Troy-Bilt 12210-6.5HP, 12209-5.5HP, 12209, 12210 User Manual

SAFETY FIRST!

Before operating this equipment, read this Owner's Manual and the separate manual supplied by the engine manufacturer.

Models

12227 – 3.75HP TUFFY®

12209 – 5.5HP BRONCOTM

12210 – 6.5HP Super BRONCOTM

$ 4.50

OWNER’S MANUAL

Rear-Tine Tillers

•Safety

•Assembly

•Controls

•Operation

•Maintenance

•Parts List

Model

12227 |

TUFFY |

|

Model

12209 |

BR |

ONCO |

|

|

Model 12210

GARDEN WAY INCORPORATED

2

Dear Owner:

You now own one of the finest standard-rotating-tine tillers available. Your new tiller allows you to till and cultivate your garden with ease, and accomplish other property management projects as well. Your tiller is famous for its ruggedness, performance and high-quality engineering. We know you’ll enjoy using it.

Please carefully read this Manual. It tells you how to safely and easily assemble, operate and maintain your machine (four tiller models are covered in this Manual—be sure to use only the information that applies to your model). Be sure that you and any other operators carefully follow the recommended safety practices at all times. Failure to do so could result in personal injury or property damage.

Of course, if you should ever have any problems or questions, please contact your local authorized dealer or call the Factory (see back cover of this Manual). We want to be sure that you are completely satisfied at all times.

NOTE: Be sure to fill out and return the Warranty Registration Card that was supplied with this Manual.

See Back Cover for Customer Service information

Safety Alert Symbol

This is a safety alert symbol. It is used in this manual and on the unit to alert you to potential hazards. When you see this symbol, read and obey the message that follows it. Failure to obey safety messages could result in personal injury or property damage.

This machine meets voluntary safety standard B71.8 – 1996, which is sponsored by the Outdoor Power Equipment Institute, Inc., and is published by the American National Standards Institute.

