3M TiO2 User Manual

Customer Application Brief

Chemical

TiO2 Pigment Slurry Filtration

Introduction

Pigment slurries are used in the plastics, fiber, and film manufacturing industries to add desirable properties such as surface appearance or color to the final products. Titanium dioxide, (TiO2), is often a major component of these slurries. Filtration of the TiO2 pigment slurry, a critical part of the manufacturing process, eliminates oversize pigment or agglomerated pigment particles. Particles that, if not entirely removed from the process stream on a consistent basis, will cause the plugging of:

•melt filters,

•screen packs, and

•spinnerets.

This Customer Application Brief (CAB) addresses the production of fibers and discusses the benefits obtained by appropriate slurry filtration using Betapure™ NT-T filters as illustrated by an application of TiO2 and the control of surface gloss, known as delustering, of polyester fibers.

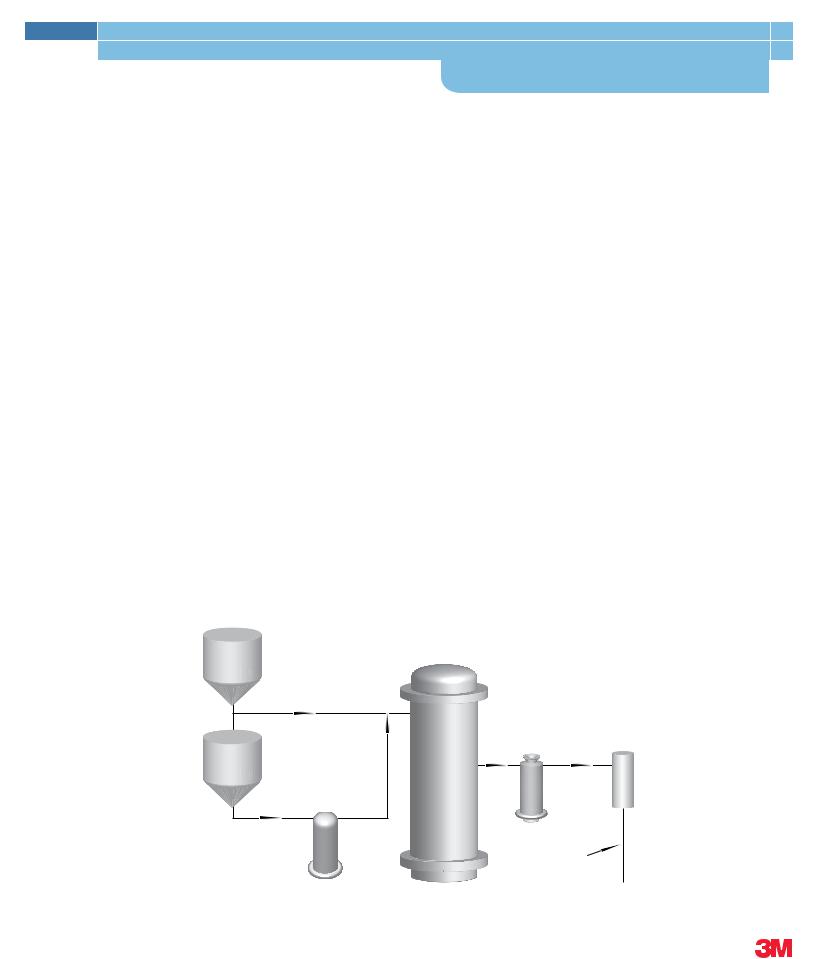

The Process: Pigment Slurries Used in Delustering

The surface gloss of man-made fibers is controlled at fiber producing plants by modifying the surface using TiO2 pigment slurries. TiO2 is dispersed in a liquid carrier such as glycol, and is commonly added to the monomer ahead of polymerization (Figure 1). After polymerization is complete, the molten polymer is extruded through spinnerets for making textile fiber. A fiber plant uses polymer melt filters, called “candles”, immediately downstream of the reactor. “Candles” are long pleated metallic media filter elements. Metal screen pack filters, also called spin packs, filter the polymer just prior to extrusion. These are flat porous metal screen type elements. Both filter types are “last chance” filters and must prevent spinneret orifice plugging in order to avoid poor quality fiber. The fiber then goes through spinning, drawing, dyeing, and other finishing operations.

