Troy-Bilt TBSS User Manual

Operator’s Manual

Straight Shaft

Trimmer

TBSS

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

P/N 769-02489 |

(7/06) |

INTRODUCTION

THANK YOU

Thank you for buying this quality product. This modern outdoor power tool will provide many hours of useful service. You will find it to be a great labor-saving device. This operator’s manual provides you with easy-to- understand operating instructions. Read the whole manual and follow all the instructions to keep your new outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS AND SPECIFICATIONS

All information, illustrations and specifications in this manual are based on the latest product information available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2002 MTD SOUTHWEST INC All Rights Reserved.

Troy-Bilt® is a registered trademark of MTD PRODUCTS INC SpeedSpool® is a registered trademark of MTD SOUTHWEST INC

SERVICE INFORMATION

For service call 1-800-520-5520 in the United States, or 1-800-668-1238 in Canada to obtain a list of authorized service dealers near you. For more details about your unit, visit our website at www.troybilt.com.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS. OTHER PATENTS PENDING.

Service on this unit both within and after the warranty period should be performed only by an authorized and approved service dealer.

WARNING!

Read the Operator’s Manual(s) and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

TABLE OF CONTENTS

I. Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . 3-6 A. Important Safety Information . . . . . . . . . . . . . . . 3-4 B. Safety and International Symbols . . . . . . . . . . . . .5 C. Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

II. Operating Instructions . . . . . . . . . . . . . . . . . . . . . |

7-8 |

|

A. Assembling the coupler . . . . . . . . . . . . . . . . . . |

. . 7 |

|

B. Holding the Trimmer . . . . . . . . . . . . . . . . . . . . |

. . 8 |

|

C. Adjusting Trimming Line Length . . . . . . . . . . . |

. . 8 |

|

D. Tips for Best Trimming Results . . . . . . . . . . . . |

. . 8 |

|

E. Decorative Trimming . . . . . . . . . . . . . . . . . . . . |

. . 8 |

|

III. Maintenance and Repair Instructions . . . . . . . . . |

9-11 |

|

A. Line Installation for the SpeedSpool® . . . . . . |

. . 9 |

|

B. Installing a Prewound Reel . . . . . . . . . . . . . . . |

. 10 |

|

C. Cleaning the SpeedSpool® . . . . . . . . . . . . . . . |

. 10 |

|

D. SpeedSpool® Replacement Parts . . . . . . . . . . |

. 11 |

|

E. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

|

F. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

|

G. Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

|

IV. Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . |

. 12 |

|

V. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 13 |

|

VI. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 16 |

|

CONTENTS OF CARTON |

|

|

This unit should consist of the following: |

|

|

• TBSS Straight Shaft Trimmer |

|

|

• |

Hanger |

|

• |

Operator's Manual |

|

• |

Product Registration Card |

|

NOTE: This product has been rated for use on both gas and electric powerheads.

2

RULES FOR SAFE OPERATION

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not, by themselves, eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates danger, warning, or caution. Attention is required in order to avoid serious personal injury. May be used in conjunction with other symbols or pictographs.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock, and personal injury.

WARNING: Failure to obey a safety warning can result in injury to yourself and others. Always follow the safety precautions to reduce the risk of fire, electric shock, and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock, and personal injury.

• IMPORTANT SAFETY INFORMATION •

READ ALL INSTRUCTIONS

WARNING: When using the unit, the safety rules must be followed. For your own safety and that of bystanders, please read these instructions before operating the unit. Please keep the instructions safe for later use.

BEFORE OPERATING

•Carefully read and understand the operator's manual of the unit that powers this Add-On.

•Read this operating instruction manual carefully. Be thoroughly familiar with the controls and the proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

•Do not operate this unit when tired, ill, or under the influence of alcohol, drugs, or medication.

•Never allow children to operate the equipment. Never allow adults unfamiliar with the instructions to use the unit. Never allow adults to operate the equipment without proper instruction.

•All guards and safety attachments must be installed properly before operating the unit.

•Inspect the unit before use.

•Clear the area before each use. Remove all objects such as rocks, broken glass, nails, wire, or string which can be thrown or become entangled in the attachment.

•Use only 0.080 inch (2.03 mm) diameter Genuine Factory Parts™ replacement line. Never use metalreinforced line, wire, or rope, etc. These can break off and become a dangerous projectile.

•This unit was not designed to be used as a brushcutter. Do not attach or operate this unit with any type of brushcutting blade or brushcutting attachment.

SAFETY WARNINGS FOR GAS POWERHEADS AND STRAIGHT SHAFT TRIMMER

WARNING: Gasoline is highly flammable, and its vapors can explode if ignited. Take the following precautions:

•Store fuel only in containers specifically designed and approved for the storage of such materials.

