external breakage, and/or internal breakage of the filter can result if the system is dropped or bumped.

Handle with care at all times during transportation and installation.

Protect from organic solvents and concentrated acids

Prevent any and all contact of the membrane with strong solvents, solvents containing chlorine, or concentrated acids. Do

NOT use strong solvents or concentrated acids on any plastic

parts of the filter system. Examples of some solvents to avoid:

acetone, methyl acetate (nail polish remover); hexane (spot

removers); turpentine, toluene (paint thinners); dry cleaning

solutions, insecticides.

CAUTION

This equipment is to be installed to comply with the

basic plumbing code of the Building Officials and Code

Administrators, Inc. (BOCA) and the Food Service

Sanitation Manual of the Food and Drug Administration

(FDA).

CAUTION

Water Flow Regulator Assemblies are NOT interchangeable. Operating the system with the wrong Water Flow

Regulator or without a regulator can damage the system, cause personal injury, and voids the warranty!

CAUTION

All electrical connections must be in accordance with

local electrical codes and any other applicable codes.

A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

When installed on metallic plumbing, a properly sized

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this unit.

Protect from abrasive material

The membranes must be protected from abrasive materials

like shavings left in a pipe. Abrasive materials in contact with

the membrane can cause irreversible damage to the membrane. All pipes must be flushed clean before installing the filter. All plastic parts of the filter system must be protected from

sharp objects like knives, sand paper, or other tools. Cutting

or nicking a plastic part can weaken it and cause a leak. Do

NOT use abrasive cleansers on any plastic parts.

Protect from water hammer

The system must be protected from shock, pressure surges,

or pulsation that may occur inside water pipes. Water hammer occurs in pipes when a valve or faucet shuts quickly.

Install a water hammer arrestor (pressure vessel containing

compressed air separated from the water by a diaphragm) to

reduce pressure shock.

P/N 1011114 Rev. H 12/13

5

Page 6

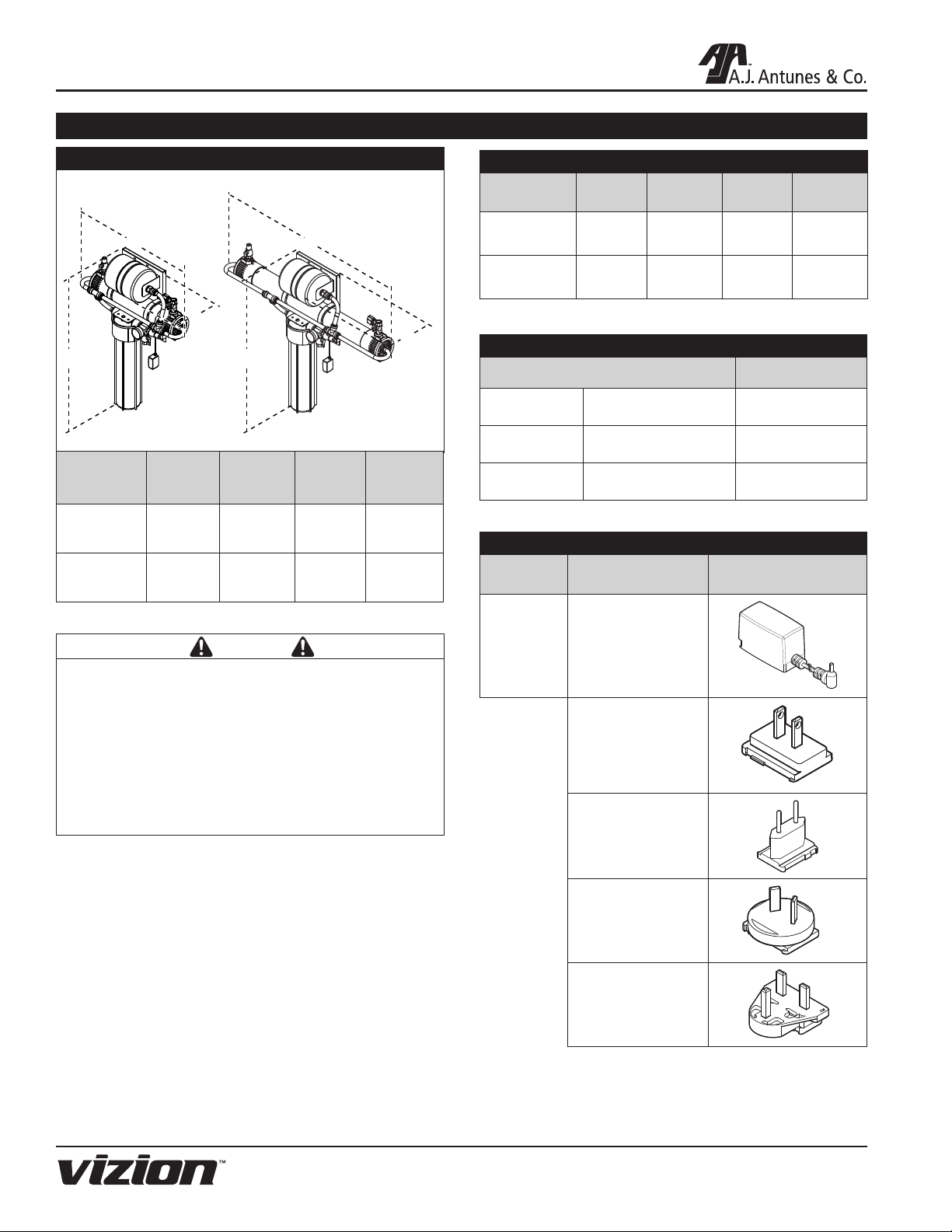

VZN SERIES

MAY VA RY

SPECIFICATIONS

Dimensions

C

Model &

Mfg. No.

VZN-421HC

9700770

VZN-441HC

9700772

A

B

Width

(A)

31"

(79 cm)

50"

(127 cm)

C

Depth

(B)

9"

(23 cm)

9"

(23 cm)

VZN-441HCVZN-421HC

A

Height

(C)

39"

(99 cm)

39"

(99 cm)

B

Operating

Weight

67 lbs.

(31 kg)

83 lbs.

(38 kg)

Electrical Ratings

Model &

Mfg. No.

VZN-421HC

9700770

VZN-441HC

9700772

NOTE: Includes plug adaptors for US, Europe, Australia, and UK.

