Page 1

MANUFACTURING

A

S

D

L

I

S

T

E

CM

O

I

N

N

I

T

A

T

T

S

E

NUMBERS:

9300530

9300532

9300534

93 00571

930 0574

9300575

9300577

9500593

EGG STATION

Model ES-600, ES-602, ES-604, & ES-1200

C

US

L

I

D

P/N 1010883 Rev. K 08/14

ES-1200

ES-600

Owner’s Manual

Page 2

EGG STATION

TABLE OF CONTENTS

Owner Information .....................................................2

General ......................................................................2

Warranty Information .................................................2

Service/Technical Assistance ....................................3

Important Safety Information ....................................4

Specifications .............................................................5

Electrical Ratings .......................................................5

Electrical Cord & Plug Configurations .......................5

Shipping Weight ........................................................5

Net Weight .................................................................5

Dimensions ................................................................5

Installation ...................................................................6

Unpacking ..................................................................6

Equipment Setup .......................................................6

Operation .....................................................................7

OWNER INFORMATION

General

This product cooks/steams eggs (refrigerated) in

approximately 150 seconds and reheats sliced meat

for sandwiches. Eggs within the Egg Rings are cooked

with a combination of heat and steam. With the cover

closed, water is poured into a trough on the cover and

drips onto a hot Platen, producing steam and cooking

the eggs. The unit is equipped with audio/visual signals

for operation.

This manual provides the safety, installation, and operating procedures for the Egg Station. We recommend

that all information contained in this manual be read

prior to installing and operating the unit.

Preparing Unit ............................................................7

Egg Cooking Procedure ............................................7

Bacon Timer* .............................................................9

Maintenance ..............................................................10

Daily Cleaning .........................................................10

Checking Cycle Times (Monthly) .............................10

Checking Grill Platen Temperature ..........................11

Troubleshooting .......................................................12

Control Board LEDs ................................................13

Green LED Blink Codes ..........................................13

Wiring Diagram .........................................................14

Replacement Parts ...................................................15

Notes..........................................................................18

Limited Warranty ......................................Back Cover

The warranty does NOT extend to:

• Damages caused in shipment or damage as

result of improper use.

• Installation of electrical service.

• Installation, calibration, or adjustment.

• Normal maintenance outlined in this manual.

• Consumable parts such as Egg Rings, gaskets,

rubber feet, labels, O-rings, light bulbs, etc.

• Malfunction resulting from improper service or

maintenance.

Your Egg Station is manufactured from the finest materials available, assembled to Roundup’s strict quality

standards, and tested at the factory to ensure dependable trouble-free operation.

Warranty Information

Please read the full text of the Limited Warranty printed

on the back cover of this manual.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with them. Save all

packing materials when filing a claim. Freight damage

claims are the responsibility of the purchaser and NOT

covered under warranty.

IMPORTANT! Keep these instructions for future reference. If the unit changes

ownership, be sure this manual accompanies the equipment.

• Damage caused by improper installation, abuse,

or careless handling.

• Damage from moisture getting into electrical

components.

• Damage from tampering with, removal of, or

changing any preset control or safety device.

• Damage caused by parts or components not

provided by A.J. Antunes & Co.

2

P/N 1010883 Rev. J 08/14

Page 3

OWNER INFORMATION (continued)

EGG STATION

Service/Technical Assistance

If you experience any problems with the installation

or operation of your unit, contact your local Roundup

Authorized Service Agency. They can be found in the

service agency directory packaged with the equipment.

Fill in the information below and have it handy when

calling your Authorized Service Agency for assistance.

The serial number is on the specification plate located

on the rear of the unit.

Purchased From:

Date of Purchase:

Model No.:

Serial No.:

Mfg. No.:

Refer to the service agency directory and fill in the

information below:

Authorized Service Agency

Name:

Phone No.:

Address:

Use only genuine Roundup replacement parts in this

unit. Use of replacement parts other than those supplied by the manufacturer will void the warranty. Your

Authorized Service Agency has been factory trained

and has a complete supply of parts for this unit.

You may also contact the factory at 1-877-392-7854

or 1-630-784-1000 if you have trouble locating your

Authorized Service Agency.

IMPORTANT

A.J. Antunes & Co. reserves the right to change specifications and product design

without notice. Such revisions do NOT entitle the buyer to corresponding changes,

improvements, additions, or replacements for previously purchased equipment.

P/N 1010883 Rev. J 08/14

3

Page 4

EGG STATION

IMPORTANT SAFETY INFORMATION (continued)

In addition to the warnings and cautions in this manual,

use the following guidelines for safe operation of the

unit.

• Read all instructions before using equipment.

• For your safety, the equipment is furnished with

a properly grounded cord connector. Do NOT

attempt to defeat the grounded connector.

• Install or locate the equipment only for its intended use as described in this manual. Do NOT use

corrosive chemicals in this equipment.

• Do NOT operate this equipment if it has a damaged cord or plug, if it is not working properly, or

if it has been damaged or dropped.

• This equipment should be serviced by qualified

personnel only. Contact the nearest Roundup

Authorized Service Agency for adjustment or

repair.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do NOT allow cord to hang over edge of table or

counter.

