Troy-Bilt TB4516CC User Manual

Operator’s Manual

Electric Chain saws

Model TB3516

&

Model TB4516CC

WARNING • PLEASE READ

Beware of kickback. Hold chain saw firmly with both hands when using. For your own safety, please read and follow the safety precautions in this manual before attempting to operate your chain saw. Improper use can cause serious injury.

SAVE THESE INSTRUCTIONS DO NOT THROW AWAY

P/N 6096-211402 (5/04)

PRINTED IN CHINA

INTRODUCTION

THANK YOU

Thank you for buying this quality product. This modern outdoor power tool will provide many hours of useful service. You will find it to be a great labor-saving device. This operator’s manual provides you with easy-to- understand operating instructions. Read the whole manual and follow all the instructions to keep your new outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS AND SPECIFICATIONS

All information, illustrations, and specifications in this manual are based on the latest product information available at the time of printing. We reserve the right to make changes at any time without notice.

Copyright© 2004 MTD SOUTHWEST INC, All Rights Reserved.

SERVICE INFORMATION

Service on this unit both within and after the warranty period should be performed only by an authorized and approved service dealer.

For service call 1-800-520-5520 to obtain a list of authorized service dealers near you. For more details about your unit, visit our website at www.troybilt.com.

DO NOT RETURN THE UNIT TO THE RETAILER. PROOF OF PURCHASE WILL BE REQUIRED FOR WARRANTY SERVICE.

Before beginning, locate the unit’s model plate. It lists the model and serial numbers of your unit. Refer to the sample plate below and copy the information for future reference.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . .2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . .3

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starting/Stopping Instructions . . . . . . . . . . . . . . . .10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . .11

Maintenance and Repair Instructions . . . . . . . . . . .13

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . .19

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Warranty Information . . . . . . . . . . . . . . . . . . . . . . .20

Parts List . . . . . . . . . . . . . . . . . . . .Inside Back Cover

|

MODEL : |

S/N : |

ITEM : |

Copy the model and parent part number here:

Copy the serial number here:

Make sure you carefully read and understand this manual before starting or operating this equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS. OTHER PATENTS PENDING.

2

RULES FOR SAFE OPERATION

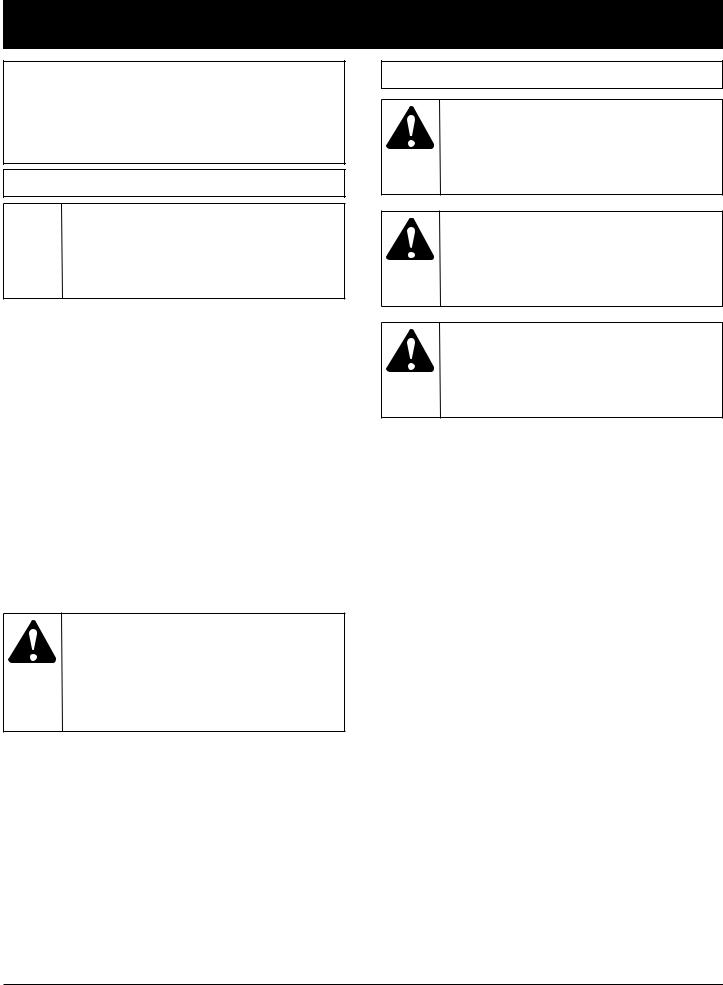

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

SAFETY ALERT: Indicatesdanger, warning or caution. Attention is required in order to avoid serious personal injury. May be used in conjunction with other symbols or pictographs.

SAFETY ALERT: Indicatesdanger, warning or caution. Attention is required in order to avoid serious personal injury. May be used in conjunction with other symbols or pictographs.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

Read the Operator’s Manual(s) and follow all warnings and safety instructions.

Failure to do so can result in serious injury to the operator and/or bystanders.

FOR QUESTIONS, CALL 1-800-520-5520

SYMBOL MEANING

DANGER: Failure to obey a safety warning will

result in serious injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can

result in injury to yourself and others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may

result in property damage or personal injury to yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

• IMPORTANT SAFETY INSTRUCTIONS •

READ ALL INSTRUCTIONS

BEFORE OPERATING

WARNING: If correctly used, the chain saw is a

quick, easy to handle and efficient tool; if used improperly or without the due precautions it could become a dangerous tool. For pleasant and safe work,always strictly comply with the safety rules that follow and throughout this manual.

•Read the instructions carefully. Be familiar with the controls and proper use of the unit.

•Do not operate this unit when tired, ill or under the influence of alcohol, drugs or medication.

•Only responsible individuals who are familiar with the instructions may operate the chain saw (no one under the age of 16). Provide parental supervision at all times.

•Inspect the unit before use. Replace damaged parts. Make sure all fasteners are in place and secure. Replace parts that are cracked, chipped or damaged in any way.

•Know the controls and know how to stop the chain saw quickly.

•Carry the chain saw with the motor stopped, and with the guide bar and saw chain to the rear.

•When transporting your chain saw, use the appropriate guide-bar scabbard (sheath).

WHILE OPERATING

•Keep all parts of your body away from the chain when the motor is running.

•Wear safety glasses or goggles that are marked as meeting ANSI Z87.1-1989 standards. Also wear ear/hearing protection when operating this unit. Wear a face or dust mask if the operation is dusty. Long sleeve shirts are recommended.

•Wear heavy, long pants, boots or safety footwear and protective gloves. Do not wear loose clothing, jewelry, short pants, sandals or go barefoot. Secure hair above shoulder level.

•Use the unit only in daylight or good artificial light.

•Before you start the motor, make sure that the saw’s chain is not contacting anything. Do not cut near electrical cables or power lines.

•Do not start cutting until you have a clear work area, secure footing, and a planned retreat path from the falling tree.

3

RULES FOR SAFE OPERATION

•Do not operate a chain saw that is damaged, improperly adjusted, or not completely and securely assembled. Be sure that the saw’s chain stops moving when the throttle control trigger is released.

•Use extreme caution when cutting small-sized brush and saplings because slender material may catch the chain saw and whip towards you or pull you off balance.

•When cutting a limb that is under tension, be alert for springback so that you will not be struck when the tension in the wood fibers is released

•Do not cut through nails, rods in the tree, railroad ties or pallates. Inspect a tree that you are going to cut for foreign objects that could cause injury or damage to your chain saw.

•After striking a foreign object, stop the motor and thoroughly inspect for damage. Repair as necessary.

•We do not recommend using the chain saw in a tree or on a ladder.

•All chain saw service, other that the items listed in this instruction manual maintenance instructions, should be performed by competent chain saw service personnel.

•Use the right tool. Only use this chain saw for its intended purpose, to cut wood.

•Do not overreach. Always keep proper footing and balance.

•Always hold the unit with both hands when operating. Keep a firm grip on all handles or grips.

•Apply chain brake prior to any repositioning of the operator in the cutting area. As an additional safety precaution, apply the chain brake prior to setting down the saw.

•Never touch the chain or attempt to service the saw while the motor is running. Make sure all moving parts have stopped. Allow the chain saw to cool, as the chain can be hot.

•Check the bar and chain at frequent intervals for proper adjustment. Make sure the bar and chain are properly tightened and sharpened. Visually inspect for damage. Repair any damage before restarting or operating the chain saw.

