York SHP48, AHP18, 60 User Manual

255029-YTG-J-1007

TECHNICAL GUIDE

SINGLE PIECE AIR HANDLERS

FOR USE WITH SPLIT-SYSTEM COOLING & HEAT PUMPS

MODELS: AHP18 THRU 60 AND SHP48 THRU 60

ISO 9001

Certified Quality

Management System

Due to continuous product improvement, specifications are subject to change without notice.

Visit us on the web at www.york.com

Additional rating information can be found at www.ari.org/aridirectory.

DESCRIPTION

This fan coil line offers the ultimate in application flexibility. The AHP (non-variable speed motor) models can be ordered upflow only or as multi-position. The multi-position model can be installed in downflow, upflow, horizontal right or left without the need for additional field installed kits.

The SHP 48 & 60 models are upflow only models designed into a shorter cabinet than the AHP version, for those special applications where reduced height is required.

All UPG air handlers and coils utilize a TXV to provide our customers with the optimum performance and refrigerant control required for 13+ systems. Air handlers can be ordered with a R22 TXV factory installed that can be easily converted to R410A by changing the bolt-on TXV. Air handlers are also available with “Flex-coils” without a factory installed metering device. For added flexibility, an R22 or R410A TXV can be field installed to meet your refrigerant choice.

FEATURES

Thermal Expansion Valve - Provides the ultimate refrigerant control required for today’s high efficient product. The UPG bolt-on TXV provides the added flexibility to convert the air handler to the required refrigerant. The UPG TXV is a true bolt-on which does not require brazing to replace or install.

MicroBlueTM Coated Fins - All air handler coils are treated with the MicroBlueTM hydrophilic coating to enhance the removal of condensate during the refrigeration cycle and reduce the possibility of water blow-off. The MicroBlueTM coating also reduces the growth of germ causing microbes for a healthier home environment.

Insulated Cabinet - All air handler cabinets are thermally insulated with 1” foil faced insulation (R-4.2) to prevent sweating. For applications in extreme humidity conditions an optional, field installed, external insulating wrap kit is also available.

Durable Finish Inside and Out - Air handler casings are made of pre-painted galvanized steel which provides a better paint to steel bond that resists corrosion and rust creep. All internal coil sheet metal parts are made of G90 pre-painted steel (i.e. triangular plates, top plates, horizontal supports etc). Coil header plates are not painted due to the brazing process during production. The coil header plates are treated after the brazing process with a corrosion resistant spray to reduce the probability of rust.

High Efficiency - 5 ton unit has high efficiency DC motor.

New 4 HK Heat Kit - Installation friendly, easy service, more robust, unique to new design.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

