3M AS-400LBC, AS-600LBC User Manual

3

3M Occupational Health and

Environmental Safety Division

3M Center, Building 0235-02-W-70

St. Paul, MN 55144-1000

Printed in U.S.A.

3M Occupational Health

and Environmental Safety Division

3M Canada Company

P.O. Box 5757 London, Ontario N6A 4T1

Printed in U.S.A.

Division des produits d’hygiène industrielle et de sécurité environnementale de 3M Compagnie 3M Canada

C.P. 5757

London (Ontario) N6A 4T1

Imprimé aux É.-U.

3M México S.A. de C.V.

Av. Santa Fe No. 190

Col. Santa Fe, Del. Álvaro Obregón México D.F. 01210

Impreso en EUA

3M do Brasil Ltda.

Via Anhangüera, km 110 - Sumaré - SP CNPJ 45.985.371/0001-08

Impresso nos EUA

|

Tychem® and Tyvek® are registered trademarks of DuPont. |

|

Tychem® and Tyvek® are registered trademarks of DuPont. Used under |

|

license in Canada. |

|

Tychem® et Tyvek® sont des marques déposées de DuPont, utilisées sous |

|

licence au Canada. |

|

Tychem® y Tyvek® son marcas registradas de DuPont. |

|

Tychem® e Tyvek® são marcas comerciais registradas da DuPont. |

©3M 2008 |

98-0060-0014-9/2 |

|

34-8701-7650-9 |

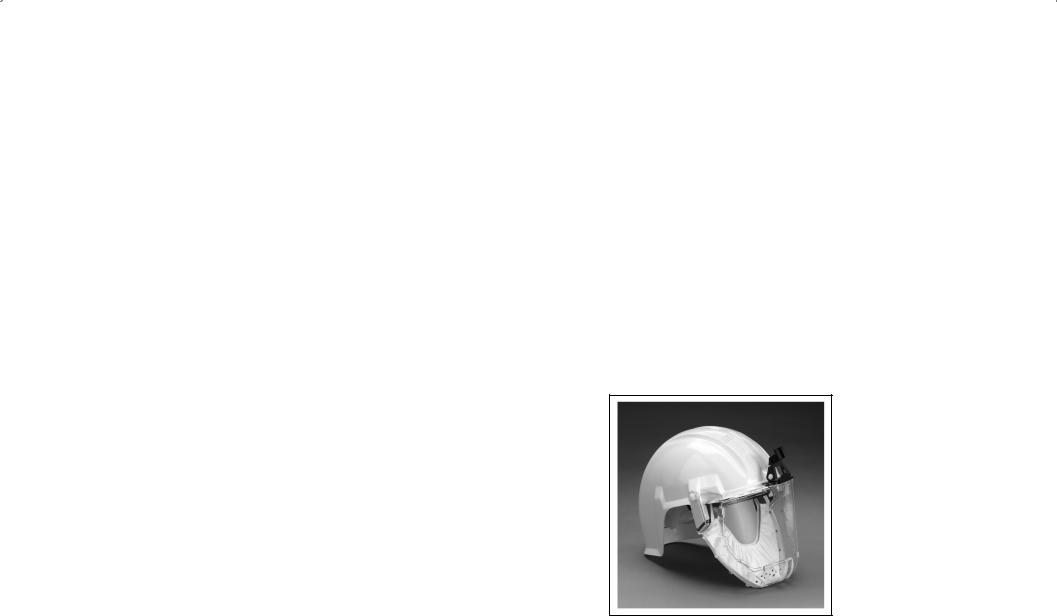

3Airstream™

Headgear-Mounted PAPR System

User Instructions for 3M™ Airstream™ Headgear-Mounted PAPR System, AS-400LBC and AS-600LBC

Respirateur d’épuration d’air propulsé pour pièce faciale Airstream™

Directives d’utilisation pour les respirateurs d’épuration d’air propulsé pour pièces faciales AS 400LBC et AS 600LBC Airstream™ 3M™

Sistema PAPR montado en casco Airstream™

Instrucciones para Sistema PAPR montado en casco Airstream™,

AS-400LBC y AS-600LBC

Sistema Airstream Capacete Motorizado (PAPR)

Instruções para o usuário do Sistema Airstream™ Capacete

Motorizado (PAPR) AS-400LBC e AS-600LBC da 3M™

Important: Before use, the wearer must read and understand these User Instructions. Keep these User Instructions for reference.

Important : Avant de se servir du produit, l’utilisateur doit lire et comprendre les présentes directives d’utilisation. Conserver ces directives à titre de référence.

Importante: Antes de usar el producto, el usuario debe leer y entender estas Instrucciones. Conserve estas Instrucciones para referencia futura.

Importante: Antes do uso, o usuário deve ler e entender estas Instruções de Uso. Guarde estas Instruções de Uso para referência.

TABLE OF CONTENTS |

|

GENERAL SAFETY INFORMATION ...................................................................................................... |

5 |

– Intended Use.................................................................................................................................. |

5 |

– General Description........................................................................................................................ |

5 |

– Use For.......................................................................................................................................... |

5 |

– Do Not Use For............................................................................................................................... |

5 |

– Respirator Selection and Training................................................................................................... |

6 |

– Listing of Warnings and Cautions within these User Instructions..................................................... |

6 |

– NIOSH Approval............................................................................................................................ |

12 |

– NIOSH Cautions and Limitations................................................................................................... |

12 |

– Eye and Face Protection............................................................................................................... |

12 |

– Assigned Protection Factor........................................................................................................... |

12 |

SPECIFICATIONS.............................................................................................................................. |

13 |

SYSTEMS, REPLACEMENT PARTS AND ACCESSORIES...................................................................... |

14 |

– 3M™ Airstream™ Headgear-Mounted PAPR Systems................................................................. |

14 |

– 3M™ Replacement Parts and Accessories................................................................................... |

15 |

– Service Life of Chemical Cartridges and Filters............................................................................. |

16 |

– Shelf Life of Chemical Cartridges and Filters................................................................................ |

16 |

ASSEMBLY...................................................................................................................................... |

16 |

– NiCd Battery................................................................................................................................. |

16 |

– Prefilter........................................................................................................................................ |

17 |

– Main Filter/Cartridge and Motor Housing Assembly....................................................................... |

17 |

– Faceseal 527-01-15R10, with Tychem® QC Fabric ..................................................................... |

19 |

– Faceseal AS-101-10 and 102-10, Elastomeric:............................................................................. |

21 |

– Visor Surround............................................................................................................................. |

21 |

– Visor............................................................................................................................................ |

22 |

– Comfort Band............................................................................................................................... |

23 |

– Headband and Cradle Assembly................................................................................................... |

23 |

– Adjusting the Headband............................................................................................................... |

24 |

– Head Seal.................................................................................................................................... |

25 |

– Temple Seals............................................................................................................................... |

25 |

INSPECTION.................................................................................................................................... |

25 |

USER PERFORMANCE CHECK.......................................................................................................... |

26 |

DONNING........................................................................................................................................ |

27 |

OPERATING INSTRUCTIONS............................................................................................................. |

27 |

CLEANING AND STORAGE................................................................................................................ |

28 |

TROUBLESHOOTING........................................................................................................................ |

30 |

IMPORTANT NOTICE........................................................................................................................ |

31 |

FOR MORE INFORMATION................................................................................................................ |

31 |

ENGLISH

|

|

|

3 |

4 |

|

GENERAL SAFETY INFORMATION

WARNING

WARNING

This product helps protect against certain airborne contaminants.

Misuse may result in sickness or death. For proper use, see supervisor, User Instructions, or call 3M in U.S.A., 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

Intended Use General Description

The 3M™ Airstream™ Headgear-Mounted Powered Air Purifying Respirator (PAPR) System is a NIOSH-approved, loose fitting facepiece system. The blower and filter are mounted inside the headgear shell and powered by a rechargeable NiCd battery pack, which clips to the user’s belt. The 3M™ Airstream™ Headgear-Mounted PAPR System is designed to help provide respiratory protection against particulates when using the AS-140-5 high efficiency filter or from hydrogen fluoride when using the AS-176 cartridge.

Ambient air is drawn through the outer pre-filter and passes up through the top of the headgear, where it passes through the filter/cartridge “sock”. The filtered air then flows down over the user’s

face and exits at the periphery of the faceseal (Fig. 1). A head seal, faceseal, and temple seals plus positive air flow help prevent mixing of filtered air inside the visor with ambient air. When not in the contaminated area, the visor assembly can be lifted and locked in the up position. This respirator headpiece will accommodate limited facial hair without compromising the level of protection, provided there is no facial hair between the elasticized edge of the faceseal and the face.

Use For

Respiratory protection against certain airborne particulate contaminants (including dusts, fumes, mists, radionuclides and asbestos) or hydrogen fluoride.

Do Not Use For

-Oxygen deficient atmospheres.

-Gases and vapors other than hydrogen fluoride.

-Contaminant concentrations that are unknown or immediately dangerous to life or health (IDLH).

-Contaminant concentrations that exceed 25 times the applicable exposure limit (the assigned protection factor, APF, for this respirator system) or the APF mandated by specific government standards, whichever is lower.