•Always stop the engine and allow it to cool before filling the fuel tank. Never remove the cap of the fuel tank, or add fuel, when the engine is hot. Never operate the unit without the fuel cap securely in place. Loosen the fuel tank cap slowly to relieve any pressure in the tank.

•Mix and add fuel in a clean, well-ventilated area outdoors where there are no sparks or flames. Slowly remove the fuel cap only after stopping engine. Do not smoke while fueling or mixing fuel. Wipe up any spilled fuel from the unit immediately.

•Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

•Move the unit at least 30 feet (9.1 m) from the fueling source and site before starting the engine. Do not smoke. Keep sparks and open flames away from the area while adding fuel or operating the unit.

•Never start or run the unit inside a closed room or building. Breathing exhaust fumes can kill. Operate this unit only in a well ventilated area outdoors.

SAFETY WARNINGS FOR ELECTRIC POWER HEADS AND STRAIGHT SHAFT TRIMMER

WARNING: To reduce the risk of electrical shock, use only extension cords approved for outdoor use, such as an extension cord of cord type SW-A, SOW-A, STW-A, STOW-A, SJW-A, SJOW-A, SJTW-W or SJTOW-A. Extension cords are available from your local retailer. Use only round-jacketed extension cords approved for outdoor use.

3

RULES FOR SAFE OPERATION

•CORD SETS: Make sure your cord set is in good condition. When using a cord set, be sure to use a cord that is heavy enough to carry the current that your unit will draw. An undersized cord set will cause a drop in line voltage resulting in loss of power and overheating. See the operator’s manual for the unit that will power this add-on for the recommended cord size.

•Inspect all extension cords and the unit power connection periodically. Look closely for deterioration, cuts or cracks in the insulation. Also inspect the connections for damage. Replace the cords if any defects or damage appear.

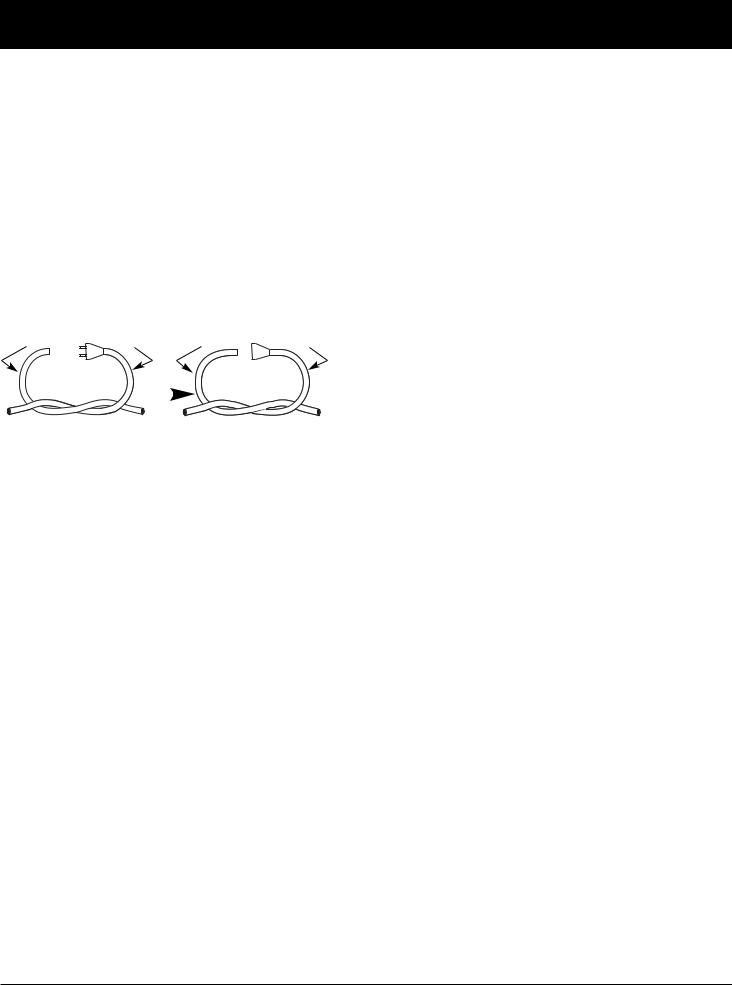

•Prevent disconnection of the straight shaft trimmer powerhead from extension cord during operation by using a plug-receptacle retaining strap, connector, or by making a knot as shown below:

Extension |

|

|

Straight Shaft |

Extension |

|

Straight Shaft |

||

Cord |

|

|

|

Trimmer Cord |

Cord |

|

Trimmer Cord |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•Avoid dangerous environments. Never operate your unit in damp or wet conditions. Moisture is a shock hazard.

•Do not use the unit in the rain. Do not use in or around water.

•Do not handle the plug or unit with wet hands or standing on any wet surfaces.

•Do not leave the unit plugged in when not in use, changing attachments or add-ons, or while being serviced.