Volts Watts Amps Hertz

100–240 10 .08 50/60

100–240 10 .08 50/60

Replacement Cartridges

Replacement Part Number

VZN-421HC L-420 Ultra Filter 7000411

VZN-441HC L-440 Ultra Filter 7000412

VZN-421HC

VZN-441HC

* Tested and verified by independent laboratory testing

Chloramine Carbon

Element*

7000762

Electrical Cord & Plug Configurations

Kit Model

Number

Description Configuration

CAUTION

All electrical connections must be in accordance with

local electrical codes and any other applicable codes.

A ground fault circuit interrupter (GFCI) must be

installed on the circuit to this system.

When installed on metallic plumbing, a properly sized

electrical bonding jumper must be installed across the

inlet and outlet pipes serving this unit.

0012146

DC Power Supply

100 - 240 VAC

Includes the

4 plug adaptors

below

US

NEMA 1-15 (2 pin)

or NEMA 5-15

(3 Pin)

Euro

CEE 7/16

AS/NZS

3112

AUS

(2 Pin)

UK

BS 136 3

NOTE: PLUG STYLE

6

P/N 1011114 Rev. H 12/13

Page 7

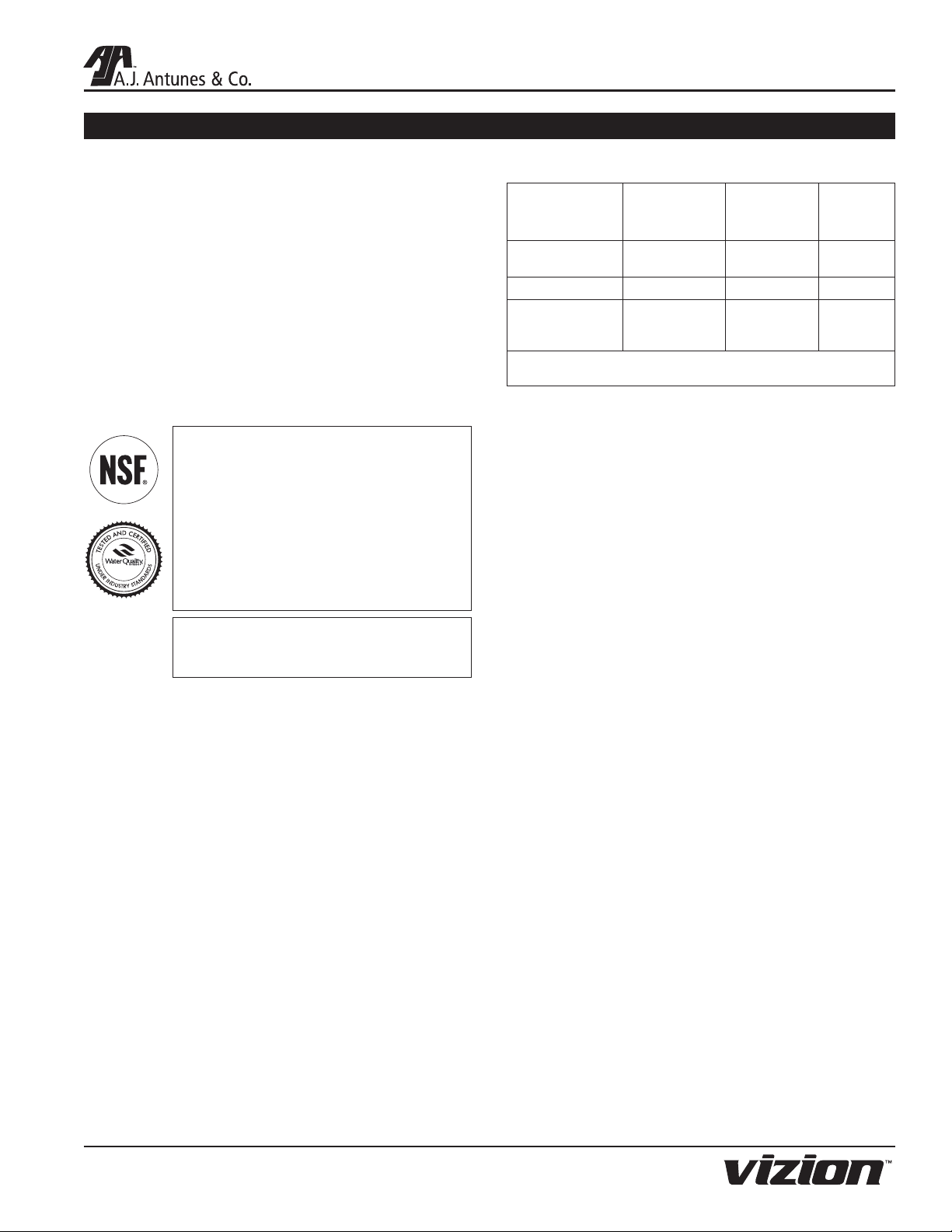

PERFORMANCE DATA SHEET

VZN SERIES

Filter Cartridge Capacities

Maximum Operating Pressure 100 psig (690 kPa)

Maximum Operating Temperature 100°F (38°C)

Minimum Operating Temperature 40°F (4°C)

Maximum Trans Membrane Pressure 45 PSI (3.1 Bar)

pH Range 3-10

MWCO 100 kD

NSF/WQA Certified Rated Service

Flow:

VZN-421HC 7.9 gpm (30 l/m)

VZN-441HC 13 gpm (49 l/m)

System Tested and Certified by NSF

International and WQA against NSF/ANSI

Standard 42 and 53 for the reduction of:

Standard No. 42: Aesthetic Effects

Nominal Particulate Reduction Class I

Standard No. 53: Health Effects

Cyst Reduction & Turbidity Reduction

as verified and substantiated by test data.

Performance Claims for Percent Reduction

Substance Influent

1

cyst

Turbidity 11 ± 1 NTU ≤ 0.5 NTU 99.1%

Particulate Class I

Particles 0.5 to <

1µm

1

based on the use of microspheres or Cryptosporium parvum oocysts

Challenge

Concentration

minimum

50,000/L

at least 10,000

particles /mL

Reduction

Requirement

99.95% 99.95%

≥ 85% N/A

Minimum

Reduction

%

System Tested and Certified by WQA

against NSF/ANSI Standard 372

for lead-free compliance

System has been tested according to NSF/ANSI Standard 42

and 53 for reduction of the substances listed below. The concentration of the indicated substances in water entering the

system was reduced to a concentration less than or equal to

the permissible limit for water leaving the system, as specified

in NSF/ANSI 42 or 53. While testing was performed under

standard laboratory conditions, actual performance may vary.