-Atmospheres containing paint spray or oil aerosols.

Respirator Selection and Training

Use of these respirators must be in accordance with applicable health and safety standards, respirator selection tables contained in such publications as American National Standards Institute (ANSI) Z88.2- 1992, Canadian Standards Association (CSA) Standard Z94.4 or pursuant to the recommendations of an industrial hygienist. Before occupational use of these respirators, a written respiratory protection program must be implemented meeting all the requirements of OSHA 29 CFR 1910.134 such as training, fit testing, medical evaluation, and applicable OSHA substance specific standards. In Canada, CSA standards Z94.4 requirements must be met and/or requirements of the applicable jurisdiction, as appropriate.

If you have any doubts about the applicability of these respirators to your job situation, consult an industrial hygienist or call 3M OH&ESD technical service department at 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

WARNING

WARNING

Each person using this respirator must read and understand the information in these User Instructions before use. Use of these respirators by untrained or unqualified persons, or use that is not in accordance with these User Instructions, may adversely affect respirator performance and result in sickness or death.

Listing of Warnings and Cautions within these User Instructions.

WARNING

WARNING

•This product helps protect against certain airborne contaminants. Misuse may result in sickness or death. For proper use, see supervisor, User Instructions, or call 3M in U.S.A., 1-800-243-4630. In Canada, call Technical Service at 1-800-267-4414.

•Each person using this respirator must read and understand the information in these User Instructions before use. Use of these respirators by untrained or unqualified persons, or use that is not in accordance with these User Instructions, may adversely affect respirator performance and may result in sickness or death.

•Because the faceshields of the 3M™ Airstream™ Headgear-Mounted PAPR System can be raised from the normal position, ANSI Z87.1-2003/CSA Z94.3 states that safety spectacles or goggles must be worn in conjunction with this respirator. Failure to do so may result in serious eye injury.

•Do not use with parts or accessories other than those manufactured by 3M as described in these User Instructions or on the NIOSH approval label for this respirator. Do not attempt to repair or modify any component of the system except as described in these User Instructions.

Failure to do so may adversely affect respirator performance and result in sickness or death.

•Use of excessive force during the insertion of the filter/cartridge may damage the filter/cartridge and/or the filter/cartridge holder. Do not attempt to repair or use damaged filter/cartridges. If damage is suspected, remove and start over with new components as necessary. Failure to do so may adversely affect respirator performance and may result in sickness or death.

ENGLISH

|

|

|

5 |

6 |

|

WARNING

WARNING

•A user inspection and performance check must be performed prior to each use to verify that the filter and blower assemblies have been correctly installed. If the respirator fails any of the requirements of the user inspection and performance check, refer to the “Troubleshooting” section in these User Instructions. Do not use the respirator until all necessary repairs have been made and the respirator passes the performance check. Failure to do so may adversely affect respirator performance and result in sickness or death.

•The faceseal must be changed if it becomes torn, worn excessively or the elastic is stretched-out. Exposure to solvents and/or ultraviolet light may accelerate the degradation of the elastic. This could result in exposure to airborne contaminants and could result in sickness or death.

•Incorrect fitting of the visor will reduce face, eye and respiratory protection, and may result in sickness or death.

•Incorrect fitting of the headband/cradle assembly may reduce head protection provided by the headgear, possibly rendering it totally ineffective, resulting in serious injury or death.

•Impact to the headgear may weaken the shell and/or suspension system and reduce head protection from subsequent impact, even if there is no visible damage. If the headgear shell has been subject to impact or if other damage to the headgear is suspected, the headgear shell and suspension system must be replaced. Failure to do so may result in serious injury or death.

•Failure to conduct an inspection and complete all necessary repairs before use may adversely affect respirator performance and result in sickness or death.

•Failure to pass a user performance check and complete all necessary repairs before use may adversely affect respirator performance and result in sickness or death.

•Use of this respirator in atmospheres for which it was not NIOSH certified and designed may result in sickness or death. Do not wear this respirator where:

–Atmospheres contain hazardous vapors or gases other than hydrogen fluoride

–Atmospheres are oxygen deficient.

–Contaminant concentrations are unknown.

–Contaminant concentrations are Immediately Dangerous to Life or Health (IDLH).

–Contaminant concentrations that exceed 25 times the applicable exposure limit (the assigned

protection factor, APF, for this respirator system) or the APF mandated by specific government standards, whichever is lower.

•Do not enter a contaminated area until the respirator system is properly donned. Do not remove the respirator before leaving the contaminated area. Doing so may result in sickness or death.

•Contaminants that are dangerous to your health include those that you may not be able to see or smell. Leave the contaminated area immediately if any of the following conditions occur. Failure to do so may result in sickness or death.

–Any part of the system becomes damaged.

–Airflow into the respirator decreases or stops.

–Breathing becomes difficult.

–You feel dizzy or your vision is impaired.

–You taste or smell contaminants.

–Your face, eyes, nose or mouth become(s) irritated.

–You suspect that the concentration of contaminants may have reached levels at which this respirator system may no longer provide adequate protection.

7

|

|

|

WARNING |

|

|

• Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator |

|

|

components and reduce respirator effectiveness. Inspect all respirator components before each |

|

ENGLISH |

in damage to the filter membrane allowing hazardous particles to enter the breathing zone, |

|

|

use to ensure proper operating conditions. Failure to do so may result in sickness or death. |

|

|

• Never attempt to clean filters by knocking or blowing out accumulated material.This may result |

|

|

resulting in sickness or death. |

|

|

• The 3M AS-176 hydrogen fluoride cartridge is not NIOSH approved for particulates. Misuse |

|

|

may result in sickness or death. |

|

|

|

|

|

|

|

|

8

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

St. Paul, Minnesota, USA |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1-800-243-4630 |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AirstreamTM |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Headgear Mounted PAPR |

|

|

|

|

|

|

|

|

||||||

|

|

|

THESE RESPIRATORS ARE APPROVED ONLY IN THE FOLLOWING CONFIGURATIONS: |

|

|

|

|

||||||||||||||||||||

|

|

|

ALTERNAT |

HEADGEAR |

|

ALTERNAT FACESEALS |

|

CARTRIDGE |

|

FILTER |

|

POWER SOURCE |

|

|

|

|

|

|

|

|

ACCESSORIE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AIR FLOW INDICATOR |

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AS-400 |

AS-600 |

527-01-15 |

AS-101 |

AS-102 |

AS-176 |

|

AS-140 |

|

520-01-02 |

|

061-44-01 |

522-01-01 |

|

AS-131 |

060-75-02 |

529-02-37 |

529-01-09 |

AS-120 |

529-01-56 |

1455 |

520-01-61 |

520-03-72 |

520-03-73 |

|

|

|

|

E |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTIONS AND |

|

TC- |

PROTECTION1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LIMITATIONS2 |

9 |

21C-0742 |

HE |

X |

X |

X |

X |

X |

|

|

X |

|

X |

|

X |

X |

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

ABCFIJLMNOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23C-2139 |

HF |

X |

|

X |

X |

X |

X |

|

|

|

X |

|

X |

X |

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

ABCFHIJLMNO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. PROTECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HE - High Efficiency Particulate filter for powered, air-purifying respirators |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

HF - Hydrogen Fluoride |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. CAUTIONS AND LIMITATIONS

A - Not for use in atmospheres containing less than 19.5 percent oxygen. B - Not for use in atmospheres immediately dangerous to life or health.

C - Do not exceed maximum use concentrations established by regulatory standards.

F - Do not use powered air-purifying respirator if less than four cfm (115 lpm) for tight fitting facepieces or six cfm (170) for hoods and/or helmets.

H - Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridge and canisters are replaced before breakthrough occurs I - Contains electrical parts that may cause an ignition in flammable or explosive atmospheres.

J - Failure to properly use and maintain this product could result in injury or death.

L - Follow the manufacturer's User's Instructions for changing cartridges, canisters and/or filters.

M - All approved respirators shall be selected fitted, used, and maintained in accordance with MSHA, OSHA and other applicable regulations. N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as specified by the manufacturer.

O - Refer to User's Instructions, and/or maintenance manuals for information on use and maintenance of these respirators. P - NIOSH does not evaluate respirators for use as surgical masks.

Rev F: 02-19-08

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

St. Paul, Minnesota, USA |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

1-800-243-4630 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

AS-176 HF Cartridge |

|

|

|

|

|

|

|

||||

|

|

|

THIS CARTRIDGE IS APPROVED ONLY IN THE FOLLOWING CONFIGURATIONS: |

|

|

|

|||||||||||||||||

|

|

|

CARTRIDGE |

|

HEADGEAR |

|

ALTERNAT FACESEALS |

|

POWER SOURCE |

|

AIR FLOW INDICATOR |

|

|

|

|

|

ACCESSORIES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

AS-176 |

|

AS-400 |

527-01-15 |

AS-101 |

AS-102 |

520-01-02 |

|

061-44-01 |

522-01-01 |

AS-131 |

060-75-02 |

529-02-37 |

529-01-09 |

AS-120 |

529-01-56 |

1455 |

520-01-61 |

520-03-72 |

520-03-73 |

CAUTIONS AND |

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TC- |

PROTECTION1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LIMITATIONS2 |

|

23C-2139 |

HF |

X |

|

X |

X |

X |

X |

X |

|

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

X |

ABCFHIJLMNO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. PROTECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HF - Hydrogen Fluoride |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. CAUTIONS AND LIMITATIONS

A - Not for use in atmospheres containing less than 19.5 percent oxygen. B - Not for use in atmospheres immediately dangerous to life or health.

