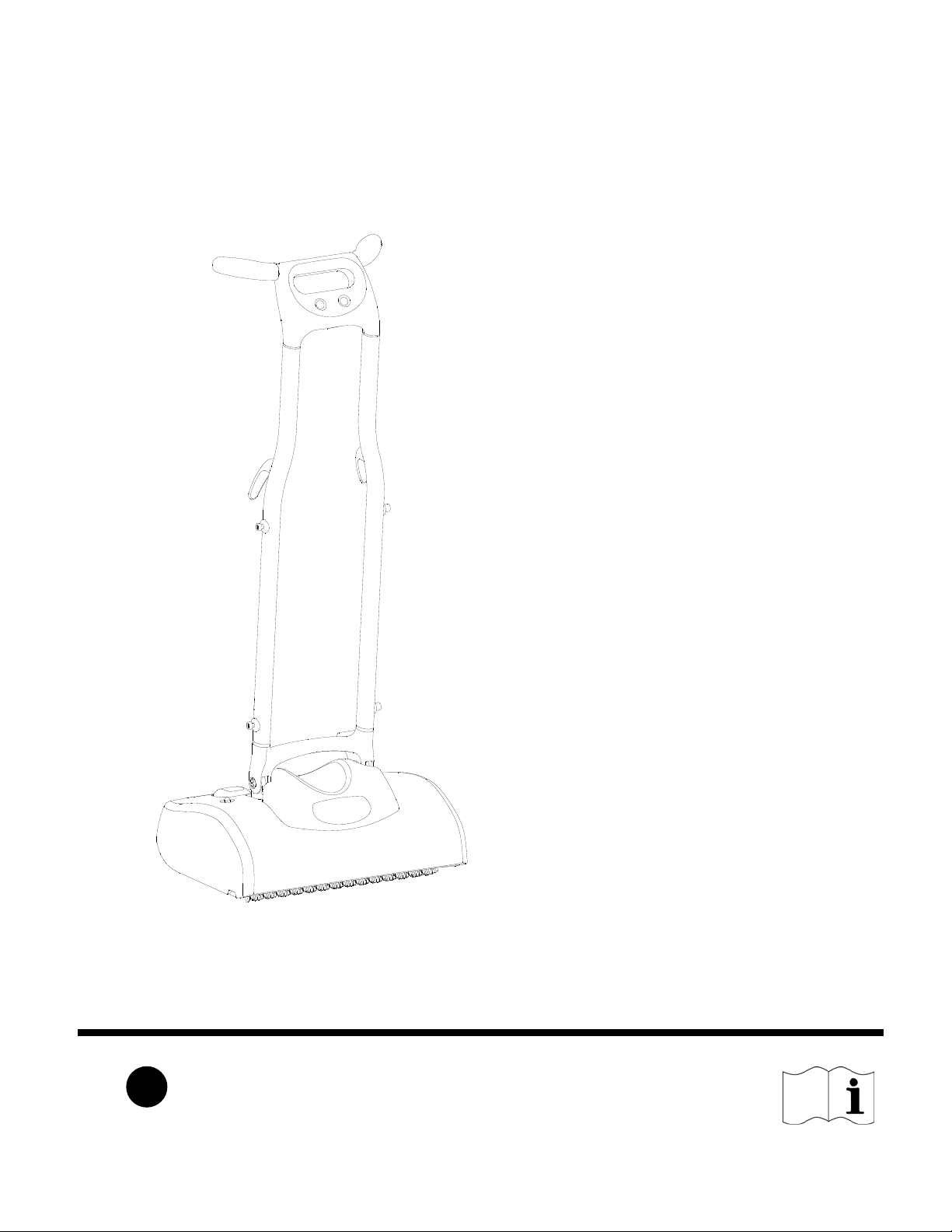

Windsor IMXIE17 10066410, IMX 10066400, IMIE17 10066550, IM 10066360 User Manual

Carpet Maintainer

Read instructions before operating the machine.

Operating Instructions (ENG)

L

86269870 08/20/08

PRV NO. 980305

MODELS: IM

10066360

IMIE17

10066550

IMX

10066400

IMXIE17

10066410

DATA LOG/OVERVIEW

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

NAME: __________________________________________________________________________________________________

ADDRESS:_______________________________________________________________________________________________

PHONE NUMBER: _______________________________________________________________________________________

YOUR DEALER

OVERVIEW

The Carpet Maintainer is designed to maintain carpet using the Quick Dry Carpet Care

System. The machine has two counter rotating brushes that scrub chemical into the

carpet. The chemicals, iCapsol or Prochem ProCaps, encapsulates the dirt, allowing both

to be vacuumed up once the chemical has dried. The brushes also raise the pile of the

carpet. The Deluxe models have a solution tank and pump powered spraying system,

which applies the chemical to the carpet as the machine is used.