NOTE: The NSF/WQA information provided applies to the

Ultra Filter cartridge.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain filterable cysts.

P/N 1011114 Rev. H 12/13

7

Page 8

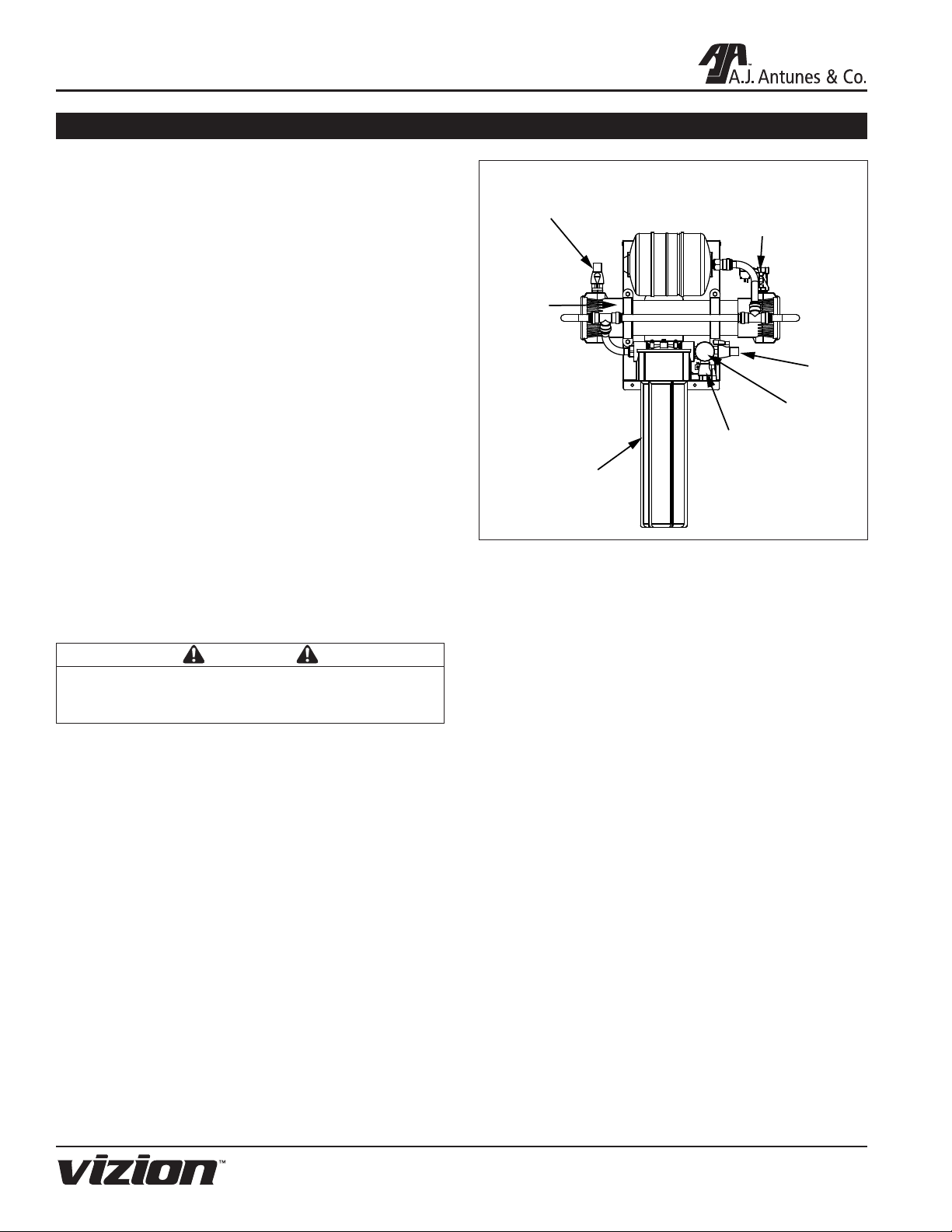

VZN SERIES

OPERATION

Overview

The VZN system operates in two modes:

• Normal Operation Mode

• Flush Mode

During Normal Operation Mode, water enters the Inlet and

flows through the Ultra Filter before exiting the Permeate

Outlet as usable product water.

During Flush Mode, the Drain Valve opens and water entering the Inlet flushes and cleans the Ultra Filter membrane by

removing any debris collecting on the membrane wall.

The Drain Valve is only powered during Flush Mode.

NOTE: Do NOT unplug the power cord or turn off the system during Flush Mode. If there is a power outage or the

system is unplugged, water will continue to be filtered

but the system will NOT flush. This could cause the Ultra

Filter to plug prematurely and may reduce the life of the

filter.

The flush is automated by the Universal Pulse Controller to

last 10 seconds and take place in one-hour intervals. This

interval can be changed (see Changing the Interval Setting

in the Maintenance section of this manual).

Ball Valve

(Manual)

Ultra Filtration

Cartridge

Inlet

Carbon Element

Housing

Figure 1. System Components

Solenoid

(Automatic)

Rinse

Ball Valve

(Manual)

System

Flush

Valve

Outlet

Ball Valve

(Manual)

Check Valve

Assembly

with Outlet

Pressure Gauge

CAUTION

Changing the flush interval may cause the Ultra Filter

to plug prematurely and may reduce the life of the filter.

Consult the factory for more information.

Manual Flushing

A manual flush can be activated at any time by pressing the

FLUSH button on the Universal Pulse Controller.

When the FLUSH button is pressed, the Flush LED on the

controller flashes and the Drain Valve opens for 10 seconds.

After flushing is complete, the Drain Valve will close, the Flush

LED will stop flashing and the unit will automatically return to

Normal Operation Mode.

NOTE: A manual flush will not affect the interval flush

setting.

8

P/N 1011114 Rev. H 12/13

Page 9

INSTALLATION

VZN SERIES

Unpacking

1. Open the large box. It should contain:

A. Plate-mounted VZN system with Ultra Filter

Cartridge installed

B. Padded envelope containing:

• Power Adaptor

• Adaptor Plugs

• Owner’s Manual

• Mounting Bracket

• Filter Wrench

• Glove and Sticker Kit

• Sanitizing T-Fitting and Plug

C. Carbon Element and Carbon Element Housing

3. Remove all packing materials and protective coverings

from the system.

4. Remove the information packet. Fill out and mail the

warranty card immediately to prevent any delay in

obtaining warranty coverage.

NOTE: If any parts are damaged, contact A.J. Antunes &

Co. IMMEDIATELY at 1-800-253-2991 (toll free in the U.S.

and Canada) or 1-630-784-1000.