C - Do not exceed maximum use concentrations established by regulatory standards.

F - Do not use powered air-purifying respirator if less than four cfm (115 lpm) for tight fitting facepieces or six cfm (170) for hoods and/or helmets.

H - Follow established cartridge and canister change schedules or observe ESLI to ensure that cartridge and canisters are replaced before breakthrough occurs I - Contains electrical parts that may cause an ignition in flammable or explosive atmospheres.

J - Failure to properly use and maintain this product could result in injury or death.

L - Follow the manufacturer's User's Instructions for changing cartridges, canisters and/or filters.

M - All approved respirators shall be selected fitted, used, and maintained in accordance with MSHA, OSHA and other applicable regulations. N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as specified by the manufacturer.

O - Refer to User's Instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

Rev C: 02-19-08

ENGLISH

3M St. Paul, Minnesota, USA 1-800-243-4630 AS-140 HE Filter |

ONLY IN THE FOLLOWING CONFIGURATIONS: |

RESPIRATOR COMPONENTS |

|

THIS FILTER IS APPROVED |

|

|

2 |

|

|

CAUTIONSAND LIMITATIONS |

|

|

520-03-73 |

|

|

520-03-72 |

|

|

520-01-61 |

|

|

1455 |

|

|

529-01-56 |

|

ACCESSORIES |

AS-120 |

|

|

529-01-09 |

|

|

529-02-37 |

|

|

060-75-02 |

|

|

AS-131 |

|

|

522-01-01 |

|

INDICATOR |

061-44-01 |

|

AIRFLOW |

||

|

||

POWERSOURCE |

520-01-02 |

|

|

AS-102 |

|

FACESEALS |

AS-101 |

|

ALTERNAT |

||

E |

||

|

527-01-15 |

|

HEADGEAR |

AS-600 |

|

|

||

ALTERNAT |

E |

|

|

AS-400 |

|

FILTER |

AS-140 |

|

|

1 |

|

|

PROTECTION |

|

|

TC- |

|

|

|

X X X X X X X X X X X X X X X X X X X ABCFIJLMNOP

HE

21C-0742

Rev E: 02-19-08

|

|

2. CAUTIONS AND LIMITATIONS A - Not for use in atmospheres containing less than 19.5 percent oxygen. B - Not for use in atmospheres immediately dangerous to life or health. C - Do not exceed maximum use concentrations established by regulatory standards. F - Do not use powered air-purifying respirator if less than four cfm (115 lpm) for tight fitting facepieces or six cfm (170) for hoods and/or helmets. I - Contains electrical parts that may cause an ignition in flammable or explosive atmospheres. J - Failure to properly use and maintain this product could result in injury or death. L - Follow the manufacturer's User's Instructions for changing cartridges, canisters and/or filters. M - All approved respirators shall be selected fitted, used, and maintained in accordance with MSHA, OSHA and other applicable regulations. N - Never substitute, modify, add, or omit parts. Use only exact replacement parts in the configuration as specified by the manufacturer. O - Refer to User's Instructions, and/or maintenance manuals for information on use and maintenance of these respirators. P - NIOSH does not evaluate respirators for use as surgical masks. |

1. PROTECTION |

HE - High Efficiency Particulate filter for powered, air-purifying respirators |

|

|

NIOSH Approval

For a listing of the components of NIOSH approved 3M™ Respirator Systems using 3M™ Airstream™ Headgear-Mounted PAPR System, refer to the NIOSH approval label and the “Systems, Replacement Parts and Accessories” section in these instructions.

NIOSH Cautions and Limitations

A– |

Not for use in atmospheres containing less than 19.5 percent oxygen. |

B– |

Not for use in atmospheres immediately dangerous to life or health. |

C– |

Do not exceed maximum use concentrations established by regulatory standards. |

F– |

Do not use powered air-purifying respirator if airflow is less than four cfm (115 lpm) for tight fitting |

|

facepieces or six cfm (170 lpm) for hoods and/or helmet. |

H– |

Follow established cartridge and canister change schedules or observe ESLI to ensure that |

|

cartridge and canisters are replaced before breakthrough occurs. |

I– |

Contains electrical parts which have not been evaluated as an ignition source in flammable or |

|

explosive atmospheres by MSHA/NIOSH. |

J– |

Failure to properly use and maintain this product could result in injury or death. |

L– |

Follow the manufacturer's User's Instructions for changing cartridges, canister and/or filters. |

M– All approved respirators shall be selected, fitted, used, and maintained in accordance with MSHA, OSHA, and other applicable regulations.

N– Never substitute modify, add, or omit parts. Use only exact replacement parts in the configuration as specified by the manufacturer.

O– Refer to User's Instructions, and/or maintenance manuals for information on use and maintenance of these respirators.

P– NIOSH does not evaluate respirators for use as surgical masks.

Eye and Face Protection

WARNING

WARNING

Because the faceshields of the 3M™ Airstream™ Headgear Mounted PAPR System can be raised from the normal position, ANSI Z87.1-2003/ CSA Z94.3 states that safety spectacles or goggles must be worn in conjunction with this respirator. Failure to do so may result in serious eye injury.

Assigned Protection Factor

3M recommends an assigned protection factor (APF) of 25 for loose fitting facepiece respirators. Where local, state, or federal standards specify APFs, the lowest applicable APF should be used. In Canada, follow the requirements of the authority having jurisdiction and CSA Standard Z94.4.

ENGLISH

|

|

|

11 |

12 |

|

SPECIFICATIONS

Airflow: |

Greater than 6 cfm (170 lpm) |

|

|

|

|

Weight: |

Headgear Assembly: Approx. 2.2 lb (998 g) |

|

Battery Pack: Approx. 1.2 lb (544 g) |

||

|

||

|

|

|

Headgear Shell Material: |

ABS Plastic |

|

|

|

|

Visor Dimensions: |

47 in2 (305 cm2) |

|

Visor Material: |

Polycarbonate (visor overlays are clear acetate) |

|

|

|

|

|

Headgear meets the requirements of ANSI Z87.1-2003 |

|

Eye and Face Protection: |

“American National Standard for Occupational and Educational |

|

|

Personal Eye and Face Protection Devices”. |

|

|

|

|

|

Headgear meets the requirements of ANSI Z89.1-2003 Type |

|

Head Protection: |

I, Class C “American National Standard for Industrial Head |

|

|

Protection”. |

|

|

|

|

Heat and Flame Resistance: |

This respirator system is not designed for use in high temperature |

|

environments and should not be exposed to sparks or flame. |

||

|

||

|

|

|

|

The AS-400LBC and AS-600LBC systems have been tested |

|

|

and classified by UL for intrinsic safety. They can be used in the |

|

|

following Division 1 locations: Class I, Group D, Class II, Groups |

|

|

E, F, G; and Class III. |

|

Intrinsic Safety: |

|

|

|

In addition, the headgear-mounted PAPR system AS 600LBC |

|

|

has been examined by the U.S. Department of Labor, Mine |

|

|

Safety and Health Administration (MSHA) and has been |

|

|

approved for use in methane-air mixtures. |

|

|

|

|

Powered Air Purifier |

|

|

|

|

|

Noise Level (excluding external noise): |

Less than 80 dBA |

|

|

|

|

Operating Temperature Range: |

10ºF to 120ºF (-12ºC to 49ºC) |

|

|

|

|

Voltage: |

4.8 volts DC |

|

|

|

|

Estimated Motor Life: |

1000 hours (Dependent on use conditions) |

|

|

|

|

Battery Pack |

|

|

|

|

|

Type: |

Rechargeable NiCd |

|

|

|

|

Service Time (after approximately 8 hour |

Approximately 8 hours of continuous use |

|

charge): |

||

|

||

|

|

|

Maximum Time on Continuous Charge: |

Up to 30 days |

|

|

|

|

Storage Time: |

Battery will lose approx. 25% capacity per month |

|

|

|

|

Maximum Operating Temperature Range: |

10ºF to 120ºF (-12ºC to 49ºC) |

|

|

|

|

Battery Charging Temperature Range: |

50ºF to 80ºF (10ºC to 27ºC) |

|

|

|

|

Voltage: |

4.8 volts DC |

|

|

|

|

|

Approximately 500 discharge cycles. Number of cycles |

|

Battery Life: |

is dependent on temperature conditions during use and |

|

|

recharging. |

|

|

|

SYSTEMS, REPLACEMENT PARTS AND ACCESSORIES

WARNING

WARNING

Do not use with parts or accessories other than those manufactured by 3M as described in these User Instructions or on the NIOSH approval label for this respirator. Do not attempt to repair or modify any component of the system except as described in these User Instructions. Failure to do so may adversely affect respirator performance and result in sickness or death.

