Universal L60 User Manual

L60

Label Applier

Operator’s Manual

Serial #

Operator’s Manual

Version: D 12/18/2001

The information contained in this manual is the sole property of Universal Labeling Systems, Inc. No parts of this manual may be reproduced or transmitted in any form or purpose other than the purchaser’s personal use without prior consent of Universal Labeling Systems, Inc.

Universal Labeling Systems, Inc.

3501 8th Ave South, Saint Petersburg, FL 33711

Phone (727) 327-2123 Fax (727) 323-4403

Page 2

Table of Contents |

|

|

SECTION 1 |

OVERVIEW ................................................................................................. |

4 |

|

INTRODUCTION...................................................................................................... |

4 |

|

UN-PACKING INSTRUCTIONS .............................................................................. |

5 |

|

PRODUCT WARRANTY ......................................................................................... |

6 |

|

SPECIFICATIONS ................................................................................................... |

7 |

SECTION 2 SETUP AND OPERATION ......................................................................... |

8 |

|

|

ASSEMBLING THE L60.......................................................................................... |

8 |

|

FUNCTION OF UNWIND ASSEMBLY.................................................................... |

9 |

|

WASTE REMOVAL ............................................................................................... |

10 |

|

MOUNTING THE L-60 ........................................................................................... |

11 |

|

THEORY OF OPERATION.................................................................................... |

12 |

|

LOWER “HALL EFFECT” SENSOR (OPTIONAL) .............................................. |

13 |

|

“SMART HEAD” (OPTIONAL) ............................................................................. |

14 |

|

EXPLANATION OF LABEL TRANSFER.............................................................. |

15 |

|

WEBBING THE L60 .............................................................................................. |

17 |

|

RUNNING THE L60 ............................................................................................... |

19 |

|

LABEL SENSING STAR WHEEL ......................................................................... |

20 |

|

DATA LOGIC SENSOR (OPTIONAL) .................................................................. |

21 |

|

LION SENSOR (OPTIONAL) ................................................................................ |

22 |

SECTION 3 |

MAINTENANCE........................................................................................ |

23 |

|

STARWHEEL MAINTENANCE............................................................................. |

23 |

|

GENERAL MAINTENANCE.................................................................................. |

24 |

SECTION 4 |

TROUBLESHOOTING.............................................................................. |

25 |

|

TROUBLESHOOTING (continued)...................................................................... |

26 |

|

TROUBLESHOOTING (continued)...................................................................... |

27 |

|

TROUBLESHOOTING (Registration)................................................................. |

28 |

SECTION 5 |

TECHNICAL.............................................................................................. |

29 |

|

VACUUM HEAD FUNDAMENTALS..................................................................... |

29 |

TECHNICAL SUPPORT ..................................................................................................... |