Equipment Setup

GENERAL

When placing the system into service, pay attention to the

following guidelines:

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

ELECTRICAL

The line voltage must match the voltage on the specification

label. The plug on the power cord must match the appropriate

outlet. Do NOT connect the system to a switched electrical

outlet.

PLUMBING

NOTE: The system must be connected to the COLD water

line. Do NOT connect the system to the hot water line.

The VZN system uses the following connections:

System Inlet 3/4" NPT

System Outlet

(Product Water)

Drain 3/4" FNPT

Rinse Outlet 3/4" (Garden Hose or 3/4" ID Hose)

When making a plumbing connection to the system, use a

back-up wrench on the supporting plumbing. Always use a

quality, approved pipe sealant or thread seal tape on pipe

threads. Do NOT allow pipe sealant inside pipes.

Do NOT over tighten the connections. Use plastic fittings

when connecting to the plastic connections of the system.

3/4" NPT

P/N 1011114 Rev. H 12/13

If soldered plumbing is used, do NOT apply heat to, or near,

the filtration system. Use union (O-ring seal) connections for

ease of installation and future servicing.

SUGGESTED TOOLS AND SUPPLIES FOR INSTALLATION

The following tools and supplies are suggested to help with

the installation:

• Screwdriver • Adjustable Wrenches

• Drill with Bits • Level

• Tape Measure • Pipe Dope or Thread Seal Tape

• Two Gallon Bucket • Fresh, Unscented Liquid Chlorine

Bleach

• Pipe Wrenches • Garden Hose (for rinsing)

• Hose or pipe for drain line

9

Page 10

VZN SERIES

INSTALLATION (continued)

CAUTION

Due to its weight and size, the VZN system MUST be

mounted with the provided Mounting Bracket. Read

the Mounting the System section before attempting to

mount the VZN system. Use care when lifting heavy

objects.

Mounting the System

NOTE: Use caution when lifting and mounting the system. The system MUST be mounted using the provided

Mounting Bracket.

The VZN system comes with a Mounting Bracket. When

mounting the system, pay attention to the following guidelines:

• • Allow sufficient access for cartridge replacement.

VZN-421HC units should be mounted with 20 inches to

the left or right. VZN-441HC units should be mounted

with 40 inches to the left or right.

• • Mount the system near but NOT above an appropriate electrical outlet.

• • Mount the system near a drain for flushing operations.

• • Mount the system before all consumable water

filtration processes.

• • Mount the system with the provided Mounting

Bracket and hardware capable of supporting 120 lbs. or

more.

• • Secure the Mounting Bracket into wall studs or with

the appropriate heavy duty mounting hardware.

The system is pre-assembled to a Back Plate. The Back Plate

has mounting holes across the bottom portion to secure the

The system is

designed to hang from

Back Plate

(holes along bottom

for additional

mounting stability)

the Mounting Bracket.

Secure Mounting Bracket

to wall studs using

appropriate hardware.

Figure 2. Mounting the System

bottom of the system to the wall. Some of the bottom mounting holes may be obscured. Plan your mounting accordingly.

Follow these steps to secure the Mounting Bracket to the wall

and seat the VZN system:

1. Use a stud finder and level to attach the Mounting

Bracket securely to the wall with the appropriate

mounting hardware (Figure 2).

2. The Mounting Bracket is designed so that the VZN

system can be lifted and hung on the Mounting Bracket.

With assistance, lift the system and seat it onto the

Mounting Bracket securely (Figure 2).

3. Secure the bottom portion of the VZN system to the

wall using the holes provided. Make sure the mounting

hardware secures the system into wall studs or use the

appropriate mounting hardware.

4. Screw the Carbon Element Housing onto the Carbon

Element Head without the Carbon Element installed.

NOTE: Do NOT install the Carbon Element at this time.

The Carbon Element should only be installed after the

Ultra Filter Cartridge has been rinsed.

10

P/N 1011114 Rev. H 12/13

Page 11

INSTALLATION (continued)

Drain Valve Connection

The drain is for flushing particle buildup out of the

system during self cleaning.

1. Cut a length of tubing (not supplied) so it reaches the

drain from the Drain Valve.

2. Connect one end of the hose to the Drain Valve with an

appropriate fitting (not supplied) (Figure 3).

3. Direct the other end of the hose to the drain (Figure 3).

When connecting the drain hose, pay attention to the following guidelines:

• The drain line plumbing must be able support the flow

rate whenever the system flushes. This flow rate is

dependent on the inlet water pressure, inlet pipe size,

and system.

VZN SERIES

Example Drain Valve

Connection

Secure Hose

with Worm

Clamp

Direct Hose

to Drain

• The drain line leading out of the system must be as

short as possible and slope downwards without any

kinks or loops.

• The drain line plumbing must be positioned and

secured at least 2 inches above the drain (Figure 4).

This air gap protects the system from contamination in

the event of a backed-up drain.

• The drain used must not be blocked or restricted.

• The drain used must be as large or larger than the

drain line plumbing.

Figure 3. Drain Valve Connection

Secure

End

Drain

Drain Line from

System

Secure

End

Drain Line from

System

2” (5.1 cm)

minimum

Standpipe

P/N 1011114 Rev. H 12/13

Floor

Drain

2” (5.1 cm)

minimum

Figure 4. Drain Line Plumbing

11

Page 12

VZN SERIES

INSTALLATION (continued)

Rinse Valve Connection

1. Obtain a length of 3/4” garden hose long enough to

reach from the Rinse Valve to the drain.

2. Install a gasket in the end of the hose (non-drain end).

Rinse Valve Connection

3. Connect the hose to the Rinse Valve fitting. Use a backup wrench on the fitting if required (Figure 5).

4. Direct the other end of the hose to the drain. Secure as

necessary.

NOTE: The drain MUST accommodate a flow of up to

15 gpm.

CAUTION

Do NOT use the Rinse Valve for consumable water.

System Inlet Connection

The System Inlet has a 3/4” NPT male thread at the Inlet

Valve (Figure 6). Do NOT overtighten fittings as this could

cause the plastic ball valve to crack.

Use plastic fittings and a pipe thread sealant approved for use

on PVC fittings when making connections.

Filtered Water Permeate Outlet Connection

The System Outlet has a 3/4” NPT male thread at the Outlet

Valve (Figure 6). Do NOT overtighten fittings as this could

cause the plastic ball valve to crack.

Use plastic fittings and a pipe thread sealant approved for use

on PVC fittings when making connections.