Polymerization Process |

|

|

Monomers |

Reactor |

|

|

|

|

|

Melt |

Extruder |

Pigment Slurry |

Filters |

Spinnerets |

|

|

|

Slurry Filter |

|

|

|

Delustered |

|

|

Fiber |

|

Figure 1 — General Fiber Manufacturing Process

The Problem

Disruptions can occur in the fiber spinning process, because of contaminants in the TiO2 pigment slurry. Contaminants include oversize TiO2 particles not broken down enough during pigment grinding and agglomerated TiO2 pigment particles. The contaminants can cause process problems by plugging melt filters and by damaging fibers containing them.

Melt filters are employed prior to extrusion of the synthetic polymer into the fibers. Depending on the kind of fiber being processed, the melt filters may either filter the polymer in a molten state, or they may filter a polymer solution that further interacts with a chemical bath downstream of the spinneret. For molten polymers, the melt filters must withstand high temperature and typically consist of pleated metal, or metallic “screen packs” or “spin packs” associated with the fiber extrusion operation. For polymer solutions, the processing temperatures are typically lower, but

metal filters are generally used, because of pressure requirements in fiber spinning. Regardless of the type of polymer being processed into fibers, it is important to avoid plugging the melt filters. Their unscheduled change-out causes high costs associated with interrupted fiber production as well as the labor and material costs of replacing and cleaning the melt filters. Production downtime can be two hours or more and in-house cleaning of the screen packs can require four to five hours.

Following the melt filter is the spinneret extrusion die (Figure 2) that can have hundreds or thousands of small holes, used to form the synthetic fiber, depending on the fiber product manufactured. Plugging of the spinneret holes by contaminants in the polymer can raise the pressure drop across the spinneret, and distort the fiber cross-section

resulting in non-uniform fibers. Again, unscheduled change-out of the spinneret Figure 2 — Spinneret interrupts production and represents added labor and material costs.

Defective fibers can occur if contaminant particles make it through the melt filter and the spinneret holes. In this case, contaminant particles buried within the fiber can cause unwanted variation in the fiber cross-section which leads to processing problems for the fiber’s end-user in making fabric or other products from the fiber. In the manufacturing process, fibers are stretched to orient the polymer molecules to increase their strength. Contaminants that are imbedded in the fiber cause weak spots and make it more susceptible to breaking during the stretching process.

The Solution

The effective pre-filtration of TiO2 pigment slurries requires a filter design that will “classify” the slurry by reducing the oversized particles and allowing the small desirable pigment particles (9 - 100 micron, depending on fiber type) to pass through. Rigid depth filter cartridges that utilize a fixed structure of uniform pore size are the

most efficient and cost effective means of filtering TiO2 pigment slurries. The uniform pore size of the media, if properly selected, will retain the unwanted oversize particles and allow the desirable small particles to pass and remain in the slurry. Rigid media with fixed pore structures ensure that particles previously retained within the filter’s matrix are not unloaded due to fluctuations in pressure or flow as occurs with many non-rigid filters. The contaminant holding capacity of depth filters is significantly increased if the particles are evenly distributed throughout the entire depth of the media and are not trapped at just the outermost surface of the filter cartridge.

3M Purification offers a wide range of filtersfor pre-filtration of TiO2 pigment slurries ahead of the reactor will provide excellent long term protection of the melt filters

and screen packs, and can significantly impact process economics by dramatically reducing the production downtime spent during their change-out and replacement. As indicated above, one to two hours of production downtime is required for each screen pack change. Cartridge filters, usually rated at 20 micron absolute or finer, are used to

classify the slurry ensuring that the melt filters and screen packs continue to protect the Figure 3 — Betapure™ NT-T Filters orifices in the spinneret and do not prematurely plug. This will help prevent spinneret

plugging and fiber breakage (Figure 2).

Loading...

Loading...