2

86269870 04/02/07

Data Log/Overview. ...................................2

Table of Contents.......................................3

HOW TO USE THIS MANUAL

How to use this Manual..............................1-1

SAFETY

Important Safety Instructions.....................2-1

Hazard Intensity Level. ..............................2-2

Grounding Instructions...............................2-3

Safety Label Location ................................2-4

OPERATIONS

Technical Specifications. ...........................3-1

How the Machine Works............................3-2

Machine Operation.....................................3-3

Pre-run Inspection..............................3-3

Starting Machine.................................3-3

Shut-down and Storage......................3-4

Components...............................................3-5

MAINTENANCE

Brush Cleaning and Maintenance..............4-1

Machine Maintenance................................4-1

Daily Maintenance..............................4-1

Periodic Maintenance.........................4-1

Annual Maintenance...........................4-1

Machine Troubleshooting...........................4-2

86269870 07/11/07

TABLE OF CONTENTS

PARTS LIST

Brush ........................................................5-1

Brush Lift ...................................................5-3

Decal..........................................................5-5

Electrical-120V...........................................5-7

Electrical-230V...........................................5-9

Frame ........................................................5-11

Frame-Deluxe............................................5-13

Handle .......................................................5-15

Hopper.......................................................5-17

Motor..........................................................5-19

Rear Wheel................................................5-21

Solution Tank-Deluxe ................................5-23

Wiring-120V...............................................5-25

Wiring-230V...............................................5-27

Suggested Spare Parts..............................5-29

Warranty....................................................5-30

3

HOW TO USE THIS MANUAL

This manual contains the following sections:

- HOW TO USE THIS MANUAL

- SAFETY

- OPERATIONS

- MAINTENANCE

- PARTS LIST

The HOW TO USE THIS MANUAL section will tell

you how to find important information for ordering

correct repair parts.

Parts may be ordered from authorized dealers.

When placing an order for parts, the machine model

and machine serial number are important. Refer to

the MACHINE DATA box which is filled out during

the installation of your machine. The MACHINE

DATA box is located on the inside of the front cover

of this manual.

_____________________________

MODEL

DATE OF PURCHASE ___________________

SERIAL NUMBER _____________________

SALES REPRESENTATIVE # _____________

The model and serial number of your machine is on

the operator’s left hand side, side panel of base.

The SAFETY section contains important information

regarding hazard or unsafe practices of the

machine. Levels of hazards is identified that could

result in product or personal injury, or severe injury

resulting in death.

The OPERATIONS section is to familiarize the

operator with the operation and function of the

machine.

The MAINTENANCE section contains preventive

maintenance to keep the machine and its

components in good working condition.

1-1

86269870 04/02/07

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts

lists include a number of columns of information:

- REF – column refers to the reference

number on the parts illustration.

- PART NO. – column lists the part

number for the part.

- QTY – column lists the quantity of the

part used in that area of the machine.

- DESCRIPTION – column is a brief

description of the part.

- SERIAL NO. FROM – column indicates

the first machine the part number is

applicable to. When the machine design

has changed, this column will indicate

serial number of applicable machine.

The main illustration shows the most

current design of the machine. The

boxed illustrations show older designs. If

column has an asterisk (*), call

manufacturer for serial number.

- NOTES – column for information not

noted by the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement

parts numbers needed for ordering future parts.

NOTE: The 98# on the lower left corner of the front

cover is the part number for this manual.

SAFETY

!

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

WARNING:

Connect to a properly grounded outlet. See Grounding Instructions.

Do not leave the machine unattended. Unplug machine from outlet when not in use and before

maintenance or service.

Do not allow machine to be used as a toy. Close attention is necessary when used by or near

children.

Use only as described in this manual. Use only manufacturer’s recommended components and

attachments.

Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding

the machine. If the machine is not working properly, has been dropped, damaged, left outdoors, or

dropped into water, return it to an authorized service center.

To reduce the risk of fire, electric shock, or injury:

Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord

around sharp edges or corners.

Do not run machine over cord or allow the rotating brushes to come in contact with the cord. Keep cord

away from heated surfaces.

Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.

Do not handle the electrical plug or machine with wet hands.

Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce

airflow.

Machine is designed for indoor use only and must not be operated or stored outdoors in wet

conditions.

Turn off all controls before unplugging.

This machine is suitable for commercial use, including hotels, schools, hospitals, factories,

shops and offices for more than normal housekeeping purposes.

Maintenance and repairs must be done by qualified personnel.

Machine can cause a fire when operating near flammable vapors or materials. Do not operate this

machine near flammable fluids, dust or vapors.

SAVE THESE INSTRUCTIONS

86269870 04/02/07

2-1

SAFETY

HAZARD INTENSITY LEVEL

he following symbols are used throughout this guide as indicated in their descriptions:

T

There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR

SAFETY. The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which could result in severe personal injury or death.

! WARNING

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property

damage.

! CAUTION

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper

operating condition. Following is information that signals some potentially dangerous conditions to the

operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate

all safety devices on the machine. Please take the necessary steps to train the machine operating

personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the

machine. Use approved replacement parts.

2-2

86269870 04/02/07

THIS PRODUCT IS FOR COMMERCIAL USE

ONLY.

ELECTRICAL

In the USA, this machine operates on a standard 15

amp 120V, 60 hz, A.C. power circuit. The amp,

hertz, and voltage are listed on the data label found

on each machine. Using voltages above or below

those indicated on the data label will cause serious

damage to the motors.

EXTENSION CORDS

If an extension cord is used, the wire size must be at

least one size larger than the power cord on the

machine, and must be limited to 50 feet (15.5m) in

length.

