Wayne WLS200, WLS75, WLS150, WLS100 User Manual

Operating Instructions and Parts Manual

WLS75, WLS100 WLS150, WLS200

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Lawn Sprinkler

Lawn Sprinkler

Pump

Description

This pump is a high capacity, selfpriming centrifugal pump suitable for lawn sprinkling or other applications where large quantities of water are required. Flammable liquids such as gasoline, chemicals or corrosive liquids should never be used with this pump.

Safety Guidelines

This manual contains information that is very important to know and understand. This information is provided for SAFETY and to

PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following symbols.

Danger indicates an imminently

hazardous situation which, if not avoided, will result in death or serious injury.

Warning indicates a potentially

hazardous situation which, if not avoided, could result in death or serious injury.

Caution indicates a potentially hazardous

situation which, if not avoided, may result in minor or moderate injury.

Notice indicates important

information, that if not followed, may cause damage to equipment.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or its power cord may

contain chemicals, including lead, known to the State of California to cause cancer and birth defects or other reproductive harm. Wash hands after handling.

GENERAL SAFETY INFORMATION

1. Read these rules and

instructions carefully. Failure

MANUAL

to follow these instuctions could cause serious bodily injury and/or property damage.

This pump is nonsubmersible.

Pump only clear water. Do not pump flammable or explosive fluids such as gasoline, fuel oil,

Pump only clear water. Do not pump flammable or explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in a flammable and/or explosive atmosphere. Personal injury and/or property damage could result.

This pump is not designed to handle

salt water, brine, laundry discharge or any other application which may contain caustic chemicals and/or foreign materials. Pump damage could occur if used in these applications and will void warranty.

All wiring must be performed by a qualified

electrician. The pump must

be installed in compliance with all local and national codes.

2.Connect this product to a grounded circuit equipped with a ground fault interruptor device.

3.Before installing this product, have the electrical circuit checked by an electrician to ensure proper grounding.

4.BE CERTAIN the pump power source is disconnected before installing or servicing pump.

5.Check motor voltage setting on motor end plate and make sure the line voltage of the electrical current supply is correct.

6.Be sure the water source and piping is clear of sand, dirt and scale. Debris will clog pump and void warranty.

7.Failure to protect pump and piping from freezing could cause severe damage and will void the warranty.

8.Do not run pump dry. Follow priming instructions.

Installation

Protect pump from the elements by installing in a basement, garage, tool shed or pump house. Install the pump so the center line of the pump is as close as possible to the water level. Keep installation area clear to provide access for service and maintenance. Protect the pump against flooding and excess moisture.

Make sure the pump has adequate ventilation. The surrounding temperature should not exceed 100°F (38°C) or nuisance tripping of the motor may occur.

PUMP PIPING INSTALLATION

Use new pipe for best results. Galvanized or plastic pipe can be used. When using galvanized pipe, provide independent supports for both suction and discharge piping near the pump to avoid strain on the pump. Minimize use of elbows and fittings to reduce friction loss. Refer to the friction loss chart for specific information.

Increase diameter of suction or discharge piping if length is over 50 feet.

SUCTION PIPING

Install foot valve or strainer screen

over intake of suction piping.

Never use pipe smaller than 2” in diameter for suction piping. The suction pipe must be kept free of air leaks. For horizontal runs, lay pipe from the water source so the upward slope is at least 1/2” per foot. This eliminates trapped air. The threaded inlet of the pump is 2” NPT.

Do not install suction piping near

swimming areas.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

© 2009 Wayne Water Systems |

For parts, product & service information |

320201-001 4/09 |

visit www.waynepumps.com

Operating Instructions and Parts Manual

WLS75, WLS100 WLS150, WLS200

Installation (Continued)