30 |

|

DRAWINGS AND BILL OF MATERIALS........................................................................... |

31 |

|

|

MAIN ASSEMBLY ................................................................................................. |

31 |

|

FRONT SIDE PANEL ASSEMBLY ....................................................................... |

31 |

|

REAR SIDE PANEL ASSEMBLY ......................................................................... |

31 |

|

BELT TENSIONER ASSEMBLY........................................................................... |

31 |

|

TAMP ASSEMBLY ................................................................................................ |

31 |

|

BLOW ASSEMBLY ............................................................................................... |

31 |

|

GAUGE ASSEMBLY ............................................................................................. |

31 |

|

FRONT PANEL ASSEMBLY................................................................................. |

31 |

|

FRONT PANEL (PLC) ASSEMBLY...................................................................... |

31 |

|

GUIDE ASSEMBLY............................................................................................... |

31 |

|

VALVE ASSEMBLY .............................................................................................. |

31 |

|

UNWIND ASSEMBLY ........................................................................................... |

31 |

|

WEBBING DIAGRAM............................................................................................ |

31 |

|

TAMP PNEUMATIC DIAGRAM ............................................................................ |

31 |

|

BLOW PNEUMATIC DIAGRAM ........................................................................... |

31 |

|

LION EYE OPTICAL LABEL SENSOR ASSEMBLY ........................................... |

31 |

|

DATA LOGIC OPTICAL LABEL SENSOR ASSEMBLY ..................................... |

31 |

|

RECOMMENDED SPARE PARTS ....................................................................... |

31 |

|

POWER MODULE SETUP SHEET....................................................................... |

31 |

|

ELECTRICAL DIAGRAM ...................................................................................... |

31 |

|

ELECTRICAL DIAGRAM (PLC) ........................................................................... |

31 |

Page 3

SECTION 1 OVERVIEW

INTRODUCTION

Featuring solid-state circuitry and an AC Synchronous Motor, the L60 is a high performance, low maintenance label applicator. The L60 applicator is designed to apply a pressure sensitive label to a product through the action of an air-cylinder-mounted, or blow-on, vacuum head. The labeling process can be automatic when interfaced with a conveyor, or semi-automatic with a table-based product fixture. When triggered, the L60 Tamp vacuum head extends to meet the product. When the air cylinder returns the vacuum head to the home position, another label is indexed onto the head and is waiting to be applied to the next product. The L60 BLOW vacuum head blows the label onto the product, and another label is indexed and ready for the next product.

Switches:

There are two switches on the front panel of the applicator. The Main switch turns the power on or off, and if a Hot Stamp Coder is used, will allow it to heat up. The Motor switch controls the motor that turns the drive roller and waste rewind. Fig 1

Product Detection:

The product can be detected on the leading or trailing edge. To change from leading to trailing edge, set switch 4 of the power module to the ON position. (See lower left of Drawing L15-D-02)

Recommended Settings:

There are many different label compositions, so there is no one set of machine settings (air pressure, etc.), which will work on all types of labels. The following recommended air regulator settings will give the operator a place to start.

Set the air cylinder pressure to about 15 psi. The vacuum pump input pressure will vary according to label density and size, which you can start at 5-10 psi. Turning the regulator knobs on the side of the machine can regulate air pressures. Fig 1

Air regulators

Switches

Fig 1

Page 4

UN-PACKING INSTRUCTIONS

When the machine is received, the shipping carton will contain the following items.

Fig 2

1.L-60 Body.

2.Unwind assembly.

3.Unwind assembly-backing plate.

4.Unwind assembly label roll retainer.

5.Air Fitting Part #100373 ¼ NPT x 3/8.

6.10’ of 3/8” hose.

7.Product switch in a padded envelope.

8.This manual in manila envelope.

Extended peeler bar assembly (OPTIONAL). See notes below. **

5

1

6

2

7

3

4

8

Fig 2

**When the machine is ordered with an extended peeler bar assembly, it will be packed disassembled from the machine body.

Remove the machine body by placing your hands under the bottom for lifting. Refer to the packing list, and check all packing materials to insure all of the machine parts and accessories are accounted for.

Page 5

PRODUCT WARRANTY

Universal Labeling Systems, Inc. warranties all parts to be free from defects in material and workmanship for a period of one year from the date of shipment from our facility.

This guarantee is based upon equipment being used 8 hours per day, or 40 hours per week, or in any increment which does not total more than a single shift operation, or 2,080 hours per year. Warranty will be reduced proportionally.

This warranty does not cover parts failure caused by lack of normal maintenance, abuse or misuse of the equipment.

PERFORMANCE GUARANTEE

All equipment manufactured by Universal Labeling Systems, Inc. carries a 30-day performance guarantee. If your machinery does not perform as described in our quote to you within 30 days of shipping, Universal Labeling Systems, Inc. will make every attempt to correct it. If after a reasonable period of time, the machinery does not meet the specified performance, we will take your machine back and reimburse you in full.

Page 6

SPECIFICATIONS

Electrical Power: |

115VAC, 3 Amps, 60Hz |

Compressed Air: |

Clean, Dry, 40PSI, 5CFM |

Lubrication: |

The L60 label Applicator requires no lubrication |

Label Apply speed: |

Depends on label size |

Label Size: |

4-3/8” wide on 3” Core -12” Diameter roll |

Optional Wide label kit: |

6-3/8” wide on 3” Core -12” Diameter roll |

Standard Size: |

19” Wide x 21” Deep x 24.75” Tall |

Weight: |

62 lbs (23.44 Kg) |

L60 w/ Base Plate |

68 lbs (25.71 Kg) |

Page 7

SECTION 2 SETUPAND OPERATION

ASSEMBLING THE L60

Using a square, mount the Unwind Assembly to the back of the L60 using the 2 screws provided. The top screw is a ¼-20x1-1/2” socket head cap screw, the bottom screw is ¼-20x1-1/4”.