The following warnings and cautions appear

throughout this manual and should be carefully

observed:

• Turn the power off, unplug the power cord,

and allow unit to cool down before performing

any service or maintenance.

• WARNING ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THESE INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR

DEATH.

- Electrical ground is required on this

appliance.

- Do NOT modify the power supply cord

plug. If it does not fit the outlet, have a

proper outlet installed by a qualified electrician.

- Do NOT use an extension cord with this

appliance.

- Check with a qualified electrician if you

are unsure if the appliance is properly

grounded.

• If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agent.

• Do NOT clean this appliance with a water jet.

• Do NOT use a sanitizing solution or abrasive

materials. The use of these may cause damage to the stainless steel finish.

• Chlorides or phosphates in cleaning agents

(e.g. bleach, sanitizers, degreasers, or detergents) could cause permanent damage to

stainless steel equipment. The damage is

usually in the form of discoloration, dulling

of metal surface finish, pits, voids, holes, or

cracks. This damage is permanent and NOT

covered by warranty.

• The equipment should be grounded according to local electrical codes to prevent the

possibility of electrical shock. It requires a

grounded receptacle with separate electrical

lines, protected by fuses or circuit breaker of

the proper rating.

• All electrical connections must be in accordance with local electrical codes and any

other applicable codes.

• The following tips are recommended for maintenance of your stainless steel equipment:

- Always use soft, damp cloth for cleaning,

rinse with clear water and wipe dry. When

required, always rub in direction of metal

polish lines.

- Routine cleaning should be done daily

using soap, ammonia detergent, and water.

- Stains and spots should be removed using

a vinegar solution as required.

- Finger marks and smears should be

removed using soap and water.

- Hard water spots should be removed using

a vinegar solution.

4

P/N 1010883 Rev. J 08/14

Page 5

SPECIFICATIONS

EGG STATION

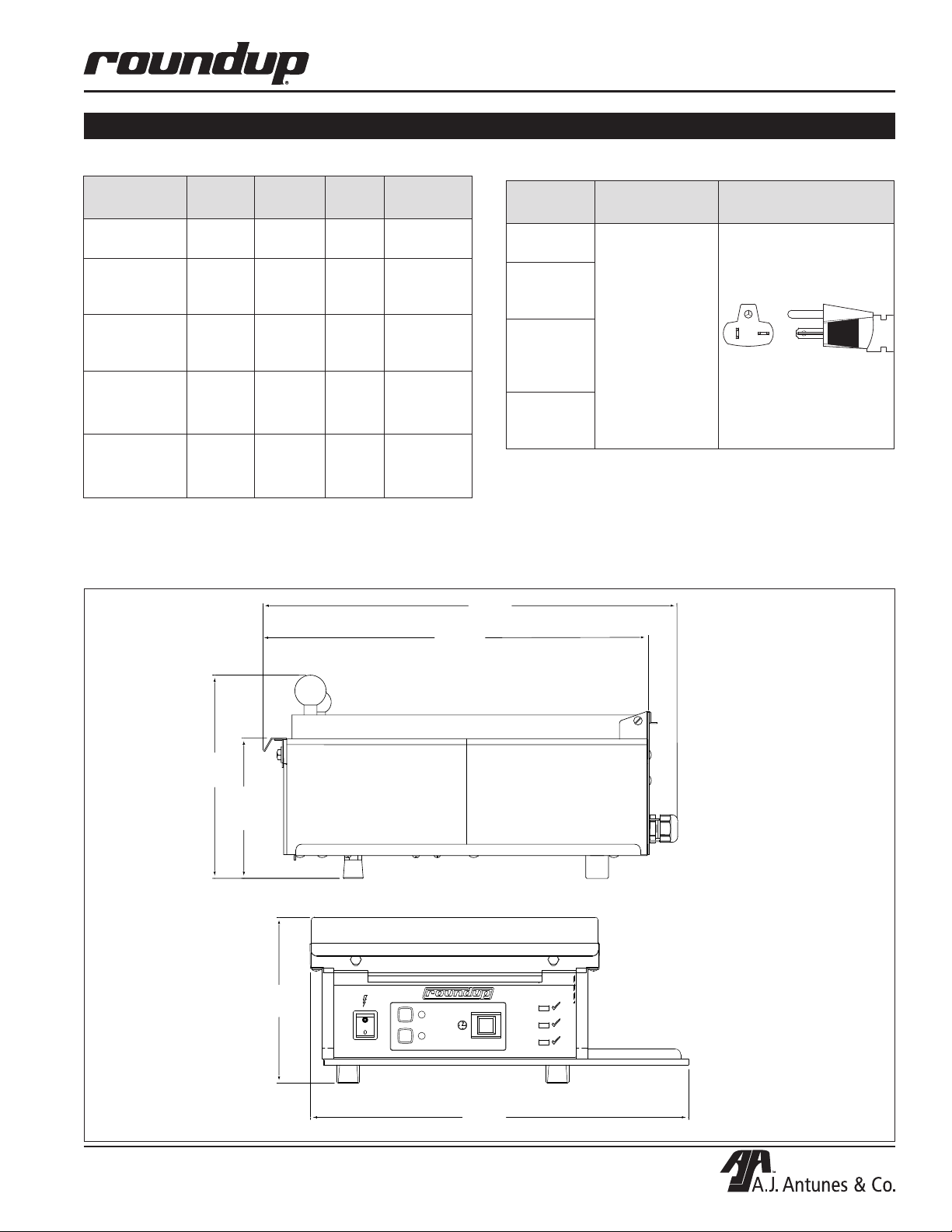

Electrical Ratings

Model &

Mfg. No.