WARNING: KICKBACK may occur when the nose

or tip of the guide bar touches an object, or when the wood closes in and pinches the saw chain in the cut. Tip contact in some cases may cause a lightning-fast reverse reaction, kicking the guide bar up and back towards the operator. Pinching the saw chain along the top of the guide bar may push the guide bar rapidly back toward the operator. Either of these reactions may cause you to lose control of the saw, which could result in serious personal injury.

Do not rely exclusively upon the safety devices built into your saw. As a chain saw user, you should take several steps to keep your cutting jobs free from accident or injury.

KICKBACK SAFETY PRECAUTIONS

•With a basic understanding of kickback, you can reduce or eliminate the element of surprise. Sudden surprise contributes to accidents. Be alert to the potential for kickback at all times.

•Keep a good firm grip on the saw with both hands, the right hand on the rear handle and the left hand on the front handle, when the motor is running. Use a firm grip with thumbs and fingers encircling the chain saw handles. A firm grip will help you reduce kickback and maintain control of the saw. Don’t let go.

•Make sure that the area in which you are cutting is free from obstructions. Do not let the nose of the guide bar contact a log, branch, fence, or any other obstruction that could be hit while you are operating the saw.

•Always cut with the motor running at full speed. Fully squeeze the throttle trigger and maintain a steady cutting speed.

•Use only the correct original equipment manufacturer replacement bars, chains and other parts and accessories. These are available from your authorized service dealer. Use of any unauthorized parts or accessories could lead to serious injury to the user, or damage to the unit, and will void your warranty.

•Follow the manufacturer’s sharpening and maintenance instructions for the saw chain.

•Use only the replacement guide bars and low kickback chains specified for your saw to avoid injury.

4

RULES FOR SAFE OPERATION

OTHER SAFETY PRECAUTIONS

•Do not operate a chain saw with one hand! Serious injury to the operator, helpers, bystanders, or any combination of these persons may result from onehanded operation. A chain saw is intended for twohanded use.

•Do not operate a chain saw if you are fatigued.

•Use safety footwear; snug-fitted clothing; protective gloves; and eye, hearing, and head protection devices.

•Do not allow other persons to be near the chain saw when starting or cutting with the chain saw. Keep bystanders and animals out of the work area.

•Do not remove, damage or de-activate any of the safety devices. Never use a damaged, modified, or improperly repaired or assembled chain saw. Check their proper operation regularly. Only use bars and chains of the length indicated in the table herein.

•Never carry out operations or repairs on your own that are other than routine maintenance. For information, contact specialized and authorized workshops only.

•If your chain saw is no longer usable, dispose of it properly without damaging the environment by handing it in to your local dealer who will arrange for its correct disposal.

•Use caution when felling a tree. Make sure you have planned an escape path when felling, and keep all bystanders away.

•Be alert; stop the machine if anyone enters the cutting area, which is usually 3 to 4 feet around the operator.

•Use caution when working in a crew to avoid injury to a fellow worker who may enter the cutting area.

•Only loan your saw to experienced users who are completely familiar with saw operation and correct use. Give other users this manual, which they should read before using the saw. Provide them the operating instructions.

•Shut off the motor before setting down the saw. Do not leave the motor running unattended.

•Store the unit in a dry area, locked up, located up high and located out of the reach of children to prevent unauthorized use or damage.

•Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean and free from debris. Clean after each use.

•Keep these instructions. Refer to them often and use them to instruct other users. If you loan someone this unit, also loan them these instructions.

•Do not use the unit in the rain, in a storm or in inclement weather. Wait until the storm danger has passed before operation of this product.

ELECTRICAL SAFETY WARNINGS

•Since the tool is double-insulated, a 2-wire extension cord (an extension cord without a ground) may be used. A 3-wire extension cord (an extension cord with a ground) that uses a NEMA type connector (parallel blade, U ground) is recommended. Extension cords are available from your local retailer. Use only roundjacketed extension cords approved for outdoor use.

•This tool is double-insulated. Repair or replace damaged cords.

•To reduce the risk of electrical shock, this unit has a polarized plug (one blade is wider than the other). This unit will fit with a polarized plug in one way only. If the plug does not fit fully into the unit, reverse the plug. If it still does not fit, use a cord with the correct connection. Do not modify the unit in any way.

WARNING: To reduce the risk of electrical shock, use

only SW-A, SOW-A, STW-A, STOW-A, SJW-A, SJOW-A, SJTW-W or SJTOW-A cord types.

5

RULES FOR SAFE OPERATION

ELECTRICAL SAFETY WARNINGS (CONT’D)

•CORD SETS: Make sure your cord set is in good condition, with a cord that is heavy enough to carry the current that your unit will draw. An undersized cord set will cause a drop in line voltage resulting in a loss of power, as well as overheating. The table shown above illustrates the correct size to use depending on the cord length and nameplate amperage rating. If in doubt, use the next heavier size line gauge. The smaller the gauge number, the heavier the cord. To prevent the cord from disconnecting from the unit, use the cord hook shown in the Operating Instructions.

•Ground Fault Circuit Interrupter (GFCI) protection should be provided on the circuit(s) or outlet(s) that will be used for the unit. Use receptacles with built-in GFCI protection for an extra measure of safety.

•Avoid dangerous environments. Never operate your unit in damp or wet conditions. Moisture is a shock hazard.

•Inspect all extension cords and the unit power connection periodically. Look closely for deterioration, cuts or cracks in the insulation. Also inspect the connections for damage. Repair or replace the cords if any defects appear.

•Do not handle the plug or the unit with wet hands.

•Examine the electrical switches. Do not use the chain saw if the switches do not properly turn on and off. Do not attempt to make any repairs to the electric switches. Take your saw to an Authorized Service Center.

•Keep the cord away from the cutting area and to position cord so that it will not be caught on branches, and the like, during cutting.

•Use an extension cord heavy enough to carry the current the tool will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating.

•This electric powered saw is classified by CSA as a Class 2C saw. It is intended for infrequent use by homeowner’s, cottagers and campers, and for such general applications such as clearing, pruning, cutting firewood, etc. It is not intended for prolonged use. If the intended use involves prolonged periods of operation, this may cause circulatory problems in the user’s hands due to vibration. It may be appropriate to use a saw having an anti-vibration feature.

Minimum Gauge Wire

Saw Model |

Ampere |

Volts AC |

Length of Power Cord |

|||

Rating |

25 ft. / 7.5m |

50 ft. / 15m |

100 ft. / 30m |

|||

|

|

|||||

|

|

|

|

|

|

|

TB3516 |

13.5 |

110 / 120 |

16 Gauge |

16 Gauge |

14 Gauge |

|

TB4516 |

15 |

110 / 120 |

14 Gauge |

12 Gauge |

Not |

|

Recommended |

||||||

|

|

|

|

|

||

SAVE THESE INSTRUCTIONS

6

RULES FOR SAFE OPERATION

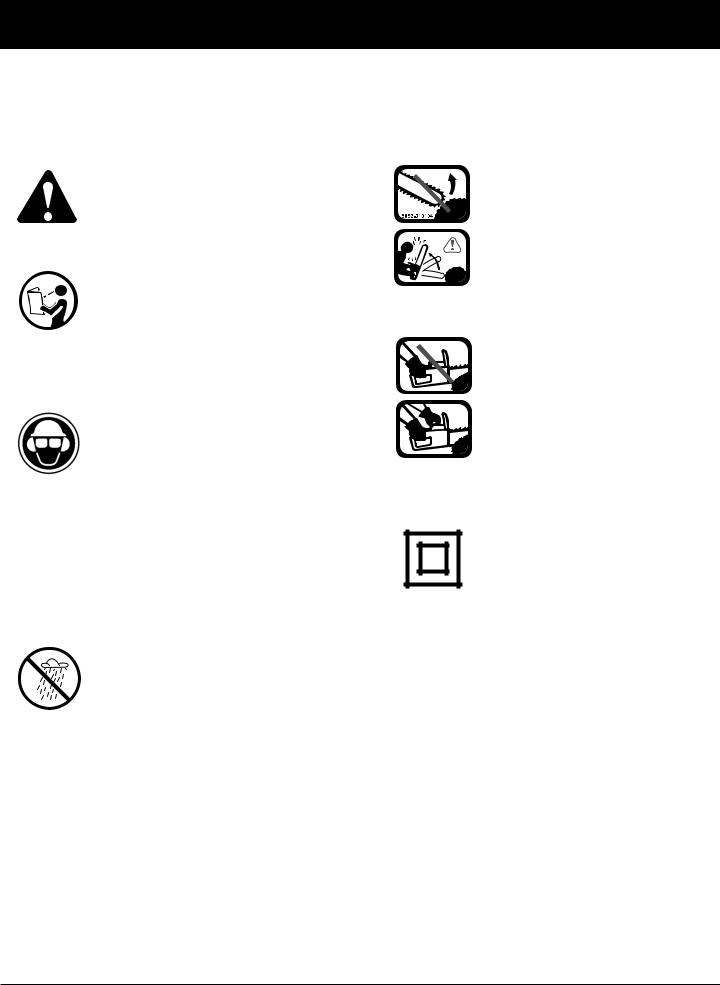

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product. Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL |

MEANING |

SYMBOL |

MEANING |

•SAFETY ALERT SYMBOL

Indicates danger, warning, or caution. May be used in conjunction with other symbols or pictographs.