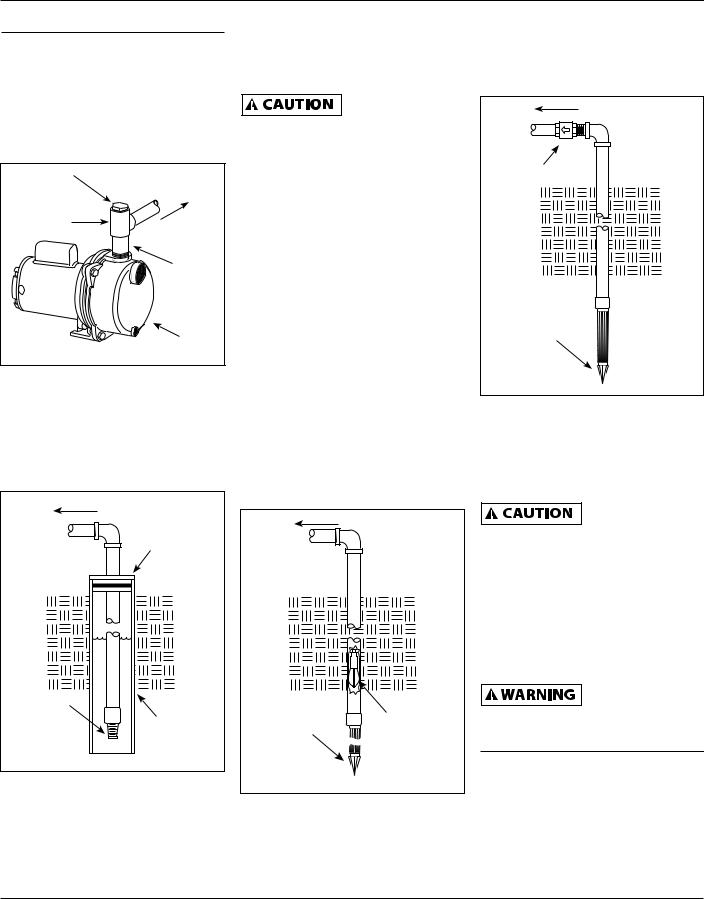

DISCHARGE PIPING

Install a 1-1/2” pipe tee in the pump discharge to allow easy priming. Plug the end of the tee opposite the pump to allow the branch piping to go to the spray nozzles (See Figure 1). Remove the pipe plug to fill the pump with water for priming.

Pipe Plug |

To Spray |

|

Nozzles |

1-1/2” Pipe |

|

Tee |

|

|

Short |

|

Section |

|

of Pipe |

Figure 1 |

Pump |

|

CONNECTION TO WATER SOURCE

The maximum vertical suction lift from pump to the water level is 25 feet.

DRILLED WELL

1.Install a foot valve on the first section of pipe (see Figure 2).

To Pump

Well Seal

Foot Valve

Well

Casing

Figure 2

2.Lower the pipe into the well.

3.Add pipe until the foot valve is 10 feet below the lowest anticipated water level.

Leaking joints or couplings will allow air to leak into the pipe and cause poor pump operation. Make sure to use pipe joint compound or Teflon® tape on all pipe connections.

Locate foot valve no closer than 2 feet

from the bottom of the well so sand or sediment is not drawn into the system.

4.After the proper depth is reached, install a well seal or pitless adapter to support the pipe.

5.Slope the horizontal pipe upward toward the pump to eliminate trapping air.

6.When using a foot valve, a priming tee and plug above the well seal is recommended.

DRIVEN WELL

•Drive the point several feet below the water table.

NOTE: A packer-type foot valve can be installed in the well (See Figure 3). This type of foot valve allows the well pipe to be filled with water when priming and makes the inlet pipe much easier to test for leaks. Follow the manufacturer’s instructions when installing the packertype foot valve.

As an alternative, an in-line check valve can be used with a driven well (See Figure 4).

To Pump

Drive Point |

Packer Type |

|

Foot Valve |

||

|

Figure 3

It may be necessary to supply the pump with multiple well points to maintain the high flow capability of this pump. Consult with a plumbing professional for appropriate materials and installation instructions.

Leaking joints or couplings will allow air to leak into the pipe and cause poor pump operation. Make sure to use pipe joint compound or Teflon® tape on all pipe connections.

To Pump

Inline Check Valve

Drive Point

Figure 4

Dug Well, Cistern, Lake

And Spring Installation

•Install a foot valve on the inlet pipe and lower into the water.

Locate foot valve no closer than 2 feet

from the bottom of the water source so sand or sediment is not drawn into the system.