Figure 5. Rinse Valve Connection

Inlet

Ball Valve

(Manual)

3/4”

Garden

Hose

Connection

3/4”

Garden Hose

(not supplied)

directed

to drain

Outlet

Ball Valve

(Manual)

Inlet Water Plumbing

The "T" Fitting with plug (supplied) should be installed at the

System Inlet. This fitting will be used for sanitizing the system

and downstream plumbing (Figure 6a).

Before connecting the fitting to the System Inlet, the plumbing to the system must be flushed clear of all debris. Hold a

bucket at the inlet water line and slowly open the Inlet Water

Valve. Allow the pipe to flush until all debris is removed.

12

Figure 6. Inlet and Outlet Connections

Sanitation

Plug

T-Fitting

(not supplied)

Inlet

Inlet Ball

Valve

Figure 6a. Installing a T-Fitting for Sanitizing

P/N 1011114 Rev. H 12/13

Page 13

INSTALLATION (continued)

VZN SERIES

Water

Flow

Tee

Inlet Ball

Valve

(Manual)

Water

Flow

Outlet Ball

Valve

(Manual)

Fully

Ported

Ball Valve

Figure 7. Install Bypass

Installing a Bypass

It is recommended that an optional bypass be installed to help

with replacing cartridges and servicing the system. Installation

of a bypass can be done easily as the Inlet and Outlet Ball

Valves are already installed.

Rinsing the Ultra Filter Cartridge

The Ultra Filter Cartridge comes pre-installed in the VZN

system. The Ultra Filter Cartridge must be rinsed before the

system is used to remove any air and protective solution.

NOTE: Ultra Filter Cartridge must be rinsed to drain

before use. Rinsing to drain removes storage solution

and air. Do NOT rinse into carbon if present. Carbon life

and/or performance may be affected.

NOTE: Make sure the Carbon Element and TAC Cartridge,

if present, are NOT installed. These should only be

installed after the Ultra Filter Cartridge has been rinsed.

1. Direct water from the Rinse Ball Valve to a drain.

2. Close the Outlet Ball Valve.

3. Close the Inlet Ball Valve.

4. Open the Rinse Ball Valve.

5. Slowly turn on the water supply to the VZN system.

6. Slowly open the Inlet Ball Valve. Air and water will come

out of the Rinse Ball Valve.

7. Press the FLUSH button. The Drain Valve will open and

air and water will come out of the drain line. Repeat six

times to ensure all air and storage solution are flushed

out of the Ultra Filter Cartridge.

1. Install tees on the end of the plumbing leading to the

Inlet and Outlet Ball Valves.

2. Connect the two tees by installing plumbing and a fully

ported (preferably 3/4”) Ball Valve.

3. When the system is in use, open the Inlet and Outlet

Ball Valves and close the Bypass Ball Valve.

4. When servicing is needed, close the Inlet and Outlet Ball

Valves and open the Bypass Ball Valve.

Starting the Controller

1. Select the proper AC plug for your electrical outlet and

install it onto the power supply.

2. Plug the appropriate end of the power cord into the

controller.

3. Plug the other end of the power cord into the electrical

outlet. The LEDs on the controller will light up.

4. The controller automatically enters Flush Mode and the

Flush LED starts to flash.

5. When flushing is complete, the Flush LED will stop

flashing and one or more LEDs will remain lit, indicating

the unit has power and which interval is selected in the

controller.

8. Continue to allow water to run at full flow out of the

Rinse Ball Valve for at least 15 minutes.

9. After 15 minutes, close the Rinse Ball Valve and allow

the system to sit for 15 minutes without any water

flow to release any trapped air from the Ultra Filter

Cartridge.

10. Inspect the unit for any leaks, repairing as needed.

11. After 15 minutes, open the Rinse Ball Valve and wait for

five minutes to flush out any remaining air.

12. Close the Rinse Ball Valve and disconnect the garden

hose.

13. Press the FLUSH button to open the Drain Valve.

Repeat six times to ensure any remaining air is flushed

out of the system.

14. Open the closest downstream tap or faucet.

15. Slowly open the Outlet Ball Valve and allow water to run

through the system and out the faucet for five minutes.

P/N 1011114 Rev. H 12/13

13

Page 14

VZN SERIES

INSTALLATION (continued)

Sanitizing the System and Lines

The plumbing must be sanitized to eliminate possible contamination that may have occurred during the installation process.

One ounce (30 ml) of liquid chlorine bleach (regular bleach,

unscented 5.25 % - 6 % sodium hypochlorite) or Kay-5

sanitizer solution (Sodium Dichloro-s-Triazinetrione Dihydrate,

6%) or equivalent can be used to sanitize the plumbing.

The Kay-5 sanitizer solution is made by dissolving a 1 oz.

packet of Kay-5 powder in 2 oz. (60 ml) of clean warm water.

This can be done by removing 1 inch from the top of the

Kay-5 packet and adding the 2 oz. of warm water to the packet. Mix with a coffee stirrer to dissolve. When added to the

system, this will create a 60-100 ppm chlorine solution.

NOTE: Follow the handling and safety instructions

supplied with the sanitizer.

NOTE: If installed, remove the Carbon Element and TAC

Cartridge from the system BEFORE Sanitizing.

1. Follow the steps in the Rinsing the Ultra Filter

Cartridge in the Installation section of this manual.

2. Turn off the water to the system.

3. Open the faucet or tap closest downstream to the

system.

4. Allow the system and plumbing to drain.

5. Remove the plug installed in the sanitizing "T" fitting at

the inlet of the system. Allow the water to drain out of

the system.

6. Pour the sanitizer into the inlet sanitation fitting using a

cup or funnel. Be careful not to spill the sanitizer onto

clothing or skin.

7. Reattach the plug on the sanitation fitting.

8. Slowly turn on the water supply to the system.

9. Allow water to flow through the system and out of the

open faucet or tap until the smell of sanitizer is present.

10. Close the faucet or tap.

11. Let the system stand without water flow for at least 15

minutes to allow the sanitizer to sanitize the pipes.

Installing and Rinsing the Carbon Element

The Carbon Element MUST be rinsed before using the

system the first time.

1. Install the new Carbon Element into the Carbon

Element Housing.

2. Screw the Carbon Element Housing (containing the

Carbon Element) into place on the Carbon Element

Head. The housing will come to a hard stop at the end

of the thread. Use a Filter Wrench if necessary.

NOTE: Do NOT overtighten the Carbon Element Housing.

