Windsor SCC264, 10052250, SC264, 10052210 User Manual

Read these instructions before using the machine

Lea las instrucciones antes de utilizar la máquina

MODELS: SC264

10052210

SCC264

10052250

Operating Instructions (ENG)

Instrucciones de funcionamiento (SPA)

86039070 02/20/09

PR V NO. 98963

BM

WALK BEHIND SCRUBBER

IPX4

MACHINE DATA LOG/OVERVIEW

CUTTER 24V 86039070 04/10/07

2

For the name and address of your dealer contact: Windsor Industries

YOUR DEALER

Name: __________________________________________________________________________________________________

Address: _______________________________________________________________________________________________

Phone Number: _________________________________________________________________________________________

OVERVIEW

The Saber Cutter is a battery powered, self-propelled, hard floor scrubber intended for

commercial use. The appliance applies a cleaning solution onto a hard floor, scrubs the floor

with brushes or pads, and then vacuums the soiled water back into the recovery tank.

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

DEALER NAME ________________________________

OPERATIONS GUIDE NUMBER ___________________

PUBLISHED

__________________________________________

Copyright 2002 Windsor Industries, Printed in USA

TABLE OF CONTENTS

CUTTER 24V 86039070 04/10/07

3

Machine Data Log/Overview.........................2

Table of Contents..........................................3

HOW TO USE THIS MANUAL

How to use this Manual.................................1-1

SAFETY

Important Safety Instructions........................2-1

Hazard Intensity Level. .................................2-2

Safety Label Location. ..................................2-3

OPERATIONS

Technical Specifications. ..............................3-1

How the Machine Works...............................3-3

Components..................................................3-4

Controls.........................................................3-5

Machine Operation........................................3-9

Pre-Run Machine Inspection......................3-9

Starting Machine........................................3-9

Emergency Stop Procedures.....................3-9

Filling the Solution Tank.............................3-9

Scrubbing................................................ 3-10

Emptying & Cleaning Tanks.................... 3-11

MAINTENANCE

Service Schedule.............................. ........ 4-1

Batteries........................................................4-3

Battery Maintenance..................................4-3

Checking Battery Specific Gravity..............4-4

Charging the Batteries...............................4-4

Changing Batteries. ...................................4-5

Battery Connections...................................4-5

Squeegee Blades..........................................4-6

Adjusting Squeegee......................................4-6

Replace or Rotate Rear Squeegee Blade.. ..4-6

Replace or Rotate Front Squeegee Blade. ..4-6

Adjusting Squeegee Pitch................. ........ ..4-7

Adjusting Rear Deflection. ................ ........ ..4-7

Replacing Aqua-Mizer Squeege Blades.......4-7

Scrub Brushes. .............................................4-8

Types.........................................................4-8

Replacing or Installing Scrub Brushes.......4-8

Float Shut-Off................................................4-8

Solution Strainer ...........................................4-9

Brush Motor Replacement............................4-9

Traction Motor Brush Replacement.. .........4-10

Circuit Breaker.................................. .........4-10

Brush Shrouds & Brush Skirts.......... .........4-10

Vacuum Motor .................................. .........4-11

Greasing Instructions........................ .........4-12

Machine Troubleshooting ................. .........4-13

GROUP PARTS LIST

Control Handle............................................ 5-1

Cover (Front) & Tank Mount....................... 5-3

Cover (Top) & Tank Mount......................... 5-5

Decal........................................................... 5-7

Electrical Panel........................................... 5-9

Lift Handle................................................... 5-11

Lift Handle Linkage..................................... 5-13

Recovery Tank............................................ 5-15

Scrub Brush/Pad Driver.............................. 5-17

Scrub Deck Aqua-Mizer-26 in Scrubhead .. 5-19

Scrub Deck Motors..................................... 5-21

Scrub Deck Skirt......................................... 5-23

Scrub Deck Lift Linkage-26 in Scrubhead .. 5-25

Scrub Deck Lift-Center ............................... 5-27

Scrub Deck Lift Linkage-Front & Rear........ 5-29

Solution....................................................... 5-31