•WARNING - READ OPERATOR'S MANUAL

Read the Operator’s Manual(s) and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders.

•WEAR EYE, HEARING AND HARDHAT PROTECTION

WARNING: Thrown

objects and loud noise can cause severe eye injury and hearing loss. Wear eye protection meeting ANSI Z87.1-1989 standards and ear protection when

operating this unit. Wear a hard hat. Use a full face shield when needed.

• DO NOT USE IN THE RAIN

WARNING: Avoid

dangerous environments. Never operate your unit in the rain, or in damp or wet conditions. Moisture is a shock hazard.

•GUIDE BAR WARNING:

Contact of the guide bar tip with any object should be avoided. Tip contact may cause the guide bar to move suddenly upward and backward, which may cause serious injury.

•USE BOTH HANDS

Always use both hands while operating the chain saw. Never use only one hand to operate the saw.

Avoid bar nose contact.

•DOUBLE INSULATED

Two systems of insulation are provided instead of grounding. There is no grounding provided and no means of grounding should be added to this unit.

7

RULES FOR SAFE OPERATION

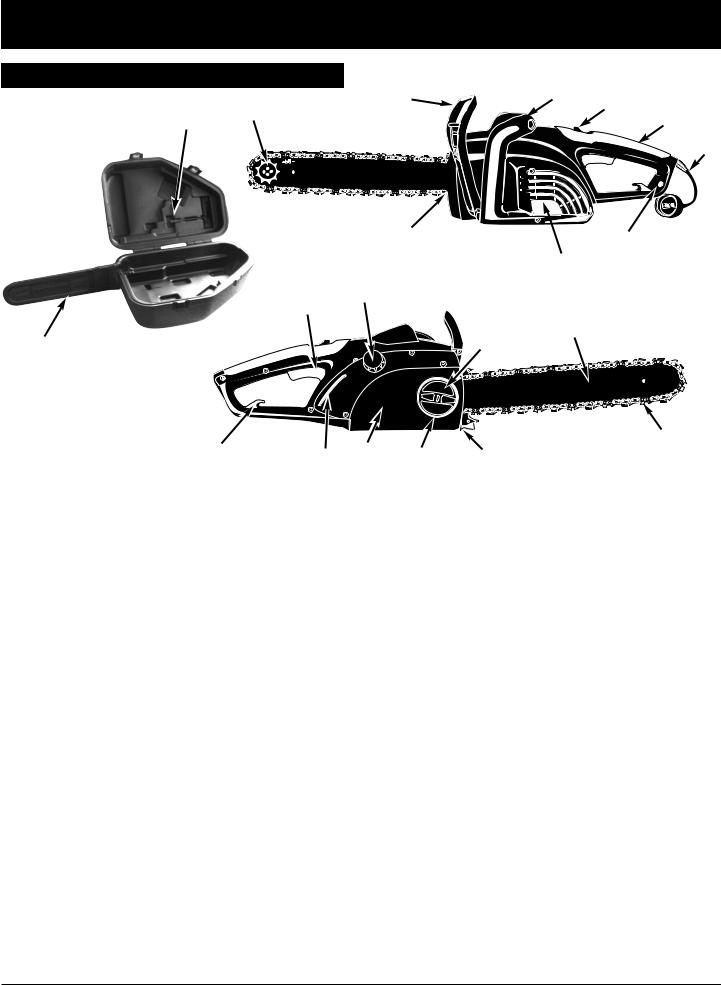

KNOW YOUR UNIT

|

9 |

11 |

|

|

16 |

10 |

|

20 |

1 |

||

|

8

14 |

15 |

7

2

3

12

21 |

5 |

13

18 |

17 |

4 |

6 |

19 |

|

|

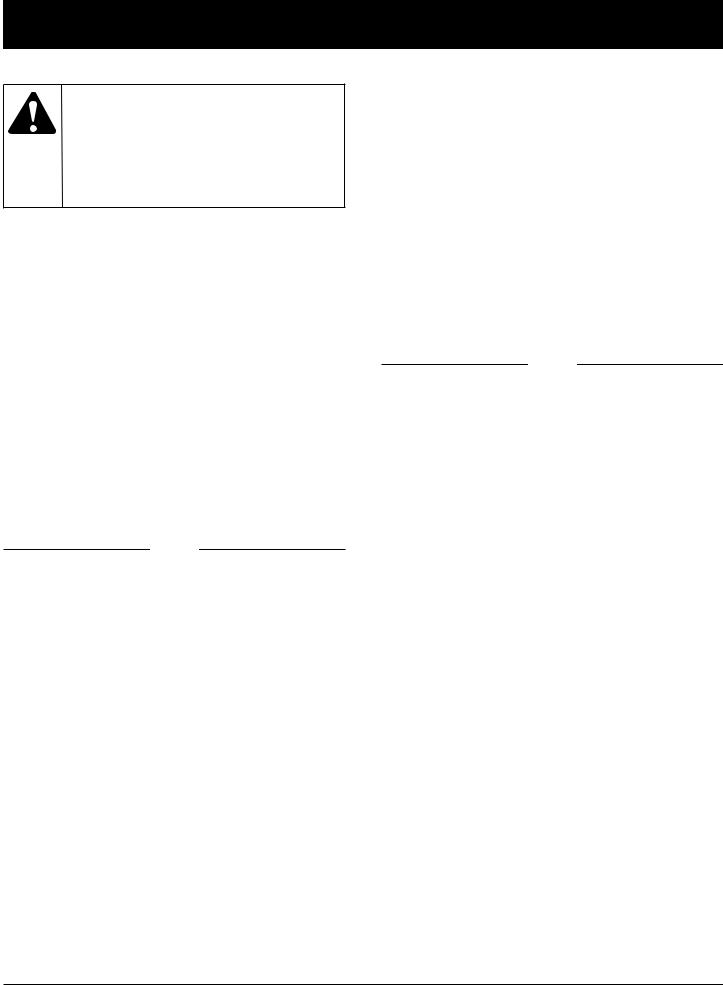

CHAIN SAW COMPONENTS

1.REAR HANDLE

2.OIL TANK CAP

3.TRIGGER START/STOP SWITCH

4.SPROCKET COVER

5.BAR BOLT KNOB

6.CHAIN TENSIONING RING

7.ELECTRIC MOTOR

8.ELECTRIC CORD

9.CHAIN BRAKE® LEVER / HAND GUARD

10.LOCK / OFF BUTTON

11.FRONT HANDLE

12.GUIDE BAR

13.SAW CHAIN

14.SPIKES

15.REAR HAND GUARD

16.SPROCKET

17.OIL TANK WINDOW

18.CORD RETAINER

19.CHAIN CATCHER

20.SCREWDRIVER / WRENCH

21.CARRY CASE (Available on some models)

SAFETY FEATURES

Numbers preceding the descriptions correspond with the numbers above to help you locate the safety feature.

3TRIGGER START / STOP SWITCH stops saw motor when released.

7ELECTRIC MOTOR is double insulated for added safety.

9CHAIN BRAKE® LEVER / HAND GUARD protects the operator’s left hand in the event it slips off the front handle while saw is running.

10LOCK / OFF BUTTON prevents accidental acceleration of the saw motor. The trigger cannot be squeezed unless lock/off button is depressed.

13LOW KICKBACK SAW CHAIN helps significantly reduce kickback, or the intensity of kickback, due to specially designed depth gauges and guard links.

19CHAIN CATCHER reduces the danger of injury in the event saw chain breaks or derails during operation. The chain catcher is designed to intercept a whipping chain.