WARNING

WARNING

The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Table of Contents |

|

|

SECTION 1: SAFETY ........................................... |

|

3 |

Safety Decals ............................................................. |

|

5 |

Operating Symbols ..................................................... |

|

5 |

SECTION 2: ASSEMBLY ....................................... |

|

6 |

Attach Handlebar ........................................................ |

|

6 |

Move Tiller Off Shipping Platform .............................. |

|

6 |

Install Forward Clutch Cable ....................................... |

|

7 |

Install Reverse Clutch Cable (Models 12209/12210) .. |

8 |

|

Check Level of Transmission Gear Oil ........................ |

|

9 |

Add Motor Oil to Engine ............................................. |

|

9 |

Check Hardware for Tightness.................................... |

|

9 |

Check Air Pressure in Tires ........................................ |

|

9 |

SECTION 3: FEATURES & CONTROLS ........................ |

|

10 |

Engine Controls .......................................................... |

|

10 |

Wheel Drive Pins ........................................................ |

|

10 |

Forward Clutch Bail .................................................... |

|

11 |

Reverse Clutch Control ............................................... |

|

11 |

Depth Regulator Lever................................................ |

|

11 |

Handlebar Height Adjustment ..................................... |

|

11 |

SECTION 4: OPERATION ...................................... |

|

12 |

Break-In Operation ..................................................... |

|

12 |

Starting and Stopping the Engine ............................... |

|

12 |

Operating the Tiller ..................................................... |

|

13 |

Tilling Tips & Techniques ........................................... |

|

14 |

Loading and Unloading the Tiller ................................ |

|

16 |

SECTION 5: MAINTENANCE .................................. |

|

17 |

Maintenance Schedule................................................ |

|

17 |

Tiller Lubrication......................................................... |

|

17 |

Check for Oil Leaks..................................................... |

|

17 |

Check Hardware ......................................................... |

|

17 |

Check Tire Pressure.................................................... |

|

17 |

Transmission Gear Oil Service.................................... |

|

17 |

Bolo Tines................................................................... |

|

18 |

Checking and Adjusting Forward Drive Belt Tension .. |

19 |

|

Forward Clutch Bail Adjustment ................................. |

|

20 |

Checking and Adjusting Reverse Drive Belt Tension... |

20 |

|

Engine Cleaning .......................................................... |

|

20 |

Air Cleaner Service ..................................................... |

|

20 |

Engine Oil Service....................................................... |

|

20 |

Spark Plug Service ..................................................... |

|

21 |

Spark Arrester Screen Service .................................... |

|

21 |

Throttle Lever Adjustment .......................................... |

|

21 |

Carburetor/Governor Control Adjustments ................. |

|

21 |

Off Season Storage..................................................... |

|

21 |

Troubleshooting ............................................... |

|

22 |

Parts List ........................................................ |

|

23 |

Customer Service Information .................... |

Back Cover |

|

1

SPARK ARRESTER WARNING TO RESIDENTS OF CALIFORNIA AND SEVERAL OTHER STATES

Under California law, and under the laws of several other states, you are not permitted to operate an internal combustion engine using hydrocarbon fuels on any forest, brush, hay, grain, or grass covered land; or land covered by any flammable agricultural crop without an engine spark arrester in continuous effective working order.

The engine on the unit is an internal combustion engine which burns gasoline, a hydrocarbon fuel, and must be equipped with a spark arrester muffler in continuous effective working order. The spark arrester must be attached to the engine exhaust system in such a manner that flames or heat from the system will not ignite flammable material. Failure of the owner/operator of the unit to comply with this regulation is a misdemeanor under California law (and other states) and may also be a violation of other state and/or federal regulations, laws, ordinances or codes. Contact your local fire marshal or forest service for specific information about which regulations apply in your area.

3

Safety

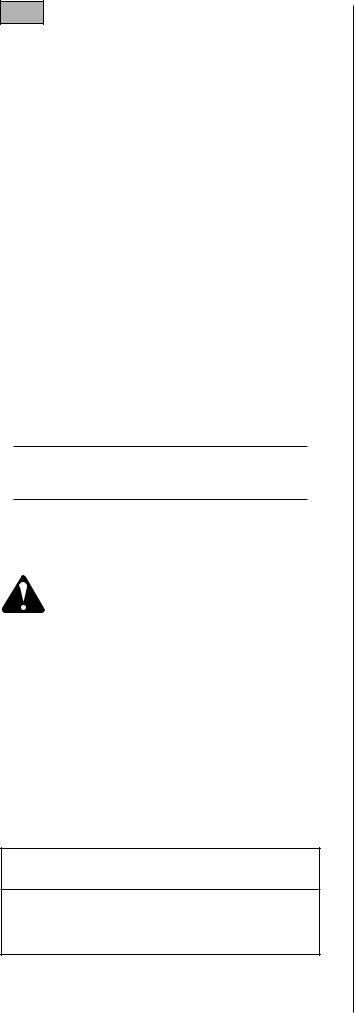

Reverse Clutch

Forward Clutch Bail Control (Models

12209/12210)

BRONCO

Depth Regulator

Tine Hood Flap

Standard-Rotating-

Tines (SRT)

Wheel Drive Pin (on each wheel)

Figure 1-1: Tiller features and controls (5.5HP Model shown). See separate Engine Owner’s Manual to identify engine controls.

Training

1. Carefully read this Owner’s Manual, the separate Engine Owner’s Manual, and any

other literature you may receive. Be thoroughly familiar with the controls and the proper use of the tiller and its engine.

Know how to stop the unit and disengage the controls quickly.

2. Never allow children to operate the tiller. Never allow adults to operate the tiller without proper instruction.

3. Keep the area of operation clear of all persons, particularly children and pets.

4. Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property, and themselves.

Preparation

1.Thoroughly inspect the area where the tiller is to be used and remove all foreign objects.

2.Be sure all tiller controls are released and both wheels are in the Wheel Drive position before starting the engine.

3.Do not operate the tiller without

wearing adequate outer garments. Avoid loose garments or jewelry that could get caught in moving parts.

4.Do not operate the tiller when barefoot or wearing sandals, sneakers, or light footwear. Wear protective footwear that will improve footing on slippery surfaces.

5.Do not till near underground electric cables, telephone lines, pipes or hoses. If in doubt, contact your telephone or utility company.

6.Warning: Handle fuel with care; it is highly flammable and its vapors are explosive. Take the following precautions:

a. Store fuel in containers specifically designed for this purpose.

b. The gas cap shall never be removed or fuel added while the engine is running. Allow the engine to cool for several minutes before adding fuel.

c. Keep matches, cigarettes, cigars, pipes, open flames, and sparks away from the fuel tank and fuel container.

d. Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors. Use a funnel or spout to prevent spillage.

e. Replace all fuel tank and container caps securely.

f.If fuel is spilled, do not attempt to start the engine, but move the machine away from the area of spillage and avoid creating any source of ignition until fuel vapors have dissipated.