WHILE OPERATING

•Keep bystanders, especially children and pets, at least 50 ft (15 m) away.

•Wear safety glasses or goggles that are marked as meeting ANSI Z87.1 standards, and ear/hearing protection when operating this unit. Wear a face or dust mask if the operation is dusty.

•Wear heavy, long pants, boots, gloves and a long sleeve shirt. Do not wear loose clothing, jewelry, short pants, sandals or go barefoot. Secure hair above shoulder level.

•Use the unit only in daylight or good artificial light.

•Use the right tool. Only use this tool for the purpose intended.

•Do not force unit. It will do the job better and with less likelihood of injury at a rate for which it was designed.

•Do not overreach, take extra care when working on steep slopes or inclines. Always keep proper footing and balance.

•Always hold the unit with both hands when operating. Keep a firm grip on both the front and rear handle or grips.

•Keep hands, face, and feet at a distance from all moving parts. Do not touch or try to stop the cutting attachment when it is rotating. Do not operate without guards in place.

•Do not operate the engine faster than the speed needed to do the job. Do not run the engine at high speed when not in use.

•Always stop the engine/motor when operation is delayed or when walking from one location to another.

.• If you strike or become entangled with a foreign object, stop the engine/motor immediately and check for damage. Have any damage repaired before attempting further operations.

•Stop the unit IMMEDIATELY if you feel excessive vibration. Vibration is a sign of trouble. Inspect thoroughly for loose nuts, bolts or damage before continuing. Repair or replace affected parts as necessary.

•Stop and switch the unit to off for maintenance, repair, or for changing add-ons or other attachments. The unit must be stopped and the cutting head no longer turning to avoid injury.

•Use only Genuine Factory Parts™ and accessories for this unit. These are available from your authorized service dealer. Use of any unauthorized parts or accessories could lead to serious injury to the user or damage to the unit, and void your warranty.

MAINTENANCE AND STORAGE

•Allow the unit to cool before storing or transporting. Be sure to secure the unit while transporting.

•Store the unit in a locked up and dry or high and dry place to prevent unauthorized use or damage, out of the reach of children.

•Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean and free from debris. Clean unit and labels with a damp sponge. Clean after each use.

•Keep these instructions. Refer to them often and use them to instruct other users. If you loan someone this unit, also loan them these instructions.

•Only qualified personnel should perform any repairs or maintenance procedures that are not described in this manual.

•Check shear bolts, engine mounting bolts and other bolts at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

•Inside a building store the machine away from ignition sources. Allow the engine to cool before storing in any enclosure.

•Always refer to the Operator’s Manual instructions for important details if the unit is to be stored for an extended period.

•Do not attempt to repair the machine unless you have the proper tools, and instructions for disassembly and repair of the machine.

SAVE THESE INSTRUCTIONS

4

RULES FOR SAFE OPERATION

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING

•SAFETY ALERT SYMBOL

Indicates danger, warning, or caution. May be used in conjunction with other symbols or pictographs.

•WARNING - READ OPERATOR'S MANUAL

Read the Operator’s Manual(s) and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

•WEAR EYE AND HEARING PROTECTION

WARNING: The operation of any power tool can be the source of thrown objects and loud noise which can cause severe eye injury and hearing loss. Always wear safety glasses or goggles eye protection meeting ANSI Z87.1 standards and ear protection when operating this unit. Use a full face shield when needed.

• KEEP BYSTANDERS AWAY

WARNING: Keep all bystanders, especially children and pets, at least 50 feet (15 m) from the operating area.

• THROWN OBJECTS CAN CAUSE SEVERE INJURY

WARNING: Do not operate unit without proper attachments and guards in place.

•SHARP BLADE

WARNING: Sharp blade on cutting attachment shield. To prevent serious injury, do not touch line cutting blade.