ES-600

9300530

ES-602

9300571

9300577

ES-604

9300574

9300575

ES-1200

9300532

9300534

ES-604

9300593

Volts Watts Amp Hertz

208 2400 11.5 50/60

208 2400 11.5 50/60

208 2400 11.5 50/60

208 2400 11.5 50/60

208/220

- 240~

2400 /

3150

11.5 /

10.9 -

13.1

50/60

Shipping Weight

• ES-600: 48 lbs (21.7 kg)

• ES-602, ES-604 & ES-1200: 50 lbs (22.6 kg)

Dimensions

18 3/16"

(462 mm)

16 15/16"

(430 mm)

Electrical Cord & Plug Configurations

Model &

Mfg. No.

ES-600

9300530

ES-602

93 00 571

9300577

ES-604

93 005 74

9300575

9300593

ES -120 0

9300532

9300534

Description Configuration

6-20P, 20 Amp.,

250 VAC.,

Non-Locking

(Assembly Only)

Net Weight

• ES-600: 41 lbs (18.6 kg)

• ES-602, ES-604 & ES-1200: 43 lbs (19.5 kg)

8 15/16"

(227 mm)

6 3/16"

(157 mm)

7 9/32"

(185 mm)

P/N 1010883 Rev. J 08/14

POWER

2'-00"

1

2'-30"

2

START/STOP

16 5/8"

(422 mm)

READY

BACON

COOKING

5

Page 6

EGG STATION

INSTALLATION

Unpacking

1. Remove unit and all packing materials from

shipping carton.

NOTE: If any parts are missing or damaged,

contact A.J. Antunes & Co. Technical Service

IMMEDIATELY at 1-877-392-7854 (Toll free in the

U.S. and Canada) or 630-784-1000.)

2. Remove information packet.

3. Remove all packing materials and protective

coverings from the unit.

4. Wipe all surfaces of the unit with a hot damp

cloth.

NOTE: Do NOT use a dripping wet cloth. Wring it

out before use.

5. Clean the Egg Rings, Egg Rack, Top Cover, and

Service Pans in hot, soapy water. Rinse in clear

water and allow to air dry.

6. Reassemble all parts to unit.

Equipment Setup

When placing the unit into service, pay attention to the

following guidelines:

• Make sure power is off and the unit is at room tem-

perature.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do NOT allow cord to hang over edge of table or

counter.

• Place the unit on a sturdy, level table or other work

surface.

• Ensure that the line voltage corresponds to the

stated voltage on the unit’s specification label.

If unsure, have an electrician confirm correct

line voltage before connecting unit.

CAUTION

All electrical service connections must be in

accordance with local electrical codes and any

other applicable codes.

WARNING

ELECTRICAL SHOCK HAZARD.

FAILURE TO FOLLOW THE INSTRUCTIONS IN

THIS MANUAL COULD RESULT IN SERIOUS

INJURY OR DEATH.

• Electrical ground is required on this appliance.

• Do NOT modify the power supply cord plug. If

it does not fit the outlet, have a proper outlet

installed by a qualified electrician.

• Do NOT use an extension cord with this

appliance.

• The unit should be grounded according to

local electrical codes to prevent the possibility of electrical shock. It requires a grounded

receptacle with separate electrical lines, protected by fuses or circuit breaker of the proper

rating.

• Check with a qualified electrician if you are in

unsure if the appliance is properly grounded.

IMPORTANT

When installing the unit, use a leveler to ensure

that the table/cart is level and that the unit is

level when placed. If necessary, adjust the two

front bottom legs of the unit to level it. Failure to

level the table and/or unit may result in unevenly

cooked product.

• Place the unit on a sturdy, level surface.

• Make sure the unit is also level so that water does

not run from one side to the other. Adjust the legs as

needed to level the unit.

6

P/N 1010883 Rev. J 08/14

Page 7

OPERATION

EGG STATION

Preparing Unit

1. Turn the unit on and allow it to warm up for

approximately 20–30 minutes.

NOTE: During warmup, the Ready Indicator Light

flashes. The Ready Indicator Light stays on once

the unit reaches operating temperature.

2. If necessary, install the Top Cover according to

Figure 1.

3. Install the Egg Rack by holding it vertically and

sliding the pins of the Egg Rack into the slots on

the back of the Top Cover.

4. Install the Egg Rings into the Egg Rack (Figure

3). Make sure the Egg Rings are seated flat on

the Platen surface.

5. Ensure that the Egg Rack and Top Cover are in

the down position while the cooker warms up.

6. Add melted butter (or equivalent) to one Service

Pan (if desired) and slide the Service Pan into the

tray on right side of unit.

7. Slide the second Service Pan into the tray for

use for collecting scraps and unused product (if

desired).