7.Never make adjustments when engine is running (unless recommended by manufacturer).

Operation

1. Do not put hands or feet near or under rotating parts.

2. Exercise extreme caution when on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine, remove the wire from the spark plug wire and prevent it from touching the spark plug. Thoroughly inspect the machine for any damage and repair the damage before restarting and operating the machine.

4 Section 1: Safety

4. Exercise caution to avoid slipping or falling.

5. If the unit should start to vibrate abnormally, stop the engine, disconnect the spark plug wire and prevent it from touching the spark plug, and check immediately for the cause. Vibration is generally a warning of trouble.

6. Stop the engine, disconnect the spark plug wire and prevent it from touching the spark plug, whenever you leave the operating position, before unclogging the tines, or when making any repairs, adjustments or inspections.

7.Take all possible precautions when leaving the machine unattended. Stop the engine. Disconnect the spark plug wire and move it away from the spark plug. Be sure that both wheels are in the Wheel Drive position.

8.Before cleaning, repairing, or inspecting, stop the engine and make certain all moving parts have stopped. Disconnect the spark plug wire and prevent it from touching the spark plug to prevent accidental starting.

9.The flap on the tine hood must be down when operating the tiller.

10.Never use the tiller unless proper guards, plates, or other safety protective devices are in place.

11.Do not run the engine in an enclosed area. Engine exhaust contains carbon monoxide gas, a deadly poison that is odorless, colorless, and tasteless.

12.Keep children and pets away.

13.Never operate the tiller under engine power if the wheels are in the Freewheel position. In the Freewheel position, the wheels will not hold the tiller back and the revolving tines could propel the tiller rapidly, possibly causing loss of control. Always engage the wheels with the wheel drive pins in the Wheel Drive position before starting the engine or engaging the tines/wheels with the Forward Clutch Bail (all models) or the Reverse Clutch control (Models 12209/12210 only).

14.Be aware that the tiller may unexpectedly bounce upward or jump forward if the tines should strike extremely hard packed soil, frozen ground, or buried obstacles like large stones, roots, or stumps. If in doubt about the tilling conditions, always use the following

operating precautions to assist you in maintaining control of the tiller:

a.Walk behind and to one side of the tiller, using one hand on the handlebars. Relax your arm, but use a secure hand grip.

b.Use shallower depth regulator settings, working gradually deeper with each pass.

c.Use slower engine speeds.

d.Clear the tilling area of all large stones, roots and other debris.

e.Avoid using downward pressure on the handlebars. If need be, use slight upward pressure to keep the tines from digging too deeply.

f.Before contacting hard packed soil at the end of a row, reduce engine speed and lift the handlebars to raise the tines out of the soil.

g.In an emergency, stop the tines and wheels by releasing whichever clutch control is engaged. Do not attempt to restrain the tiller.

15.Do not overload the tiller’s capacity by attempting to till too deeply at too fast a rate.

16.Never operate the tiller at high transport speeds on hard or slippery surfaces. Look behind and use care when backing up.

17.Do not operate the tiller on a slope that is too steep for safety. When on slopes, slow down and make sure you have good footing. Never permit the tiller to freewheel down slopes.

18.Never allow bystanders near the unit.

19.Only use attachments and accessories that are approved by the manufacturer of the tiller.

20.Use tiller attachments and accessories when recommended.

21.Never operate the tiller without good visibility or light.

22.Never operate the tiller if you are tired; or under the influence of alcohol, drugs or medication.

23.Operators shall not tamper with the engine-governor settings on the machine; the governor controls the maximum safe operating speed to protect the engine and all moving parts from damage caused by overspeed. Authorized service shall be sought if a problem exists.

24.Do not touch engine parts which may be hot from operation. Let parts cool down sufficiently.

25.Please remember: You can always stop the tines and wheels by releasing the Forward Clutch Bail or on Models 12209 and 12210 the Reverse Clutch control, (whichever control is engaged), or by moving the ignition switch and/or throttle control lever on the engine to “OFF” or “STOP”.

26.To load or unload the tiller, see the instructions in Section 4 of this Manual.

27.Use extreme caution when reversing or pulling the machine towards you.

28.Start the engine carefully according to instructions and with feet well away from the tines.