NOTE: When a lake is used for the water supply, make sure the suction pipe is deep enough to be submerged at all times. Slope the pipe upward toward the pump to eliminate trapping air. The pipe must be removed during winter months or protected against freezing.

Protect the pipe from damage by

swimmers and boaters.

Electrical Connections

Connect the pump to a separate electrical circuit with a dedicated circuit breaker. Refer to the electrical specifications in wiring chart for recommended circuit breaker and wire size.

Install and maintain wiring for this

www.waynepumps.com

2

Operating Instructions and Parts Manual

WLS75, WLS100 WLS150, WLS200

Electrical Connections

(Continued)

pump in accordance with the National Electrical code and all applicable local electrical codes.

The motor must be grounded by connecting a copper conductor to the grounding screw provided within the wiring compartment.

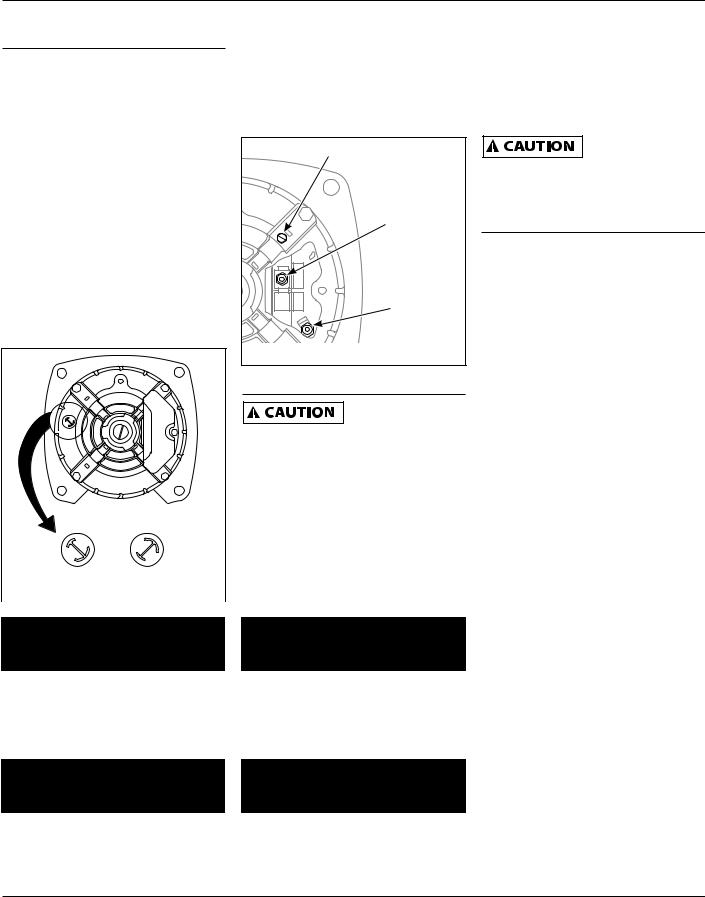

The voltage of power supply must match the voltage of the pump. The WLS75, WLS100 and WLS150 have dual voltage motors preset at the factory to 230 volts. The motors can be converted to 115 volts by turning the voltage selector to the desired voltage (See Figure 5). Use a needle nose pliers to pull the selector out approximately 1/4”, rotate and then reinsert in correct position. The WLS200 cannot be converted; the motor is 230 volts only.

230 V

115 V

115 V

|

|

230 V |

|

|

|

115 V |

|

|

|

Figure 5 - Voltage Selector |

|

|||

|

|

|||

Lift |

3/4 HP Pump Capacity in |

|||

GPH Operating Pressure (psi) |

||||

in |

|

|

|

|

Feet |

10 |

20 |

30 |

|

5 |

3900 |

3320 |

2320 |

|

10 |

3780 |

3120 |

2100 |

|

15 |

3600 |

2910 |

1190 |

|

20 |

3250 |

2670 |

990 |

|

25 |

3010 |

2560 |

840 |

|

Lift |

1 HP Pump Capacity in GPH |

|||

Operating Pressure (psi) |

||||

in |

||||

|

|

|

||

Feet |

10 |

20 |

30 |

|

5 |

4410 |

3920 |

2570 |

|

10 |

4180 |

3520 |

2300 |

|

15 |

3830 |

3340 |

1780 |

|

20 |

3680 |

3060 |

1160 |

|

25 |

3340 |

2720 |

1260 |

|

CONNECTING WIRES

Terminal cover must be in place for safe operation. Ground in accordance with local and national electrical codes. Keep fingers and objects away from openings and rotating parts. Disconnect power sources before touching internal parts. See figure 6 for appropriate wiring locations.