Egg Cooking Procedure

To ensure proper cooking, place eggs into rings in numerical

FIFO (First in,

first out) The

first egg in

should always

be the first egg

out

order from 1 to 12 as shown below.

1 0

7

4

1

1 1 1 2

8 9

5 6

2 3

Front of Unit

LILO (Last in,

last out) The

last egg in

should always

be the last egg

out

NOTE: The size and number of

Egg Rings may vary based on

the type of unit installed.

Figure 2. Sample Egg Cooking Procedure

Read these instructions prior to cooking eggs.

1. Make sure the grill is clean and free of all extra

butter, oils, or egg product.

2. Raise the Top Cover and brush the Egg Rings and

Grill surface with melted butter or equivalent.

Slide notch

over tab

The Top Cover

Shown is for

Reference only.

Different units use

different covers.

Figure 1. Installing Top Cover

P/N 1010883 Rev. J 08/14

7

Page 8

EGG STATION

OPERATION (continued)

3. Crack the eggs into the Egg Rings from right to left

as shown in Figure 2, starting at the row closest to

the front of the unit.

6. Break the egg yolks if desired and close the Top

Cover.

7. Fill the troughs on the Top Cover with warm water

until they are completely full. This is very important to get a completely cooked egg with a jelled

yolk. Using less water results in under-cooked

eggs.

8. Select the desired cooking cycle (Figure 4).

All units Except Mfg. No. 9300534:

Use a two-minute cycle for room temperature eggs

or the two-and-a-half-minute cycle for refrigerated

eggs (Figure 4 top).

No. 9300534 Only:

Select 6 for six eggs or 12 for twelve eggs

(Figure 4 bottom)

9. All units EXCEPT Mfg. No. 9300534:

If desired, place sliced meat (Canadian bacon,

ham, etc.) on the front part of the Platen when

Bacon Indicator Light begins to flash and the

audio signal sounds (see Bacon Timer in the

Operation section of this manual).

10. Press the START/STOP button to begin the

cooking cycle.

NOTE: The Cooking Indicator Light will light when

the START/STOP button is pressed and released.

11. At the end of the cycle, when the Cooking

Indicator Light turns off, press the START/STOP

button to turn off the audio signal (Figure 2)

12. All units EXCEPT Mfg. No. 9300534:

Remove the meat from the Platen surface (see

the Bacon Timer section of this manual).

13. Open the cover and raise the Egg Rack about

1 inch (26 mm), then drop the rack to loosen the

eggs.

14. Raise the Egg Rack completely off the eggs and

use a spatula to remove the eggs.

NOTE: Refer to Figure 1. Remove eggs starting

with the first egg added and finish with the last egg

added. This ensures even cooking for all eggs.

15. Scrape and waste from Platen grill surface into

the Service Pan.

16. Lower the Egg Rack and Cover. The unit is ready

for further cooking.

Cover

Assembly

(12 Egg)

Egg

Cracker

Egg Rack

(12 Egg)

Trough

Egg Ring

Egg

Cracker

Egg Ring

Trough

Cover

Assembly

(6 Egg)

Egg Rack

(6 Egg)

Trough

Egg Ring

Cover

Assembly

(6 Egg)

Egg Rack

(6 Egg)

(4 inch rings)

Cracker

Trough

Egg

Figure 3. Cover Assembly (12 Egg Rings, 6 Egg Rings, and 2 Omelet Rings)

8

P/N 1010883 Rev. J 08/14

Cover

Assembly

Omelet Ring

Egg

Rack

Egg

Cracker

Page 9

OPERATION (continued)

START/STOP

POWER

2'-00"

2'-30"

READY

COOKING

BACON

1

2

For Mfg. No. 9300530, 532, 571, 574, & 575:

NOTE: The following are factory pre-set cooking times.

Time 1 Button: 2 minute cooking time.

Time 2 Button: 2 minutes and 30 seconds cooking time.

2'-45"

6

2'-30"

POWER

12

For Mfg. No. 9300534 Only:

NOTE: The following are factory pre-set cooking times.

Time 6 Button (6 eggs): 2 minutes 45 seconds cooking time.

Time 12 Button (12 eggs): 2 minutes 30 seconds cooking time.

START/STOP

Figure 4. Time Selector Switch

READY

COOKING

EGG STATION

Bacon Timer*

(All units EXCEPT Mfg. No. 9300534)

If, during the standby mode, the Bacon Indicator Light

is not lit, it means that the Bacon Timer is disabled. To

enable the Bacon Timer, with the unit turned on, press

the TIME 1 and TIME 2 buttons simultaneously for 3 or

more seconds. The Bacon Indicator Light will turn on.

The Bacon Timer is now enabled.

To disable the Bacon Timer, press the TIME 1 and

TIME 2 buttons simultaneously for 3 or more seconds.

The Bacon Indicator Light will turn off. The Bacon

Timer is now disabled.

USING THE BACON TIMER

If the Bacon Timer is enabled, an audio signal will

sound for a few seconds and the Bacon Indicator Light

will begin to flash 30 seconds before the end of the

cooking cycle.

During this time, the product should be placed on the

front part of the grill so that it will heat for 30 seconds.