Please note:

Screws.

Top one is longer.

Fig 3

Maximum reliability is assured when the Compressed Air supplied to the L60 is Clean & Dry. Over time, moisture will take its toll on the Solenoid Valves and Air cylinder. Also it is not recommended to add Oil to the Compressed Air line supplied to the L60. The air valves and air cylinder will eventually fail and oil will end up on the label from the Air Assist tube which helps feed the label on to the vacuum head. This will cause the label to not adhere properly to the product.

Run 40 psi @5CFM minimum compressed air to the L60 and procure necessary fittings to make the connection to the air inlet located on the side opposite the label drive and rewind. DO NOT CONNECT THE AIR TO THE UNIT AT THIS TIME.

Page 8

FUNCTION OF UNWIND ASSEMBLY

The unwind is simple, but important to the operation of the L-60 machine. When the motor starts, the web and labels are pulled through the machine by the drive roller.

The label stock pulls on the brake arm, releasing the brake, and allows the roll of labels to unwind. When the motor stops, the brake arm returns to the rest position.

This movement tightens the brake band around the 3" diameter main unwind hub and the roll of labels stops unwinding.

The L-60 has a fixed speed, AC drive motor that transmits power to the drive roller. The AC drive is directly influenced by the load it is trying to pull. In this case, the load is the tension of the brake arm spring and the weight of the roll of labels. The brake arm spring shown below in Fig # 4, should be fastened to the unwind assembly mounting bar in the tapped hole which provides the least amount of tension at the brake arm. (The hole closest to the hub.)

If the L-60 is dispensing a long label (10" for example), you may have to increase the tension on the brake arm spring (Move spring attachment point to lower hole -

See Fig # 4) to keep the brake arm from bottoming out.

The length and speed figures mentioned above are only examples. Your observation of the unwind operation will be the best indication of when a tension change may be needed.

Dancer Arm

Spring located in top hole. Move to bottom hole for larger labels.

Fig 4

Page 9

WASTE REMOVAL

1.To remove waste web, turn off the machine, and remove the rewind spool clamp.

Fig 5

2.Tear the web first.

3.While holding the rewind backing plate, turn the whole waste web in the opposite direction and pull.

Page 10

MOUNTING THE L-60

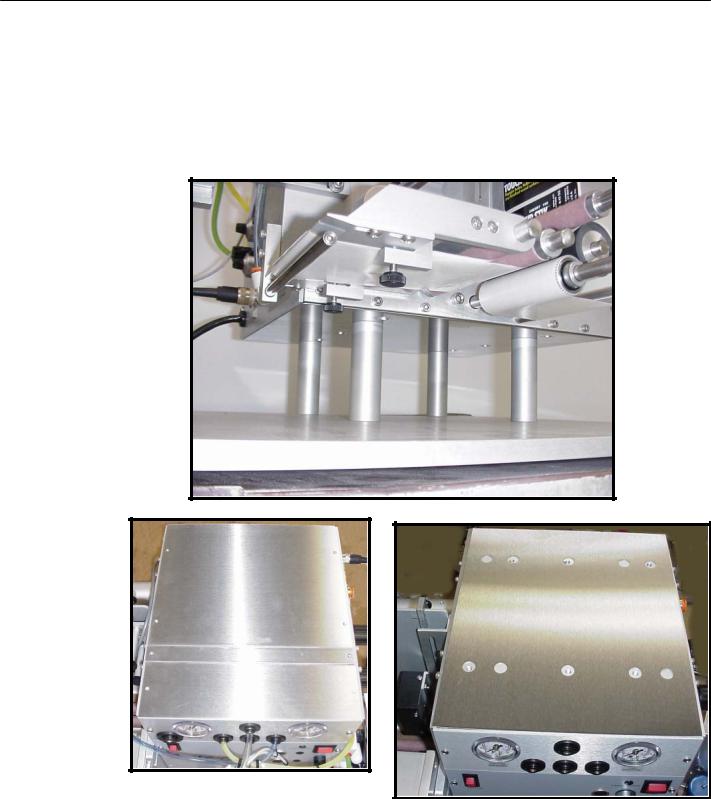

The L-60 can be mounted from the bottom or the top. The most common method is bottom mount (see Fig 6). Fig 6 shows the L-60 mounted to the optional base plate with standoffs. Fig 7 shows the top of an L-60 ordered with standard mounting and can accept a coder. Fig 8 shows an L-60 Ordered for top mount.