29.Never pick up or carry a machine while the engine is running.

Maintenance and Storage

1.Keep the tiller, attachments and accessories in safe working condition.

2.Check all nuts, bolts, and screws at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

3.Never store the tiller with fuel in the fuel tank inside a building where ignition sources are present such as hot water and space heaters, furnaces, clothes dryers, stoves, electric motors, etc.). Allow the engine to cool before storing the unit in any enclosure.

4.To reduce the chances of a fire hazard, keep the engine free of grass, leaves, or excessive grease.

5.Store gasoline in a cool, well-ventilated area, safely away from any sparkor flame-producing equipment. Store gasoline in an approved container, safely away from the reach of children.

6.Refer to the Maintenance sections of this Manual and the separate Engine Owner’s Manual for instructions if the unit is to be stored for an extended period.

7.Never perform maintenance while the engine is running or the spark plug wire is connected, except when specifically instructed to do so.

8.If the fuel tank has to be drained, do this outdoors.

|

Section 1: Safety |

5 |

|

|

|

|

|

|

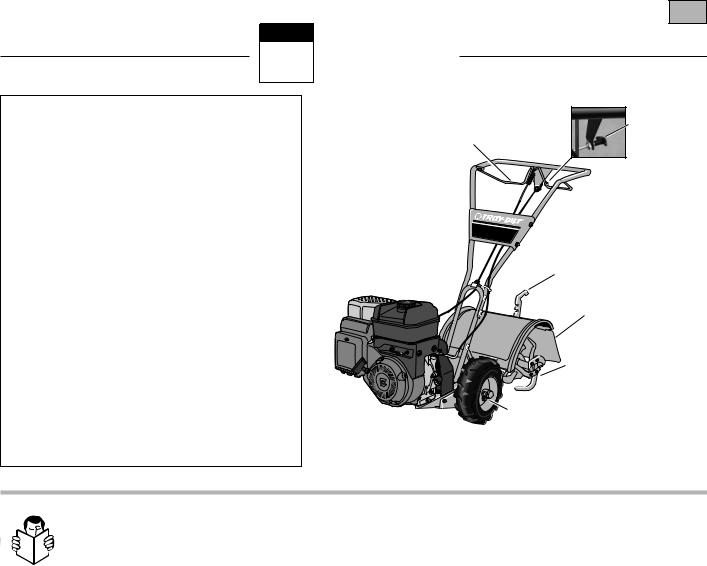

Decals

For your safety and the safety of others, various safety and operational decals are located on your unit (see Figure 1-2).

Keep the decals clean and legible at all times. Contact your local service dealer or the factory for replacements if any decals are damaged or missing.

Refer to the Parts List pages in this Manual for decal locations, descriptions and part numbers.

Forward Clutch Bail |

Reverse Clutch Control |

Operating Instruction |

|

Operating Instruction |

(Models 12209/12210) |

Starting Stabilization |

|

Message (on engine) |

BRONCO |

|

Warning Messages |

Hot Surfaces Warning

(on belt cover)

Figure 1-2: Location of safety and operating decals (5.5HP Model shown).