3M™ Airstream™ Headgear-Mounted PAPR Systems

AS-400LBC |

Includes: * |

|

• Motor Housing Assembly AS-115, Ultra |

|

• Visor 522-01-01 (standard) |

|

• Battery Pack 520-01-02R01 |

AS-600LBC |

Includes: * |

•Motor Housing Assembly AS-115, Ultra

•Visor AS-131,Antifog, Scratch Resistant

•Battery Pack 520-01-02R01

*In addition, the following items are packed out with each system: Prefilter AS-120, HE Filter AS-140, Tychem® QC Faceseal 527-01-15R10, Airflow Indicator 061-44-01, Carrying Bag 520-01-81.

|

|

6 |

7 |

8 |

1 |

|

|

2

5 12

16 15

14 |

13 |

|

4

11 9

3 10

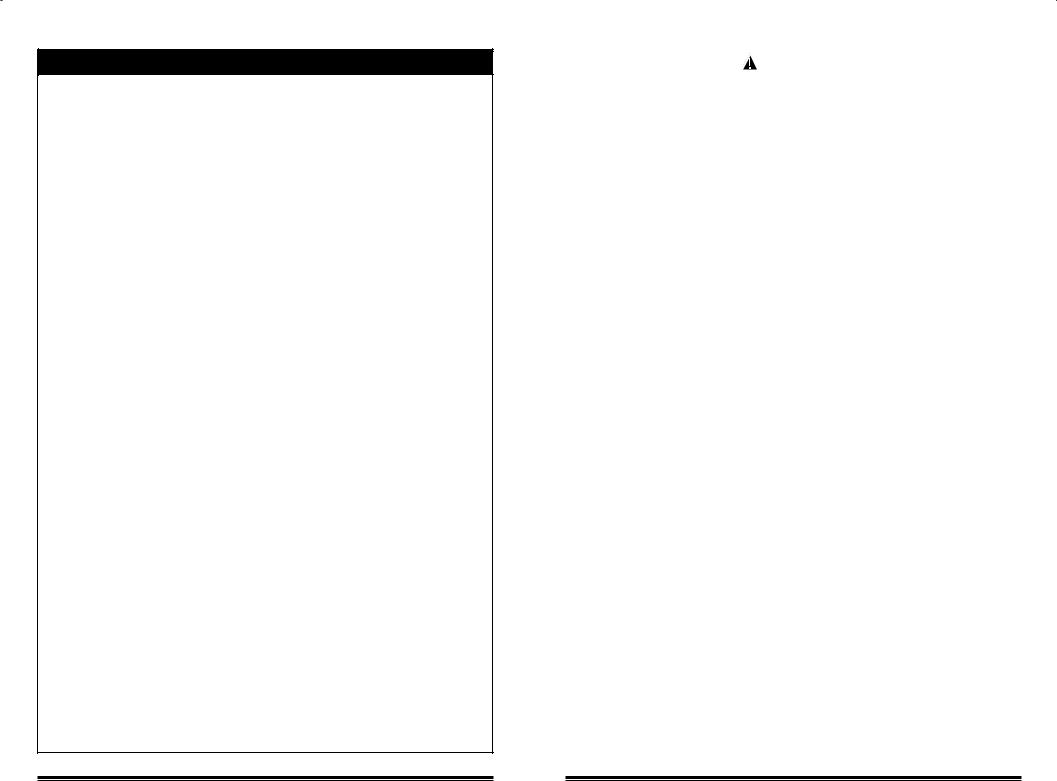

Fig. 2

ENGLISH

13 |

14 |

3M™ Replacement Parts and Accessories

(Fig. 2) |

|

|

|

|

||

Part Number |

Description |

Part Number |

Description |

|||

[1] |

|

060-46-34R01 |

Headgear Shell, White |

[-] |

529-02-37R10 |

Protective Overlay |

|

|

|

(for AS 400LBC and |

|

|

(10/pack) |

|

|

|

AS 600LBC) |

[15] AS-170 |

Visor Surround |

|

[-] |

520-01-86R01 |

Headgear Shell |

|

|

Assembly, without |

|

|

|

|

Assembly, White, with |

|

|

Lamp Bracket and |

|

|

|

Visor Surround, (for |

|

|

Hinge (for AS-400LBC) |

|

|

|

AS 400LBC) |

[15] AS-170M |

Visor Surround |

|

[-] AS-650 |

Headgear Shell |

|

|

Assembly, with Lamp |

||

|

|

|

Assembly, with |

|

|

Bracket and Hinge (for |

|

|

|

Bracket and Hinge (for |

|

|

AS 600LBC) |

|

|

|

AS 600LBC) |

[16] 520-01-62 |

Mining Lamp Bracket |

|

[2] |

AS-140-5 |

High Efficiency Filter |

|

|

and Hinge (for AS- |

|

|

|

|

(5/pack) |

|

|

600LBC) |

[2] |

AS-140-25 |

High Efficiency Filter |

[-] |

1455 |

Headgear-Mounted |

|

|

|

|

(25/pack) |

|

|

Ear Muff Kit (NRR 23/ |

[2] AS-176 |

Hydrogen Fluoride |

|

|

CSA Class B) |

||

|

|

|

Cartridge2 (25/pack) |

[-] |

527-01-15R10 |

Faceseal, Tychem® |

[3] AS-120-10 |

Prefilter (10/pack) |

|

|

QC (10/pack) |

||

[4] |

AS-110-2 |

Filter/cartridge holder |

[-] |

AS-101-10 |

Faceseal, Elastomeric |

|

|

|

|

(2/pack) |

|

|

(Small/Medium)1 |

[5] 060-39-01R10 |

Comfort Band (10/pack) |

[-] AS-102-10 |

Faceseal, Elastomeric |

|||

[6] AS-150 |

Cradle Assembly |

|

|

(Medium/Large)1 |

||

[7] 060-38-05R01 |

Headband |

[-] 529-01-09R01 |

Chin Strap |

|||

[8] 060-28-03R01 |

Head Seal |

[-] |

529-01-59R01 |

Clip (for Mining Lamp |

||

[9] 060-19-00R01 |

Prefilter Inner Grill |

|

|

Cord) |

||

[10] 060-20-00R01 |

Prefilter Outer Grill |

[-] |

529-01-56R01 |

Battery Cover, Water |

||

[11] 060-04-03R01 |

Motor Housing Assembly |

|

|

Repellent |

||

[11] AS-115 |

Motor Housing Assembly, |

[-] |

520-03-73 |

Smart Battery Charger, |

||

|

|

|

Ultra (for AS-400LBC and |

|

|

Single Unit |

|

|

|

AS-600LBC) |

[-] |

520-01-61SGL |

Smart Battery Charger, |

[-] 520-01-81 |

Carrying Bag |

|

|

Single Unit (Canada |

||

[-] |

520-01-02R01 |

Battery Pack, Intrinsically |

|

|

only) |

|

|

|

|

Safe (for AS 400LBC and |

[-] |

520-03-72 |

Smart Battery Charger, |

|

|

|

AS 600LBC) |

|

|

5 Unit |

[-] |

520-01-82 |

Clothing Clip and Screw |

[-] |

520-01-61FIV |

Smart Battery Charger, |

|

|

|

|

(for Battery) |

|

|

5 Unit (Canada only) |

[12] 061-37-00R02 |

Pivot and Cams, pair |

[-] |

520-01-61 |

Smart Battery Charger, |

||

[13] 060-49-02R10 |

Temple Seal (10/pack) |

|

|

10 Unit |

||

[14] 522-01-01R10 |

Visor (10/pack) |

[-] |

061-44-01R01 |

Airflow Indicator |

||

[14] |

060-75-02R10 |

Visor, Gray Tinted |

|

|

|

|

|

|

|

(10/pack) |

|

|

|

[14] |

AS-131-10 |

Visor, Antifog, Scratch |

|

|

|

|

|

|

|

Resistant (10/pack) |

|

|

|

Notes:

1The 3M™ Faceseals, AS-101-10 and AS-102-10, are approved for use with 3M™ HeadgearMounted Assemblies AS-400LBC and AS-600LBC equipped with the motor housing assembly AS-115. The faceseals, AS-101-10 and AS-102-10, are NOT approved for use with the 3M™ Battery Pack 520 01 18R01 or the 3M™ Standard Motor Assembly 060-04-03R01.

2The 3M™ Hydrogen Fluoride Cartridge AS-176 is approved for use only with the headgearmounted assembly AS-400LBC equipped with the motor housing assembly AS-115, ultra. The hydrogen fluoride cartridges AS-176 are NOT approved for use with the 3M™ Battery Pack 520-01-18R01 or the 3M™ Standard Motor Assembly 060-04-03R01. The AS-176 is not NIOSH approved for particulates.

Service Life of Chemical Cartridges and Filters

The useful service life of the 3M™ Hydrogen Fluoride Cartridges AS-176 will depend upon the flow rate, the specific type, volatility and concentration of the contaminants and environmental conditions such as humidity and temperature. Replace cartridges in accordance with an established cartridge change schedule or time-use restrictions, whichever occurs first. Cartridges should be changed immediately if smell, taste or irritation from the contaminant is detected. 3M™ High Efficiency Filters AS-140-5 must be replaced immediately if they become damaged, soiled or if required airflow cannot be achieved.