Squeegee-26 in Scrubhead........................ 5-35

Squeegee Lift Linkage (Lower)................... 5-37

Vacuum....................................................... 5-39

Wheels & Frame......................................... 5-41

Wiring-Battery............................................. 5-43

Wiring-Control Panel................................... 5-45

Wiring-Main Harness.................................. 5-47

Wiring-Schematic-SC264 ........................... 5-49

Wiring-Schematic-SCC264......................... 5-50

Brake-Option............................................... 5-51

Emergency Stop-Option ............................. 5-53

Accessory Pump-Option............................. 5-55

Battery Charger- SCC264........................... 5-57

Suggested Spare Parts............................... 5-59

EC Declaration of Conformity..................... 5-60

Warranty..................................................... 5-61

HOW TO USE THIS MANUAL

CUTTER 24V 86039070 04/10/07

1-1

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized Windsor

dealers.

When placing an order for parts, the

machine model and machine serial number are

important. Refer to the MACHINE DATA box which

is filled out during the installation of your machine.

The MACHINE DATA box is located on the inside of

the front cover of this manual.

The model and serial number of your machine is on

the back panel of the machine.

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards are identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition. They are

listed in this general order:

- Batteries

- Scrub Brushes

- Adjusting Squeegee

- Scrub Deck Skirts

- Squeegee Blade

- Service Schedule

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- PRV NO. – reference number

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs. If

column has an asterisk (*), call

manufacturer for a serial number.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

MODEL _____________________________________

DATE OF PURCHASE ________________________

SERIAL NUMBER ____________________________

SALES REPRESENTATIVE # ___________________

DEALER NAME ______________________________

OPERATIONS GUIDE NUMBER __________________

PUBLISHED ________________________________

Copyright 2002 Windsor Industries, Printed in USA

CUTTER 24V 86039070 04/10/07

2-1

IMPORTANT SAFETY INSTRUCTIONS

When using an battery powered appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

To reduce the risk of fire, electric shock, or injury:

Use only indoors. Do not use outdoors or expose to rain.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into

water, return it to an authorized service center.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

This machine is not suitable for picking up hazardous dust.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

This machine is suitable for commercial use, for example in hotels, schools, hospitals,

factories, shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

If foam or liquid comes out of machine, switch off immediately.

Disconnect battery before cleaning or servicing.

Before the machine is discarded, the batteries must be removed and properly disposed of.

Make sure all warning and caution labels are legible and properly attached to the machine.

During operation, attention shall be paid to other persons, especially children.

Before use all covers and doors shall be put in the positions specified in the instructions.

When leaving unattended, secure against unintentional movement.

The machine shall only be operated by instructed and authorized persons.

When leaving unattended, switch off or lock the main power switch to prevent unauthorized use.

Only chemicals recommended by the manufacturer shall be used.

This appliance has been designed for use with the brushes specified by the manufacturer. The fitting

of other brushes may affect its safety.

Do not use on surfaces having a gradient exceeding 2% unless the optional parking brake is installed

on the machine.

SAVE THESE INSTRUCTIONS

!

WARNING:

HAZARD INTENSITY LEVEL

CUTTER 24V 86039070 04/10/07

2-2

The following symbols are used throughout this guide as indicated in their descriptions:

HAZARD INTENSITY LEVEL

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use Windsor approved replacement parts.

Batteries emit hydrogen gas. Explosion or fire can result. Keep sparks and open flame away. Keep

top cover in raised position when charging. Keep sparks and flames away from the batteries. Do

not smoke around batteries.

Disconnect batteries before working on machine. Only qualified personnel should work inside

machine. Always wear eye protection and protective clothing when working on or near batteries.

Avoid skin contact with the acid contained in the batteries.

Never allow metal to lie across battery tops.