GROUNDING INSTRUCTIONS –

120V ONLY

This appliance must be grounded. If it should

malfunction or break down, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This appliance is equipped

with a cord having an equipment-grounding

conductor and grounding plug. The plug must be

inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

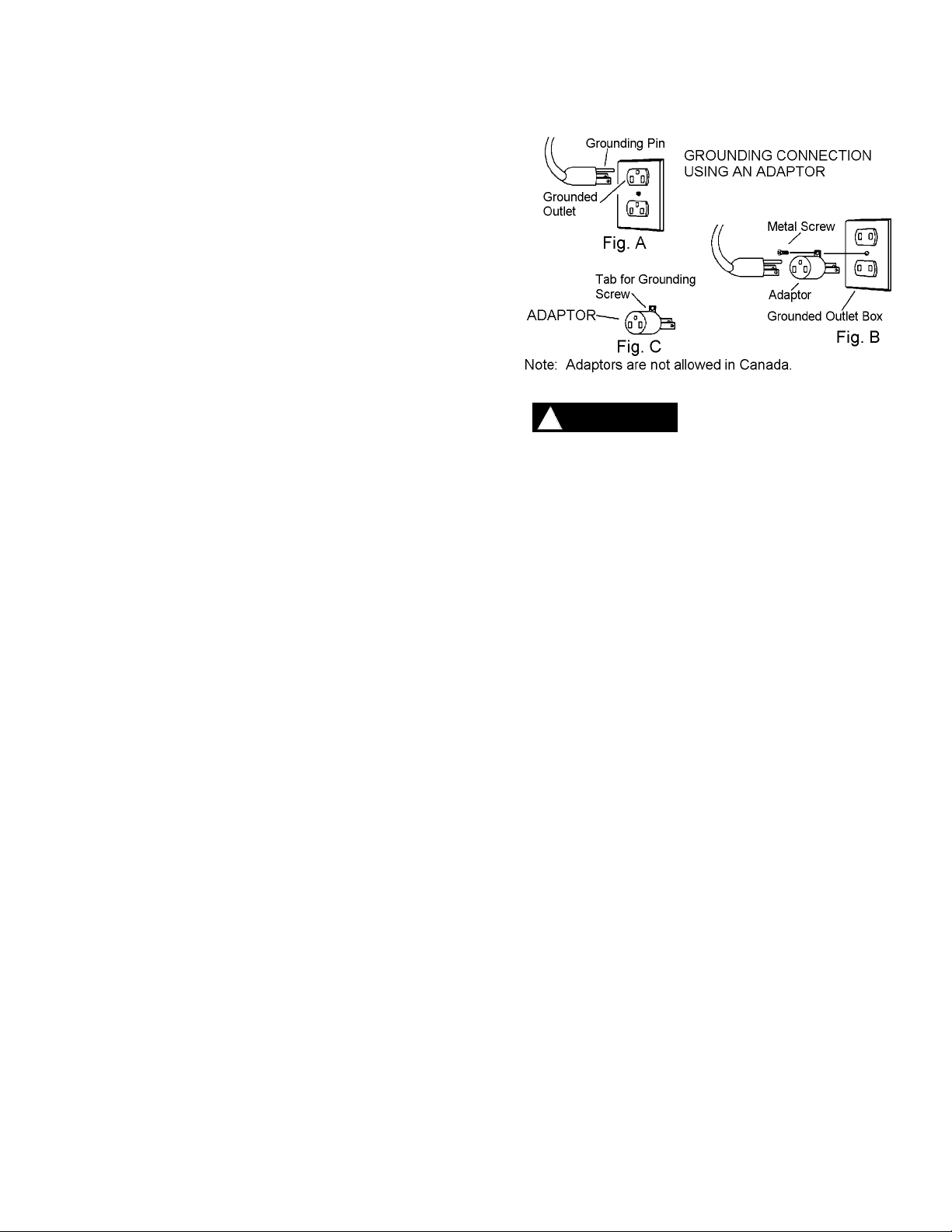

This appliance is for use on a nominal 120-volt

circuit, and has a grounded plug that looks like the

plug in “Fig. A”. A temporary adaptor that looks like

the adaptor in “Fig. C” may be used to connect this

plug to a 2-pole receptacle as shown in “Fig. B”, if a

properly grounded outlet is not available. The

temporary adaptor should be used only until a

properly grounded outlet (Fig. A) can be installed by

a qualified electrician. The green colored rigid ear,

lug, or the like extending from the adaptor must be

connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the

adaptor is used, it must be held in place by a metal

screw.

86269870 04/02/07

SAFETY

! WARNING

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. Check with a qualified electrician

or service person if you are in doubt as to

whether the outlet is properly grounded. Do not

modify the plug provided with the appliance - if it

will not fit the outlet, have a proper outlet

installed by a qualified electrician.