8

RULES FOR SAFE OPERATION

KICKBACK SPECIFICS

WARNING: Kickback can lead to dangerous loss of

control of the chain saw and result in serious or fatal injury to the saw operator or to anyone standing close by. Always be alert. Rotational kickback and pinch-kickback are major chain saw operational dangers and the leading cause of most accidents.

Beware of:

Rotational Kickback

A B

A

A

A = Kickback path

B = Kickback reaction zone

Fig. 1

KICKBACK SPECIFICS

Beware of:

Pinch Kickback

A

B B

A = Pull

B = Solid objects

C = Push

C

Fig. 2

KICKBACK may occur when the NOSE or TIP of the guide bar touches an object, or when wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast reverse reaction, kicking the guide bar up and back toward the operator.

PINCHING the saw chain along the BOTTOM of the guide bar may PULL the saw forward away from the operator. PINCHING the saw chain along the TOP of the guide bar may PUSH the guide bar rapidly back toward the operator.

Any of these reactions may cause you to lose control of the saw, which could result in serious personal injury.

9

STARTING/STOPPING INSTRUCTIONS

WARNING: Never operate the saw without the bar and

chain properly installed.

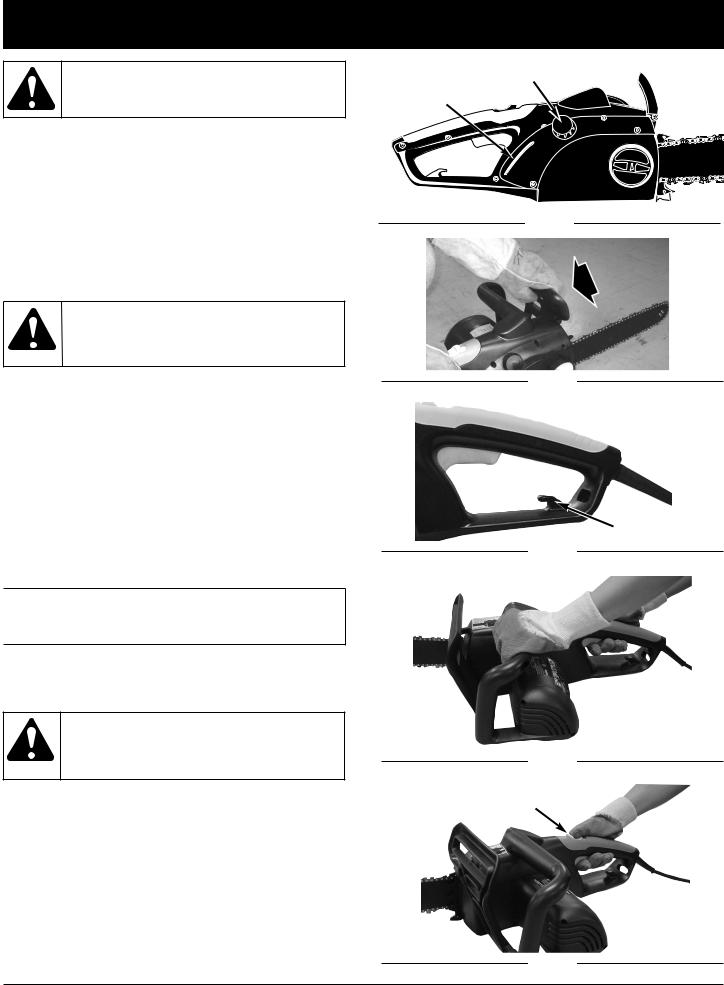

STARTING INSTRUCTIONS

1.Fill the oil tank with correct chain and bar oil (Fig. 3). Use a funnel, wipe up any spills and make sure no dirt gets into the tank.

NOTE: The saw chain requires lubrication when in use to minimize friction with the guide bar. The oil tank holds 4.5 ozs of oil, enough to lubricate the chain for 12-15 minutes of sawing. We recommend using original equipment manufacturer Bar and Sprocket Oil, which contains additives to reduce friction wear and reduce resin residue formations.

CAUTION: The oil tank level should be frequently

checked during operation to avoid starving the bar and chain of lubrication.

NOTE: Your chain saw is equipped with an Automatic Oiler system and is the ONLY source of lubrication for the bar and chain.

2.Be certain the Chain Brake® is disengaged before starting unit (Fig. 4). Disengage it by pulling backward toward the motor.

3.Hook the extension cord to the extension cord retainer

(A) (Fig. 5) that is built into the rear handle. This will prevent the cord from pulling out of the handle. Double the extension cord, about a foot from the end, and insert it into the end of the handle. Hook the loop formed by doubling the cord over the tab. Gently tug on the cord to ensure that it is firmly retained in the saws handle. Plug the receptacle end of the extension cord into the tool’s power supply cord.

WARNING: Ensure the extension cord is of the proper

WARNING: Ensure the extension cord is of the proper

size and type for your saw.

4.Grip the saw with both hands, left hand holding the front /handle (DO NOT HOLD CHAIN BRAKE®) and the right hand holding the rear handle. Thumbs and fingers should encircle both handles (Fig. 6).

WARNING: Make sure the extension cord does

not come in contact with the guide bar and saw chain.

5.With your right thumb, depress the LOCK/OFF button

(C) on the top of the rear handle, and at the same time squeeze the trigger. To stop the saw, release the trigger (Fig. 7).

NOTE: It is not necessary to maintain pressure on the LOCK/OFF button once the trigger is squeezed and the motor is running. The LOCK/OFF button is a safety device to avoid accidental starting.

STOPPING INSTRUCTIONS

The saw motor will automatically stop when the trigger is released. To restart the motor, you will have to depress the LOCK/OFF button and squeeze the trigger.

Oil Cap

Oil Tank

Inspection Spot

Fig. 3

A

Fig. 4

A

Fig. 5

Fig. 6

C

Fig. 7

10

OPERATING INSTRUCTIONS

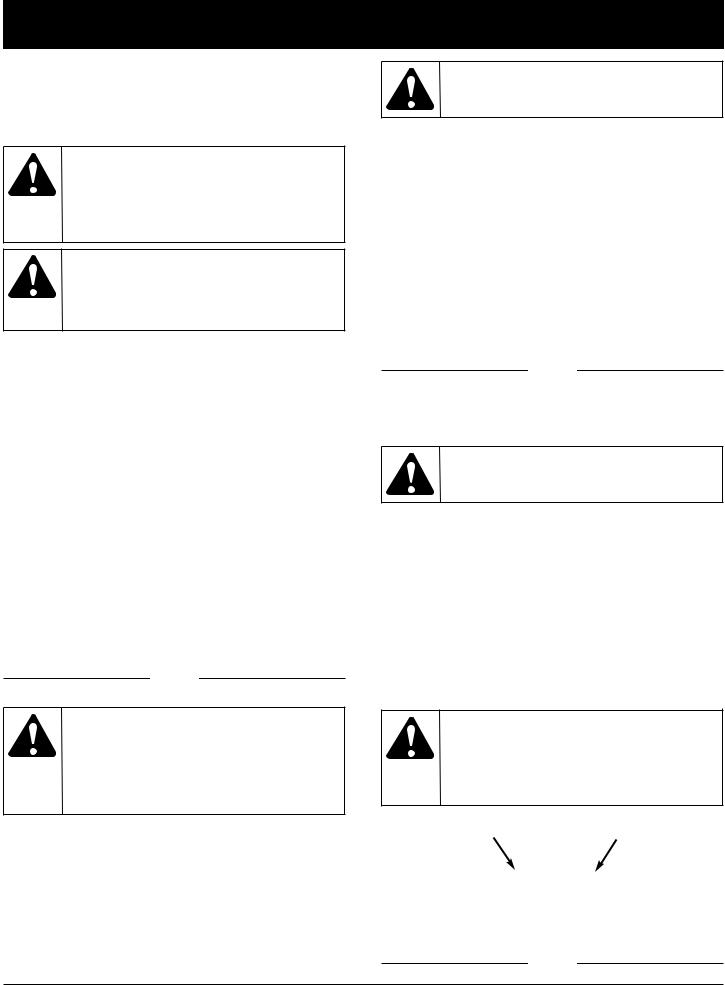

FELLING

Felling is the term for cutting down a tree. Small trees up to 6-7 inches (15-18cm) in diameter are usually cut in a single cut. Larger trees require notch cuts. Notch cuts determine the direction the tree will fall.