! WARNING

! WARNING

! WARNING

! WARNING

! CAUTION

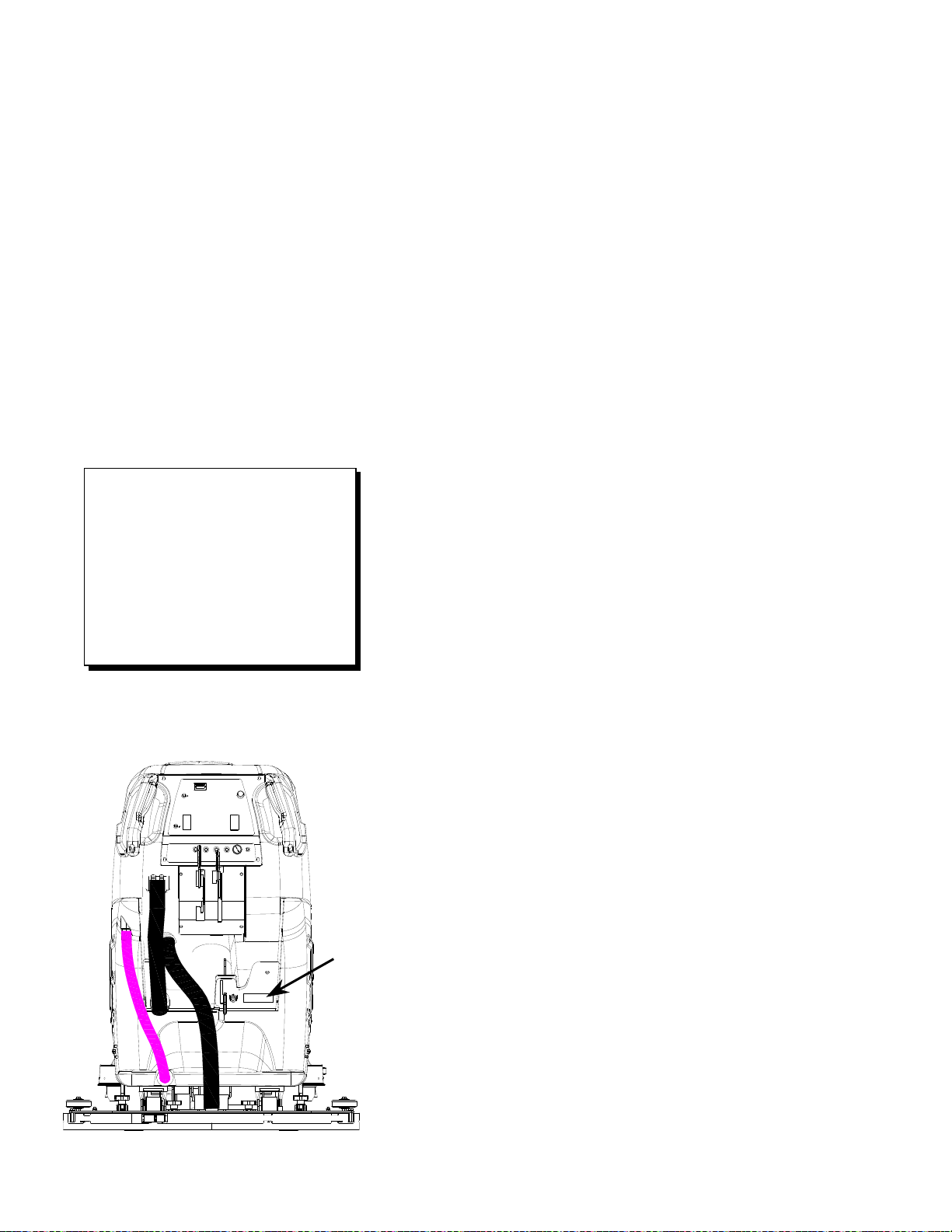

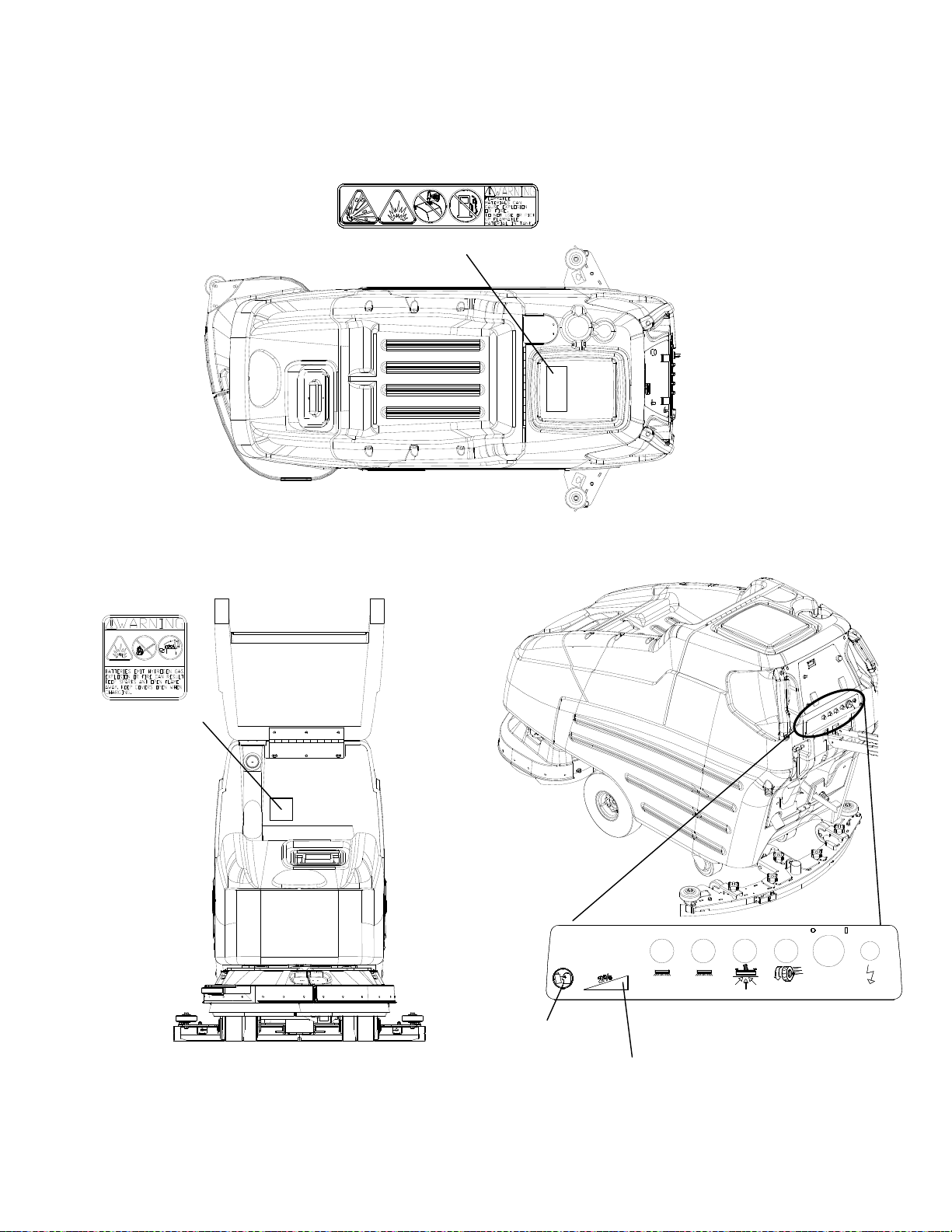

SAFETY LABEL LOCATION

CUTTER 24V 86039070 04/10/07

2-3

NOTE: These drawings indicate the location of safety labels on the machine. If at any time the labels become

illegible, promptly replace them.

CIRCUIT BREAKER DECAL

86243530

PRV NO. 500565

2% GRADE WARNING

SEE MANUAL

SAFETY DECAL

86252530

PRV NO. 81494

BATTERY CAUTION

86252520

PRV NO. 80885

TECHNICAL SPECIFICATIONS

CUTTER 24V 86039070 04/10/07

3-1

ITEM DIMENSION/CAPACITY

Nominal power 1450 W

Rated Voltage 24VDC

Rated Amperage 60 Amps

Batteries 4 X 6 Volt 250-305-335 AH @

20 hr rate

Scrub Brush Motors 2 X .75 hp (0.56 kW)

Vacuum Motor .75 hp (0.56 Kw)

Propelling Motor .3 hp (0.22 Kw)

Mass (GVW) 915 lbs. (415 kg) with 335 AH

Weight empty without batteries 346 lbs. (157 kg)

Solution Control Gravity feed, fully variable with

automatic shut-off in neutral

Solution tank capacity 23 gal. (87 l)

Recovery tank capacity 25 gal. (95 l)

Scrub brush diameter for 26 in. (66 cm) scrub head 13 in (33.0 cm)

Scrub brush pressure Mechanical 80 lbs. (356N)

Floating 130 lbs. (578N)

restricted

Scrub brush speed 200 rpm

Tires 2 x 10 in (25.4 cm) non-marking

foam-filled

Casters 2 X 4 in (10.2 cm) polyurethane

solid non-marking

Foundation Pressure 21 lbs./in

2

(140 kPa)

Maximum Speed 3.2 Miles/hour (5.2 km/hour)

Coverage with 26 in. (66 cm) scrub head 31,680 ft

2

/hour at 3.0 mph with

2 in. overlap*

Frame Construction Steel plate with epoxy

powdercoat finish.