2-3

SAFETY

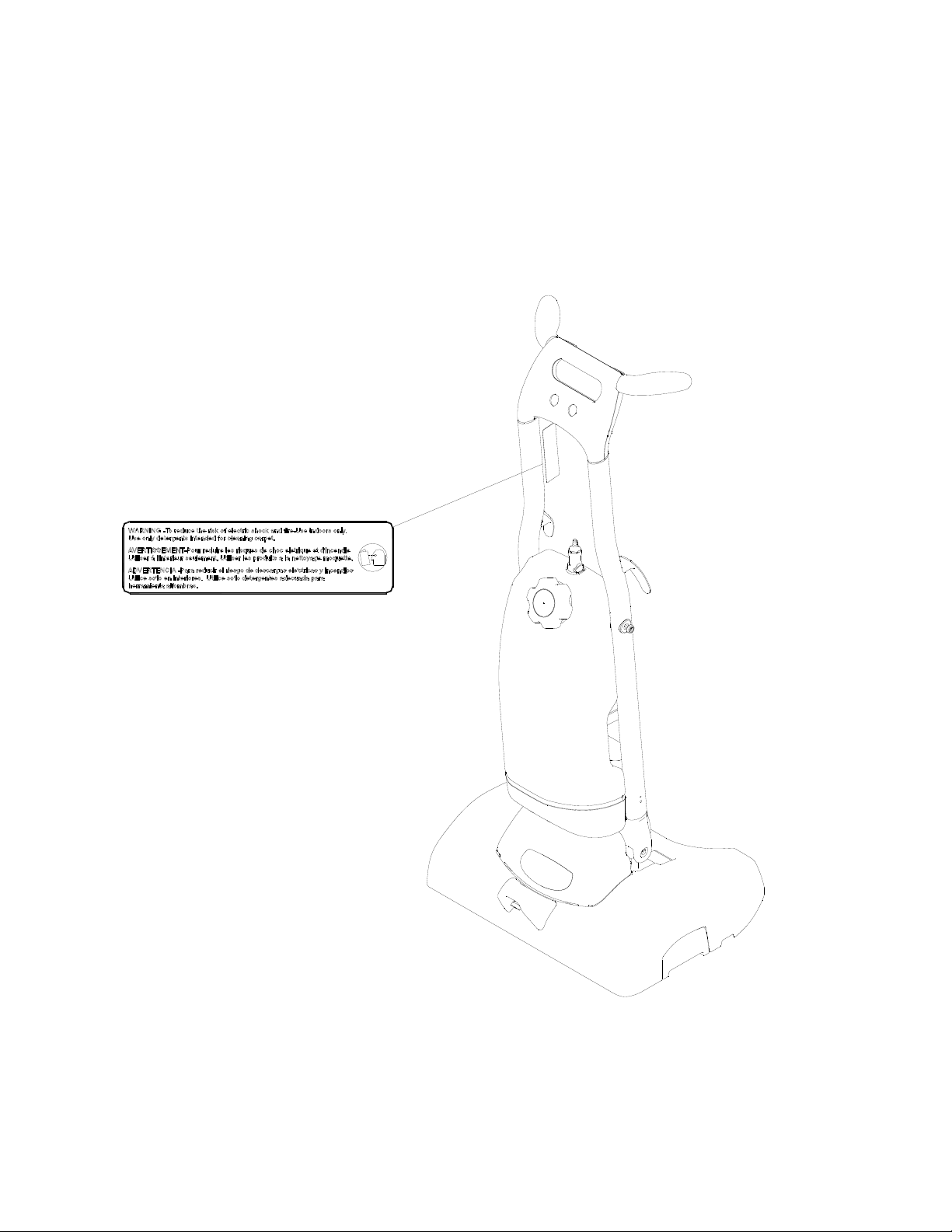

SAFETY LABEL LOCATION

The following WARNING LABEL(S) are found on your cleani ng unit. These labels point out important

Warnings and Cautions which should be followed at all times. Failure to follow warnings and cautions could

result in fatality, personal injury to yourself and/or others, or property damage. Follow these instructions

carefully! DO NOT remove these labels.

NOTE: If at any time the labels become illegible, promptly replace them.