5

RULES FOR SAFE OPERATION

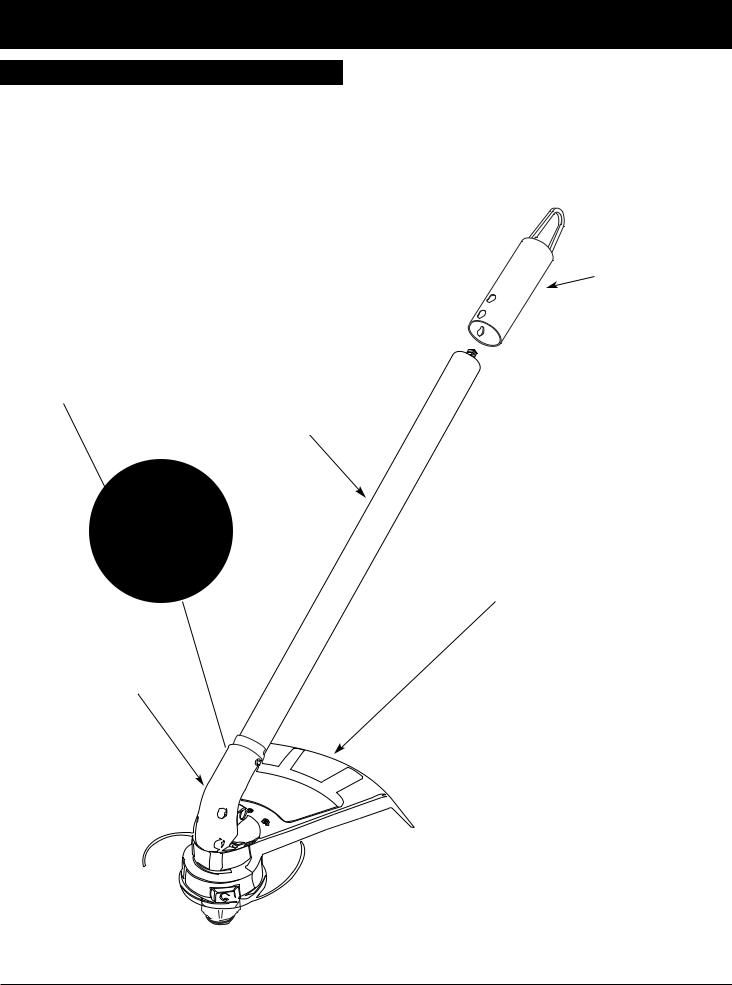

KNOW YOUR UNIT

APPLICATIONS

With Trimmer Add-On:

•Cutting grass and light weeds.

•Decorative trimming around trees, fences, etc.

Hanger

Line Cutting Blade

Shaft Housing

Cutting Attachment Shield

Gear Housing

Cutting Attachment

Cutting Attachment

6

OPERATING INSTRUCTIONS

ASSEMBLING THE COUPLER

The following Troy-Bilt Add-Ons are also available for your unit: Blower/Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . TBBV Cultivator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TBGC Hedge Trimmer . . . . . . . . . . . . . . . . . . . . . . . . . . . TBHS Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TBLE Snow Thrower . . . . . . . . . . . . . . . . . . . . . . . . . . . . TBST Turbo Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TBTB Tree Pruner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TBTP

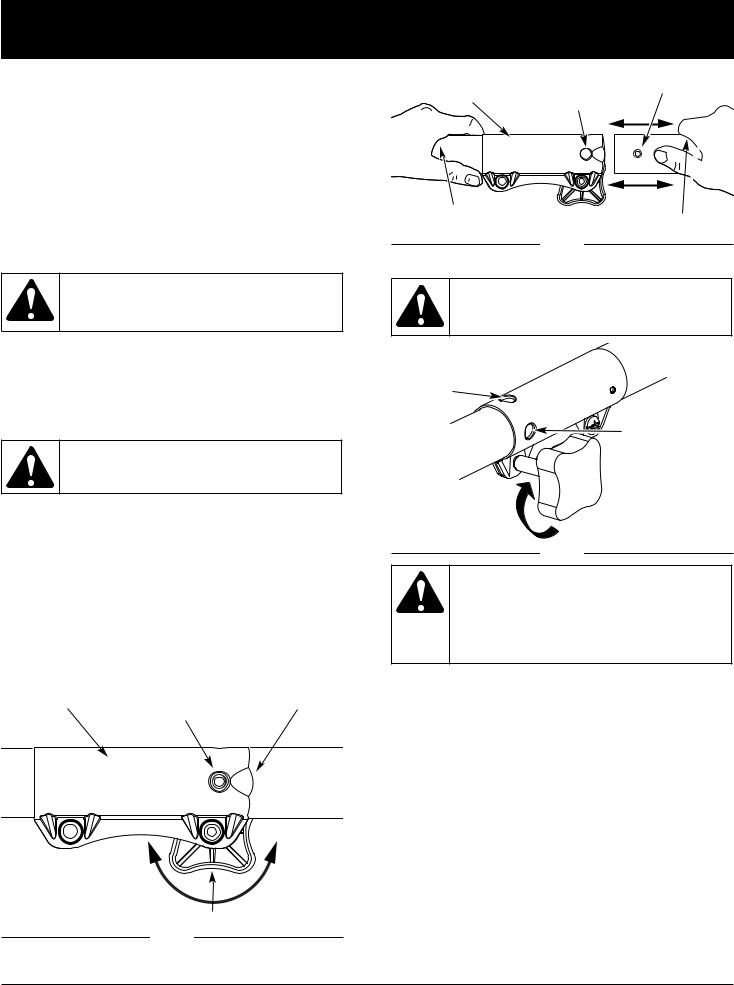

Removing the Add-Ons

WARNING: Read and understand operator’s manual for unit to be used with this add-on prior to operation.