Shelf Life of Chemical Cartridges and Filters

Filters must be stored in their original packaging at normal room temperature in a clean and dry location. If stored in this manner, there is no specific expiration date for the AS-140 filters. Chemical cartridges have a 3-year shelf life starting from the date of manufacture. The expiration or “use before” date is marked on the collar of each cartridge. Do not use cartridges if the date stamp is missing or not legible.

ASSEMBLY

NiCd Battery

Use of the NiCd Battery:

•3M batteries provide up to 500 charge/discharge cycles, however, the life of 3M batteries will be significantly reduced when they are exposed to high heat over an extended period of time.

•Infrequently used battery packs should be fully charged, initially, then recharged periodically to maintain a full charge.

• Allowing a battery to self-discharge during extended storage will not harm the battery pack. Batteries subjected to prolonged storage (longer than 6 months) may lose their capacity to hold a full charge.

• To properly dispose of the battery pack, follow local solid waste disposal regulations or call the RBRC Battery Recycling Information Helpline at 1 800 8 BATTERY (1 800-822-8837).

Charging the NiCd Battery:

•Use 3M™ Smart Chargers (520-03-73 Single Unit, 520-03-72 Five Unit or 520-01-61 Ten Unit.

•A new or completely exhausted battery pack should be charged for 16 to 24 hours.

•To use the smart charger, place the charging station horizontally on a flat surface and plug the station AC power cord into a regulated 120v-60Hz outlet.

ENGLISH

|

|

|

15 |

16 |

|

•The green LED light will turn on.

•Insert the charging lead into the battery pack.

•The LED will turn off, indicating that the battery pack attached is being charged in a high rate mode.

•After approximately eight hours (depending on the amount of charging required) the LED will turn back on, indicating that the charger has switched to a trickle rate mode, preventing damage to the battery from overcharge. For Canadian chargers, when in trickle mode, the LED light will cycle on and off every 3 – 5 seconds.

•To maximize battery life, these guidelines should be followed:

–Charge 3M battery packs before they are completely discharged. Damage may occur if the battery pack is completely discharged (“deep discharged”).

–3M battery packs may be charged any time during the discharge cycle. Voltage depression (AKA, memory) is not a significant factor for 3M PAPR battery packs. Whether it has been used 30 minutes or 8 hours, the battery pack may be charged.

–Always charge batteries at a temperature between 50° and 80°F (10° and 27ºC). At higher temperatures, the battery pack may not accept a full charge. If a battery pack feels hot, let it cool for 1/2 hour before charging.

–Batteries may be left on trickle rate mode to maintain optimum capacity for up to 30 days. Without periodic charging, a NiCd battery in storage loses approximately 1% of its charge each day.

•Do not charge multiple battery packs in an enclosed cabinet without ventilation.

Prefilter

Unclip the outer grill and remove the prefilter. Replace with a clean prefilter. Snap the outer grill into place.

Note: If the outer grill hinge is opened beyond its normal position, it will disengage from the motor housing assembly without damage. Reattach by pressing the hinge tab back into the socket on the back of the headgear shell.

Main Filter/Cartridge and Motor Housing Assembly

The filter/cartridge must be changed immediately when:

–High Efficiency Filter AS-140-5: The filter is damaged or the airflow indicator is not retained in place during an airflow check when running on fully charged battery (see “Operating Instructions” section in these User Instructions);

–Hydrogen Fluoride Cartridge AS-176: The cartridge has exceeded its estimated service life, contaminant odor is detected or the airflow indicator is not retained in place during an airflow check when running on a fully charged battery (see “Operating Instructions” section in these

User Instructions);

–The filter/cartridge has been damaged by outside forces;

–An excessive amount of water has been permitted to enter the filter/cartridge; or

–When applicable regulations or administrative procedures dictate.

WARNING

WARNING

Never attempt to clean filters. Knocking or blowing out accumulated material may result in damage to the filter membrane allowing hazardous particles to enter the breathing zone, resulting in sickness or death.

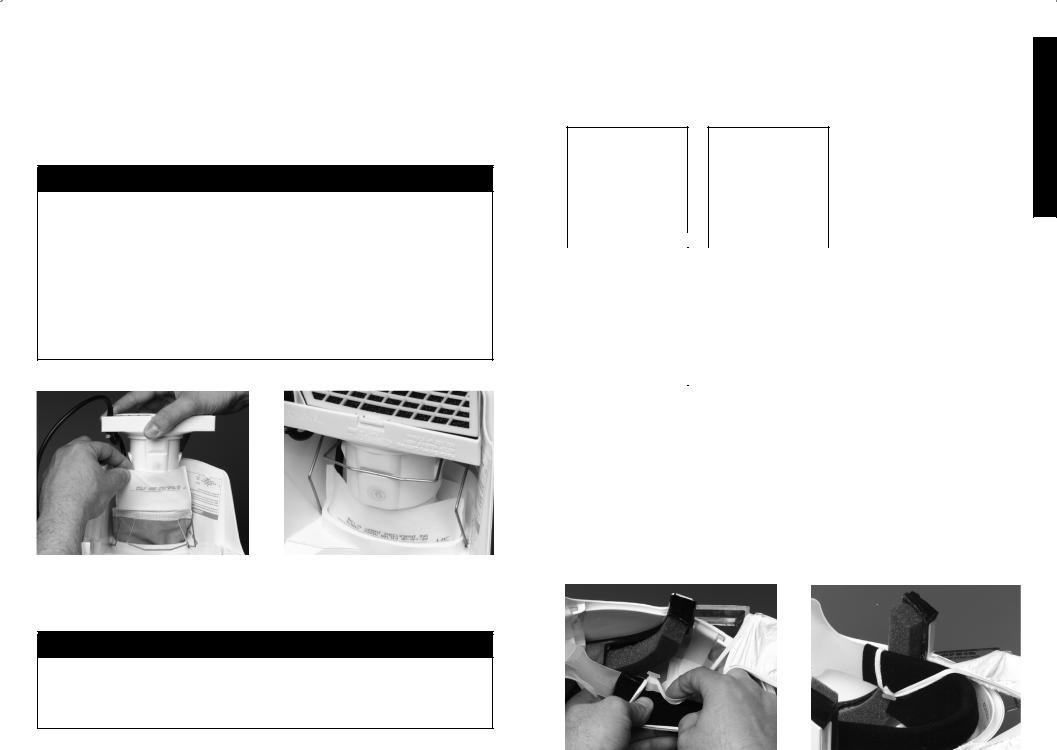

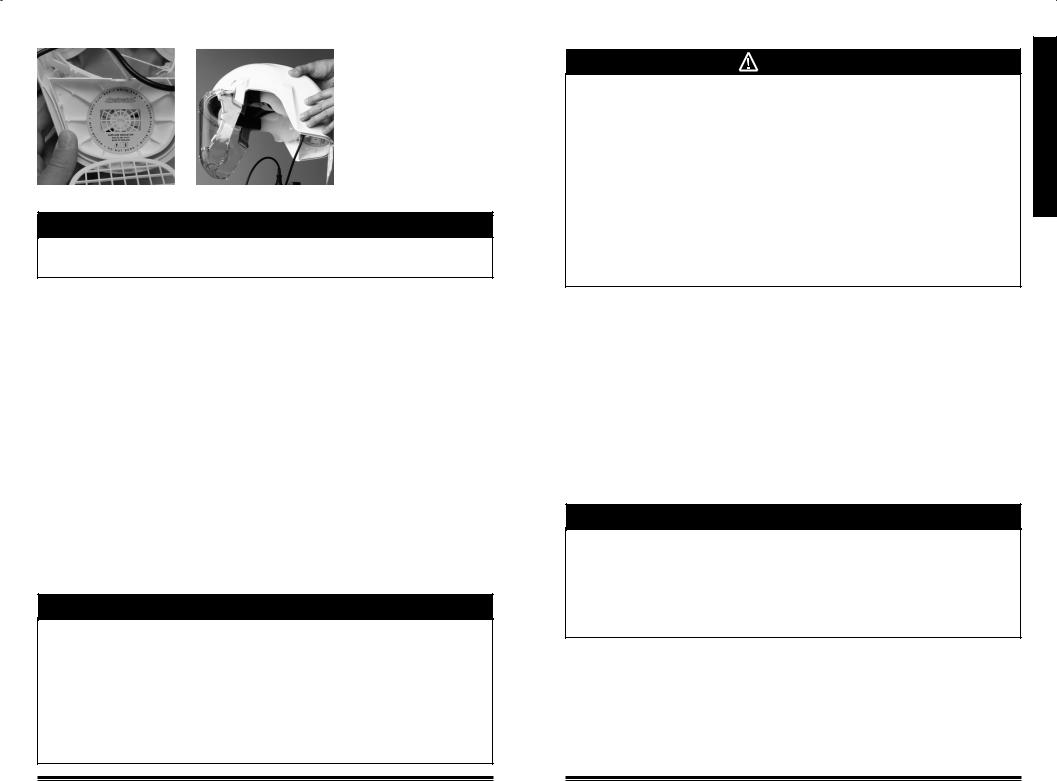

Removal

Disconnect the battery pack. Pull the spring clip towards the center of the headgear to disengage the motor housing assembly. Pull the motor housing assembly out of the headgear shell (Fig. 3).