WARNING LABEL

PART NUMBER 86220140

PRV 500895

2-4

86269870 04/02/07

OPERATIONS

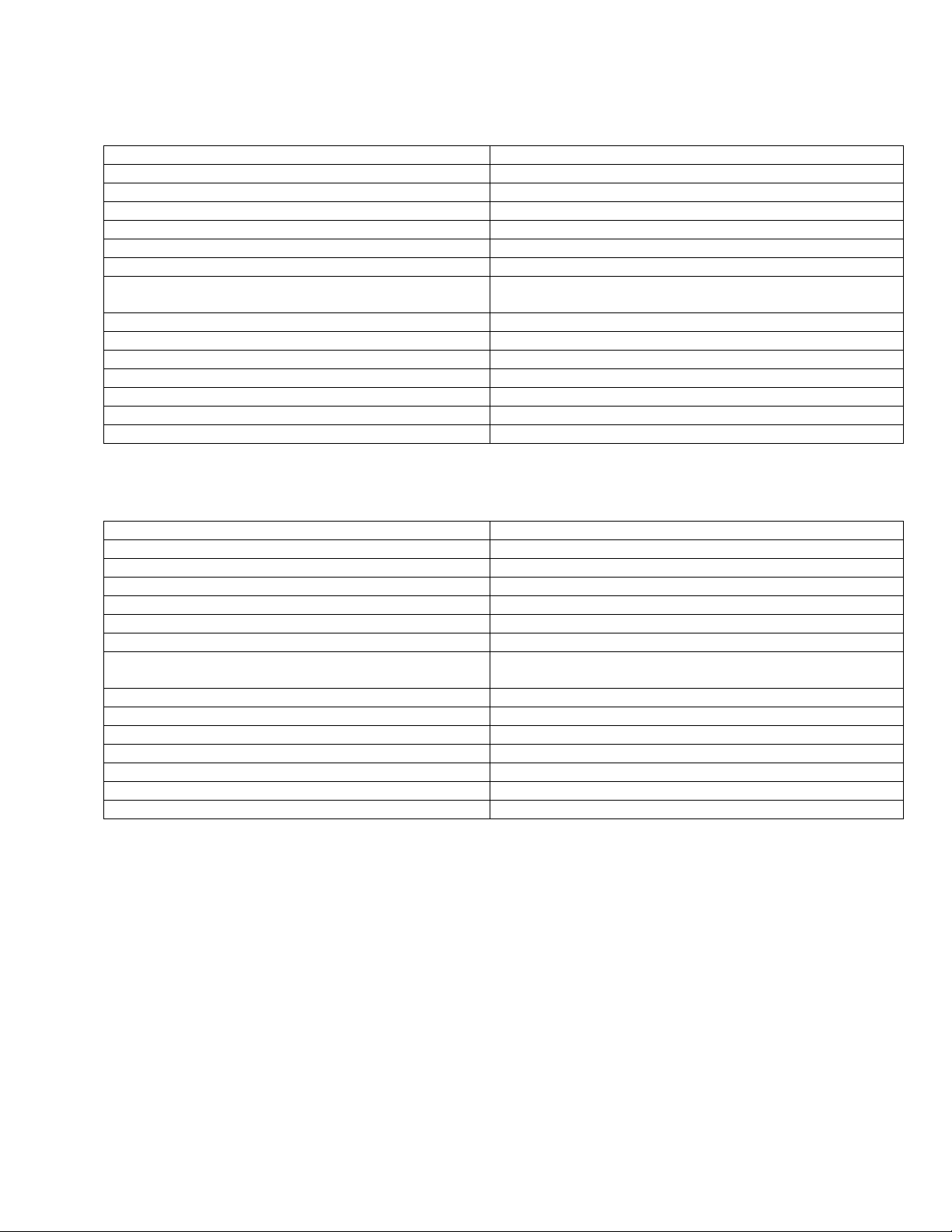

TECHNICAL SPECIFICATIONS

120V

ITEM DIMENSION/CAPACITY

Electrical 120V

Nominal Power 0.5 HP

Rated Amperage 7 Amps

Brush Width 17 – 16.5” (430 - 420 mm)

Brush RPM 470 RPM

Wheels 3 inches (75 mm) non-marking grey

Dimensions - Weight

- Weight - Deluxe

Dimensions – Height with handle 45.5” (1.16 m)

Dimensions – Depth 16 inches (0.4 m)

Power Cord 40 feet (12.2 m)

Solution Tank Volume - Deluxe 2 gallon

Pump Pressure - Deluxe 50 psi

Solution Flow - Deluxe 0.1 gpm

Spray Jet Size - Deluxe .010

230V

ITEM DIMENSION/CAPACITY

Electrical 230V

Nominal Power 0.5 HP

Rated Amperage 4 Amps

Brush Width 17 – 16.5” (430 - 420 mm)

Brush RPM 470 RPM

Wheels 3 inches (75 mm) non-marking grey

Dimensions - Weight

- Weight - Deluxe

Dimensions – Height - with handle 45.5” (1.16 m)

Dimensions – Depth 16 inches (0.4 m)

Power Cord 40 feet (12.2 m)

Solution Tank Volume - Deluxe 2 gallon

Pump Pressure - Deluxe 50 psi

Solution Flow - Deluxe 0.1 gpm

Spray Jet Size - Deluxe .010

48 lbs. (22 kg)

56 lbs. (25 kg)

48 lbs. (22 kg)

56 lbs. (25 kg)

SPECIAL NOTES:

The sound pressure level at the operator’s ear was

measured to be 67.7dBA . This was a nearfield, broadband measurement taken on a carpeted floor. This

appliance contains no possible source of impact noise.

The instantaneous sound pressure level is below 63 Pa.

NOTES:

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do

not play with the appliance.

86269870 04/14/08

The weighted root mean square acceleration at the

operator’s arms was measured to be below 2.5m/s

This was a tri-axial, third-octave-band measurement

made during normal operation on a composite tile

floor. The measurement and related calculations were

made in accordance with ISO 5349-1.

2

.

3-1

OPERATIONS

HOW THE MACHINES WORK

The Carpet Maintainer is designed to maintain your

carpet using the Quick Dry Carpet Care System. By

using the Carpet Maintainer in conjunction with

iCapsol or Prochem ProCaps chemical solution, you

can perform a regular light cleaning and grooming of

your carpet very quickly, and have the carpet dry

and ready for traffic within 20 minutes.

The handle movement flexibility allows the machine

to clean under low furniture. There is a hand

operated on/off switch and auto-handle lock keeping

the handle in an upright position. This unit is

equipped with a safety feature that when unplugged

from the wall or the handle dropped, will

automatically reset to the off position .

The debris tray is used to catch unwanted carpet

debris and should be cleaned regularly and prior to

transporting.

This appliance conforms with international and

national safety directives: EN55014-2, EN5504-1,

EN61000-3-2/3-3, EN60335-1/2-10/2-69/2-67. IEC

60335-1/2/10/2-67/2-69. LVD 73/23/EEC.

DELUXE

This unit is equipped with an onboard spray pump

and solution tank. By using the onboard spraying

system a light treatment of chemical can be applied

to the carpet and brushed in during a single pass of

the machine.

QUICK DRY CARPET CARE SYSTEM

INSTRUCTIONS

Test for colorfastness in an inconspicu ous area

before use.

1. Vacuum carpet to remove loose soil.

2. Dilute iCapsol or Prochem ProCaps at 8oz. per

gallon of water (1:16) into the solution tank.

3. Pre-spray carpet to be cleaned at a rate of 600–

1000 sq. ft. per gallon of diluted solution. Do not

over wet.