1.Turn the knob counterclockwise to loosen (Fig. 1).

2.Press and hold the release button (Fig. 1).

3.While firmly holding the upper shaft housing, pull the add-on straight out of the coupler (Fig.2).

Installing the Add-Ons

WARNING: To avoid serious personal injury and damage to the unit, shut unit off before removing or installing add-ons.

NOTE: To make installing or removing the add-on easier, place the unit on the ground or on a work bench.

1.Remove the hanger from the top of the lower shaft housing.

2.Turn the knob counterclockwise to loosen (Fig. 1).

3.While firmly holding the add-on, push it straight into the coupler (Fig. 2).

NOTE: Aligning the release button with the guide recess will help installation (Fig. 1).

Coupler |

Release Button |

Guide Recess |

|

|

Counterclockwise |

Clockwise |

Knob

Fig. 1

Coupler |

Release Button |

|

Primary Hole |

||

|

Upper Shaft Housing

Lower Shaft Housing

Fig. 2

3. Turn the knob clockwise to tighten (Fig. 3).

CAUTION: Lock the release button in the primary hole and securely tighten the knob before operating this unit.

90° Edging Hole

180° Edging Hole

Knob

Knob

Fig. 3

CAUTION: The add-ons with the coupler system are to be used in the primary hole only unless stated otherwise in the specific add-ons operator’s manual. Using the wrong hole could lead to personal injury or damage to the unit.

For edging when using the straight shaft trimmer add-on, lock the release button of the cutting attchment into the 90° edging hole or the 180° edging hole (Fig. 3).

Check Flex Shaft Engagement Prior to Using

1.Start the unit.

2.Briefly engage and release the trigger.

3.Check that add-on is operating.

4.If the add-on is not operating, remove add-on and repeat steps for installing the add-on.

5.Recheck operation of add-on attachment.

7

OPERATING INSTRUCTIONS

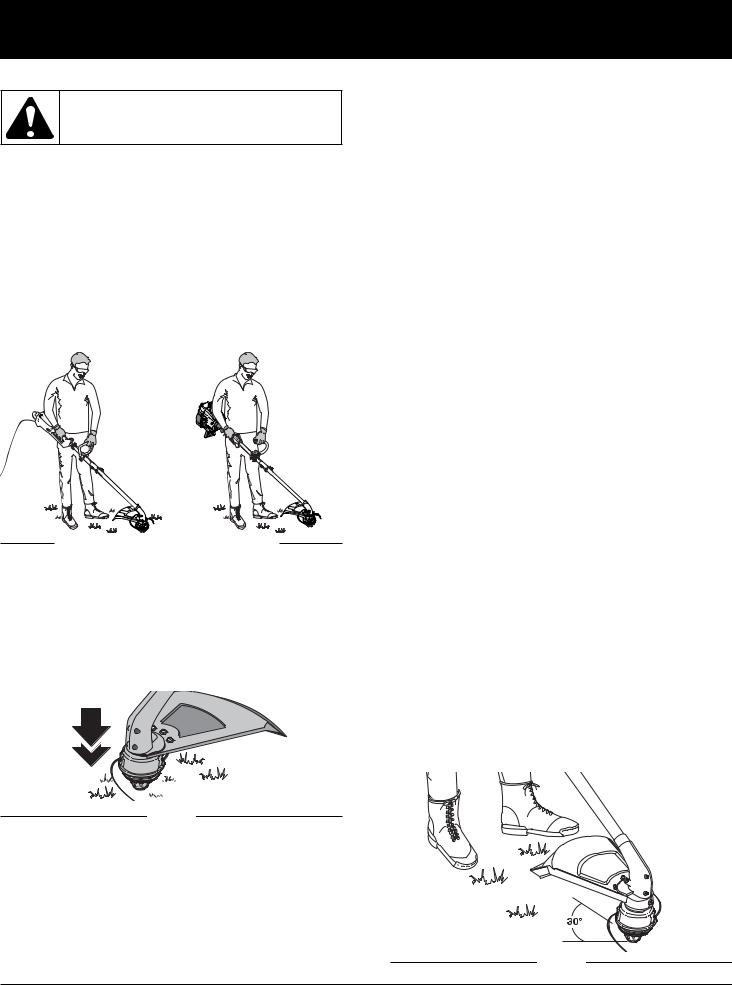

HOLDING THE TRIMMER

WARNING: Always wear eye, hearing, foot and body protection to reduce the risk of injury when operating this unit.

Before operating the unit, stand in the operating position (Figs. 4 & 5). Check for the following:

•The operator is wearing eye protection and proper clothing.

•The right arm is slightly bent, and the hand is holding the shaft grip.

•The left arm is straight, and the hand is holding the D-handle or J-handle.

•The unit is at waist level.