The head seal and headgear suspension can be removed for easier access if desired. With the filter/ |

ENGLISH |

|

|

cartridge holder still in place, grasp the end of the filter/cartridge at the front end of the headgear and |

|

carefully pull the filter out of the headgear toward the front (Fig. 4). |

|

Remove the filter/cartridge holder and discard the filter/cartridge in accordance with applicable |

|

regulations. Do not clean or reuse filter/cartridges. Avoid inhaling dust from the inside of the used filter. |

|

Remove accumulated dust from the filter/cartridge holder before reuse. |

|

|

|

|

|

|

|

Fig. 3 |

|

|

Fig. 4 |

Replacement

Insert the rounded end of the filter/cartridge holder into the new filter/cartridge. Push the filter/ cartridge holder into the filter/cartridge bag as far as it can go. For HE filters AS-140-5, make sure the writing and dashed line on the collar is on the inside curve of the filter/cartridge holder (Fig. 5).

Slide the closed end of the filter/cartridge into the oval inlet in the back of the headgear.

Work the filter into position by gently pushing on the open end of the filter/cartridge and holder and by pulling on the closed end of the filter from inside the headgear (Fig. 6).

The filter should be inserted until the filter sleeve is approximately two inches above the rim of the oval inlet.

|

|

|

|

|

|

|

Fig. 5 |

|

|

Fig. 6 |

|

|

|

|

|

|

|

|

|

|

17 |

18 |

|

Insert the oval end of the motor housing into the opening of the filter/cartridge sleeve. As you pull the end of the filter/cartridge forward from the inside, seat the motor housing in the oval inlet. For HE

filters AS-140-5, ensure that the dashed line remains exposed just above the rim of the oval inlet (but not more than 1/8 in [3.2 mm] above) after the motor housing is in place. For HF cartridges AS-176, approximately 1/2 in [12.7 mm] of the sleeve should remain above the rim of the oval inlet. Also ensure that the location lug on the motor housing engages with the slot in the back of the headgear. Engage the spring clip to retain the motor housing (Fig. 7 and 8).

WARNING

WARNING

Use of excessive force during the insertion of the filter/cartridge may damage the filter/cartridge and/or the filter/cartridge holder. Do not attempt to repair or use damaged filter/cartridges. If damage is suspected, remove and start over with new components as necessary. Failure to do so may adversely affect respirator performance and may result in sickness or death.

A user inspection and performance check must be performed prior to each use to verify that the filter and blower assemblies have been correctly installed. If the respirator fails any of the

requirements of the user inspection and performance check, refer to the “Troubleshooting” section in these User Instructions. Do not use the respirator until all necessary repairs have been made and the respirator passes the performance check. Failure to do so may adversely affect respirator performance and result in sickness or death.

|

|

|

|

|

|

Fig. 7 |

|

|

Fig. 8 |

Faceseal 527-01-15R10, with Tychem® QC Fabric

Note: If using the elastomeric faceseals AS-101-10 or AS-102-10, refer to installation and fitting instructions provided with the faceseals.

WARNING

WARNING

The faceseal must be changed if it becomes torn, worn excessively or the elastic is stretched-out. Exposure to solvents and/or ultraviolet light may accelerate the degradation of the elastic. This could result in exposure to airborne contaminants and could result in sickness or death.

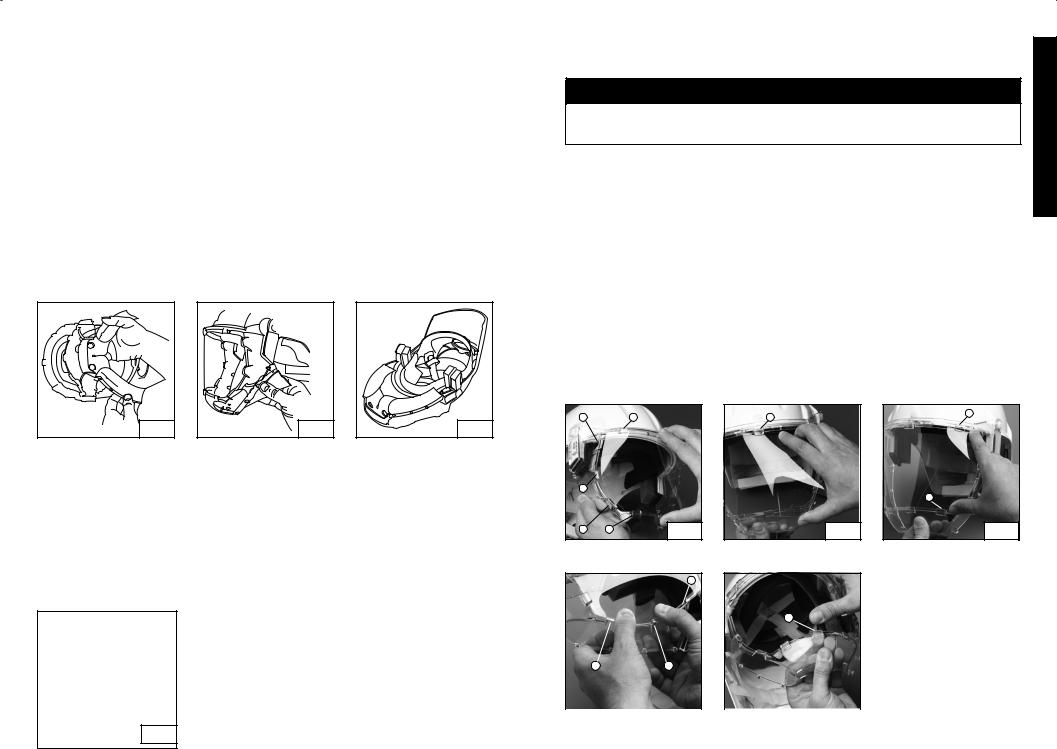

Removal |

|

Raise the visor surround to the horizontal position. Hold the headband away from the temple seals, and |

|

unhook and pull the elastic loops from the headband. Remove the faceseal from each of the studs, and |

|

unhook the center elastic loop from the lug on the front of the visor surround (Fig. 9 - 12). |

ENGLISH |

|

|

Fig. 9 |

|

|

Fig. 10 |

|

|

|

|

|

|

Fig. 11 |

|

|

Fig. 12 |

|

|

|

|

|

Replacement

Attach the Tychem® QC faceseal to the visor surround as follows: hook the center elastic loop over the lug at the front center of the visor surround. Fit each of the holes along the edge of the faceseal over each of the studs on the visor surround.

Attach the faceseal to the headband as follows: turn the headgear assembly upside down, with the visor facing away from you. Pull one of the larger loops on the faceseal down over the inside of the headband and secure it over the headband lug. Push the part of the loop closest to you down between the headband and the edge of the headgear assembly, securing it over the same headband lug. Repeat for the other loop (Fig. 13 and 14).

|

|

|

|

|

|

Fig. 13 |

|

|

Fig. 14 |

|

|

|

19 |

20 |

|

Faceseal AS-101-10 and 102-10, Elastomeric:

The hook & loop fastener pieces should be joined and the protective backing film removed prior to installation.

Wipe the inside of the visor surround with a mild cleaning solution as necessary to remove all dirt and oil residue. When replacing an existing elastomeric faceseal, remove and discard the existing hook & loop section from the visor surround. Place the exposed adhesive section on the inside of the flat surface at the bottom of the visor surround (Fig. 15). Press the studs on the visor surround through the corresponding holes in the faceseal (Fig. 16). Complete assembly and User Performance Check as described in these User Instructions prior to use.

After donning, lower the visor until it snaps into place. The closing action should cause the faceseal flaps to fold forward toward the users face. Do not pull the flaps out so they are folded outward towards the neck and ears. Check for gaps between the rubber flaps and the face. If gaps are present when using the AS-102-10 Medium/Large faceseal, switch to the AS-101-10 Small/Medium faceseal. If gaps are present with the AS-101, do not use and select an alternative respirator system.

Fig. 15 |

Fig. 16 |

Fig. 17 |

Visor Surround

Removal

Remove the faceseal as described above. Using a coin, rotate the quick-release visor pivots a quarter turn in either direction to unlock the visor surround as shown (Fig. 18). Ease one side from the headgear, releasing the pivot. Repeat this for the other side.

Replacement

Hold the visor surround in the raised position on the headgear. Press the pivots in and rotate them a quarter turn in either direction using a coin. Ensure that the visor surround locks in the lowered position.

Visor

WARNING

WARNING

Incorrect fitting of the visor will reduce face, eye and respiratory protection, and may result in sickness or death.

Removal

Grip the upper edge of the visor surround at the center in one hand and the lower edge in the other hand. Spread the edges apart and pop the visor from the center lugs of the visor surround. Gently push the visor outward from the remaining lugs until it is completely released from the visor surround.