3-2

86269870 07/11/07

4. No dwell time is required. Do not allow

chemical to dry before brushing.

5. Brush treated area to emulsify soils using

the Windsor iCapsol or other carpetbrushing machine.

6. Allow to dry until dry to touch (approximately

20 minutes) before opening area to traffic.

7. Vacuum carpet when fully dry to remove

encapsulated soil.

Tips: Pre-treat carpet spots with iCapsol Interim

cleaning solution. Work on a manageable area

and do not allow cleaning solution to dry on

carpet before brushing.

DELUXE

The Deluxe is provided with a removable

solution tank. To remove tank for filling and

cleaning, press the gray release button on the

blue coupler located at the top of the tank. Next

remove upper straps from mounting pegs. The

tank will now freely separate from the machine

base. After filling tank remount to machine by

reversing the process mentioned above.

The proper 1:16 dilution ratio can be achieved

by adding one pint (16 oz.) of recommended

chemical and slowly filling the tank with water (2

gallons). Adding water slowly will help prevent

foaming.

To achieve a coverage rate of 600–1000 sq. ft.

per gallon using the onboard sprayer, spray

solution only during the forward stroke of

operation. Use the backstroke to brush the

chemical into the carpet.

MACHINE OPERATION

PRE-RUN INSPECTION

Perform a pre-run inspection to find possible

problems that could cause poor performance or

lost time from breakdown. Check the rating plate

to confirm voltage and frequency is the same as

the power supply. NOTE: A 10% variation in

voltage is acceptable.

STARTING MACHINE

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before starting machine, make

sure that all covers are in place and secured

properly.

1. Connect the machine to a power supply.

2. Release the handle lock.

3. (a) Press green button to power on the

machine,120V only.

(b) Set black on/off switch to “on” position,

230V only.

4. Press green button to start brushes.

After applying a light spray of diluted interim

carpet cleaner onto the carpet using a pressurized

tank sprayer, commence cleaning by pushing and

pulling the machine slowly over the wetted carpet.

Move the machine in multiple directions and

overlapping strokes.

For best results use Windsor iCapsol or Prochem

ProCaps products.

OPERATIONS

STARTING MACHINE – DELUXE

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before starting machine, make

sure that all covers are in place and secured

properly.

1. Connect the machine to a power supply.

2. Release the handle lock.

3. (a) Press green button to power on machine,

120V only.

(b) Set black on/off switch to “on” position,

230V only.

4. Press green button to start brushes.

5. Press and hold blue button to spray chemical.

Once machine is plugged in spray function is

operational.

Apply a light spray of diluted interim carpet

cleaner onto the carpet using the onboard

spraying system. Spray chemical while pushing

the machine forward. Brush the chemical into the

carpet while pulling the machine slowly over the

wetted carpet. Move the machine in multiple

directions and overlapping strokes.

For best results use Windsor iCapsol or Prochem

ProCaps products.

! WARNING

Flammable materials can cause an explosion or

fire. Do not use flammable materials with this

machine.

86269870 08/20/08

3-3

OPERATIONS

TRANSPORTING A SPRAYER

1. This machine has the capability to mount a

small pump-up sprayer.

TRANSPORTING CHEMICAL - DELUXE

1. This machine has the capability to mount

chemical bottles or trigger sprayers to the

back of the solution tank.

! WARNING

This Machine is not intended to carry more than

30 pounds. Carrying more than 30 pounds could

cause damage to the machine.

3-4

86269870 08/20/07

SHUT-DOWN AND STORAGE

1. Flush the spray jet and tank with hot water

2. After flushing, uncouple quick disconnect to

3. a. Press red button to power off machine

4. Lock handle in the upright position.

5. Disconnect the power cord from the power

6. Remove the brushes for cleaning. See Brush

7. Clean debris tray.

The machine is now ready for storage until the

next use. Make sure to store your equipment in a

dry place to prolong the life of your machine.

Storage outdoors or unprotected could cause

damage to your machine or internal parts,

therefore voiding your warranty.

(Deluxe only)

prevent water from dripping out of front jet.

120V only.

b. Set black on/off switch to “off” position

230V only.

supply. Wind the power cord around the cable

holders on the handle.

Cleaning and Maintenance section.