The Bacon Indicator Light will continue to flash until the

end of the cooking cycle.

* ES-600 units are designed to operate with the Bacon Timer

enabled. ES-602, ES-604 and ES-1200 units are designed to

operate with the Bacon Timer disabled.

P/N 1010883 Rev. J 08/14

9

Page 10

EGG STATION

MAINTENANCE

WARNING

Turn the power off, unplug the power cord, and

allow the unit to cool down before performing any

service or maintenance.

CAUTION

Chlorides or phosphates in cleaning agents (e.g.

bleach, sanitizers, degreasers, or detergents)

could cause permanent damage to stainless steel

equipment. The damage is usually in the form of

discoloration, dulling of metal surface finish, pits,

voids, holes, or cracks. This damage is permanent and NOT covered by warranty. The following

tips are recommended for maintenance of your

stainless steel equipment:

• Always use soft, damp cloth for cleaning, rinse

with clear water and wipe dry. When required,

always rub in direction of metal polish lines.

• Stains and spots should be removed using a

vinegar solution.

• Finger marks and smears should be removed

using soap and water.

• Hard water spots should be removed using a

vinegar solution.

5. Clean the Egg Rings, Egg Rack, Cover, and

Service Pans in hot, soapy water. Rinse these

items in clear water and allow to air dry.

6. Reassemble the unit.

Checking Cycle Times (Monthly)

(All units EXCEPT Mfg. No. 9300534)

CAUTION: Grill surfaces will be hot. Care should be

taken when operating this piece of equipment.

NOTE: A stopwatch is required for this procedure.

1. Turn the unit on and allow it to warm up for

30 minutes.

2. Ensure that the TIME 1 button is lit. If not, press

and release the TIME 1 button. This button

should now be lit.

3. With the stopwatch in hand, press and release the

START/STOP button and start the stopwatch.

4. Record the time when the Bacon Indicator Light

begins to flash (if the Bacon Timer is enabled).

Then, record the time when the Cooking Indicator

Light turns off.

CAUTION

Do NOT use a sanitizing solution or abrasive

materials. The use of these may cause damage to

the stainless steel finish.

CAUTION

If a chemical cleaner is used, be sure it is safe to

use on cast aluminum. Observe all precautions

and warnings on product label.

Daily Cleaning

1. Turn the unit off, unplug the power cord, and

allow the unit to cool down before proceeding.

2. Scrape the Platen surface clean of any residue.

3. Wipe the entire Platen surface clean with damp

grill cloth.

4. Wipe the entire cooker cabinet clean with clean,

damp cloth.

NOTE: Do NOT use a dripping wet cloth. Wring the

cloth out before use.

5. Repeat this test with the TIME 2 button selected.

When set at 2’-00”, the Bacon Indicator Light

should flash at 1 minute and 30 seconds (90 seconds), and the Cooking Indicator Light should turn

off at 2 minutes (120 seconds).

When set at 2’-30”, the Bacon Indicator Light

should flash at 2 minutes (120 seconds), and the

Cooking Indicator Light should turn off at 2 minutes and 30 seconds (150 seconds).

All times are to be within +/- five (5) seconds.

6. Turn the power off.

10

P/N 1010883 Rev. J 08/14

Page 11

MAINTENANCE (continued)

EGG STATION

Checking Cycle Times (Monthly)

(Mfg. No. 9300534 ONLY)

CAUTION: Grill surfaces will be hot. Care should

be taken when operating this piece of equipment.

NOTE: A stopwatch is required for this procedure.

1. Turn the unit on and allow it to warm up for

30 minutes.

2. Ensure that the TIME 6 button is lit. If not, press

and release the TIME 6 button. This button

should now be lit.

3. With the stopwatch in hand, press and release the

START/STOP button and start the stopwatch.

4. Record the time when the Cooking Indicator Light

turns off.

5. Repeat this test with the TIME 12 button selected.

When set at 2’-45”, the Cooking Indicator Light

should turn off at 2 minutes and 45 seconds (165

seconds).

When set at 2’-30”, the Cooking Indicator Light

should turn off at 2 minutes and 30 seconds (150

seconds).

Checking Grill Platen Temperature

NOTE: A pyrometer is required for this procedure.

WARNING

This procedure exposes you to hot surfaces. Use

extreme care when performing procedure to avoid

personal injury.

1. Remove the cover and the Egg Rack by lifting the

whole assembly until clear of the base.

2. Turn the power on and allow 30 minutes for the

unit to warm up.

3. Using a pyrometer, measure the temperature

at the middle of the Platen surface (Figure

4). The temperature should be 250°F–300°F

(121°C–149°C).

If temperature is within range, proceed to Step 4.

If temperature is above or below the proper

calibrated range, call your Authorized Service

Agency.

4. Turn the power off.

5. Reinstall cover and Egg Rack and Top Cover.

All times are to be within +/- five (5) seconds.

6. Turn the power off.

Grill

Platen

Figure 4. Grill Platen (ES-600 Shown)

P/N 1010883 Rev. J 08/14

11

Page 12

EGG STATION

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test and repair of electrical equipment should be performed by qualified service personnel. The unit should be unplugged when servicing.