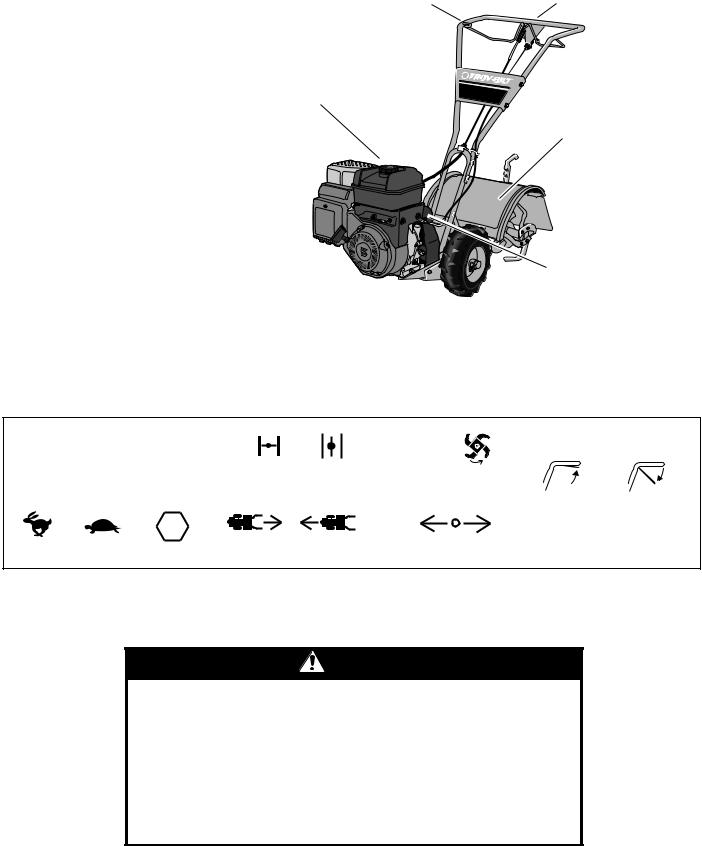

Operating Symbols

Various symbols (shown here, with word descriptions) may be used on the tiller and engine. Your unit may not have all of the symbols.

|

|

STOP |

FAST |

SLOW |

STOP |

|

|

R

CHOKE |

CHOKE |

REVERSE |

|

ROTATING |

|

||

ON |

OFF |

|

|

TINES |

|

||

|

|

BAIL |

|

|

|

BAIL |

|

|

|

ENGAGED |

DISENGAGED |

TILLER DIRECTION |

LEVER DIRECTION |

|

|

WARNING

TO AVOID SERIOUS INJURY:

•READ THE OWNER’S MANUAL.

•KNOW LOCATIONS AND FUNCTIONS OF ALL CONTROLS.

•KEEP ALL SAFETY DEVICES AND SHIELDS IN PLACE AND WORKING.

•NEVER ALLOW CHILDREN OR UNINSTRUCTED ADULTS TO OPERATE TILLER.

•SHUT OFF ENGINE AND DISCONNECT SPARK PLUG WIRE BEFORE MANUALLY UNCLOGGING TINES OR MAKING REPAIRS.

•KEEP BYSTANDERS AWAY FROM MACHINE.

•KEEP AWAY FROM ROTATING PARTS.

•USE EXTREME CAUTION WHEN REVERSING OR PULLING THE MACHINE TOWARDS YOU.

6

Section2 Assembly

WARNING

WARNING

To prevent personal injury or property damage, do not start the engine until all assembly steps are complete and you have read and understand the safety and operating instructions in this manual.

INTRODUCTION

Carefully follow these assembly steps to correctly prepare your tiller for use. It is recommended that you read this Section in its entirety before beginning assembly.

NOTE: Various tiller models are presented in this Manual. Use only the information appropriate for your tiller model.

INSPECT UNIT

Inspect the unit and carton for damage immediately after delivery. Contact the carrier (trucking company) if you find or suspect damage. Inform them of the damage and request instructions for filing a claim. To protect your rights, put your claim in writing and mail a copy to the carrier within 15 days after the unit has been delivered. Contact the factory if you need assistance in this matter.

TOOLS/MATERIALS NEEDED FOR ASSEMBLY

(1)3/8” open-end wrench*

(2)7/16" open-end wrench*

(2) 1/2" open-end wrench*

(2) 9/16" open-end wrench*

(1) Large adjustable wrench (Models 12209/12210 only)

(1) Scissors (to trim plastic ties)

(1) Ruler (for belt tension check)

(1) Block of wood (to support tiller when removing wheels)

(1) Tire pressure gauge (for models with pneumatic tires)

(1) Clean oil funnel

(1)Motor oil. Refer to the Engine Owner’s Manual for oil specifications and quantity required.

*Adjustable wrenches may be used.

ASSEMBLY STEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE: While unpacking, do not severely bend any control cables.

1. The tiller weighs approximately 133 lbs. Do not attempt to remove it from the shipping platform until instructed to do so in these Assembly steps.

2.Remove any packaging material from the carton. Remove any staples from the bottom of the carton and remove the carton from the shipping platform.

3.Remove all unassembled parts and the separate hardware bag from the carton. Check that you have the items listed in the Loose Parts List (contact your local dealer or the factory items are missing or damaged). NOTE: Use the screw length template (Fig. 2-1) to identify screws.