WARNING: A retreat path (A) should be planned

and cleared as necessary before cuts are started. The retreat path should extend back and diagonally to the rear of the expected line of fall, as illustrated in Fig. 8.

CAUTION: If felling a tree on sloping ground, the

chain saw operator should keep on the uphill side of the terrain, as the tree is likely to roll or slide downhill after it is felled.

NOTE: Direction of fall (B) is controlled by the notching cut. Before any cuts are made, consider the location of larger branches and natural lean of the tree to determine the way the tree will fall.

B

A

Fig. 8

WARNING: Never walk in front of a tree that has been

notched.

Make the felling cut (D) from the other side of the tree and 1.5 - 2.0 inches (3-5 cm) above the edge of the notch (C) (Fig. 9).

Fig. 9

Never saw completely through the trunk. Always leave a hinge. The hinge guides the tree. If the trunk is completely cut through, control over the felling direction is lost.

WARNING: Before making the final cut, always recheck

the area for bystanders, animals or obstacles.

Insert a wedge or felling lever in the cut well before the tree becomes unstable and starts to move. This will prevent the guidebar from binding in the felling cut if you have misjudged the falling direction. Make sure no bystanders have entered the range of the falling tree before you push it over.

Felling Cut:

1.Use wooden or plastic wedges (G) to prevent binding the bar or chain (H) in the cut. Wedges also control felling (Fig. 10).

2.When diameter of wood being cut is greater than the bar length, make 2 cuts as shown (Fig. 11).

WARNING: Do not cut down a tree during high or

changing winds or if there is a danger to property. Consult a tree professional.Do not cut down a tree if there is a danger of striking utility wires; notify the utility company before making any cuts.

Normally felling consists of 2 main cutting operations, notching (C) and making the felling cut (D).

Start making the upper notch cut (C) on the side of the tree facing the felling direction (E). Be sure you don t make the lower cut too deep into the trunk.

The notch (C) should be deep enough to create a hinge

(F) of sufficient width and strength. The notch should be wide enough to direct the fall of the tree for as long as possible.

WARNING: As the felling cut gets close to the

hinge, the tree should begin to fall. When tree begins to fall, remove saw from cut, stop motor, put chain saw down, and leave area along retreat path (Fig. 8).

G H

Fig. 10

11

OPERATING INSTRUCTIONS

Fig. 11

LIMBING

Limbing a tree is the process of removing the branches from a fallen tree. Do not remove supporting limbs (A) until after the log is bucked (cut) into lengths (Fig. 12). Branches under tension should be cut from the bottom up to avoid binding the chain saw.

A

Fig. 12

WARNING: Never cut tree limbs while standing on a

tree trunk.

BUCKING

Bucking is cutting a fallen log into lengths. Make sure you have a good footing and stand uphill of the log when cutting on sloping ground. If possible, the log should be supported so that the end to be cut off is not resting on the ground. If the log is supported at both ends and you must cut in the middle, make a downward cut halfway through the log and then make the undercut. This will prevent the log from pinching the bar and chain. Be careful that the chain does not cut into the ground when bucking as this causes rapid dulling of the chain.

When bucking on a slope, always stand on the uphill side.

1.Log supported along entire length: Cut from top (overbuck), being careful to avoid cutting into the ground (Fig. 13).

2.Log supported on 1 end: First, cut from bottom (underbuck) 1/3 diameter of log to avoid splintering. Second, cut from above (overbuck) to meet first cut and avoid pinching (Fig. 14).

3.Log supported on both ends: First, overbuck 1/3 diameter of log to avoid splintering. Second, underbuck to meet first cut and avoid pinching (Fig. 15).

NOTE: The best way to hold a log while bucking is to use a sawhorse. When this is not possible, the log should be raised and supported by the limb stumps or by using supporting logs. Be sure the log being cut is securely supported.

Fig. 14

Fig. 15

BUCKING USING A SAWHORSE

For personal safety and ease of cutting, the correct position for vertical bucking is essential (Fig. 16).

A.Hold the saw firmly with both hands and keep the saw to the right of your body while cutting.

B.Keep the left arm as straight as possible.

C.Keep weight on both feet.

CAUTION: While the saw is cutting, be sure the

CAUTION: While the saw is cutting, be sure the

chain and bar are being properly lubricated.

A B

|

Fig. 13 |

|

|

|

|

C |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12

MAINTENANCE AND REPAIR INSTRUCTIONS

INSTALL THE GUIDE BAR

CAUTION: Disconnect the chain saw from power

CAUTION: Disconnect the chain saw from power

source before checking or adjusting the chain saw tension.

1.Place the power on a flat surface.

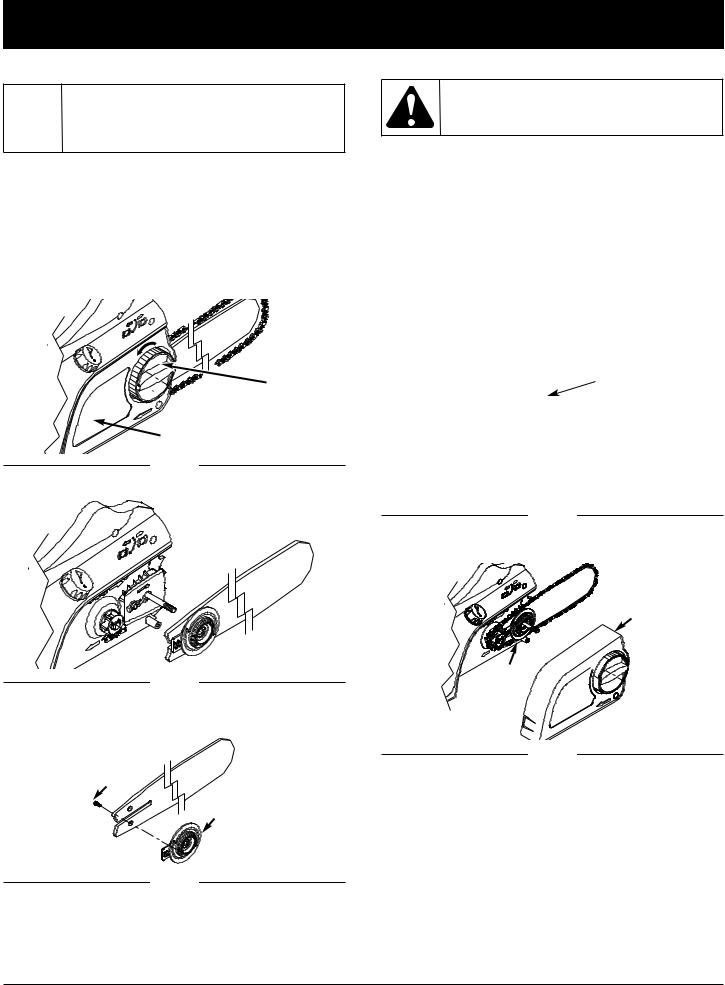

2.To remove the side cover (A), turn the knob (B) counter-clockwise (Fig. 17).

3.Screw (C) the tension plate (D) on the bar (Fig. 19).

These instructions are for replacing a bar. The unit is fully assembled when shipped.

B

A

A

Fig. 17

Fig. 18

C

D

INSTALL THE SAW CHAIN

WARNING: Always use protective gloves

when handling the saw chain.

1.Spread the chain out with the cutting edges (E) of the chain pointing in the DIRECTION OF ROTATION (Fig. 20).

2.To fit the chain on the bar, turn the tension plate (D) counter-clockwise to the end. Install the chain and bar on the power unit, turn the tension plate (D) clockwise and then put the side cover (A) on (Fig. 21).

3.Turn the knob clockwise, adjust the chain tension ring (F) and then tighten the knob.

4.After running the chain saw about 1 hour, retension the chain. If needed, follow the tension adjustment instructions in the next section.