Problem Possible Cause Corrective Action

Unit fails to operate and

control panel lights fail

to signal on.

Unit fails to heat. Loose connections. Contact your maintenance person or an

Eggs do NOT cook

properly.

Eggs sticking to Platen. Dirty Platen. Clean Platen.

Eggs sticking to Egg

Rings.

Not signaling on “Bacon”

or “Ready”.

No power/low power. Make sure the power is on and the power cord

is locked into place. Check the main circuit

breakers.

Inoperable electrical outlet. Plug the power cord into a different outlet of

same amperage rating.

Inoperable power switch. Contact your maintenance person or an

Inoperable power cord.

Loose connections.

Inoperable Platen.

Low voltage.

Inoperable Hi-Limit Thermostat.

Inoperable Thermocouple.

Inoperable Solid State Relay.

Using refrigerated eggs and TIME 1

button selected.

Using room temperature eggs and

TIME 2 button selected.

Incorrect amount of water added to

trough in cover.

Platen temperature too low or too

high.

Loose connections. Contact your Authorized Service Agency.

Unit/table is not level Level the table and unit as necessary.

Insufficient butter being used. Refer to the Operating section of this manual.

Insufficient butter being used. Refer to the Operating section of this manual.

Dirty Egg Rings. Clean the Egg Rings but do NOT use an

Inoperable Egg Ring. Replace Egg Ring.

Inoperable indicator light or audio

signal.

Inoperable control board.

Loose connection.

Bacon Timer is disabled. Enable Bacon Timer according to the Operation

Authorized Service Agency.

Authorized Service Agency.

Use TIME 2 button when using refrigerated eggs.

Use TIME 1 button when using room temperature eggs.

Fill trough in cover with water before starting time

cycle.

Check the Platen temperature according to the

Maintenance section of this manual.

abrasive scrubbing pad.

Contact your maintenance person or an

Authorized Service Agency.

section of this manual.

If the troubleshooting steps listed do not solve your problem, contact an

A.J. Antunes Authorized Service Agency for further assistance.

12

P/N 1010883 Rev. J 08/14

Page 13

TROUBLESHOOTING (continued)

R17

Control Board LEDs

The control Board has three on board LEDs (Figure

5) to determine the status of the unit and to assist in

troubleshooting.

Green (Diagnostic): This LED should be off in normal

operation. If any of the 5 potential faults are detected by

the Control Board, this LED will repeatedly blink either 1

through 5 times with a 2-second pause in between (see

the Green LED Blink Codes section below).

Yellow (Audio): When lit, this LED indicates that the

Control Board is supplying approximately 10-15 VDC

to the audio signal. The audio signal should sound with

this LED is lit.

Red (Heat): When lit, this LED indicates that the

Control Board is calling for heat by supplying VDC to

terminals 3(+)4(-) of the Solid State Relay. When off,

this LED indicates that the grill Platen is up to operating

temperature and satisfied.

Green LED Blink Codes

EGG STATION

YELLOW

BUZZ

STATUS

HEAT

Figure 5. Control Board

LEDs

NOTE: During heat mode, this Red LED is very dim,

so it may be difficult to verify if the Control Board

is or is not calling for heat. It is recommended that

you observe the small round green LED on the

Solid State Relay (Figure 6) for mode and diagnostic purposes. When the green LED on the Solid

State Relay is on, it means that the Control Board is

calling for heat. When off, it means that the Control

Board is NOT calling for heat. Typically, the VDC at

the Solid State Relay will be less than 1.0 VDC when

measured, but may vary because of different quality VOMs. Therefore, it is recommended that you do

NOT attempt to measure the VDC at the Solid State

Relay for diagnostic purposes.

GREEN

RED

CR5

R18

R20

CR3

CR4

Solid State

Relay

LED

TUV

PRODUCT SERVICE

1/L1

Bauart

.

gapruit

4/A2-

50 AMP 24-280 VAC

Crouzet

GN

84137220

3-32 VDC

Figure 6. Solid State

Relay

2/T1

R

+3/A1

Number of Blinks Cause(s) Unit’s State and Resolution

The Green LED blinks

on and off 1 time, pauses for 2 seconds, and

repeats.

The Green LED blinks

on and off 2 times,

pauses for 2 seconds,

and repeats.

The Green LED blinks

on and off 3 times,

pauses for 2 seconds,

and repeats.

The Green LED blinks

on and off 4 times,

pauses for 2 seconds,

and repeats.

The Green LED blinks

on and off 5 times,

pauses for 2 seconds,

and repeats.

The EEPROM memory on the Control

Board is corrupted.

In this state, the unit turns off the control Signal to the Solid

State Relay and disables all front buttons and lights. The

unit will not heat up. This continues until the defaults are

reloaded into memory. To reload defaults, turn the unit off,

press and hold the TIME 2 button, turn the unit on, and

release the button.

The ambient temperature within the

control compartment has exceeded

155ºF (68ºC). Verify that there is

proper air ventilation all around the unit

and that it is not near a significant heat

In this state, the unit turns off the control signal to the

Solid State Relay and disables all front buttons and lights.

The unit will not heat up. This continues until the ambient

temperature within the electrical compartment drops below

140°F (60°C) and the unit is turned off and back on.

source.