•The cutting attachment is parallel to the ground and easily contacts the vegetation to be cut without the operator having to bend over.

|

|

|

|

Fig. 4 |

|

|

Fig. 5 |

|

|

||

|

|

|

|

ADJUSTING TRIMMING LINE LENGTH

The Bump Head™ cutting attachment allows you to release trimming line without stopping the engine. To release more line, lightly tap the cutting attachment on the ground (Fig. 6) while operating the trimmer at high speed.

NOTE: Always keep the trimming line fully extended. Line release becomes more difficult as cutting line becomes shorter.

NOTE: Do not rest the Bump Head™ on the ground while the unit is running.

Some line breakage will occur from:

•Entanglement with foreign matter

•Normal line fatigue

•Attempting to cut thick, stalky weeds

•Forcing the line into objects such as walls or fence posts

TIPS FOR BEST TRIMMING RESULTS

•For best trimming results, operate unit at full throttle.

•Keep the cutting attachment parallel to the ground.

•Do not force the cutting attachment. Allow the tip of the line to do the cutting, especially along walls. Cutting with more than the tip will reduce cutting efficiency and may overload the engine.

•Cut grass over 8 inches (200 mm) by working from top to bottom in small increments to avoid premature line wear or engine drag.

•Cut from left to right whenever possible. Cutting to the right improves the unit's cutting efficiency. Clippings are thrown away from the operator.

•Slowly move the trimmer into and out of the cutting area at the desired height. Move either in a forwardbackward or side-to-side motion. Cutting shorter lengths produces the best results.

•Trim only when grass and weeds are dry.

•The life of your cutting line is dependent upon:

•Following the previous trimming techniques

•What vegetation is being cut

•Where it’s being cut

For example, the line will wear faster when trimming against a foundation wall as opposed to trimming around a tree.

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all vegetation around trees, posts, fences, etc.

Rotate the whole unit so that the cutting attachment is at a 30° angle to the ground (Fig. 7).

Fig. 6

Each time the head is bumped, about 1 inch (25.4 mm.) of trimming line is released. A blade in the cutting attachment shield will cut the line to the proper length if excess line is released.

For best results, tap the Bump Head™ on bare ground or |

|

hard soil. If line release is attempted in tall grass, the |

|

engine may stall. Always keep the trimming line fully |

|

extended. Line release becomes more difficult as the |

|

cutting line becomes shorter. |

Fig. 7 |

|

8

MAINTENANCE AND REPAIR INSTRUCTIONS

LINE INSTALLATION FOR THE SPEEDSPOOL®

Always use Genuine Factory Parts™ 0.080 inch (2.03 mm) replacement line. Line other than specified may make the engine overheat or fail.

WARNING: Never use metal-reinforced line, wire, or rope, etc. These can break off and become a dangerous projectile.

There are two methods to replace the SpeedSpool® trimming line.

•Wind the inner reel with new line

•Install a prewound inner reel

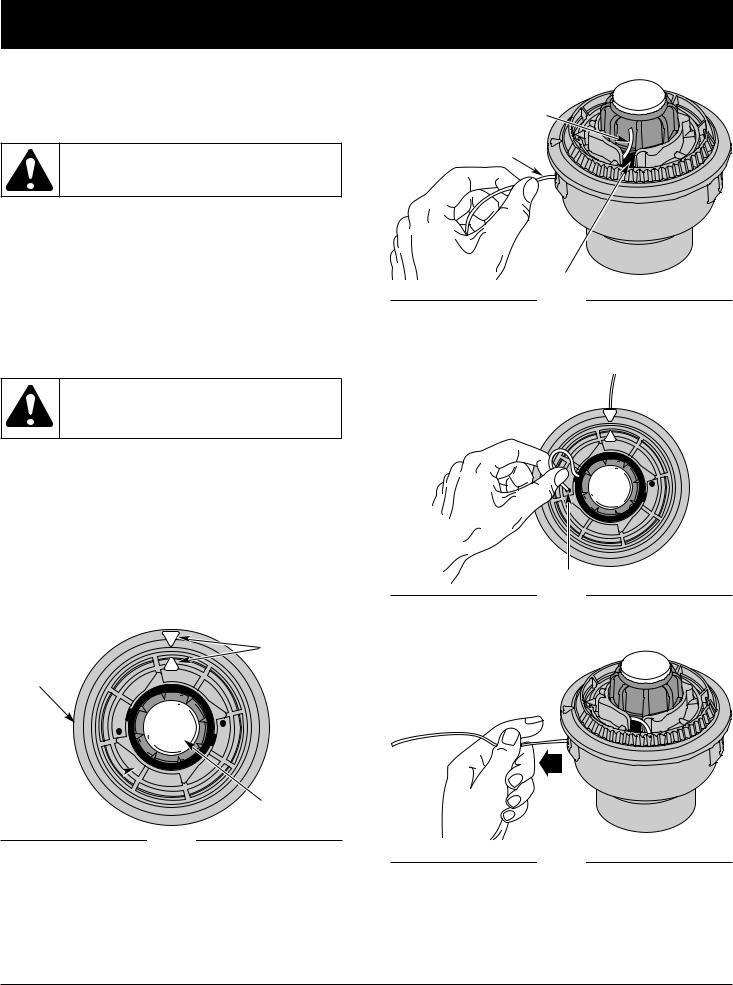

Winding the Inner Reel With New Line

NOTE: It is unnecessary to remove the bump knob to install new trimming line.