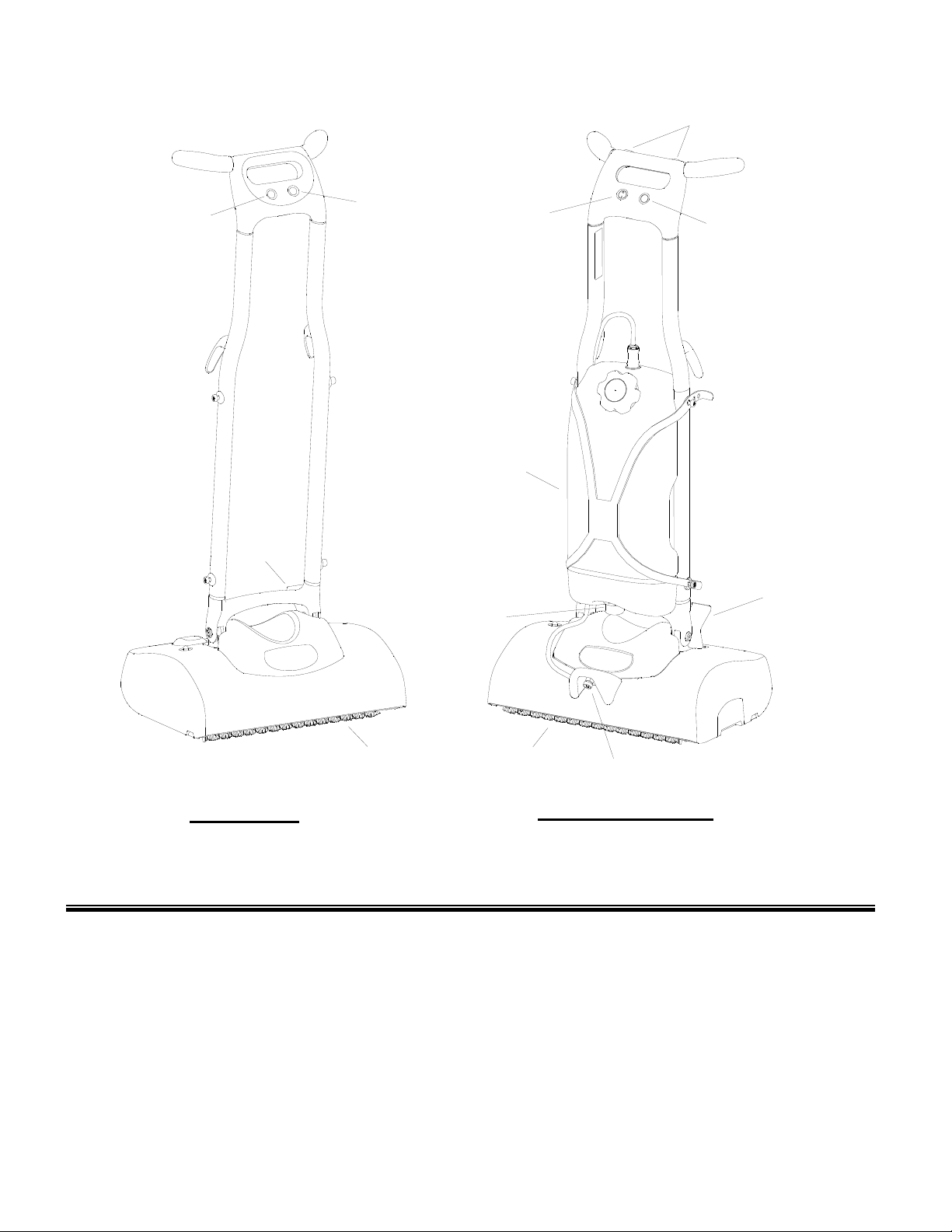

COMPONENTS

8

1A

2

1B 1B

4

1A

5

6

2

4

3

iCapsol Mini

1A. Stop Switch (red-120V only)

1B. On/Off Switch (black-230 only)

2. Start Switch (green)

3. Brushes

4. Handle Release

86269870 07/11/07

3

7

iCapsol Mini Deluxe

5. Tank

6. Strainer

7. Jet

8. Spray Pump Switch

3-5

MAINTENANCE

BRUSH CLEANING AND MAINTENANCE

After each session of carpet cleaning, the brushes

and the brush housing should be cleaned. Before

cleaning or changing the brushes, always unplug the

machine from the power supply.

Brushes are removed without tools. After handle is

in locked position, tilt the machine back and rest on

handle. To release brush from spring clip pull spring

clip away from brush end cap. Lift brush out of

machine.

The brushes may be soaked in warm or hot water

using mild detergent, and then rinsed with warm

water. NOTE: Brushes with crushed bristles can

often be restored to original condition by soaking in

hot water.

Keep brushes clean and free from debris. Rotate

brushes after every use as this will increase the life

span of the brushes and ensure even wear.

Before reinstalling brushes, clean out machine brush

housing and hopper by wiping with a clean damp

cloth.

MACHINE MAINTENANCE

The Maintainer requires very little maintenance.

Wipe down the machine periodically with a clean

cloth. DO NOT spray water directly over the top of

machine.

! CAUTION

Deformation of the brush bristles can result in

unbalanced running and excessive vibrating or

jumping.

The machine is fitted with a circuit breaker. In the

unlikely event of overloading, the circuit breaker will

automatically trip. It can be reset after approximately

30 seconds (or when the machine cools down) by

pushing the set button located on the cover housing.

4-1

86269870 07/11/07

DAILY MAINTENANCE

1. Clean and inspect brushes.

2. Clean and inspect brush housing, debris tray

and machine. Rinse debris tray if needed.

3. Inspect power cord for wear or damage.

This cable will lie on wet carpet. To prevent

electrical shock replace cords that are

frayed or have cracked insulation

immediately.

4. Flush the tank, pump and spray jet with hot

water (Deluxe only).

5. Clean Strainer.

PERIODIC MAINTENANCE

1. Check all handles, switches, electrical

cables and connections on your machine for

damage. Repair or replace immediately.

2. Inspect and/or replace brushes.

Replace brushes when main bristles are

worn to the same level as the yellow

indicator bristles.

3. Check spray pattern. Clean or replace jet if

the pattern is blocked or uneven

ANNUAL MAINTENANCE

1. Check all bearings for noise and wear.

2. Check motor for operation.

3. Check overall machine for operation.

4. Check belts for wear and change belts every

second year.