Open or disconnected Thermocouple. In this state, the unit turns off the control signal to the Solid

State Relay and disables all front buttons and lights. The

unit will not heat up. This continues until the Thermocouple

is reconnected or replaced, and the unit is turned off and

back on.

The supply voltage to the unit is below

160 VAC or above 265 VAC.

In this state, the unit turns off the control signal to the Solid

State Relay and disables all front buttons and lights. The

unit will not heat up. This continues until the supply voltage

is within the proper limits and the unit has been turned off

and back on.

The 50/60 Hz signal has been lost

due to a disconnected or an open

wire harness/wiring on the AC Isolator

Board, or from the AC Isolator Board to

In this state, the unit turns off the control signal to the Solid

State Relay and disables all front buttons and lights. The

unit will not heat up. This continues until the 50/60 Hz signal is reapplied and the unit is turned off and back on.

the Control Board.

P/N 1010883 Rev. J 08/14

13

Page 14

EGG STATION

SWITCH

MOMENTARY

COOKING

BACON

READY

1

2

T1

T2

SSR

ISOLATOR BOARD

P4P3

P1

P2

T1

T2

CORD

POWER

WHT/BLU

BLK/BRN

GRN-YEL

GRN/

HEATER

NOTE: ALL WIRES TO BE 14 GA. TFE-200°C

22 GA. TFE-200°C

UNLESS OTHERWISE SPECIFIED.

# 18 GA. TFE-200°C

T3T4

COUPLE

THERMO-

SWITCH

BOARD

230VAC 12VAC

TRANSFORMER

GRN

GND

GND

THERMOSTAT

HI-LIMIT

TERMINAL

BLOCK

CONTROL

BOARD

BLK

WHT

WHT

BLK

WHT

WHT

BLK

BLK

YEL #

YEL #

WHT

GRN

ORG

BLK

GRN

BLK

BLUE

BLK

RED

BLK

YEL

BLK

4

3

21

4 5

WIRING DIAGRAM

P/N 1010883 Rev. J 08/14

14

Page 15

REPLACEMENT PARTS

EGG STATION

76

30

3

66

8

1

54

31

51

53

59

60

63

57

62

23

52

2

32

61

18

4

29

64

25

5

26

58

55

24

6

7

33

P/N 1010883 Rev. J 08/14

69

15

Page 16

EGG STATION

28

65

48

9

27

REPLACEMENT PARTS (continued)

28

14

34

10

19

65

15

48

34

27

20

45

11

28

65

48

74

27

16

35

21

45

28

65

48

74

12

27

45

17

34

13

19

28

65

48

74

27

45

18

36

22

45

16

P/N 1010883 Rev. J 08/14

Page 17

REPLACEMENT PARTS (continued)

EGG STATION

Item Part Description Qty.

No.

1 0021327 Nose Piece Weldment 1

2 210K230 Bumper, Recess Leg 1” 1

(Set of 4 including 4 screws)

3 7000379 Grill Platen 1

7000674 Grill Platen 1

(Mfg. No. 9300593 Only)

4 040P138* Lock-nut, Conduit - 1/2” NPT 1

5 040K251 Strain Relief Kit 1

6 2180270 Service Pan 2

(For Mfg. No. 9300530 & 9300532)

7 2180277 Service Pan (For Mfg. No. 2

9300534, 9300574 & 9300575)

8 0502900 Bracket , Sensor 1

9 7000363 Cover, Rack, & Ring Assembly 1

(Incl. All Shown) ES-1200

10 7000261 Cover, Rack, & Ring Assembly 1

(Incl. All Shown) ES-600

11 7000835 Cover, Rack & Ring Assembly 1

(Incl. All Shown) ES-604

12 7000690 Cover, Rack & Ring Assembly 1

(Incl. All Shown)

(For Mfg. No. 9300534 only)

13 7000635 Cover, Rack & Ring Assembly 1

(Incl. All Shown) ES-602

14 7000451 Cover, 12 Egg 1

(Incl. #28, 48 & 65) ES-1200

15 7000453 Cover, 6 Egg 1

(Incl. #28, 48 & 65) ES-600

16 7000836 Cover, 4” Egg Rings 1

(Incl. #28, 48, & 65) ES-604

17 0012204 Cover, 12 Egg 1

(Incl. #28, 48, 65 & 74)

(For Mfg. No. 9300534 only)

18 7000639 Cover, 8” Oval Ring ES-602 1

(Incl. #28, 48, 65 & 74)

19 7000452 Rack, 12 Egg Ring 1

(Incl. #27 & 45) ES-1200

20 7000454 Rack, 6 Egg Ring 1

(Incl. #27 & 45) ES-600

21 7000837 Rack, 4” Egg Rings 1

(Incl. #27 & 45) ES-604

Item Part Description Qty.

No.