E

E

Fig. 20

A

D

F

F

Fig. 21

Fig. 19

13

MAINTENANCE AND REPAIR INSTRUCTIONS

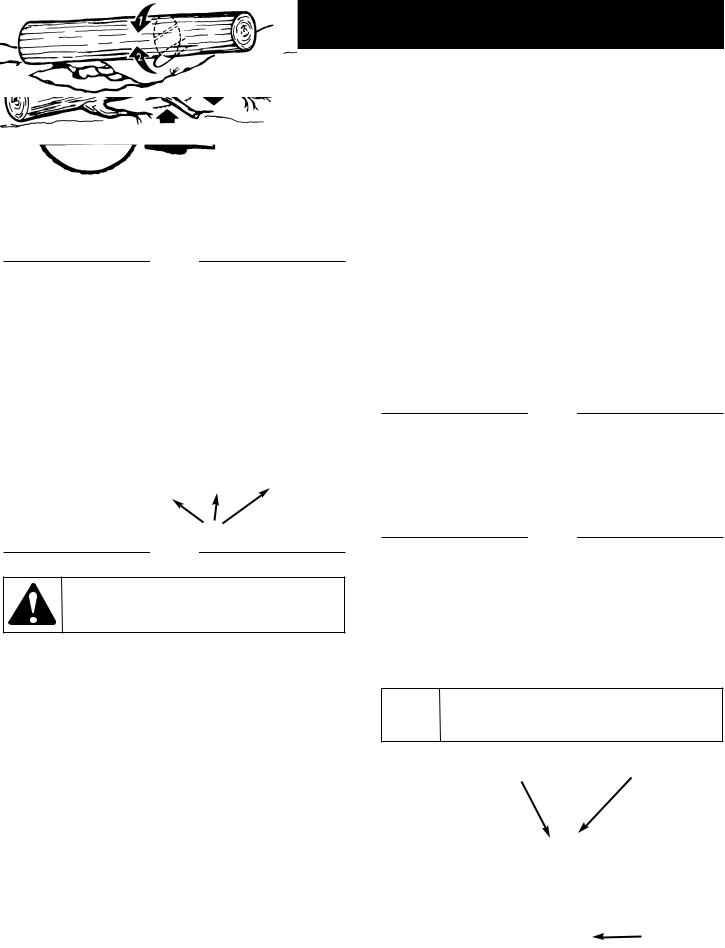

SAW CHAIN TENSION ADJUSTMENT

WARNING: Always use protective gloves

when handling the saw chain.

Proper tension of saw chain is extremely important and must be checked before starting, as well as during any cutting operation.

Taking the time to make needed adjustments to the saw chain will result in improved cutting performance and prolonged chain life.

NOTE: A new chain and bar will need readjustment after as few as 5 cuts. This is normal during the breakin period, and the interval between future adjustments will lengthen quickly (Fig. 22).

CAUTION: If saw chain is TOO LOOSE or TOO

TIGHT, the sprocket, bar, chain, and crankshaft bearings will wear more rapidly. Study Fig. 22 for information concerning correct cold tension (A), correct warm tension (B), and as a guide for when saw chain needs adjustment (C).

To adjust the saw chain:

NOTE: Make sure the Chain Brake® is disengaged.

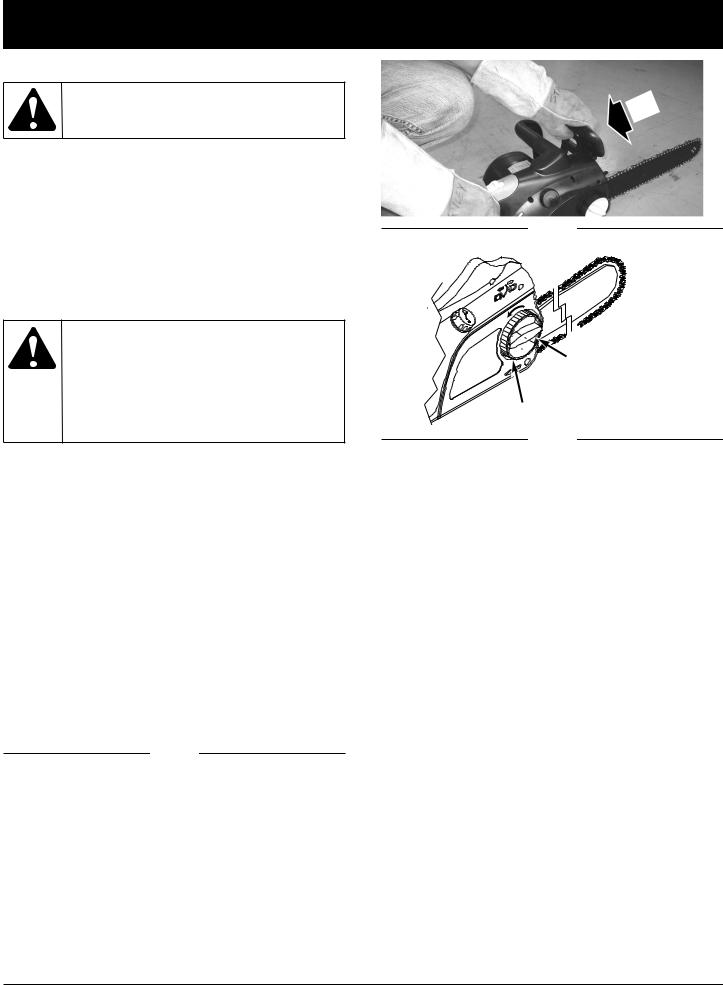

Disengage the Chain Brake® (D) by pulling it backward (Fig. 23).

1.Tensioning the chain can be accomplished with relative ease. Turn bar bolt knob (E) counter clock wise. Then turn ring (F) counter clock wise to loosen chain or clock wise to tighten chain (Fig. 24).

D

Fig. 23

E

F

Fig. 24

2.After adjustment and while wearing heavy duty work gloves, move the saw chain back and forth on the guide bar to be sure the chain moves freely and is in proper mesh with sprocket.

NOTE: If the chain is difficult to rotate or if it binds on the guide bar, too much tension has been applied and must be adjusted as described in step 1.

3.While applying tension to the chain, hold the tip of the bar up and then tighten the bar bolt knob (E).

A B C

Fig. 22

14

MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN AND BAR LUBRICATION

Adequate lubrication of the saw chain during cutting operations is essential to minimize friction with the guide bar.

Your chain saw is equipped with an automatic oiler system. The oiler automatically delivers the proper amount of oil to the bar and chain. There is no flow adjustment.

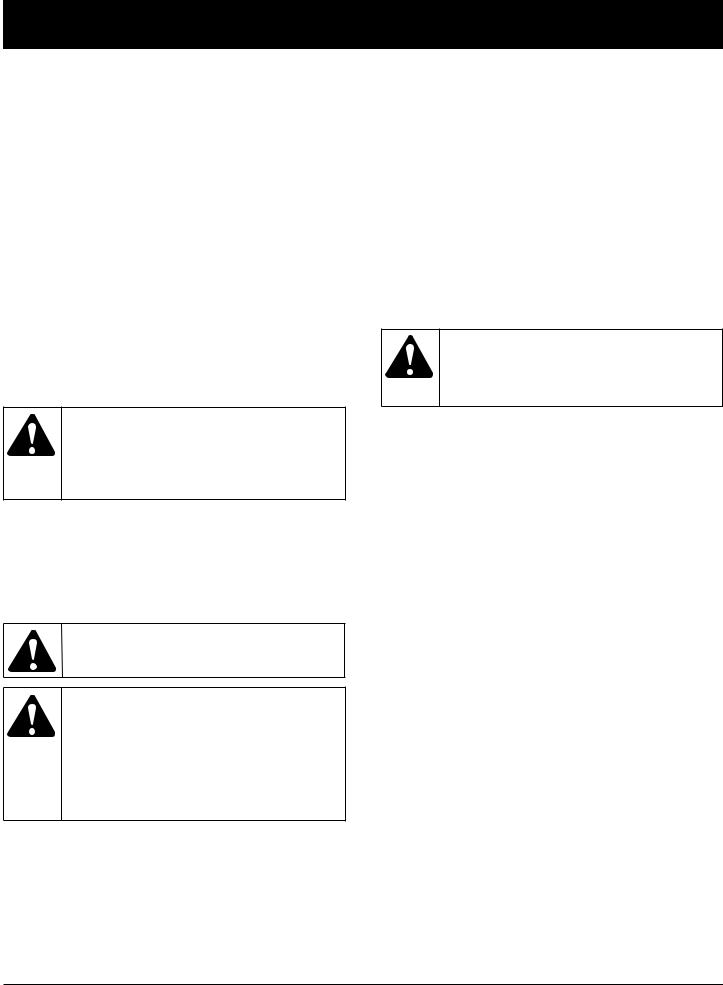

You can check the oil tank level using the inspection slot

(D) provided on the right side of the saw. The tank is full when oil is at the top of the slot (Fig. 25).