Replacement

Remove the protective covering from the new visor. With the longest edge toward the top of the visor surround, slide the visor through lugs 1 and 2 as shown (Fig. 19). Continue sliding the visor so that it rests in the three side lugs (3, 4 and 5) on the same side of the visor surround. Flex the visor downward and insert under the upper, center lug (6) as shown (Fig. 20). Do not insert the visor under

the lower, center lug (12) yet. Flex the visor by pinching from top to bottom and insert under lugs 7 and 8 as shown (Fig. 21). Push the visor under lugs 9, 10 and 11 one at a time with your thumb as shown (Fig. 22). Grip the lower edge of the visor surround at the center and twist downward until the visor can be inserted under the lower, center lug (12) as shown (Fig. 23). Check that the visor is secured in all 12 positions and there are no gaps at the visor periphery.

3 |

1 |

6 |

7 |

|

4

8

5 |

2 |

Fig. 19 |

Fig. 20 |

Fig. 21 |

9

12

11 |

10 |

|

Fig. 22 |

|

|

Fig. 23 |

|

|

|

|

|

ENGLISH

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

22 |

|||

Comfort Band

Removal

Remove the faceseal as described above. Peel the hook and loop fasteners at each end of the comfort band and unfold the comfort band from the headband.

Replacement

Wrap the comfort band (with the slits opening down) around the front of the headband. Refasten the hook and loop tabs so they are on the outside of the headband.

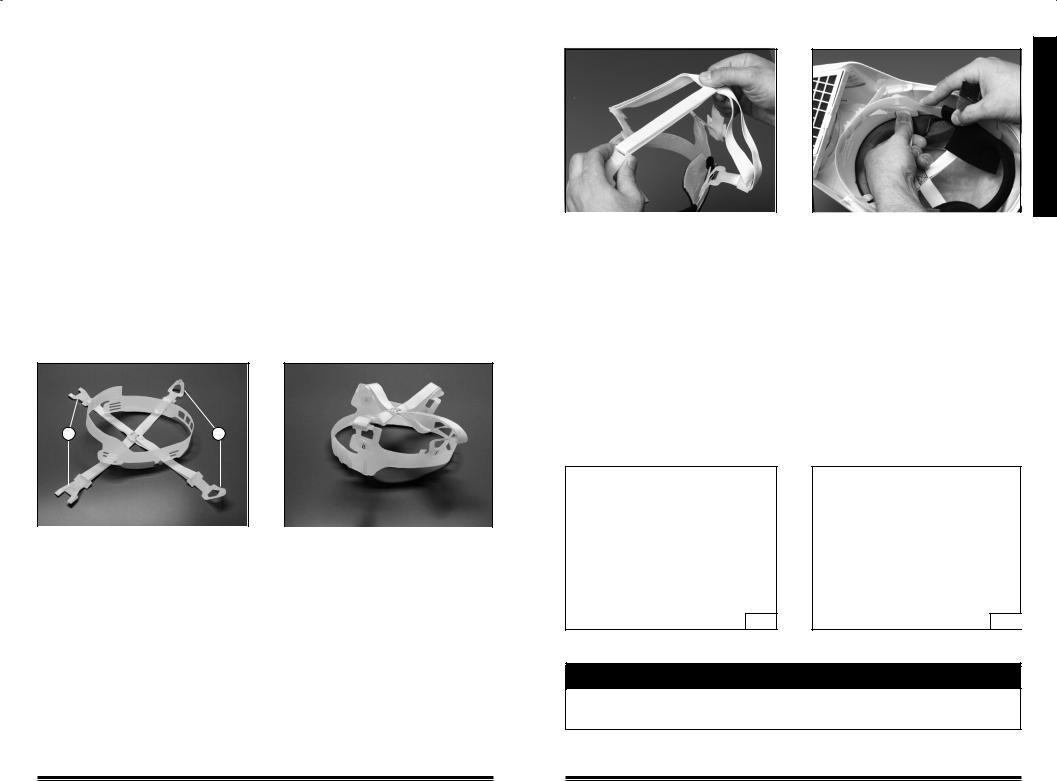

Headband and Cradle Assembly

Removal

Pull each of the four retaining anchors on the cradle assembly upward from its slot in the headgear. Unbutton the headband at the four slots attaching it to the cradle assembly.

Replacement

Lay the cradle assembly upside down on the work surface noting the orientation as determined by the letters molded on the cradle retaining buttons (F = Front, B = Back). Place the headband on top of the cradle assembly in the same orientation. The size-adjustment buckle belongs in the back. (Fig.24) Insert the four buttons into the appropriate height adjustment slot from the inside so that the head of the button ends up on the outside of the headband (Fig. 25).

B |

F |

|

Fig. 24 |

|

|

|

Fig. 25 |

Ensure that all anchors are firmly in place, that the cradle assembly straps are not twisted and are of equal length (Fig. 26).

Push each of the four retaining anchors on the cradle assembly into its corresponding slot in the headgear (Fig. 27).

23

ENGLISH

|

Fig. 26 |

|

|

Fig. 27 |

Adjusting the Headband

The adjustable headband and cradle assembly help afford maximum comfort around the head and maintain the proper balance in all directions. Adjust the headband and cradle assembly for head size and proper fit of the faceseal(s) as follows:

–Squeeze both edges of the buckle to open the headband (Fig.28).

–With the headgear assembly on your head, pull the free end of the headband through the buckle until it fits firmly and comfortably.

–Adjust the orientation of the headgear so that there is clearance between the chin and the air vents in the faceseal.

–After adjusting the orientation of the headgear, check the position of the headband around the head.

If the position of the headband does not feel comfortable and secure, the front and rear height can be adjusted independently by relocating the buttons in the slots that connect the cradle assembly to the headband. Adjusting the headband position does not affect the height that the headgear rests above the head. The cradle suspension is not adjustable (Fig.29).

WARNING

WARNING

Incorrect fitting of the headband/cradle assembly may reduce head protection provided by the headgear, possibly rendering it totally ineffective, resulting in serious injury or death.

24

Head Seal

Removal

Remove the cradle assembly as described above. The head seal is retained by three anchors, one at each side and one in the center of the headgear. Lift the side lugs up from their headgear shell anchors and remove the central lug from its aperture (Fig. 30).

Fig. 30

Insert the central lug into its aperture in the headgear shell. Slide both side lugs into their respective headgear anchor positions. Ensure all three anchor points are properly connected so the head seal remains in contact with the headgear.

Temple Seals

Removal

Remove the head seal as described above. Pull the temple seals away from the head seal. If necessary, clean to remove any foam residue adhering to the head seal.

Replacement

Remove the protective covering from the self-adhesive side of the temple seals and press the seals firmly against the head seal. Note that the temple seals have left and right orientations. Ensure they are positioned properly against the head seal.

INSPECTION

An inspection must always be performed prior to each use of the respirator as follows:

1.Look for dents, scratches, cuts, or discoloration in the headgear shell and other components;

2.Check that the visor is properly installed in the visor surround, secured at all 12 lug positions;

3.Check that the faceseal is properly fitted onto the visor surround;

4.Check that the temple seals and head-seal are properly installed and in good condition;

5.Check that the high efficiency filter is correctly installed;

6.Use a freshly charged battery.

25

|

|

|

WARNING |

|

|

Impact to the headgear may weaken the shell and/or suspension system and reduce head |

|

|

protection from subsequent impact, even if there is no visible damage. If the headgear shell has |

|

ENGLISH |

been subject to impact or if other damage to the headgear is suspected, the headgear shell and |

|

|

|

|

|

suspension system must be replaced. Failure to do so may result in serious injury or death. |

|

|

Failure to conduct an inspection and complete all necessary repairs before use may adversely |

|

|

affect respirator performance and result in sickness or death. |

|

|

|

|

|

USER PERFORMANCE CHECK |

|

|

|

||

Each time the respirator is put on, perform the following user performance check to ensure proper |

|

|

airflow. If any components are missing or damaged, replace them prior to using the system. |

|

|

1.Open the outer grill (Fig. 31), remove prefilter (Fig. 32) and inner grill (Fig. 33). Switch the battery pack on and ensure that the fan draws air through the main filter.

2.Holding the headgear upside down, place the airflow indicator over the round fan grill (Fig 34).

Ensure that the airflow indicator is not bent or damaged.

|

|

|

|

|

|

|

|

|

Fig. 31 |

|

|

Fig. 32 |

|

|

Fig. 33 |

|

|

|

|

|

|

|

|

3.Gently turn the headgear right-side up (Fig. 35). Sufficient airflow will retain the indicator in position. If the airflow will not retain the indicator, replace the main filter/cartridge as described in “Assembly” section. If an adequate airflow is still not maintained, refer to “Troubleshooting” section in these User Instructions and do not use the unit.

4.Place the inner grill and the prefilter back into the motor housing and close the outer grill. Ensure that the outer grill hinge is positioned in the recess at the rear of the motor housing assembly (Fig. 36).