1.Cut two pieces of 0.080 inch (2.03 mm) trimming line, 10 feet (3 m) long.

WARNING: Always use the correct line length when installing trimming line on the unit. The line may not release properly if the line is too long.

2.Hold the outer spool and turn the inner reel counterclockwise to line up the arrows on the outer spool and inner reel (Fig. 8).

3.Pull old line out of the line loading and line locking holes (Figs. 9 and 10).

4.Insert a piece of trimming line into one of the two eyelets in the outer spool. Push it up through the line loading hole in the inner reel (Fig. 9). Do not bend the line when inserting it into the eyelet.

Top View Of The SpeedSpool®

Arrows

Outer Spool

Inner Reel

Bump Knob

Fig. 8

Trimming Line

Eyelet

Line Loading Hole

Fig. 9

5.Insert the line into the locking hole (Fig. 10). Do not push the line more than 1/2 inch (12.7 mm) into the line locking hole. When inserted correctly the line will form a small loop (Fig. 10).

Line Locking Hole

Fig. 10

6.Pull the line from the outer spool until the line is tight against the inner reel (Fig. 11).

Fig. 11

9

MAINTENANCE AND REPAIR INSTRUCTIONS

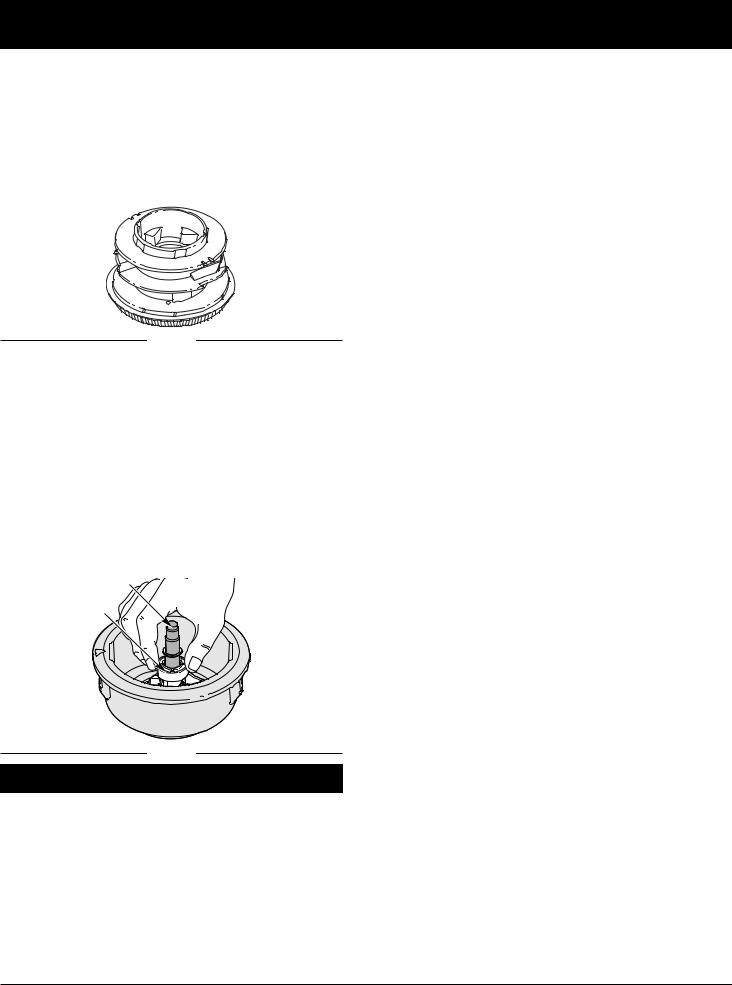

7.Repeat procedures 4-6 with the second piece of line.

8.Hold the outer spool. Wind the inner reel counterclockwise until approximately four (4) inches (102 mm) of line remain (Fig. 12).

NOTE: Do not wind the inner reel before installing the second piece of line.

2.Pull the old inner reel with existing line from the outer spool.

3.Insert the ends of the prewound inner reel line into the outer spool eyelets (Fig. 15). Push the new inner reel, arrow side up, into the outer spool.

Fig. 12

9.If winding the line becomes difficult or the line jams, pull the ends of the line from the spool (Fig. 13). Continue winding the inner reel counterclockwise .