Six holes have been provided in the two lower tie bars. Any combination may be used. The hole pattern most used is 6-1/2" square, which is where the 4 legs are shown in Fig. 6. All the holes are tapped 1/4-20.

Fig 6

Fig 7

Fig 8

Page 11

THEORY OF OPERATION

TAMP CYLINDER RETURN OPTIONS

Dwell Timer (Standard on all L60 Tamp Applicators)

“Dwell Time” is the time duration of the signal that opens the valve, which activates the air cylinder. This time duration can be adjusted with the threeturn dial located on the front panel of the machine. Turn the dial clockwise and the duration to

Dwell timer

Fig 9

increase the dwell time signal. After the label apply signal is given, the air cylinder extends and the time duration terminates, the air cylinder then retracts and returns the vacuum head to the home position.

Setting the Dwell time:

1.Turn the dial counter-clockwise to “0”.

2.Activate foot switch or product sensor. You will notice that the air cylinder will not extend.

3.Turn the dial to “10”. The air cylinder should extend a short distance and return.

4.Turn the dial until the vacuum head touches the product. The dwell time is now set. The distance of the machine from the product and air pressure will affect this setting.

Page 12

LOWER “HALL EFFECT” SENSOR (OPTIONAL)

Some L60 tamp label applicators are equipped with two sensors that are attached to the air cylinder. One is located at the top of the cylinder and the other is located below it. The upper sensor sends a signal to the machine so another label will be dispensed onto the vacuum head. The lower sensor can be adjusted to control or limit the stroke of the air cylinder that returns the vacuum head to the home position.

The lower sensor is the only one that may require adjustment.

Hall effect |

Hall effect |

|

sensors. |

connections. |

|

|

|

|

|

|

|

Fig 11

Fig 10

Adjusting the Lower “Hall Effect” Sensor:

1.With Main switch “On” and Motor switch “Off”.

2.Disconnect air supply or turn tamp regulator “Off”.

3.Bring Tamp Head down to new product height.

4.Loosen Phillips screw on Hall Effect Sensor.

5.Slide sensor to top of cylinder, then down until the indicator light on the sensor lights up.

6.Tighten the Phillips screw on the sensor.

Page 13

“SMART HEAD” (OPTIONAL)

The Smart Head is used if there is a variation in height of the product or the location of the product on the conveyor cannot be controlled. Simply put, the air cylinder is going to travel it makes contact with the product. A “smart head“ vacuum head is constructed so that the pad that holds the label compresses when the label is applied. When a sensor detects a specific amount of compression, it sends a signal to the machine telling the air cylinder to return the vacuum head to the home position.

Sensor

Fig 12

“Smart head” connection plug

Fig 13

Page 14

EXPLANATION OF LABEL TRANSFER

As the label is being peeled, it should first contact the center of the bevel on the

Vacuum Head. This will deflect the label slightly downward. The air from the Air Assist Tube will keep the label up against the face of the Vacuum Head.

NOTE: The label is deflected downward so that after it is transferred to the head, it will be resting in a position below the peeler plate edge. This is done so the label will not contact the peeler plate edge, as it is being tamped or blown onto the product.

Label deflecting off center of bevel

Fig 14

With the product sensor plugged into the proper receptacle, you can cycle the applicator by breaking the beam (photo eye) or tripping the foot switch or micro switch in the fixture. The foot or micro switch in the fixture are used when the L60 is operated as a semi-automatic labeling device, while a photoelectric switch is used when the L60 is mounted in line for automatic label application. When activated, the motor will be turned on and the air will rush through the Air Assist Tube assisting the label transfer. The amount of air rushing through the tube is most critical to a smooth transfer and ultimately the accuracy of the Label Applicator. All the applicators are tested at the factory and the Air Assist Tube airflow is set at that time.