Loose Parts List

Qty. Description

1Handlebar Support (see A, Fig. 2-2)

1Handlebar Assembly (see K, Fig. 2-2)

Hardware bag contents:

1Slotted hd. screw, #10-24 x 2"

1Hex hd. screw, 1/4-20 x 1-1/4"

6Hex hd. screw, 5/16-18 x 1-1/2"

2Hex hd. screw, 3/8-16 x 3/4"

2 Flat washer, 3/8"

6 Split lockwasher, 5/16"

1Hex locknut, 1/4"-20

6Hex nut, 5/16"-18

1Hex nut, #10-24

2Hex locknut, 3/8"-16

1 Spring, cable (see W, Fig. 2-5)

1 Bracket, forward clutch cable (see P, Fig. 2-4)

IMPORTANT: Motor oil must be added to the engine crankcase before the engine is started. Follow the instructions in this Assembly Section and in the separate

Engine Owner’s Manual.

NOTE: LEFT and RIGHT sides of the tiller are as viewed from the operator’s position behind the handlebars.

1 |

2 |

Figure 2-1: To identify length of screws, place screw on template as shown and measure distance between bottom of screw head and tip of screw.

STEP 2: ATTACH HANDLEBAR

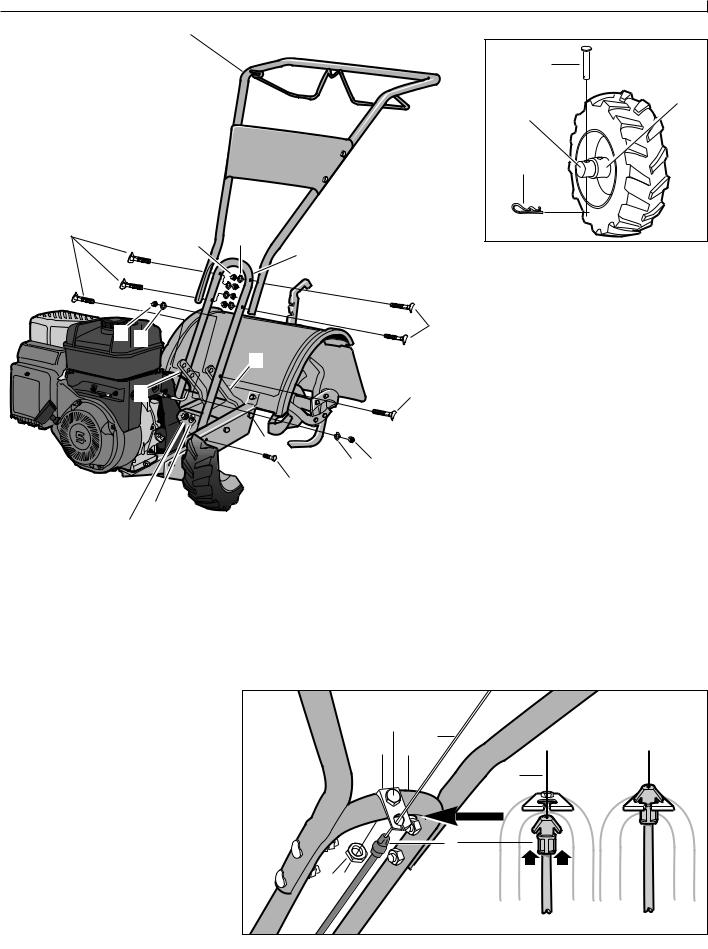

1.Loosely attach the legs of the handlebar support (A, Fig. 2-2) to the inner sides of the tiller frame using two 3/8"-16 x 3/4" hex hd. screws (B), 3/8" flat washers (C) and 3/8"-16 hex locknuts (D).

2.There are three height adjustment holes in the two handlebar support brackets (E and F, Fig. 2-2). Use a setting that will position the handlebars at approximately waist level when the tines are 3"-4" into the soil. Loosely attach the support brackets to the handlebar support (A) using two 5/16"-18 x 1-1/2" screws (G), 5/16" split lockwashers (H) and 5/16"-18 hex nuts (I). NOTE: If a support bracket will not move, loosen attaching screw (J) and nut.

3.Attach the handlebar assembly (K) to the handlebar support (A) using four 5/16"-18 x 1-1/2" screws (G), 5/16" split lockwashers (H) and 5/16"-18 hex nuts (I). Tighten the four screws securely.

4.Tighten all handlebar mounting hardware securely.