3. Direct water from the Rinse Ball Valve to a drain.

4. Open the Rinse Ball Valve and close the Outlet Ball

Valve.

5. Turn on the water to the system by slowly opening the

Inlet Ball Valve.

6. Allow water to flow through the Carbon Element and

Carbon Element Housing to flush out trapped air and

any debris that may be present.

7. To help remove trapped air from the Carbon Element

Housing, press the RED Pressure Relief Button on the

top of the housing until water just begins to come out.

8. Rinse the Carbon Element for at least 5 minutes.

NOTE: Do NOT consume water used during this process.

9. When the rinsing is complete, close the Rinse Ball

Valve and open the Outlet Ball Valve.

10. The system is now ready for use.

Flushing the Outlet Plumbing

To ensure that the highest quality water is produced from the

system, the plumbing leading from the filter system must be

flushed clear of all debris after the system is hooked up. After

making the connection to the outlet of the filter system, open

the faucet or tap closest to the filter system, then slowly open

the Inlet Water Valve. Allow the pipe to flush until all debris is

removed.

12. After 15 minutes without water flow, open the faucet or

tap.

13. Allow water to flow through the system until the

presence of sanitizer is gone.

14. Open all other faucets and taps in line with the system

to flush any remaining sanitizer from the plumbing.

15. Close all faucets and taps.

14

P/N 1011114 Rev. H 12/13

Page 15

Replacing the Ultra Filter Cartridge

VZN SERIES

MAINTENANCE

NOTE: Always install new Carbon Element after replacing

the Ultra Filter Cartridge.

1. Turn off water to the system by closing the Inlet Ball

Valve.

2. Press the FLUSH button to flush the system and relieve

pressure. Repeat several times to ensure permeate

tank is empty.

3. Locate the long hooked tubing on the right and disconnect the long end from the tee by pushing the collet

squarely against the face of the fitting.

4. With the collet pushed in place, pull the tubing from the

fitting with your right hand.

NOTE: Water may drain from the tubing as it is removed.

NOTE: Make sure there is enough room next to the system

to remove the cartridge.

5. Remove the Snap Ring (Figure 8) from the Ultra Filter

Housing. Grab the raised lug with a pair of pliers and

pull towards the center of the End Cap and away. The

Snap Ring should lift out of its groove.

6. Remove the End Cap, End Cap O-Ring, and Cartridge

(Figure 8) from the housing.

Snap Ring

End Cap

End Cap

O-Rings

Cartridge

O-Ring

Ultra Filter

Housing

Ultra Filter

Cartridge

Cartridge

O-Ring

End Cap

O-Rings

End Cap

NOTE: If the Cartridge does not easily come out of the

Housing, remove the opposite End Cap for assistance

during Step 5.

7. Inspect the Large End Cap O-rings and End Cap O-ring

for nicks or cuts. Replace as needed.

8. Lubricate all O-rings with a food-grade silicone lubricant. Apply a light coating of lubricant to the inside

center tube at both ends of the new cartridge.

9. Record the serial number of the new cartridge. The

cartridge serial number is engraved on one end of the

outer tube (for example: 05K 12013).

10. Install the End Cap O-ring on the End Cap and insert

the Large End Cap into the end of the new cartridge.

11. Position the new cartridge and End Cap at the housing

and gently insert into the housing.

12. Press the End Cap into position until it is fully seated

and the Snap Ring groove is visible.

13. Install the Snap Ring by guiding the non-lugged end

into the groove first, pushing outward and working

around the ring until it snaps into place.

NOTE: Make sure that the Snap Ring is fully seated

before turning the water on.

Snap Ring

Figure 8. Replacing the Ultra Filter Cartridge

14. Reattach the tubing that was removed in Steps 3 and 4.

Be sure the tubing is pushed past the O-ring.

NOTE: Make sure the fitting is completely inserted onto

the tubing past the O-ring. A loose connection results in

leaking at the point of connection.

15. Rinse the new Ultra Filter Cartridge before placing the

system back into operation. Follow the Rinsing the

Ultra Filter Cartridge and Sanitizing the System

and Lines procedures in the Installation section of this

manual to complete the cartridge change.

16. When rinsing is complete, repressurize the system.

P/N 1011114 Rev. H 12/13

15

Page 16

VZN SERIES

MAINTENANCE (continued)

Rinsing and Replacing the Carbon Element

NOTE: Remove the TAC Cartridge Element, if present,

and re-attach the TAC Housing before proceeding.

1. Turn off the water to the system by closing the Inlet Ball

Valve and Outlet Ball Valve.

2. Open the Rinse Ball Valve and allow the system to

drain to ensure the permeate tank is empty.

3. Press and hold the RED Pressure Relief Button on the

top of each of the Carbon Element Housing to lower the

water level inside the housings by 2 to 3 inches.

4. Remove the Carbon Element Housing (Figure 9).

5. Empty any water into a drain and discard the old

Carbon Element.

6. Inspect the O-ring on the Carbon Element Housing

(Figure 9). Replace the O-ring if it is cracked, twisted,

or missing.

7. Lubricate the O-ring with an approved food grade

lubricant and install into the Carbon Element Housing.

8. Install the new Carbon Elements into the Carbon

Element Housing.

NOTE: Make sure the Gasket remains in place in the

recessed grooves on both ends of the Carbon Element.

9. Screw the Carbon Element Housing (containing the

Carbon Element) into place on the Carbon Element

Head. The Housing will come to a hard stop at the end

of the thread. Use a Filter Wrench if necessary.

NOTE: Do NOT overtighten the Carbon Element Housing.

10. Direct water from the Rinse Ball Valve to a drain.

NOTE: Direct the Rinse Ball Valve to a drain. Do NOT use

the water resulting from the flush procedure.

11. Open the Rinse Ball Valve. Turn on the water to the

system by slowly opening the Inlet Ball Valve. Allow

water to flow through the Carbon Element and Housing.

This clears out trapped air and any carbon fines.

12. To help remove trapped air from the Carbon Element

Housing, press the RED Pressure Relief button on the

top of the Housing until water just begins to come out.

13. Rinse the Carbon Element for at least 5 minutes.

O-Ring

Carbon

Element

Housing

Figure 9. Carbon Element

RED Pressure

Relief Button

Carbon

Element

Head

Gasket

Carbon

Element

System Sanitization

The system and downstream plumbing should be sanitized

every six months. When necessary, follow the procedure in

Sanitizing the System and Lines in the Installation section

of this manual.

NOTE: Do NOT consume the water used for rinsing the

Carbon Element.