Brakes (optional) Tire lock parking brake

Minimum aisle u-turn width with 26 in. (66 cm) scrub head 69 in. (175 cm)

Maximum rated climb and descent angle with empty tanks

and without optional parking brake

2%

Maximum rated climb and descent angle with full tanks

and without optional parking brake

2%

* Cleaning rate results will vary depending on floor type, building structure, etc.

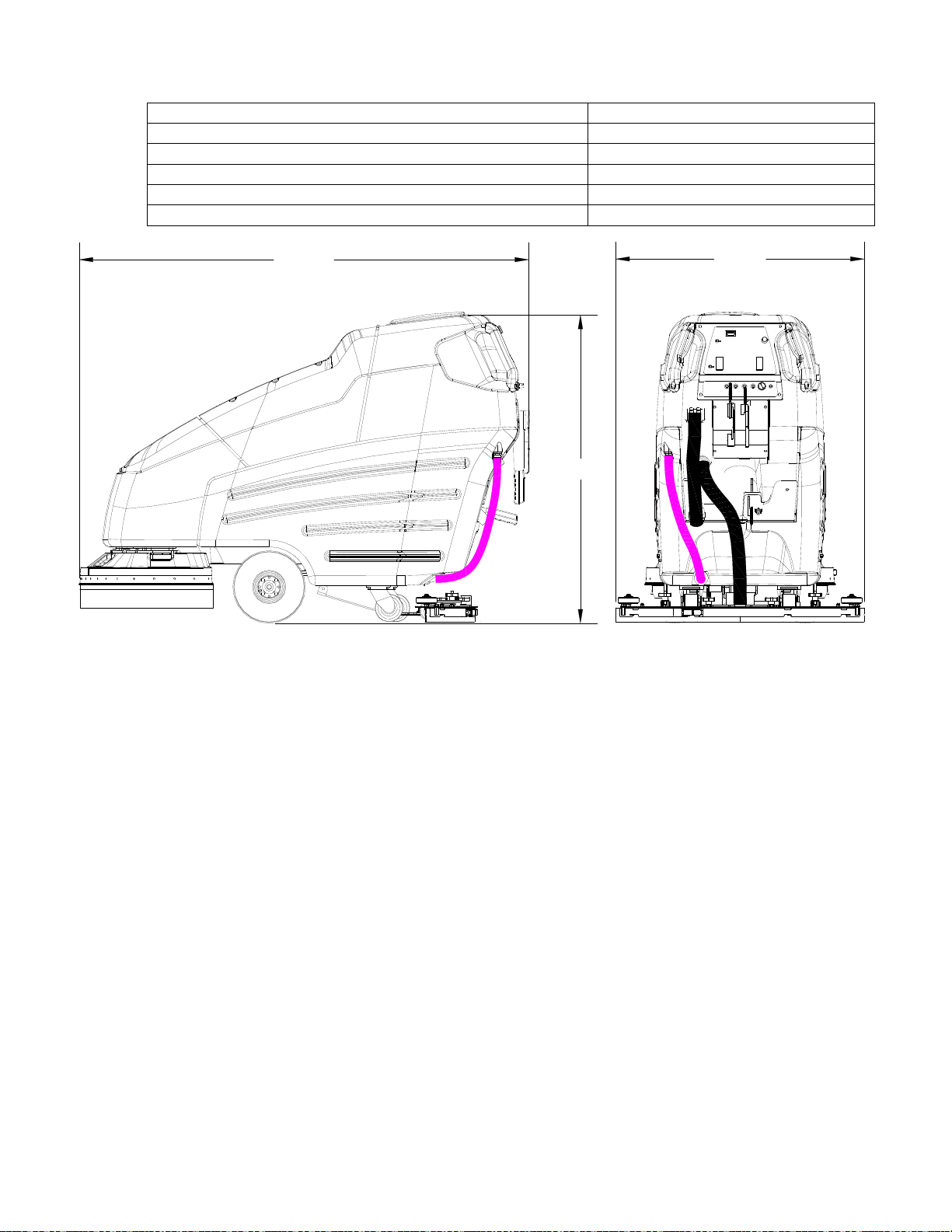

TECHNICAL SPECIFICATIONS

CUTTER 24V 86039070 04/10/07

3-2

ITEM MEASURE

Height 45 in. (114 cm)