255029-YTG-J-1007

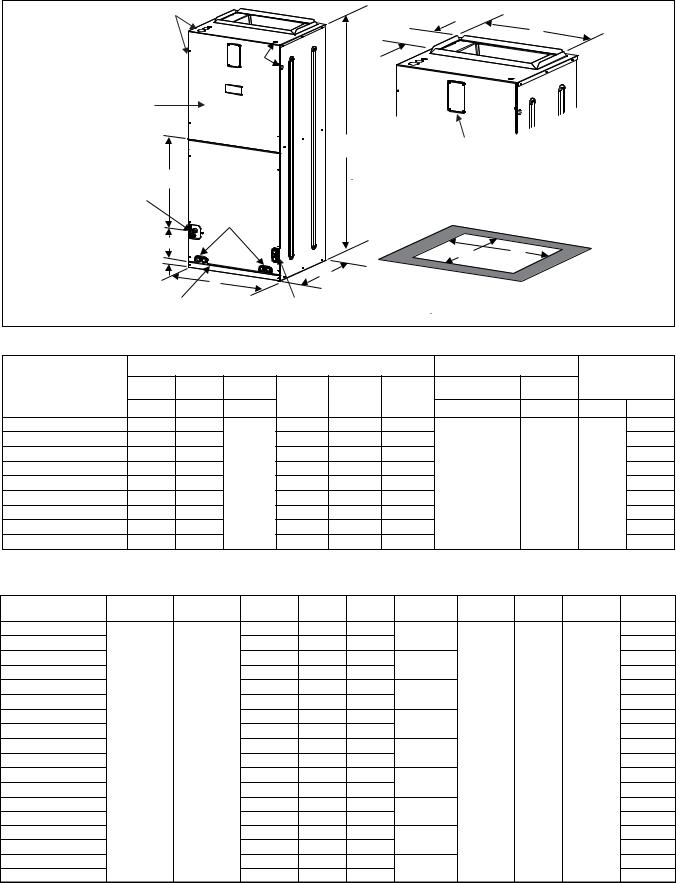

DIMENSIONS

|

J |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10-3/8” |

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K |

|

|

|

|

|

|

|

|

|

|

|

|

BLOWER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COMPARTMENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOP OUTLET |