14. Re-install the TAC Cartridge Element into the TAC

Housing with the arrow on the cartridge pointing up.

Reattach the TAC Housing to the system.

15. When the rinsing is complete, close the Rinse Ball

Valve and open the Outlet Ball Valve.

16. The system is now ready for use.

16

P/N 1011114 Rev. H 12/13

Page 17

MAINTENANCE (continued)

VZN SERIES

Changing the Interval Setting

CAUTION

Changing the flush interval may cause the Ultra Filter

to plug prematurely and may reduce the life of the filter.

Consult the factory for more information.

Though not recommended, the interval setting on the

Universal Pulse Controller can be changed. If the setting must

be changed, use the chart below. Press and hold the corresponding button. After 5 seconds, the Button LED will turn on.

After 10 seconds, the Flush LED will also turn on.

Flush

Interval

15 minutes A 10 seconds On On

30 minutes B 10 seconds On On

45 minutes C 10 seconds On On

1 hour A 5 seconds On Off

4 hour B 5 seconds On Off

6 hours C 5 seconds On Off

12 hours D 5 seconds On Off

24 hours D 10 seconds On On

Button Hold Time

Figure 10. Universal Pulse Controller

Button

LED

Flush

LED

Resetting the Timer Program

During the normal operation, the system will flush according to the set interval. It is possible the system will flush at a

time of high water use. If this poses a problem, the controller

can be reset. Unplug the power supply, wait for 5 seconds,

and then plug the power supply in. When power is restored

to the controller, it will automatically enter Flush Mode. The

controller will then begin timing from the point when power is

restored based on the interval setting selected.

Semi-Annual Tasks

Check Permeate Tank Air Pre-Charge

It is recommended the permeate tank air charge be

checked every six months.

Tools and supplies required:

• Air Pressure Gauge, 5‒40 psi range (0.3‒2.7 bar)

with tire valve (Schrader Valve) connection

CAUTION

Air pre-charge should only be checked and adjusted

under zero system pressure. The system must be

depressurized before checking the tank pre-charge.

Do NOT adjust the tank air pre-charge with the system

under pressure.

CAUTION

Be careful when adding air to the tank. Do NOT add too

much air pressure to the tank.

• Source of compressed air (manual bicycle tire

pump or air compressor)

1. Refer to Figure 1. Depressurize the system by

closing the Inlet and Outlet Valves and opening

the Rinse Valve. Make sure the Permeate Tank is

fully drained.

2. Unscrew the protective cap from the air valve on

the tank.

3. Use the pressure gauge to check the tank precharge for pressure.

NOTE: If any water comes out the air valve, the tank

bladder has ruptured and the tank needs to be

replaced.

4. The permeate tank should have a pressure of 2831 PSI.

• To add pressure to the permeate tank, use a

manual bicycle tire pump or other source of

compressed air.

• To release pressure from the permeate tank,

press the center pin on the air inlet valve.

5. Once the permeate tank is at 28-31 PSI, replace

the protective cap on the air valve.

6. Pressurize system by closing the Rinse Valve and

opening the Inlet and Outlet Valves.

P/N 1011114 Rev. H 12/13

17

Page 18

VZN SERIES

Problem Possible Cause Corrective Action

Unit does not have power.

No water comes out of the

filter system.

Low water flow comes out of the

filter system.

Water tastes bad.

Flush runs continuously.

Flush occurs at a time of high

water usage.

Water splashes at drain during

flush.

Water leaks at ends of the Ultra

Filter cartridge after changing

cartridge.

Water leaks from Carbon

Element.

Water leaks from system

fitting or connection.

TROUBLESHOOTING

The power cord is not plugged into the

appropriate outlet or control box.

The unit is plugged into a switched

electrical outlet.

Universal Pulse Controller is inoperable.

Transformer is defective.

Inlet/Outlet Ball Valves closed. Open the Inlet/Outlet Ball Valves.

System depressurized. Pressurize system.

Drain Valve is stuck open. Clean, rebuild, and/or replace the Drain Valve.

Rinse Ball Valve is open. Close the Rinse Ball Valve.

The system may be in a flush cycle. Wait for the flush cycle to end.

Inlet Strainer (if installed) is plugged. Clean or replace Inlet Strainer

Ultra Filtration Cartridge is plugged. Replace Ultra Filtration Cartridge.

Carbon Element is plugged. Replace Carbon Element.

See above. See above.

The inlet water pressure is too low. Boost the inlet water pressure.

The outlet check valve may be plugged

or defective.

The inlet flow restrictor may be plugged. Clean or replace the inlet flow restrictor.

Carbon Element need replacing. Replace Carbon Element.

Storage/shipping solution not completely

rinsed out of the system.

Biological growth in pipes. Sanitize plumbing.

Water condition changed. Consider installing additional filtration.

Broken capillaries in Ultra Filter

Cartridge.

Drain Valve stuck open. Clean, rebuild, or replace the Drain Valve.

Controller sending continuous signals to

valve.

The controller interval is set incorrectly or

setting was lost due to power loss.

Drain line not positioned properly. Reposition the end of the drain line.

Drain not capable of handling high flow

rate.

O-ring not lubricated. Lubricate O-ring with food grade lubricant.

O-ring is split, cut, or twisted. Replace O-ring.

O-ring not lubricated. Lubricate O-ring with food grade lubricant.

O-ring is split, cut, or twisted. Replace O-ring.

Fitting broken or loose. Tighten or replace the fitting.

Not enough pipe thread sealant used.

Plug power cord into the appropriate outlet.

Plug the power cord into an unswitched outlet.

Contact your maintenance person or Authorized

Service Agency.

Clean or replace the outlet check valve

assembly.

Rinse the system for a longer period of time;

replace Carbon Element.

Replace Ultra Filtration Cartridge.

Replace the controller.

Set interval.

Clean drain; find alternate drain.

Redo the fitting with the proper amount of sealant.

18

P/N 1011114 Rev. H 12/13

Page 19

REPLACEMENT PARTS

VZN-421HC Systems

VZN SERIES

34

20

14

15

8

9

10

17

18

19

21

22

23

24

25

16

26

35

32

12

13

11

10

9

21

27

8

31

1

2

3

4

36

5

6

7

P/N 1011114 Rev. H 12/13

30

33

29

28

20

14

14

19

Page 20

VZN SERIES

REPLACEMENT PARTS (continued)

20

VZN-441HC Systems

8

9

10

14

15

19

18

17

35

16

31

32

12

13

11

3

4

34

1

2

36

5

6

7

21

23

24

22

25

30

33

21

26

29

27

10

14

9

8

28

14

20

20

P/N 1011114 Rev. H 12/13

Page 21

VZN SERIES

REPLACEMENT PARTS (continued)

Replacement Parts can be purchased from an authorized dealer. Contact

A.J. Antunes & Co. at 1-630-754-1000 or toll free in the United States at 1-800-253-2991.