However, different label stocks react differently during the transfer process, therefore, the following procedure should be employed if the proper label transfer cannot be achieved.

Page 15

Air Assist Tube

The Air Assist (Drawing L60-I-30D #26) is a tube with a series of holes through which air rushes assisting the transfer of the label to the Vacuum Tamp or Blow Head. The air will rush through the tube only when the motor is running and the label is being peeled and transferred.

Air

Assist tube

Fig 15

It is our experience that as the roll of labels becomes smaller in diameter, some labels tend to curl after they are peeled from the backing web. The Air Assist tube blows the label up as it is being peeled, assisting the label onto the Vacuum Head. It is regulated by a needle valve (Drawing L60-I-30D #28) attached to the Air Assist Tube on the front of the machine. This air is supplied by the main incoming line and is subject to house line pressure. Experience will tell you how much air is needed to assist the label onto the vacuum head.

Adjusting the Air Assist Tube air pressure

1.Close the needle valve at the end of the Air Assist Tube by turning it clockwise.

2.Cycle the applicator by triggering the Product Switch Assembly.

NOTE: The label will peel, but not transfer to the head.

3.Open the needle valve by turning it counter clockwise ½ turn.

4.Repeat steps 2-3 until the label transfers onto the head with little or no deviation from a straight-line motion.

Page 16

WEBBING THE L60

Fig 16

1.Turn off the Main Power switch (22) on the Front Panel

2.Loosen the black thumbscrew (19).

3.Slide off the removable label retainer (20).

4.Place a roll of labels on the Unwind Hub (01).

5.Loosen the Socket Head Cap Screw (02) on the Clamp of the Unwind Backing Disc (03) and position the roll of labels so the labels track centered on the Vacuum Head (06) when peeled off (See FRONT VIEW). (NOTE: For round or oval labels, it is important that the Star Wheel (05) be on the centerline of the label).

6.NOTE: If the unit is equipped with photoelectric label sensing or a clear label sensor, the position of the sensor relative to the label is not critical in most cases. The clear label sensor detects the difference in thickness from the label to the backing material. Metalized graphics or alphanumeric characters will cause this sensor to false trigger. Locate the sensor away from the path of metalized material. (See SIDE VIEW PHOTO SENSOR)

7.Replace the removable label retainer (20) and tighten thumbscrew (19).

8.Pull the web over the Brake Arm (06) and down between the Web Guides (07) on the Label Guide Support Plate (08). (NOTE: If equipped with photoelectric sensor, slide web between white idler roller and web drag (21).

9.Adjust the Web Guides (07), so the web is held with minimum side play but still moves freely.

Page 17

10.Pull the web under the Star Wheel and down between the first Idler Roll (09) and the Label Guide Support Plate (08), then forward over Idler Roll (10) and under Idler Roll (11).

11.NOTE: There are 2 Web guides located here also. Adjust them as above in Step 8.

12.Next, pull the web between the Peeler Plate (12) and the Web Drag (13).

13.Pull the web until approximately 18” extends from the peeler plate, Remove any labels that are on this part of the web.

14.Bring the web back between the Peeler Plate (12) and Air Assist Tube (14), under Idler Roll (10) then up around the Drive Roller (15).

15.Push the Drive Roller (15) away from the Nip Roller (16).

16.Slide the web between the Nip Roller (16) and Drive Roller (15), under the Web Stand-Off Stud (17) then up to the Rewind Spool (18).

17.Secure the web around the Rewind Spool using Web Retention Clip (23) and turn the Rewind Spool until the web is held firmly. This may require pulling even more web, which will peel off some labels. Catch these labels so they don’t stick on something.

18.Grasp the Rewind Spool and turn it counterclockwise for Right Hand, or clockwise for Left Hand to take up slack in the web.

19.Loosen the thumbscrew on the Web Drag Assembly (13) and apply moderate pressure by lifting up on the thumbscrew, forcing the thin Web Drag Plate down on the labels. This will keep the label from buckling as it is fed onto the vacuum head.

Page 18

RUNNING THE L60

1.Turn the main switch ON (01).