Fig. 13

INSTALLING A PREWOUND REEL

1. Turn the bump knob counterclockwise and remove the bump knob, spring, and foam seal (Fig. 14).

Bump Knob

Foam Seal

Spring

Inner Reel

Fig. 14

Fig. 15

4.Hold the inner reel in place and install the bump knob, spring and foam seal. Press down and turn the bump knob clockwise. Grasp the ends and pull firmly to release the line from the holding slots in the inner reel. (Fig. 13).

Releasing the Inner Reel

If the SpeedSpool® does not release line correctly, pull the ends of the line firmly from the spool (Fig. 13). If this does not release line, follow the Cleaning the

SpeedSpool® instructions.

CLEANING THE SPEEDSPOOL®

Cleaning the SpeedSpool® may be necessary,

•To remove jammed or excess line,

•If the SpeedSpool® becomes difficult to wind or does not operate correctly when bumping the head on the ground,

1.Hold the outer spool, and unscrew the bump knob counterclockwise (Fig. 16).

Fig. 16

10

MAINTENANCE AND REPAIR INSTRUCTIONS

2.Pull out the bump knob, spring, and foam seal (Fig. 14).

3.Pull the inner reel with existing line from the outer spool (Fig. 14).

4.Remove any existing line from the inner reel before cleaning. Remove any debris or grass from the knob, spring, inner reel, and foam seal. Wash the inner reel with warm soapy water (Fig. 17).

Inner Reel

Fig. 17

5.Clean the shaft and the inner surface of the outer spool. To clean the shaft underneath the plunger, press down on the plunger (Fig. 18). Remove any dirt or debris from the shaft.

NOTE: The inner reel must be totally dry before reinstalling it into the outer spool. Do not lubricate the inner reel or outer spool assembly.

6.Place the inner reel into the outer spool.

7.Place the bump knob, spring, and foam seal into the inner reel (Fig. 14).

8.Press the bump knob down and tighten clockwise.

9.Install new line as described in Line Installation for the SpeedSpool®

Shaft

Plunger

Fig. 18

SPEEDSPOOL® REPLACEMENT PARTS

Replacement Line . . . . . . . . . . . . . . . . . . . . . . . . 181472 Replacement Line Cartridge . . . . . . . . . . . . . . . . 181460 Inner Reel Spring . . . . . . . . . . . . . . . . . . . . . . . . 181465 Foam Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181467 Inner Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181464 Bump Head™ Assembly . . . . . . . . . . . . . . . . . . . 181468 (Bump Knob, Inner Reel, Spring, )

These SpeedSpool® replacement parts can be purchased from your local authorized dealer.

CLEANING

Use a small brush to clean off the outside of the unit. Do not use strong detergents. Household cleaners that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can damage plastic housing or handle. Wipe off any moisture with a soft cloth.

STORAGE

•Check unit before storage to be sure the equipment is in safe working condition.

•Stop the engine or motor.

•Store the unit indoors, in a dry and locked place, out of the reach of children.

•Maintain or replace safety and instruction labels, as necessary.

For gas powerhead units

•Allow the unit to cool before storing in any enclosure.

•Drain fuel from unit. Never store the unit with fuel in the fuel tank inside a building where ignition sources are present such as hot water and space heaters, clothes dryers, etc.

TRANSPORTING

•Allow the unit to cool before transporting.

•Secure the unit while transporting.

For gas powerhead units

•Drain fuel from unit.

•Tighten fuel cap before transporting.

11

TROUBLESHOOTING

CUTTING HEAD WILL NOT ADVANCE LINE

CAUSE

Cutting head bound with grass

Cutting head out of line

Inner reel bound up

Cutting head dirty

Line welded

Line twisted when refilled

Not enough line is exposed

ACTION

Stop the unit and clean cutting attachment

Refill with new line

Replace the inner reel

Clean inner reel and outer spool

Disassemble, remove the welded section and rewind the line

Disassemble and rewind the line

Push the bump knob and pull out line until 4 inches (102 mm) of line is outside of the cutting attachment

CUTTING LINE ADVANCES UNCONTROLLABLY

CAUSE |

ACTION |

Oil, cleaner, or lubricant in cutting head |

Clean and thoroughly dry the cutting head |

If further assistance is required, contact your authorized service dealer.

12

SPECIFICATIONS |

|

|

|

|

|

STRAIGHT SHAFT TRIMMER ADD-ON |

|

Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . . . . 3 lbs. (1.36 kg.) |

Cutting Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

SpeedSpool® Dual String Cutting Head |

Line Spool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . Bump Line Releaser |

Line Spool Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . . 3 inches (76.2 mm) |

Trimming Line Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . 0.080 inches (2.03 mm) |

Cutting Path Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . . 17 inches (43.18 cm) |

13

NOTES

14

NOTES

15

Loading...

Loading...