STEP 3: MOVE TILLER OFF

SHIPPING PLATFORM

To roll the tiller off the shipping platform, put the wheels in FREEWHEEL, as follows:

1. Place a sturdy block under the transmission to raise one wheel about 1" off the ground.

Section 2: Assembly |

7 |

K

M

O

N

L

G |

|

I |

H |

|

|

|

A |

Fig. 2-3: Wheel in FREEWHEEL position |

|

|

|

|

||

|

|

|

|

(wheel drive pin through wheel shaft only). |

|

I |

H |

|

G |

|

|

STEP 4: INSTALL FORWARD |

||

|

|

|

||

|

|

|

E |

CLUTCH CABLE |

F |

G |

1. Attach the forward clutch cable bracket |

(P, Fig. 2-4) to the handlebar support (A) |

||

|

|

with a 1/4"-20 x 1-1/4" hex hd. screw (R) |

|

|

and 1/4"-20 hex locknut (S). Tighten |

J |

|

securely. |

H |

I |

2. Carefully unwrap the forward clutch |

B |

|

cable (cable without an attached knob) |

C |

|

from its shipping position and slide the |

|

thin cable wire (T, Fig. 2-4) into the slot in |

|

D |

|

the cable bracket. Push the cable con- |

Fig. 2-2: Attach handlebar (5.5HP Model shown). |

|

nector (U, Fig. 2-4) up through the hole in |

|

the bracket until the groove in the con- |

|

|

|

|

|

|

nector snaps into place. |

|

|

3. Insert the #10-24 x 2" slotted hd. screw |

2. Remove the hairpin cotter (L, Fig. 2-3) |

|

(V, Fig. 2-5) down through the hooked |

and wheel drive pin (M) from the wheel |

|

end of the cable spring (W) until the screw |

hub (O) and wheel shaft (N). |

|

threads extend through the spring. |

3. Slide the wheel fully inward on the |

|

|

wheel shaft (N, Fig. 2-3). Reinstall the |

|

|

wheel drive pin (M) through the wheel |

|

|

shaft only (not through the wheel hub). |

|

R |

Secure the wheel drive pin with the hairpin |

|

|

P |

T |

|

cotter (L), pushing the hairpin cotter in as |

A |

|

far as it will go. The wheel should now |

|

T |

spin freely (freewheel) on the wheel shaft. |

|

|

|

|

|

Repeat with the other wheel. |

|

|

4. Use the handlebar to roll the tiller to a flat area.

IMPORTANT: Before starting the engine,

the wheels must be placed in the WHEEL

S

DRIVE position (pins through wheel hubs and wheel shaft). This procedure is described in Wheel Drive Pins in Section 3.

and cable.

8 Section 2: Assembly

4.Thread the #10-24 hex nut (Z, Fig. 2-5) halfway onto the screw (V).

5.Thread the screw (V) into the cable adjuster (X).

6.Hook the cable spring (W, Fig. 2-6) into the V-shaped bend in the Forward Clutch Bail (Y).

7.Check for correct tension on the forward drive belt by taking two measurements of the cable spring, as follows:

a.With the Forward Clutch Bail (Y, Fig. 2- 6) in an open (released) position, measure the length of the cable spring (W) from the outermost coil to the outermost coil.

b.Squeeze the Forward Clutch Bail against the handlebar (see Fig. 2-7) and remeasure the spring length. The belt tension is correct if this second measurement is between 1/16" to 3/16" longer than the first measurement. If so, turn the hex nut (Z, Fig. 2-7) tightly against the cable adjuster (X) while preventing the cable adjuster from turning.

c.If the spring length is incorrect, you must adjust the cable tension as described in Checking and Adjusting Forward Drive Belt Tension in Section 5. Incorrect cable tension can result in belt slippage (cable tension too loose), or unintentional tine movement when the clutch bail is in Neutral (cable tension too tight).

Y

W |

W |

|

V

Z

X

Z

X

Hold bail against handlebar while taking second measurement of spring

STEP 5: INSTALL REVERSE CLUTCH CABLE (MODELS 12209 AND 12210 ONLY)

1.Unwrap the reverse clutch cable (CC, Fig. 2-8 and Fig. 2-9) from its shipping position and route it up to the handlebar. Be sure that the cable is routed beneath the Forward Clutch Bail.

2.Remove the two self-tapping screws (AA, Fig. 2-8) from the handlebars, position the reverse cable mounting bracket (BB) as shown, and reinstall the two screws.

3.Insert the cable (CC, Fig. 2-8) through the slot in the cable bracket and position the flat side of the threaded assembly next to the flat side of the hole. Slide the hex nut (DD) up the cable and tighten it securely.