Ground Screw

Ungrounded

Line (L1)

Terminal

Board (L2)

Figure 6 - Connecting Wire

Operation

Never run the pump dry. Running

pump without water may cause seal damage. Fill the pump with water before starting.

PRIMING THE PUMP

After pump installation is complete, the pump must be primed. Remove the pipe plug in the discharge piping and fill the pump and suction pipe with clean water. Turn power to pump on. If the pump does not pump water in 10 minutes, turn off the pump and refill with clean water.

Lift |

1-1/2 HP Pump Capacity in |

||||

GPH Operating Pressure (psi) |

|||||

in |

|

|

|

|

|

Feet |

10 |

20 |

30 |

40 |

|

5 |

4790 |

4480 |

3480 |

2060 |

|

10 |

4610 |

4310 |

3190 |

1520 |

|

15 |

4320 |

4040 |

2900 |

0 |

|

20 |

3900 |

3720 |

2680 |

0 |

|

25 |

3810 |

3300 |

2390 |

0 |

|

Lift |

2 HP Pump Capacity in GPH |

||||

Operating Pressure (psi) |

|||||

in |

|||||

|

|

|

|

||

Feet |

10 |

20 |

30 |

40 |

|

5 |

5980 |

5560 |

4310 |

3060 |

|

10 |

5410 |

5220 |

4090 |

2880 |

|

15 |

5230 |

4980 |

3900 |

2570 |

|

20 |

4120 |

3840 |

3510 |

2210 |

|

25 |

3980 |

3600 |

3300 |

0 |

|

If the pump does not operate after repeated attempts, check the following:

1.Vertical distance of pump to water level must not be over 25 feet.

2.Suction piping must be air tight.

3.Be sure valve(s) are open if used in discharge or suction piping.

Never run the pump with a closed

or clogged discharge. The water inside the pump could boil and damage the pump.

Maintenance

Maintain adequate ventilation for the pump motor. The motor bearings are permanently lubricated at the factory. Additional lubrication is not required.

DRAINING FOR WINTER

Always protect pump and piping against freezing temperatures. If there is any danger of freezing, drain the system. To drain the system:

1.Remove the pipe plug from the discharge tee.

2.Remove the 1/4” plug from the lower front face of the pump.

3.Drain all piping below the frost line.