|

||

|

|

|

|

|

|

|

A |

CIRCUIT BREAKER |

|

DIMENSIONS |

|

|||

|

|

|

|

|

|

|

|

PANEL |

|

|

|

|

|

|

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

REFRIGERANT |

DRAIN CONNECTIONS |

|

|

|

|

|

|

|

|

|

|

|

||

FOR UPFLOW AND |

|

|

|

|

|

|

|

|

|

|

|

|||

CONNECTIONS |

|

|

|

|

|

|

|

|

|

|

|

|||

DOWNFLOW |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

APPLICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

7-11/32” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18-9/32” |

E |

|

|

|

|

|

1-1/2” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

BOTTOM INLET |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

FILTER |

|

|

|

|

|

|

|

|

DIMENSIONS |

|

|||

|

ACCESS |

DRAIN PAN CONNECTIONS |

|

|

|

|

|

|

|

|||||

|

|

|

FOR HORIZONTAL APPLICATIONS |

|

|

|

|

|

|

|||||

DIMENSIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

|

|

|

Wiring Knockouts1 |

|

Refrigerant |

|||||

Models |

A |

B |

C |

|

|

|

|

|

J |

|

K |

|

Connections |

|

|

D |

|

E |

F |

|

|

Line Size |

|||||||

|

Height |

Width |

Depth |

|

|

Power |

|

Control |

|

Liquid |

Vapor |

|||

|

|

|

|

|

|

|

|

|||||||

AHP18B**(N,H)21 |

46 |

17.5 |

|

12-3/8 13-29/32 |

14-19/32 |

|

|

|

|

|

3/4” |

|||

AHP24B**(N,H)21 |

46 |

17.5 |

|

12-3/8 13-29/32 |

14-19/32 |

|

|

|

|

|

3/4” |

|||

AHP30B**(N,H)21 |

46 |

17.5 |

|

12-3/8 13-29/32 |

14-19/32 |

|

|

|

|

|

3/4” |

|||

AHP36C**(N,H)21 |

52 |

21 |

21.5 |

17-1/8 17-13/32 |

18-3/32 |

7/8” (1/2”) |

|

|

|

|

7/8” |

|||

AHP42C**(N,H)21 |

52 |

21 |

17-1/8 |

17-13/32 |

18-3/32 |

1 3/8” (1”) |

|

7/8” (1/2”) |

3/8” |

7/8” |

||||

AHP48D**(N,H)21 |

57 |

24.5 |

|

22-1/8 20-29/32 |

21-19/32 1 23/32” (1 1/4”) |

|

|

|

7/8” |

|||||

SHP48D**N21 |

52 |

24.5 |

|

17-1/8 20-29/32 |

21-19/32 |

|

|

|

|

|

7/8 |

|||

AHP60D**(N,H)21 |

57 |

24.5 |

|

22-1/8 20-29/32 |

21-19/32 |

|

|

|

|

|

7/8’ |

|||

SHP60D**N21 |

52 |

24.5 |

|

17-1/8 |

20-29/32 |

21-19/32 |

|

|

|

|

|

7/8 |

||

1. Actual size (Conduit size). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

COIL TECHNICAL DATA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Models |

Application |

Refrig. |

Face Area |

Rows |

Fin |

Coil Size |

Tube |

|

Tube |

|

Fin |

TXV |

||

Conn. Types (Sq. Ft.) |

Deep |

Per In. |

Geometry |

|

Dia. |

|

Type |

|||||||

AHP18B3X(N,H)21 |

|

|

3.40 |

|

|

2 |

14 |

(2) 14 x 17.5 |

|

|

|

|

|

None |

AHP18B2A(N,H)21 |

|

|

3.40 |

|

|

2 |

14 |

|

|

|

|

|

2A |

|

|

|

|

|

|

|

|

|

|

|

|||||

AHP24B3X(N,H)21 |

|

|

3.89 |

|

|

2 |

14 |

(2) 16 x 17.5 |

|

|

|

|

|

None |

AHP24B2A(N,H)21 |

|

|

3.89 |

|

|

2 |

14 |

|

|

|

|

|

2A |

|

|

|

|

|

|

|

|

|

|

|

|||||

AHP30B3X(N,H)21 |

|

|

3.89 |

|

|

3 |

12 |

(2) 16 x 17.5 |

|

|

|

|

|

None |

AHP30B2A(N,H)21 |

|

|

3.89 |

|

|

3 |

12 |

|

|

|

|

|

2A |

|

|

|

|

|

|

|

|

|

|

|

|||||

AHP36C3X(N,H)21 |

|

|

4.86 |

|

|

3 |

12 |

(2) 20 x 17.5 |

|

|

|

|

|

None |

AHP36C2A(N,H)21 |

|

|

4.86 |

|

|

3 |

12 |

|

|

|

|

|

2A |

|

|

|

|

|

|

|

|

|

|

|

|||||

AHP42C3X(N,H)21 |

Cooling / |

Sweat |

4.86 |

|

|

3 |

12 |

(2) 20 x 17.5 |

1 x 0.866 |

|

3/8 |

Enhanced |

None |

|

AHP42C2C(N,H)21 |

Heat Pump |

4.86 |

|

|

3 |

12 |

|

2C |

||||||

|

|

|

|

|

|

|

|

|

||||||

AHP48D3X(N,H)21 |

|

|

5.83 |

|

|

3 |

11 |

(2) 24 x 17.5 |

|

|

|

|

|

None |

AHP48D2C(N,H)21 |

|

|

5.83 |

|

|

3 |

11 |

|

|

|

|

|

2C |

|

|

|

|

|

|

|

|

|

|

|

|||||

SHP48D3XN21 |

|

|

5.83 |

|

|

3 |

11 |

(2) 24 x 17.5 |

|

|

|

|

|

None |

SHP48D2CN21 |

|

|

5.83 |

|

|

3 |

11 |

|

|

|

|

|

2C |

|

|

|

|

|

|

|

|

|

|

|

|||||

AHP60D3X(N,H)21 |

|

|

5.83 |

|

|

3 |

11 |

(2) 24 x 17.5 |

|

|

|

|

|

None |

AHP60D2C(N,H)21 |

|

|

5.83 |

|

|

3 |

11 |

|

|

|

|

|

2C |

|

|

|

|

|

|

|

|

|

|

|

|||||

SHP60D3XN21 |

|

|

5.83 |

|

|

3 |

11 |

(2) 24 x 17.5 |

|

|

|

|

|

None |

SHP60D2CN21 |

|

|

5.83 |

|

|

3 |

11 |

|

|

|

|

|

2C |

|

|

|

|

|

|

|

|

|

|

|

|||||

Note: H models are available with a factory installed horizontal drain pan.