22 7000640 Rack, 8” Egg Rings 1

(Incl. #27 & 45) ES-602

23 0021324 Panel, Base 1

24 0021325 Housing, Main 1

25 0504075 Cover, Insulation 2

26 0021326 Rear Panel Weldment 1

27 2100137 Knob Ball 1

28 2100138 Knob-Ball 1

29 0504078 Bracket, Hi-Limit 1

30 0700323 Power Cord, Assembly 1

6-20P

31 1001100 Label, Control 1

31a 1001248 Label, Control (not shown) 1

(For Mfg. No. 9300534 Only)

32 210K122 Adj. Leg Kit (Pack of 4) 1

33 210K108 Rubber Tip Kit (Pack of 4) 1

34 2130111 Egg Ring (Single) 6/12

ES-600/1200

213K101 Egg Ring (Pack of 6) 1/2

ES-600/1200

35 2130176 4” Egg Ring (Single) ES-604 6

213P176 4” Egg Ring (Pack of 6) ES-604 1

36 2130183 8” Round Egg Ring (Single) 1

ES-602

213P183 8” Round Egg Ring (Pack of 2) 1

ES-602

37 306P113* Screw, Mach. 2

#6-32 x 7/8” Sltrshd

38 306P123* Screw, Mach. 4

#6-32 x 5/8” Sltrshd 2

39 306P130* Nut, Hex KEPS #6-32 6

40 308P102* Washer, Int. Tooth #8 1

41 308P104* Scr, Mach 1

#8-32 x 3/8” Sltrshd

42 308P143* Nut, Hex KEPS #8-32 1

43 308P157* Screw, Tap #8-32 x 3/8” 1

44 310P102* Washer, Int Tooth-lock #10 2

45 310P109* Scr, Mach 1

#10-32 x 3/8” Sltrshd

46 310P136* Scr, Mach. 1

#10-32 x 1 and 1/4” Slpanhd

P/N 1010883 Rev. J 08/14

* Available only packages of 10.

17

Page 18

EGG STATION

REPLACEMENT PARTS (continued)

Item Part Description Qty.

No.

47 310P149* Scr, Mach. 1

#10-32 x 7/8” Slpanhd 1

48 325P101* Stud, 1/4-20 x 1-1/2” 1

49 325P104* Washer, Flat 1/4” S/S 1

50 325P109* Scr, Hxcap 1/4-20 x 3/4” 1

51 4010137 Switch, Rocker (25A-250V) 1

52 4010187 Transformer, Stepdown 1

(240V/12)

53 4010190 Switch, Momentary 1

54 4010193 PC-Board, Switch-Two Button 1

55 7000272 Thermostat, Hi-Limit 1

57 7000370 Solid State Relay 1

58 7000136 Terminal Block, 3-Pole 1

59 4060362 LED, Snap-in (Green - Ready) 1

60 4060363 LED, Snap-in (Yellow - Cooking) 1

61 4060385 LED, Snap-in (Blue - Bacon) 1

62 7000520 Control Board 1

62a 7000691 Control Board Kit 1

(For Mfg. No. 9300534 only)

63 7000391 A/C Line Isolator Board 1

64 0400337 Insulation 1

65 2120111 Spacer 1

66 4050214 Thermocouple 1

67 2180111 Plastic Dispensing Bottle 1

(not shown)

68 213K115 Spatula, Scraper and Brush Kit 1

(not shown)

69 0011251 Heat Sink Assembly 1

70 0700648 Wire Set, Main (not shown) 1

71 0700655 Wire Harness/PCB-LEDs 1

(not shown)

72 0700656 Wire Harness/PCB-Isoloator BD 1

(not shown)

73 0700657 Wire Harness/PCB-2 Button BD 1

(not shown)

74 0021401 Handle Weldment 1

75 300P102* Nut, Speed #8-32 “U” 1

76 7000838 Back Bracket Assy. Kit 1

ES-604

* Available only packages of 10.

18

P/N 1010883 Rev. J 08/14

Page 19

NOTES

EGG STATION

P/N 1010883 Rev. J 08/14

19

Page 20

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of

the finest materials available and manufactured to high quality standards. These units are warranted to be free

from electrical and mechanical defects for a period of one (1) year from date of purchase under normal use and

service, and when installed in accordance with manufacturer’s recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the Owner’s Manual. During the first 12 months,

electro-mechanical parts, non-overtime labor, and travel expenses up to 2 hours (100 miles/160 km), round trip

from the nearest Authorized Service Center are covered.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the Equipment. This warranty does not cover overtime charges or work done by unauthorized service

agencies or personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments

as specified in operating and maintenance instructions of this manual, and/or labor involved in moving adjacent

objects to gain access to the equipment. This warranty does not cover consumable/wear items. This warranty

does not cover damage to the Load Cell or Load Cell Assembly due to abuse, misuse, dropping of unit/shock

loads or exceeding maximum weight capacity (4 lbs). This warranty does not cover water contamination problems such as foreign material in water lines or inside solenoid valves. It does not cover water pressure problems

or failures resulting from improper/incorrect voltage supply. This warranty does not cover Travel Time & Mileage

in excess of 2 hours (100 miles/160 km) round trip from the nearest authorized service agency.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right

is always reserved to modify equipment because of factors beyond our control and government regulations.

Changes to update equipment do not constitute a warranty charge.

3.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection

should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt.

Damage should be reported to the carrier. This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight

and taxes are the responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE

ARE EXCLUSIVE AND IN NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Loading...

Loading...