Length with 26 in. (66 cm) scrub head 64 in. (163 cm)

Width without squeegee and scrub head 24 in. (61 cm)

Width of squeegee for 26 in. (66 cm) scrub head 35 in. (89 cm)

Width of scrub path for 26 in. (66 cm) scrub head 26 in. (66 cm)

SPECIAL NOTES:

The sound pressure level at the operator’s ear

was measured to be 72 dBA. This was a

nearfield, broad-band measurement taken in a

typical industrial environment on a tile floor.

This appliance contains no possible source of

impact noise. The instantaneous sound

pressure level is below 63 Pa.

The weighted root mean square acceleration at

the operator’s arms was measured to be below

2.5m/s

2

. This was a tri-axial, third-octave-band

measurement made during normal operation on

a composite tile floor. The measurement and

related calculations were made in accordance

with ANSI S3.34-1986.

Length

Width

Height

HOW THE MACHINE WORKS

CUTTER 24V 86039070 04/10/07

3-3

The Saber Cutter is a battery powered, self-

propelled, hard floor scrubber intended for

commercial use. The appliance applies a

cleaning solution onto a hard floor, scrubs the

floor with brushes, and then vacuums the soiled

water back into the recovery tank.

The machine's primary systems are the solution

system, scrub system, recovery system, and

directional control system.

The function of the solution system is to store

cleaning solution and deliver it to the scrub

system. The solution system consists of the

solution tank, strainer, valve and controls. The

solution tank stores cleaning solution (water and

detergent) until it is delivered to the scrub system.

The strainer protects the valve from debris. The

valve is a solenoid type valve, which controls the

delivery of cleaning solution to the scrub system.

The valve automatically prevents solution flow

unless the scrub brushes are turned on and the

machine is being propelled. The solution control

knob controls the amount of cleaning solution

delivered to the scrub system by controlling the

amount of time the valve is open.

The function of the scrub system is to scrub the

floor. The scrub system consists of two rotary

type disk scrub brushes, motors, scrub deck skirt,

lift mechanism and controls. The brushes scrub

the floor and the motors drive the brushes. The

brush drive hubs allow the scrub brushes to follow

irregularities and changes in the floor without

loosing contact with floor. The scrub deck skirt

controls the cleaning solution on the floor so that

the squeegee can pick it up. The brush lever is

used to raise and lower the deck. For heavy scrub

pressure lock the lever into the lower notch.

Pushing the lever forward allows you to push

down. Pull Back on the lever to allow it to swing

down and out of the way.

The function of the recovery system is to vacuum

the soiled water back into the recovery tank. The

recovery system consists of the squeegee,

vacuum motor, float ball filter, recovery tank and

controls. The squeegee wipes the dirty solution

off the floor as the machine moves forward. The

vacuum motor provides suction to draw the dirty

solution off the floor and into the recovery tank.

The recovery tank stores the dirty solution. The

float ball filter protects the vacuum fan from debris

and shuts off air going to the recovery tank when

tank is full.

When flow of air is shut off the vacuum motor will

continue to run. At this time the recovery tank

must be drained.

The function of the directional control system is to

control the direction and speed of the machine.

The directional control system consists of the

propel control buttons, reverse button, speed

control knob/potentiometer, controller and

transaxle. The propel control buttons actuates

switches, which signal forward pressing the

reverse button in addition to one of the propel

control buttons the machine will move in reverse.

The speed control knob actuates a potentiometer,

which signals speed. The controller interprets the

forward/reverse signals from the switches and the

speed signal from the potentiometer to command

the transaxle to propel the machine in the

direction, and at the speed, desired.

Loading...

Loading...