2 |

Unitary Products Group |

255029-YTG-J-1007

COOLING CAPACITY

Models |

Rated CFM |

Entering Air °F |

MBH@ Evaporator Temperature and Corresponding Pressure °F / PSIG |

||||

(Dry / Wet Bulb) |

35 / 61.5 |

40 / 68.5 |

45 / 76.0 |

50 / 84.0 |

|||

|

|

||||||

|

|

FULL-CASED “A” TYPE MULTI-POSITION |

|

|

|||

|

|

85/72 |

24.5 |

22.3 |

19.9 |

17.3 |

|

AHP18B2A(N,H)21 |

650 |

80/67 |

22.6 |

20.3 |

18.0 |

15.6 |

|

75/62 |

18.5 |

16.4 |

14.2 |

12.0 |

|||

|

|

||||||

|

|

70/57 |

15.0 |

13.1 |

10.9 |

8.5 |

|

|

|

85/72 |

35.0 |

31.8 |

28.4 |

24.7 |

|

AHP24B2A(N,H)21 |

800 |

80/67 |

32.2 |

29.1 |

25.7 |

22.3 |

|

75/62 |

26.4 |

23.4 |

21.0 |

17.1 |

|||

|

|

||||||

|

|

70/57 |

21.4 |

18.6 |

20.2 |

12.1 |

|

|

|

85/72 |

41.5 |

37.8 |

33.7 |

29.5 |

|

AHP30B2A(N,H)21 |

1050 |

80/67 |

36.2 |

32.4 |

28.6 |

24.5 |

|

75/62 |

29.1 |

25.3 |

24.0 |

19.2 |

|||

|

|

||||||

|

|

70/57 |

24.1 |

21.5 |

18.7 |

15.8 |

|

|

|

85/72 |

51.3 |

46.7 |

41.7 |

36.8 |

|

AHP36C2A(N,H)21 |

1200 |

80/67 |

41.1 |

36.3 |

31.8 |

27.1 |

|

75/62 |

32.1 |

27.0 |

29.4 |

21.9 |

|||

|

|

||||||

|

|

70/57 |

27.6 |

25.4 |

23.5 |

18.3 |

|

|

|

85/72 |

88.4 |

76.0 |

63.3 |

50.0 |

|

AHP42C2C(N,H)21 |

1400 |

80/67 |

70.8 |

59.4 |

48.4 |

37.0 |

|

75/62 |

55.2 |

43.9 |

35.8 |

29.9 |

|||

|

|

||||||

|

|

70/57 |

47.4 |

41.5 |

32.37 |

25.24 |

|

|

|

85/72 |

100.5 |

86.4 |

72.0 |

56.8 |

|

AHP48D2C(N,H)21 |

1600 |

80/67 |

80.4 |

67.5 |

55.0 |

42.1 |

|

SHP48D2CN21 |

|

|

|

|

|

||

75/62 |

62.7 |

49.9 |

40.7 |

34.0 |

|||

|

|||||||

|

|

70/57 |

53.9 |

47.2 |

36.81 |

28.71 |

|

|

|

85/72 |

119.9 |

101.0 |

82.0 |

62.2 |

|

AHP60D2C(N,H)21 |

1850 |

80/67 |

96.0 |

79.2 |

62.6 |

45.8 |

|

SHP60D2CN21 |

|

|

|

|

|

||

75/62 |

74.8 |

58.6 |

46.2 |

37.0 |

|||

|

|||||||

|

|

70/57 |

64.3 |

55.4 |

43.2 |

33.7 |

|

Unitary Products Group |

3 |

ACCESSORIES

Refer to Price Manual for specific model numbers.

TXV Kits - TXV kits are available for “Flex-coil” applications and converting R22 to R410A or as a service replacement. All kits are bolt-on and require no brazing to install.

Non-Combustible Bases - A combustible floor base accessory is available, if required by local codes, when the air handler is installed in the downflow position on a combustible material.

Electric Heaters - 4HK models shown under electrical data include sequential operation and temperature dual limit switches for safe, efficient operation. Circuit breakers are provided where shown.

External Insulating Wrap Kit - Provides a vinyl covered thermal insulation wrap, providing additional thermal insulation protection to prevent sweating in applications where extreme high humidity is present. Air Handler cover (or wrap) has Velcro edges for easy installation and access.

AIR FLOW DATA - 60 Hz MODELS

255029-YTG-J-1007

LIMITATIONS

These units must be wired and installed in accordance with all national and local safety codes.

Voltage limits are as follows:

Air Handler |

Voltage |

1Normal Operating |

Voltage |

code |

Voltage Range |

|

|

|

208/230-1-60 |

06 |

187-253 |

220/240-1-50 |

93 |

198-264 |

1. Rated in accordance with ARI Standard 110, utilization range “A”.

Airflow must be within the minimum and maximum limits approved for electric heat, evaporator coils and outdoor units.