MAINTENANCE

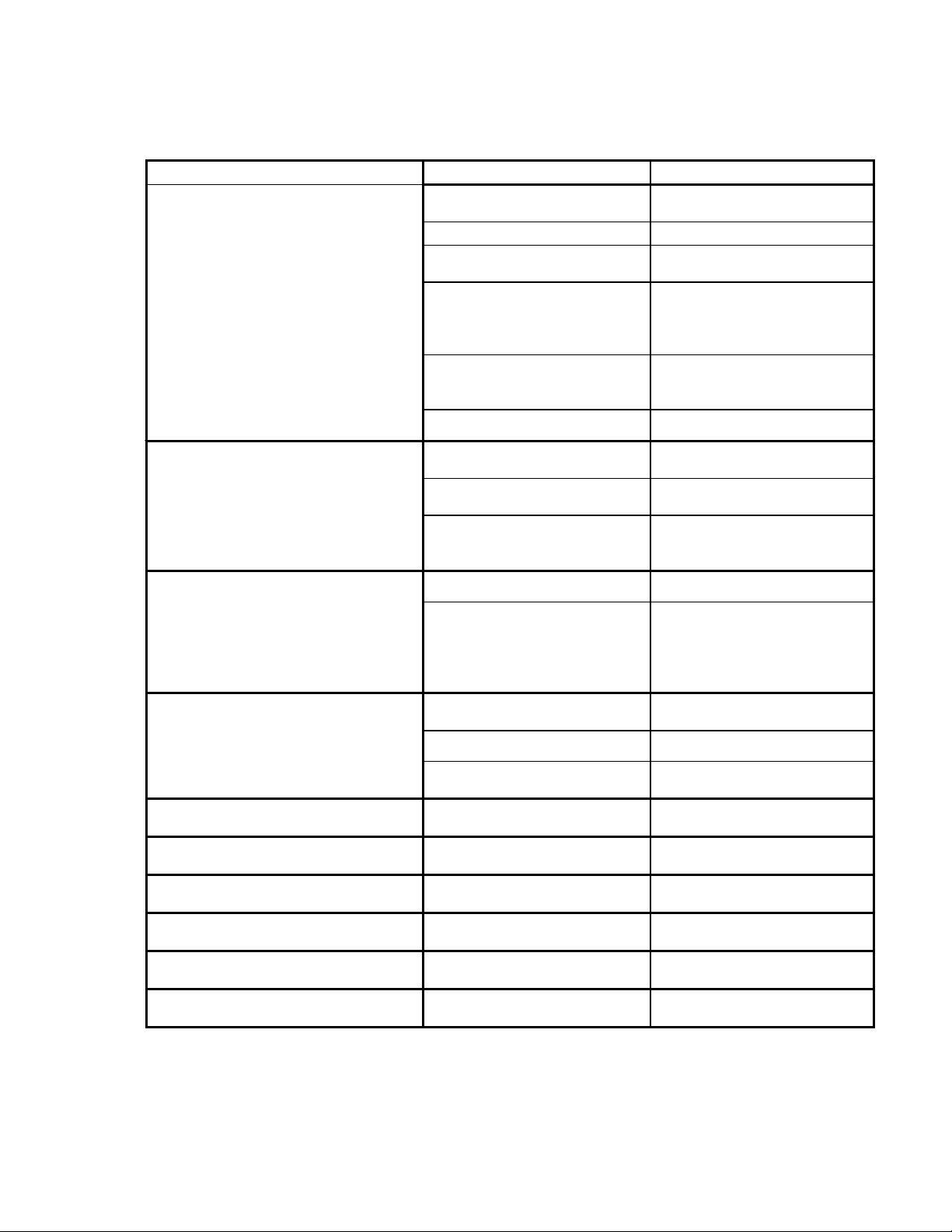

MACHINE TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

No power to machine Tripped electrical circuit

breaker in fuse box of building

Faulty power cord Replace power cord

Power switch failure or relay

failure

Tripped circuit breaker Reset circuit breaker. Higher

Internal wiring problem With machine unplugged,

Faulty rectifier Replace rectifier

Electrical Shock Equipment not grounding Follow grounding instructions,

Receptacle not grounded Have an electrician inspect

Interal electrical problem Check for any loose wire

Nuisance tripping of circuit breaker Faulty circuit breaker Replace circuit breaker

Check building circuit breaker

Replace power switch or

relay

amp draw may indicate faulty

parts. Find parts not moving

freely and correct as needed.

check for and correct, any

loose wire connections.

pg 2-3

the building’s wiring

connections, replace any

items that are short circuiting

Mechanical problem Test circuit breaker for

continuity. Higher amp draw

may indicate faulty parts. Find

parts not moving freely and

repair or replace.

Brush not turning or scrubbing Faulty bru sh motor/gear box Replace brush motor/gear

box

Belt failure Replace belts

Worn brush motor brushes Replace brushes, check

commutator

Power to motor but motor does not

run

Bearing squealing or grinding in

brush housing

Machine will only run if the green (on)

switch is continuously held down

No flow or uneven flow from jet

(Deluxe only)

Weak flow from clean jet

(Deluxe only)

Pump runs but no flow from jet

(Deluxe only)

Worn brush motor brushes Replace brushes, check

commutator

Worn bearings Replace worn bearing

Defective red (off) switch.

Sends constant “off” signal.

Clogged jet Clean or replace jet

Clogged strainer Clean strainer

Disconnect coupling at

solution tank

86269870 07/11/07

Replace or reconnect wire to

red (off) switch

Attach the quick coupling to

the solution tank

4-2

Loading...

Loading...