D

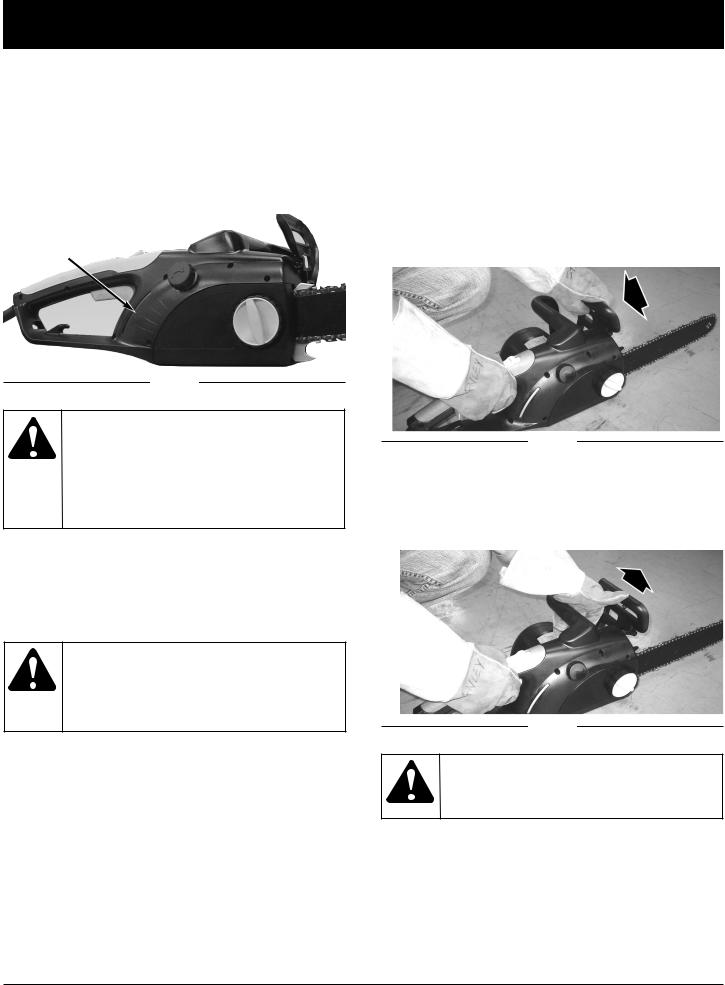

The Chain Brake® is a safety feature which is activated if pressure is applied against the guard or when, in the event of kickback, the operator’s hand strikes the lever. When the Chain Brake® is activated, chain movement abruptly stops and the power supply to the motor is immediately cut off.

The purpose of the Chain Brake® is to reduce the possibility of injury due to kickback. The Chain Brake® cannot, however, provide the measure of intended protection if the saw is carelessly operated.

The Chain Brake® is disengaged (chain can move) when the brake is pulled back and locked. This is the normal running position (Fig. 26).

Fig. 25

CAUTION: Never starve the bar and chain of

lubrication oil. Running the saw DRY or with TOO LITTLE OIL will decrease cutting efficiency, shorten chain saw life, and cause rapid dulling of the chain and excessive wear of the bar from overheating. Too little is evidenced by smoke or bar discoloration.

NOTE: The saw chain stretches during use, particularly when it is new, and occasional adjustment will be needed. A new chain requires more frequent adjustment during the break-in period. This is normal. See Section Saw Chain Tension Adjustment for instructions.

WARNING: A loose chain can jump off the bar while

you are cutting, as well as wear the bar and chain. A chain that is too tight can damage the saw. Either situation, chain too loose or too tight, could cause serious personal injury.

CHAIN BRAKE® / HAND GUARD

This chain saw is equipped with chain brake/hand guard. The Hand Guard protects your left hand in the event it slips off the front handle.

Fig. 26

The Chain Brake® is engaged (chain cannot move) when the brake is in forward position (Fig. 27).

NOTE: The motor will not start if the Chain Brake® is in the engaged position.

Fig. 27

CAUTION: The Chain Brake®

should not be used

for starting and stopping the saw during normal operation

15

MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN BRAKE® TEST

Before cutting with your saw, the Chain Brake® should be tested as follows:

A.Make sure the Chain Brake® is disengaged (Fig. 26).

B.Place the saw on a firm, flat, dry surface that is clear of any debris. Do not let the saw come in contact with any objects.

C.Plug the unit into the power source.

D.Grasp the front handle (not the Chain Brake®/Hand Guard Lever) with your left hand. Thumb and fingers should encircle the handle.

E.Grasp the rear handle with your right hand. Thumb and fingers should encircle the handle.

F.Depress the LOCK/OFF button with your right thumb. Squeeze the trigger with your index finger (Fig. 7).

G.While the motor is running, activate the Chain Brake® by rolling your left hand forward against the lever.

H.Chain and motor should stop abruptly.

WARNING: If the chain and motor fail to stop

when the Chain Brake® is engaged, take the saw to the nearest Authorized Service Center. Do not use the saw if the Chain Brake® is not in proper working order.

EXTENSION CORDS

When using an electric chain saw, plug it into the extension cord only when you are ready to cut wood. Connect the extension cord to a 110/120 voltage outlet. Refer to the Electrical Safety Warnings section.

CAUTION: A cord that is hot to the touch is

overloaded.

WARNING: Do not operate your chain saw in a wet or

damp environment. Do not expose the saw to rain, snow or sleet. Moisture will cause short circuits. Replace or repair any damaged or frayed extension cords before using your saw. Keep the cord away from the cutting area and position the cord so that it will not be caught on branches or other objects during cutting.

DOUBLE INSULATION

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

Information

Do not use if the cord or plug is damaged. Your appliance is double insulated to help protect against electric shock. Double insulation construction consists of 2 separate “layers” of electrical insulation.

Appliances built with this insulation system are not intended to be grounded. As a result, the extension cord used with your appliance can be plugged into any conventional 120 volt electrical outlet.

Normal safety precautions must be observed when operating an electrical appliance. The double insulation system is only for added protection against injury resulting from a possible internal electrical insulation failure.

WARNING: Your double insulated appliance

has no serviceable parts inside. Do not attempt to repair it yourself. For service information, dial 1-800-520-5520.

In this double insulated appliance, 2 systems of insulation, instead of grounding, are provided. No grounding means is provided on a double insulated appliance, nor should a means for grounding be added to the appliance. No serviceable parts are inside. A double insulated appliance is marked with the words, “DOUBLE INSULATION” or “DOUBLE INSULATED.” The symbol (square within a square) may also be marked on the appliance.

Maintenance

1.Place switch in OFF position and unplug the power supply before the appliance is serviced, cleaned, or maintenance is performed.

2.Keep the air intake clean and air vents free of debris to avoid overheating the motor.

3.Clean with a damp sponge and mild soap. Do not squirt with a water hose or douse with water or other liquids.

4.Inspect the saw chain for proper tension before each use and frequently during cutting. Sharpen as required.

5.Clean the guide bar and bar pad to ensure free path for oil.

6.No motor lubrication is necessary. The motor is equipped with lifetime lubricated bearings.

7.If the saw does not operate, turn switch to OFF position and disconnect the extension cord, first from the power supply, then from the saw. Check the power supply for blown fuses or tripped circuit breakers. If it still does not operate, contact a Product Service Department. Call 1-800-520-520 for more information.

Do not attempt to repair it yourself. No serviceable parts are inside.

16

MAINTENANCE AND REPAIR INSTRUCTIONS

GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar is required. Proper maintenance of the guide bar, as explained in this section, is essential to keep your saw in good working condition.

WARNING: Ensure that the power cord is

disconnected before performing any maintenance on your saw.

Sprocket Tip Lubrication

CAUTION: The sprocket tip on your new saw has

been pre-lubricated at the factory. Failure to lubricate the guide bar sprocket tip as explained below will result in poor performance and seizure, voiding the manufacturer’s warranty.

Lubrication of the sprocket tip is recommended after each saw use. Always thoroughly clean guide bar sprocket tip before lubrication.

The Lube Gun (optional) is recommended for applying grease to the guide bar sprocket tip. The Lube Gun is equipped with a needle nose tip which is necessary for the efficient application of grease to the sprocket tip.

Fig. 28

To lubricate the sprocket tip:

1. Unplug the chain saw from the power source.

NOTE: It is not necessary to remove the saw chain to lubricate the guide bar sprocket tip. Lubrication can be done on the job.

WARNING: Always use protective gloves

when handling the saw chain.

2.Clean the guide bar sprocket tip.