Entering Air Temperature Limits

Wet Bulb Temp.°F |

Dry Bulb Temp. °F |

||

Min. |

Max. |

Min. |

Max. |

57 |

72 |

65 |

95 |

|

Blower |

|

|

|

|

|

208 Volt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Models |

Motor |

|

|

|

CFM1 @ External Static Pressure - IWC |

|

|

|

|||||

|

Speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

0.10 |

0.20 |

0.30 |

|

0.40 |

0.50 |

0.60 |

0.70 |

|

0.80 |

0.90 |

1.00 |

|

|

|

|

|

||||||||||

|

High |

1142 |

1096 |

1053 |

|

997 |

925 |

828 |

721 |

|

210 |

N/A |

N/A |

AHP18B**(N,H)21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Medium |

677 |

652 |

634 |

|

615 |

572 |

486 |

295 |

|

120 |

N/A |

N/A |

|

|

Low |

442 |

427 |

395 |

|

361 |

289 |

209 |

114 |

|

N/A |

N/A |

N/A |

|

High |

1084 |

1038 |

985 |

|

935 |

856 |

762 |

665 |

|

602 |

484 |

333 |

AHP24B**(N,H)21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Medium |

840 |

807 |

767 |

|

693 |

610 |

550 |

485 |

|

387 |

323 |

221 |

|

|

Low |

654 |

614 |

548 |

|

483 |

420 |

349 |

302 |

|

218 |

179 |

130 |

|

High |

1244 |

1184 |

1138 |

|

1079 |

1004 |

903 |

841 |

|

674 |

580 |

457 |

AHP30B**(N,H)21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Medium |

956 |

913 |

868 |

|

815 |

748 |

663 |

574 |

|

487 |

384 |

N/A |

|

|

Low |

941 |

904 |

862 |

|

806 |

731 |

643 |

566 |

|

480 |

361 |

226 |

|

High |

1719 |

1650 |

1572 |

|

1482 |

1386 |

1273 |

1108 |

|

925 |

785 |

644 |

AHP36C**(N,H)21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Medium |

1119 |

1097 |

1062 |

|

1019 |

935 |

827 |

743 |

|

637 |

479 |

337 |

|

|

Low |

929 |

910 |

877 |

|

825 |

760 |

685 |

616 |

|

508 |

372 |

221 |

|

High |

1719 |

1650 |

1572 |

|

1482 |

1386 |

1273 |

1108 |

|

925 |

785 |

644 |

AHP42C**(N,H)21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Medium |

1119 |

1097 |

1062 |

|

1019 |

935 |

827 |

743 |

|

637 |

479 |

337 |

|

|

Low |

929 |

910 |

877 |

|

825 |

760 |

685 |

616 |

|

508 |

372 |

221 |

AHP48D**(N,H)21 |

High |

1941 |

1818 |

1675 |

|

1532 |

1269 |

870 |

703 |

|

362 |

146 |

N/A |

Medium |

1594 |

1474 |

1409 |

|

1260 |

1021 |

802 |

524 |

|

215 |

144 |

N/A |

|

SHP48D**N21 |

|

|

|||||||||||

Low |

1241 |

1204 |

1128 |

|

1014 |

819 |

659 |

385 |

|

165 |

N/A |

N/A |

|

|

|

|

|||||||||||

|

High / #1 |

2126 |

2093 |

2074 |

|

2048 |

1991 |

1941 |

1801 |

|

1569 |

1461 |

1366 |

AHP60D**(N,H)21 |

Medium High / #2 |

1863 |

1842 |

1804 |

|

1800 |

1758 |

1730 |

1662 |

|

1503 |

1383 |

1306 |

Medium / #3 |

1642 |

1603 |

1593 |

|

1568 |

1523 |

1471 |

1410 |

|

1334 |

1307 |

1216 |

|

SHP60D**N21 |

|

|

|||||||||||

Medium Low / #4 |

1482 |

1468 |

1427 |

|

1370 |

1324 |

1274 |

1233 |

|

1196 |

1153 |

1099 |

|

|

|

|

|||||||||||

|

Low / #5 |

1268 |

1220 |

1169 |

|

1118 |

1070 |

1037 |

982.5 |

|

949.1 |

891.9 |

831 |

1. Includes return air filter and coil.

All Air handler units are UL Listed up to 0.50" w.c. external static pressure, including air filter, wet coil, and largest KW size heater, unless otherwise noted.

4 |

Unitary Products Group |

Loading...

Loading...