www.waynepumps.com

3

Operating Instructions and Parts Manual

WLS75, WLS100 WLS150, WLS200

WIRING CHART - RECOMMENDED WIRE AND FUSE SIZES

|

|

|

|

|

|

Distance in Feet From Motor to Supply |

|||

|

|

|

|

Max. |

Fuse |

0 |

51 |

101 |

201 |

|

|

|

|

Load |

Rating |

50 |

100 |

200 |

300 |

|

Model |

HP |

Volts |

Amps |

Amps |

|

(AWG Wire Size) |

|

|

|

WLS75 |

3/4 |

115 |

13.5 |

20 |

12 |

12 |

10 |

10 |

|

|

|

230 |

7.0 |

15 |

14 |

14 |

12 |

12 |

|

WLS100 |

1 |

115 |

14.8 |

20 |

12 |

12 |

10 |

10 |

|

|

|

230 |

7.4 |

15 |

14 |

14 |

12 |

12 |

|

WLS150 |

1-1/2 |

115 |

17.0 |

30 |

10 |

10 |

8 |

8 |

|

|

|

230 |

8.5 |

15 |

14 |

14 |

12 |

12 |

|

WLS200 |

2 |

230 |

12.0 |

15 |

14 |

14 |

12 |

12 |

|

|

|

|

psi Friction Loss in 100 Feet of Plastic Pipe* |

|

|

|

|

|||

|

Pipe |

|

|

|

(Gallons per Hour) |

|

|

|

|

|

|

|

Size |

1200 |

1500 |

1800 |

2400 |

3000 |

3600 |

4800 |

6000 |

7200 |

|

|

1-1/4 |

2.6 |

3.9 |

5.5 |

9.4 |

14.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-1/2 |

1.2 |

1.9 |

2.6 |

4.4 |

6.7 |

9.4 |

15.9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

0.6 |

0.8 |

1.3 |

2.0 |

2.8 |

4.7 |

7.1 |

10.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2-1/2 |

|

|

|

0.6 |

0.8 |

1.2 |

1.3 |

3.0 |

4.2 |

|

* Multiply by 1.8 for steel pipe

Troubleshooting Chart

Symptom |

Possible Cause(s) |

|

|

|

|

Motor will not run |

1. |

Disconnect switch is off |

|

2. |

Fuse is blown |

|

3. |

Starting switch is defective |

|

4. |

Wires at motor are loose, |

|

|

disconnected or wired |

|

|

incorrectly |

Corrective Action

1.Be sure switch is on

2.Replace fuse

3.Replace starting switch

4.Refer to wiring instructions. Check and tighten all wiring

Capacitor voltage may be hazardous. To discharge capacitor, touch short capacitor

terminals with an insulated screwdriver. BE SURE to hold handle of screwdriver while making contact with capacitor terminals.

Motor runs hot and |

1. |

Motor is wired incorrectly |

1. |

Refer to wiring instructions |

overload kicks off |

2. |

Voltage is too low |

2. |

Check with power company. Install heavier wiring if wire size |

|

|

|

|

is too small (See wiring chart) |

|

3. |

Pump house not properly vented |

3. |

Be sure pump has sufficient ventilation to cool the motor |

Motor runs but no |

1. |

Pump in new installation did |

1. |

New installation: |

water is delivered |

|

not pick up prime through: |

|

|

Note: Check prime |

|

a. Improper priming |

|

a. Re-prime according to instructions |

before looking for |

|

b. Air leaks |

|

b. Check all connections on suction line |

other causes. |

|

c. Leaking foot valve |

|

c. Replace foot valve |

Unscrew priming |

2. |

Pump has lost prime through: |

2. |

Existing installations: |

plug and see if |

|

a. air leaks |

|

a. Check all connections on suction line and shaft seal |

water is in priming |

|

b. water level below suction of |

|

b. Lower suction line into water and re-prime. If receding water |

hole. |

|

pump |

|

level in well exceeds suction lift, a deep well pump is needed |

|

3. |

Impeller is plugged |

3. |

Clean impeller |

|

4. |

Check valve or foot valve is |

4. |

Replace check valve or foot valve |

|

|

stuck in closed position |

|

|

|

5. |

Pipes are frozen |

5. |

Thaw pipes. Bury pipe below frost line. Heat pit or pump house |

|

6. |

Foot valve and/or strainer are |

6. |

Raise foot valve and/or stainer above well bottom |

|

|

buried in sand or mud |

|

|

|

|

|

|

|

Pump does not |

1. |

Water level in well is lower than |

deliver water to full |

|

estimated |

capacity |

2. |

Steel piping (if used) is corroded |

|

|

or limed, causing excess friction |

|

3. |

Piping is too small in size |

1.A deep well jet pump my be needed (over 25 ft. (7.6M) to water)