3.Using the Lube Gun (optional), insert tip of lube gun into the lubrication hole and inject grease until it appears at outside edge of sprocket tip (Fig. 32).

4.Make sure that the Chain Brake® is deactivated. Rotate saw chain by hand. Repeat lubrication procedure until the entire sprocket tip has been greased.

Maintenance Procedures

Most guide bar problems can be prevented merely by keeping the chain saw well maintained. Incorrect filing and non-uniform cutter and depth gauge settings cause most guide bar problems, primarily resulting in uneven bar wear. As the bar wears unevenly, the rails widen, which may cause chain clatter and difficulty in making straight cuts.

Insufficient guide bar lubrication and operating the saw with chain that is too tight will contribute to rapid bar wear.

To help minimize bar wear, the following guide bar maintenance procedures are recommended:

BAR WEAR - Turn guide bar frequently at regular intervals (for example, after 5 hours of use), to ensure even wear on top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and carry the chain) should be cleaned if saw has been used heavily or if saw chain appears dirty. Rails should always be cleaned every time saw chain is removed.

OIL PASSAGES - Oil passages on the bar should be cleaned to ensure proper lubrication of the bar and chain during operation. This can be done using a soft wire small enough to insert into the oil discharge hole.

NOTE: The condition of the oil passages can be easily checked. If the passages are clear, the chain will automatically give off a spray of oil within seconds of starting the saw. Your saw is equipped with an automatic oiler system.

Cleaning Bar Rails

1.Remove sprocket cover, bar and chain. Refer to the Saw Chain Tension Adjustment section.

2.Using a screwdriver, putty knife, wire brush or other similar instrument, clear residue from the rails on the guide bar. This will keep the oil passages open to provide proper lubrication to the bar and chain (Fig. 29).

3.Reinstall the bar, chain, sprocket cover and bar bolt knob. See Section Install the Guide Bar / Saw Chain for more information.

Fig. 29

17

MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN MAINTENANCE

WARNING: Unless you have experience and

specialized training for dealing with kickback (see Safety Precautions), always use a low-kickback saw chain, which significantly reduces the danger of kickback. Low-kickback saw chain does not completely eliminate kickback. A lowkickback or “safety chain”, should never be regarded as total protection against injury.

A low-kickback saw chain should always be used in conjunction with other kickback protection devices such as the Chain Brake®/Hand Guard furnished with your unit.

Always use a replacement saw chain designed as “lowkickback” or a saw chain which meets the low-kickback performance requirements of ANSI (American National Standards Institute).

A standard saw chain (a chain which does not have the kickback reducing guard links) should only be used by an experienced professional chain saw operator.

What is a Low-Kickback Saw Chain?

A low-kickback saw chain is a chain which has met the kickback performance requirements of ANSI B175.1.

By keeping the Chain Brake® and saw chain in good working condition and correctly serviced as recommended in this manual, you will be able to maintain the safety system of your chain saw over the life of the product.

Chain Tension

Check the chain tension frequently and adjust as often as necessary to keep the chain snug on the bar, but loose enough to be pulled around by hand.

Breaking in a New Saw Chain

A new chain and bar will need chain readjustment after as few as 5 cuts. This is normal during the break-in period, and the interval between future adjustments will begin to lengthen quickly.

Over a period of time, however, the moving parts of the saw chain will become worn, resulting in what is called CHAIN STRETCH. This is normal. When it is no longer possible to obtain correct chain tension adjustment, a link will have to be removed to shorten the chain. See your Authorized Service Center to have this repair performed.

WARNING: Never have more than 3 links

removed from a loop of chain. This could cause damage to the sprocket.

Chain Lubrication

Always make sure the automatic oiler system is working properly. Keep the oil tank filled with Genuine Factory Parts Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cutting operations is essential to minimize friction with the guide bar.

Never starve the bar and chain of lubricating oil. Running the saw dry or with too little oil will decrease cutting efficiency, shorten saw chain life, cause rapid dulling of chain, and lead to excessive wear of bar from overheating. Too little oil is evidenced by smoke or bar discoloration.

Chain Sharpening

Chain sharpening requires special tools to ensure that cutters are sharpened at the correct angle and depth. For the inexperienced chain saw user, we recommend that the saw chain be professionally sharpened by the nearest Authorized Service Center. If you feel comfortable sharpening your own saw chain, special tools are available from your Authorized Service Center.

WARNING: Never remove, modify or make

inoperative any safety device furnished with your unit. The Chain Brake® / Hand Guard and low-kickback saw chain are major safety features provided for your protection.

CHAIN REPLACEMENT INFORMATION

There may be other quality equivalent replacement components for achieving kickback protection.

Bar Length |

Drive Links |

Part Number |

|

|

|

16” Bar |

55 DL |

49M1655P753 |

|

|

|

18

|

TROUBLESHOOTING |

|

|

|

|

|

|

|

|

|

|

UNIT WILL NOT START |

|

|

|

C A U S E |

|

A C T I O N |

|

Unit is unplugged |

|

Check cord to make sure it is plugged into an electrical outlet |

|

GFCI in outlet has tripped (if used) |

|

Reset GFCI |

|

|

|

|

|

If further assistance is required, contact your authorized service dealer.

Call 1-800-520-5520 for more information.

SPECIFICATIONS / FEATURES

Peak H.P. ........................................................................................................................................ |

3 (TB3516), 4 (TB4516) |

Approximate Weight (with bar and chain) ................................................................... |

9.7 lbs. (TB3516), 10.1 lbs. (TB4516) |

Features: |

|

Chain Brake / Hand Guard |

|

Double Insulated |

|

UL and CSA Listed |

|

Trigger Lock / Off |

|

Chain Catcher |

|

19

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by Troy-Bilt LLC with respect to new merchandise purchased and used in the United States, its possessions and territories.

Troy-Bilt LLC warrants this product against defects in material and workmanship for a period of two (2) years commencing on the date of original purchase and will, at its option, repair or replace, free of charge, any part found to be defective in material or workmanship. This limited warranty shall only apply if this product has been operated and maintained in accordance with the Operator’s Manual furnished with the product, and has not been subject to misuse, abuse, commercial use, neglect, accident, improper maintenance, alteration, vandalism, theft, fire, water or damage because of other peril or natural disaster. Damage resulting from the installation or use of any accessory or attachment not approved by Troy-Bilt LLC for use with the product(s) covered by this manual will void your warranty as to any resulting damage. This warranty is limited to ninety (90) days from the date of original retail purchase for any Troy-Bilt product that is used for rental or commercial purposes, or any other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available, WITH PROOF OF PURCHASE THROUGH YOUR LOCAL AUTHORIZED SERVICE DEALER. To locate the dealer in your area, visit our website at www.troybilt.com, check for a listing in the Yellow Pages, call 1-800-520- 5520 or write to P.O. Box 361131, Cleveland, OH 441360019.

This limited warranty does not provide coverage in the following cases:

A.Tune-ups - Filters, Bars, Chains

B.Troy-Bilt LLC does not extend any warranty for products sold or exported outside of the United States of America, its possessions and territories, except those sold through Troy-Bilt’s authorized channels of export distribution.

Troy-Bilt LLC reserves the right to change or improve the design of any Troy-Bilt Product without assuming any obligation to modify any product previously manufactured.

No implied warranty, including any implied warranty of merchantability or fitness for a particular purpose, applies after the applicable period of express written warranty above as to the parts as identified. No other express warranty or guaranty, whether written or oral, except as mentioned above, given by any person or entity, including a dealer or retailer, with respect to any product shall bind Troy-Bilt LLC During the period of the Warranty, the exclusive remedy is repair or replacement of the product as set forth above. (Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the sole and exclusive remedy arising from the sales. TroyBilt LLC shall not be liable for incidental or consequential loss or damages including, without limitation, expenses incurred for substitute or replacement lawn care services, for transportation or for related expenses, or for rental expenses to temporarily replace a warranted product. (Some states do not allow limitations on how long an implied warranty lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the amount of the purchase price of the product sold. Alteration of the safety features of the product shall void this Warranty. You assume the risk and liability for loss, damage, or injury to you and your property and/or to others and their property arising out of the use or misuse or inability to use the product.

This limited warranty shall not extend to anyone other than the original purchaser, original lessee or the person for whom it was purchased as a gift.

How State Law Relates to this Warranty: This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

To locate your nearest service dealer dial 1-800-520-5520.

Troy-Bilt LLC

P.O. Box 361131

Cleveland, OH 44136-0019

Loading...

Loading...