VZN-421HC Systems

Item Part Description Qty.

No.

1 0505870 VZN Back Plate 1

2 0012357 Universal Pulse Controller 1

3 4060438 36" Black Cable Tie 2

4 7000921 Permeate Tank Replacement Kit 1

5 0400381 Grommet, 1.75" OD x 1.197" ID 1

6 2190158 Female Connector, 3/4" CTS x 3/4" NPT 1

7 2010199 Tubing, Bent 90° 1

8 2180181 Lock Ring 2

9 2180230 End Cap 4" Quick Disconnect 2

10 7000413 O-ring Replacement Kit 1

11 2180201 Ultra Filter Housing 420 1

12 2070117 Nipple, Close 3/4" NPT 1

13 7000411 Ultra Filter Cartridge Replacement Kit 1

(Incl. #10)

14 2170131 Ball Valve, 3/4" Female to 3/4" Male 3

15 2190171 Nipple Reducer Hex, 1" to 3/4" 1

16 2180287 UFL Housing Clamp 2

17 3000116 Nut Retainer, 1/4"-20 4

18 3250154 Washer, Lock 1/4" 4

19 3250109 Screw, 1/4"-20 x 1/2" 4

VZN-441HC Systems

Item Part Description Qty.

No.

20 2010198 Tubing, UFL Bent 180° 2

21 2190155 Union Tee 2

22 2010200 Tubing, UFL 1

23 2010176 Tubing, Bent 90° 1

24 2190189 Adaptor, Tube to 1" NPT 1

25 2180220 Carbon Element Head 1

26 2180290 Check Valve Bushing 1

27 2170127 Check Valve Insert 1

28 2180281 Outlet Adaptor, Machined 1

29 2170128 PSI Pressure Gauge 1

30 2180282 Carbon Element Housing 1

31 3080213 Screw, 1/4"-15 x 3/4" 4

32 4040189 Solenoid Valve, NC 3/4" NPT 1

33 7000762 Chloramine Carbon Element 1

Replacement Kit

34 0505871 VZN Mounting Bracket 1

35 0021667 Flow Regulator Assy., 7.9 gpm 1

36 0012146 Power Adaptor Assy. 37

37 2190184 Tee, PVC, 3/4 NPT (not shown) 1

38 2190135 Plug, Nylon, 3/4" NPT (not shown) 1

Item Part Description Qty.

No.

1 0505870 VZN Back Plate 1

2 0012357 Universal Pulse Controller 1

3 4060438 36" Black Cable Tie 2

4 7000921 Permeate Tank Replacement Kit 1

5 0400381 Grommet, 1.75" OD x 1.197" ID 1

6 2190158 Female Connector, 3/4" CTS x 3/4" NPT 1

7 2010199 Tubing, Bent 90° 1

8 2180181 Lock Ring 2

9 2180230 End Cap 4" Quick Disconnect 2

10 7000413 O-ring Replacement Kit 1

11 2180202 Ultra Filter Housing 440 1

12 2070117 Nipple, Close 3/4" NPT 1

13 7000412 Ultra Filter Cartridge Replacement Kit 1

(Incl. #10)

14 2170131 Ball Valve, 3/4" Female to 3/4" Male 3

15 2190171 Nipple Reducer Hex, 1" to 3/4" 1

16 2180287 UFL Housing Clamp 2

17 3000116 Nut Retainer, 1/4"-20 4

18 3250154 Washer, Lock 1/4" 4

19 3250109 Screw, 1/4"-20 x 1/2" 4

P/N 1011114 Rev. H 12/13

Item Part Description Qty.

No.

20 2010197 Tubing, UFL Bent 180° 2

21 2190155 Union Tee 2

22 2010200 Tubing, UFL 1

23 2010176 Tubing, Bent 90° 1

24 2190189 Adaptor, Tube to 1" NPT 1

25 2180220 Carbon Element Head 1

26 2180290 Check Valve Bushing 1

27 2170127 Check Valve Insert 1

28 2180281 Outlet Adaptor, Machined 1

29 2170128 PSI Pressure Gauge 1

30 2180282 Carbon Element Housing 1

31 3080213 Screw, 1/4"-15 x 3/4" 4

32 4040189 Solenoid Valve, NC 3/4" NPT 1

33 7000762 Chloramine Carbon Element 1

Replacement Kit

34 0505871 VZN Mounting Bracket 1

35 0021666 Flow Regulator Assy., 15 gpm 1

36 0012146 Power Adaptor Assy. 1

37 2190184 Tee, PVC, 3/4 NPT (not shown) 1

38 2190135 Plug, Nylon, 3/4" NPT (not shown) 1

21

Page 22

VZN SERIES

NOTES

22

P/N 1011114 Rev. H 12/13

Page 23

NOTES

VZN SERIES

P/N 1011114 Rev. H 12/13

23

Page 24

LIMITED WARRANTY

Equipment manufactured by A.J. Antunes & Co. has been constructed of the finest materials available and manufactured to high quality standards. These units are warranted to be free from defects in materials and workmanship for a period of one year from date of purchase under normal use and service, and when installed in accordance with manufacturer’s recommendations*. The ultra filtration membrane cartridge is warranted under the

same terms and conditions on a prorated basis for 24 months from date of purchase.

*To ensure continued proper operation of the units, follow the maintenance procedure outlined in the Owner’s

Manual.

1. This warranty does not cover failures due to improper system installation, defects caused by improper storage or

handling prior to placing of the equipment into service. This warranty does not include overtime charges or work

done by unauthorized service agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specified in operating and maintenance instructions of this manual, and/or labor

involved in moving adjacent objects to gain access to the Equipment.

2. A.J. Antunes & Co. reserves the right to make changes in design or add any improvements on any product. The

right is always reserved to modify equipment because of factors beyond our control and government regulations.

Changes to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s documentation. Damage should be reported to the carrier. This damage is not covered under this warranty.

4. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE

EXCLUSIVE AND IN NO EVENT SHALL A.J. ANTUNES & CO. BE LIABLE FOR SPECIAL CONSEQUENTIAL

OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Prices and specifications are subject to change without notice.

Loading...

Loading...