2.Replace with plastic pipe where possible, otherwise with new steel pipe

3.Use larger piping

www.waynepumps.com

4

Operating Instructions and Parts Manual

WLS75, WLS100 WLS150, WLS200

For Replacement Parts or Technical Assistance, call 1-800-237-0987

Please provide following information: |

Address parts correspondence to: |

|

- |

Model number |

Wayne Water Systems |

- Serial number (if any) |

101 Production Drive |

|

- |

Part description and number as shown in parts list |

Harrison, OH 45030 U.S.A. |

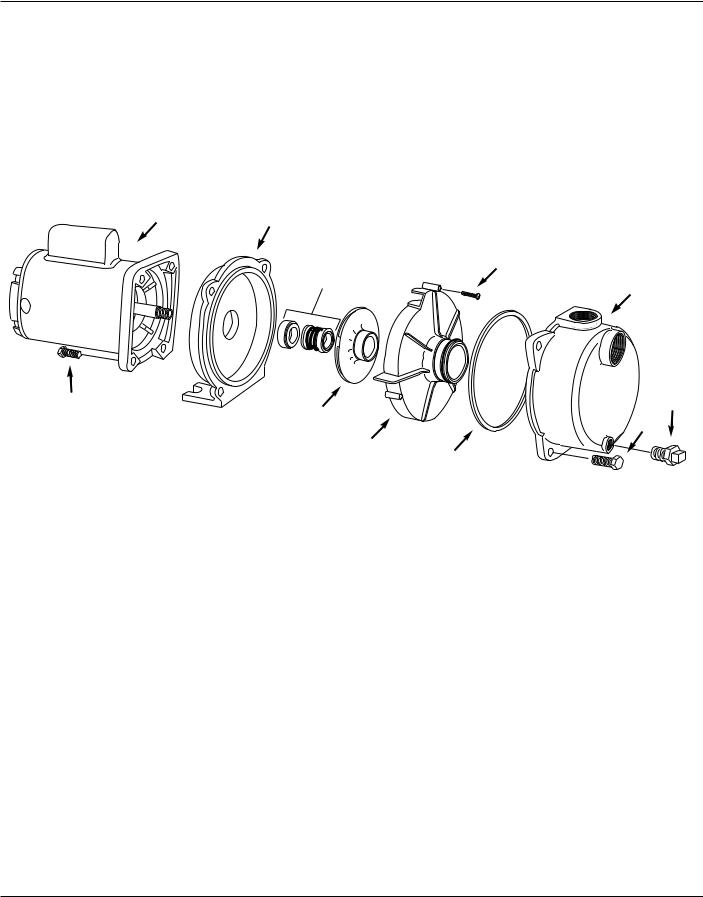

1 |

3 |

|

7

4

2

5

6

8

9

11

10

|

Ref. |

|

Part Number for Models: |

|

|

|

|

|

|

No. Description |

WLS75 |

WLS100 |

WLS150 |

WLS200 |

Qty. |

|

|

1 |

Motor |

32031-001 |

32015-001 |

32020-001 |

32021-001 |

1 |

|

|

2 |

3/8”-16 x 1” Hex cap screw |

16334 |

16334 |

16334 |

16334 |

4 |

|

|

3 |

Sealplate |

41011-001 |

41011-001 |

41011-001 |

41011-001 |

1 |

|

|

|

4 |

Shaft seal assembly |

15559-002 |

15559-002 |

15559-002 |

15559-002 |

1 |

|

5 |

Impeller |

29806-001 |

29805-001 |

29804-001 |

29803-001 |

1 |

|

|

6 |

Diffuser |

29807-001 |

29807-001 |

29807-001 |

29807-001 |

1 |

|

|

7 |

10-24 x 1” Phillips screw |

67017-001 |

67017-001 |

67017-001 |

67017-001 |

3 |

|

|

8 |

Square ring |

19013-001 |

19013-001 |

19013-001 |

19013-001 |

1 |

|

|

|

|

|

|

|

|

|

|

|

9 |

Volute |

41010-001 |

41010-001 |

41010-001 |

41010-001 |

1 |

|

|

10 |

7/16”-16 x 1.25” Hex cap screw |

67018 |

67018 |

67018 |

67018 |

4 |

|

|

11 |

1/4” NPT Sq. hd. pipe plug |

16314-002 |

16314-002 |

16314-002 |

16314-002 |

1 |

|

|

www.waynepumps.com

5

Operating Instructions and Parts Manual

WLS75, WLS100 WLS150, WLS200

Limited Warranty

For one year from the date of purchase, Wayne Water Systems ("Wayne") will repair or replace, at its option, for the original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Wayne to be defective in materials or workmanship. Please call Wayne (800-237-0987) for instructions or see your dealer. Be prepared to provide the model number and the serial number when exercising this warranty. All transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect, improper installation, improper maintenance, or failure to operate in accordance with Wayne’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Wayne or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST send a copy of the purchase receipt along with the material or correspondence. Please call Wayne (800-237-0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

www.waynepumps.com

6

Loading...

Loading...