2.Turn motor switch ON (02).

3.Connect air supply. CAUTION: This may bring the Tamp Head up abruptly.

Keep fingers clear.

4.Cycle the machine several times (trigger the Product Switch (09)) and observe the label web tracking. Web tracking should settle to a consistent line. Once you have determined a consistent line has been achieved, set the web guides on each side of the web.

NOTE: To ensure the label feeds properly onto the Vacuum Head (04), the Head (04) must be as close as possible to the edge of the peeler bar (10), without hitting it.

1.Loosen the two Thumbscrews (05) that hold the Star Wheel Assembly (06).

2.Slide the assembly up until the Star Wheel completely turns over and is down on a flat side.

3.Next, slide the Star Wheel Assembly (06) up or down until the point of the Star

Wheel (07) catches the lead edge of a label (08).

4.Tighten the Thumbscrews (05).

5.Trigger the Product Switch (09) to dispense a label.

6.It may be necessary to repeat steps 5 several times.

7.It may also be necessary to adjust the air assist blow tube pressure (See Air

Assist Tube on page 9)

NOTE: The position of the label relative to the peeling edge can also be adjusted via the three-turn dial on the front panel marked “OFF DELAY” if your machine is equipped with this feature. Release the lock (black tab) and turn clockwise for more delay.

Fig 17

Page 19

LABEL SENSING STAR WHEEL

The star wheel causes the applicator to stop dispensing a label. When the star wheel is down on a flat side, it will slide over the label until the lead edge of the next label contacts the point of the wheel causing the wheel to turn over. As it turns up on a point and back down, the star wheel arm activates a small micro-switch breaking the circuit, thus stopping the advance of the label web. If the star wheel arm fails to activate the switch as it turns over the applier will dispense labels continuously.

NOTE: If the unit is equipped with photoelectric label sensing or a clear label sensor, the position of the sensors relative to the label is not critical in most cases. The clear label sensor detects the difference in thickness from the label to the backing material. Metalized graphics or alphanumeric characters will cause this sensor to false trigger. Locate the sensor away from the path of metalized material.

Star Wheel Adjustment Procedures

Loosen the two screws (2 and 7), which hold the mounting plate (9) to the mounting bracket (1). The screw hole (7) is slotted allowing the plate to move toward or away from the label guide support plate (6). With the star wheel (5) laying flat against the label web, move the mounting plate (9) in toward the label web as far as it will go.

Then slowly bring it back until the micro-switch (3) activates. (A small “click” will be heard when this occurs). Tighten the screws (2 and 7) to hold the plate in this position. To be sure that tightening the screws did not change the position of the plate, check by raising the star wheel off the label web. A “click” should be heard when the star wheel is raised and also when it is lowered. A further check should be made by pulling the label web under the star wheel until it starts to turn up on a point. A “click” should be heard at this point and also as the star wheel drops back down onto a flat side. Be sure that the spring (8) is attached to the star wheel arm

(4) as this assures a firm contact of the star wheel to the label.

1

9 |

2 |

3

4

8

5

6

7

Fig 18

Page 20

DATA LOGIC SENSOR (OPTIONAL)

Auto SET button

OUT Light

READY Light

Fig 19

1.Remove one label from the liner to a get a bigger liner area.

2.Move the liner underneath the sensor cross hairs. Push and hold “Auto SET” button until the green “READY” light turns off. Let go of the button.

3.The “READY” light will begin to flash.

4.Now move the label underneath the cross hairs. Push and hold ”AUTO SET” button until green “Ready” light turns off. Let go of the button.

5.The “READY” light will now be on solid. The set procedure is now complete. If you make a mistake or something went wrong, you can repeat the procedure.

6.If the sensor is set up correctly, the “OUT” light should come on in the label gap.

To make sure that it does, move the label around under the cross hairs to see if it false detects called “hot spots” anywhere on the label.

7.If the sensor detects “hot spots” on the label, repeat steps 1-5 again. This time when you put the label underneath the sensor put the specific “hot spot” under the cross hairs.

8.Turning the power on or off does not affect sensitivity. Once the sensor is programmed the values are burned into the chip inside the sensor.

Page 21

Loading...

Loading...