26

|

|

|

|

|

|

|

|

|

Fig. 34 |

|

|

Fig. 35 |

|

|

Fig. 36 |

|

|

|

|

|

|

|

|

WARNING

WARNING

Failure to pass a user performance check and complete all necessary repairs before use may adversely affect respirator performance and result in sickness or death.

DONNING

1.Complete assembly, inspection and user performance check of the PAPR assembly as described in these User Instructions.

2.Insert the male plug into a fully-charged battery pack and attach the battery pack to the belt using the belt clip.

3.Turn the battery pack switch to the ON position.

4.Fit the headgear onto your head and pull the visor down until it snaps in the down position. If necessary, adjust headband as described under Assembly.

5.Pull the Tychem® face seal as far as possible under the chin. If using the elastomeric AS-101-10 or AS-102-10 faceseals, refer to installation and fitting instructions provided with the faceseals.

IMPORTANT:

Air purification is provided only when clean pre and main filter/cartridges are correctly fitted, the spring clip retaining the motor housing is in place, and air is flowing over the face.

OPERATING INSTRUCTIONS

WARNING

WARNING

Use of this respirator in atmospheres for which it was not NIOSH certified and designed may result in sickness or death. Do not wear this respirator where:

-Atmospheres contain hazardous vapors or gases other than hydrogen fluoride.

-Atmospheres are oxygen deficient.

-Contaminant concentrations are unknown.

-Contaminant concentrations are Immediately Dangerous to Life or Health (IDLH).

-Contaminant concentrations that exceed 25 times the applicable exposure limit (the assigned protection factor, APF, for this respirator system) or the APF mandated by specific government standards, whichever is lower.

27

WARNING |

|

|

Do not enter a contaminated area until properly donning the respirator system. Do not remove the |

|

|

respirator before leaving the contaminated area. Doing so may result in sickness or death. |

ENGLISH |

|

Contaminants that are dangerous to your health include those that you may not be able to see or |

||

|

||

smell. Leave the contaminated area immediately if any of the following conditions occur. Failure to |

|

|

do so may result in sickness or death. |

|

–Any part of the system becomes damaged.

–Airflow into the respirator decreases or stops.

–Breathing becomes difficult.

–You feel dizzy or your vision is impaired.

–You taste or smell contaminants.

–Your face, eyes, nose or mouth become(s) irritated.

–You suspect that the concentration of contaminants may have reached levels at which this respirator system may no longer provide adequate protection.

After successfully completing the inspection, user performance check and donning procedures, enter the contaminated area, breathing normally. Remove the respirator system in a clean area only.

Note: The PAPR blower unit and battery are not waterproof. They should not be submersed or subjected to heavy spraying with water or other liquids. If moisture is present, the battery pack must be placed in a water repellent battery cover 529-01-56R01 or in a waterproof plastic bag prior to use to avoid corrosion, deterioration, and possible battery failure.

CLEANING AND STORAGE

Follow the hygiene practices established by your employer for the specific contaminants to which you have been exposed.

WARNING

WARNING

Do not clean respirator with solvents. Cleaning with solvents may degrade some respirator components and reduce respirator effectiveness. Inspect all respirator components before each use to ensure proper operating conditions. Failure to do so may result in sickness or death.

Never attempt to clean filters by knocking or blowing out accumulated material. This may result in damage to the filter membrane allowing hazardous particles to enter the breathing zone, resulting in sickness or death.

28

Cleaning the Headgear Assembly

Use a soft cloth to remove dirt and grime. If the headgear requires further cleaning, remove the motor housing assembly, the head harness assembly, the head seal assembly, the visor assembly, the main filter, and the expander. Only the headgear shell may be immersed in a mild solution of soap and water. Rinse the visor assembly with clean running water to remove dirt and shake off the excess water. Handle the visor carefully to avoid unnecessary scratching. Allow all components to dry thoroughly before reassembling.

Cleaning the Head Harness Assembly (Headband, Comfort Band, Cradle Assembly) and Head Seal Assembly (Head Seal, Temple Seal)

Wipe with a cloth dampened with a solution of mild soap and water. Wipe off excess water and allow to dry prior to reinstallation.

Cleaning the Motor Housing Assembly

In some environments, dust may gradually accumulate within the motor housing, which could reduce the efficiency of the motor unit. The accumulated dust can be removed by first removing the prefilter from its compartment and then using a vacuum cleaner to clean the prefilter side of the motor housing. Do not use a vacuum or compressed air to force air directly through the motor/fan assembly. This may cause the motor to spin too fast and damage the motor’s bearings.

After cleaning the system, inspect all parts for damage and wear, replacing parts if necessary. Allow the components to dry completely, away from sunlight and direct heat. Store the system in a clean area, away from moisture, heat, and direct sunlight. Storage temperatures must not exceed 120°F (49ºC).

Storage

Store your respirator at room temperature in a dry area that is protected from exposure to hazardous contaminants.

TROUBLESHOOTING

Leave contaminated area immediately and follow these corrective action recommendations. Use the table below to help identify possible causes.

Problem |

Possible Cause |

Corrective Action |

|

|

|

|

Faceshield is scratched. |

Remove cover and replace. |

|

Faceshield is coated with debris. |

Wipe debris off. |

|

|

Replace visor. |

Poor visibility |

|

Consider using faceshield covers. |

through faceshield |

|

|

|

Faceshield is fogging. |

Check airflow. |

|

|

Install a new anti-fog visor AS-131. |

|

|

Switch to motor housing assembly, |

|

|

ultra AS-115 (AS-400 and AS-600 only). |

|

|

|

|

Battery discharged or worn out. |

Charge, service or replace. |

|

Filter and/or prefilter is clogged. |

Replace filter with new filter. |

|

Filter/cartridge holder is damaged, |

Remove and re-install as directed. |

|

installed incorrectly, backwards or |

Replace if neccessary. |

Poor airflow |

not installed. |

|

|

Incorrect filter/cartridge holder |

Use new holder for HE filter. |

|

installed. |

|

|

Filter sleeve out of position or inside |

Remove blower housing and re-install |

|

motor housing. |

as directed. |

|

|

|

|

Damaged or worn faceseal. |

Replace Faceseal. |

Faceseal not fitting |

|

|

tightly against face |

Cradle assembly not adjusted |

Adjust as directed. |

|

properly. |

|

|

|

|

|

Filter sleeve out of position or inside |

Remove blower housing and re-install |

|

motor housing. |

as directed. |

Dust getting inside |

|

|

visor |

Filter torn during installation. |

Replace with new filter. |

|

Filter not installed. |

Install filter as directed. |

|

|

|

ENGLISH

|

|

|

29 |

30 |

|

IMPORTANT NOTICE

WARRANTY: In the event any 3M OH&ESD product is found to be defective in material, workmanship, or not in conformation with any express warranty for a specific purpose, 3M's only obligation and your exclusive remedy shall be, at 3M’s option, to repair, replace or refund the purchase price of such parts or products upon timely notification thereof and substantiation that the product has been stored, maintained and used in accordance with 3M's written instructions.

EXCLUSIONS TO WARRANTY: THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER WARRANTY OF QUALITY, EXCEPT OF TITLE AND AGAINST PATENT INFRINGEMENT.

LIMITATION OF LIABILITY: Except as provided above, 3M shall not be liable or responsible for any loss or damage, whether direct, indirect, incidental, special or consequential, arising out of sale, use or misuse of 3M OH&ESD products, or the user’s inability to use such products. THE REMEDIES SET FORTH HEREIN ARE EXCLUSIVE.

FOR MORE INFORMATION

In United States, contact: Website: www.3M.com/OccSafety

Technical Assistance: 1-800-243-4630

For other 3M products:

1-800-3M-HELPS or 1-651-737-6501

TABLE DES MATIÈRES |

|

DIRECTIVES DE SÉCURITÉ D’ORDRE GÉNÉRAL................................................................................. |

33 |

– Usage prévu................................................................................................................................. |

33 |

– Description d'ordre général.......................................................................................................... |

33 |

– Utiliser pour................................................................................................................................. |

33 |

– Ne pas utiliser.............................................................................................................................. |

33 |

– Sélection du respirateur et formation .......................................................................................... |

34 |

– Homologation du NIOSH............................................................................................................... |

40 |

– Avertissements et restrictions du NIOSH....................................................................................... |

40 |

– Protection oculaire et faciale........................................................................................................ |

40 |

– Facteur de protection caractéristique........................................................................................... |

40 |

SPÉCIFICATIONS.............................................................................................................................. |

41 |

SYSTÈMES, PIÈCES DE RECHANGE ET ACCESSOIRES....................................................................... |

42 |

– Respirateurs d’épuration d’air propulsé pour pièce faciale Airstream™ 3M™ ............................. |

42 |

– Pièces de rechange et accessoires 3M™..................................................................................... |

43 |

– Durée utile des cartouches contre les produits chimiques et des filtres ....................................... |

44 |

– Durée de conservation des cartouches contre les produits chimiques et des filtres ..................... |

44 |

MONTAGE........................................................................................................................................ |

44 |

– Pile au nickel-cadmium................................................................................................................ |

44 |

– Préfiltre........................................................................................................................................ |

45 |