4.Fasten the reverse clutch cable to the left side handlebar with a cable tie (EE, Fig. 2-9).

5.Test the function of the reverse clutch by pulling out and releasing the cable knob. The knob should return to its neutral position (resting against bracket). If it doesn’t, contact your local dealer or the factory for technical assistance.

AA |

|

BB |

AA |

|

|

DD |

|

CC |

|

|

Flat Side |

Install reverse cable bracket and clutch cable.

CC

BRONCO

EE

(CC) as

Fig. 2-5: Cable |

|

spring and |

clutch cable spring to |

adjuster. |

forward clutch bail. |

|

Section 2: Assembly |

9 |

|

|

|

|

|

|

STEP 6: CHECK LEVEL OF TRANSMISSION GEAR OIL

The transmission was filled with gear oil at the factory. However, you should check the gear oil level at this time to make certain it is correct.

IMPORTANT: Do not operate the tiller if the gear oil level is low. Doing so will result in severe damage to the transmission components.

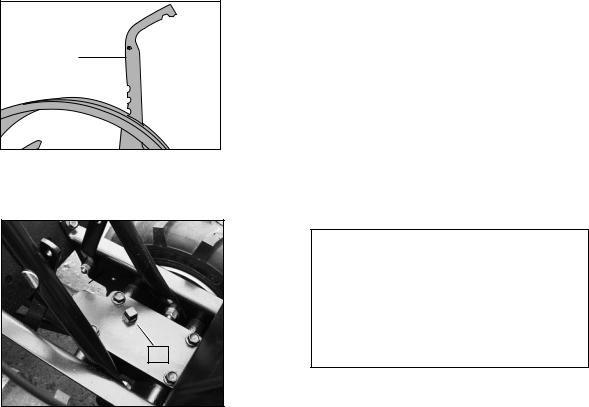

1.With the tiller on level ground, pull the Depth Regulator Lever (FF, Fig. 2-10) back and then all the way up until the lowest notch in the lever is engaged.

2.Remove the oil fill plug (GG, Fig. 2-11) from the transmission housing cover and locate the main drive shaft situated inside the housing.

3.The gear oil level is correct if the gear oil is approximately halfway up the side of the main drive shaft.

4.If the oil level is low, add gear oil by referring to A. To Check the Transmission Gear Oil Level in Section 5.

FF

Lever.

GG

STEP 7: ADD MOTOR OIL

TO ENGINE

The tiller is shipped without oil in the engine.

IMPORTANT: Do not start the engine without first adding motor oil. Severe engine damage will result if the engine is run without oil.

1.Refer to the separate Engine Owner’s Manual for engine oil specifications and capacities.

2.With the tiller on level ground, move the Depth Regulator Lever (FF, Fig. 2-10) up or down until the engine is level.

3.Add motor oil as described in the Engine Owner’s Manual.

4.Move the Depth Regulator Lever all the way down until the highest notch is engaged. This places the tines in the “travel” position, which allows the tiller to be moved without the tines touching the ground.

STEP 8: CHECK HARDWARE

FOR TIGHTNESS

Check all nuts and screws for tightness.

STEP 9: CHECK AIR PRESSURE IN

TIRES (units with pneumatic tires)

On tires equipped with air valves, check the air pressure with a tire gauge. Deflate or inflate the tires equally to 15 to 20 PSI (pounds per square inch). Be sure that both tires are inflated equally or the unit will pull to one side.

IMPORTANT: This completes the assembly steps. Before operating your tiller, make sure you read the following sections in this Manual, as well as the separate Engine Owner’s Manual:

•Section 1: Safety

•Section 3: Features and Controls

•Section 4: Operation

Fig. 2-11: Remove gear oil fill plug.

10

Section3 Features and Controls

WARNING

WARNING

Before operating your machine, carefully read and understand all safety, controls and operating instructions in this Manual, the separate Engine Owner’s Manual, and on the decals on the machine.

Failure to follow these instructions can result in serious personal injury.

INTRODUCTION

This Section describes the location and function of the controls on your tiller. Refer to the following Section, Operation for detailed operating instructions.

Practice using these controls, with the engine shut off, until you understand the operation of the controls and feel confident with each of them.

ENGINE CONTROLS

Refer to the engine manufacturer’s Engine Owner’s Manual (included in the tiller literature package) to identify the controls on your engine.

IMPORTANT: The control for stopping the engine is located on the engine.

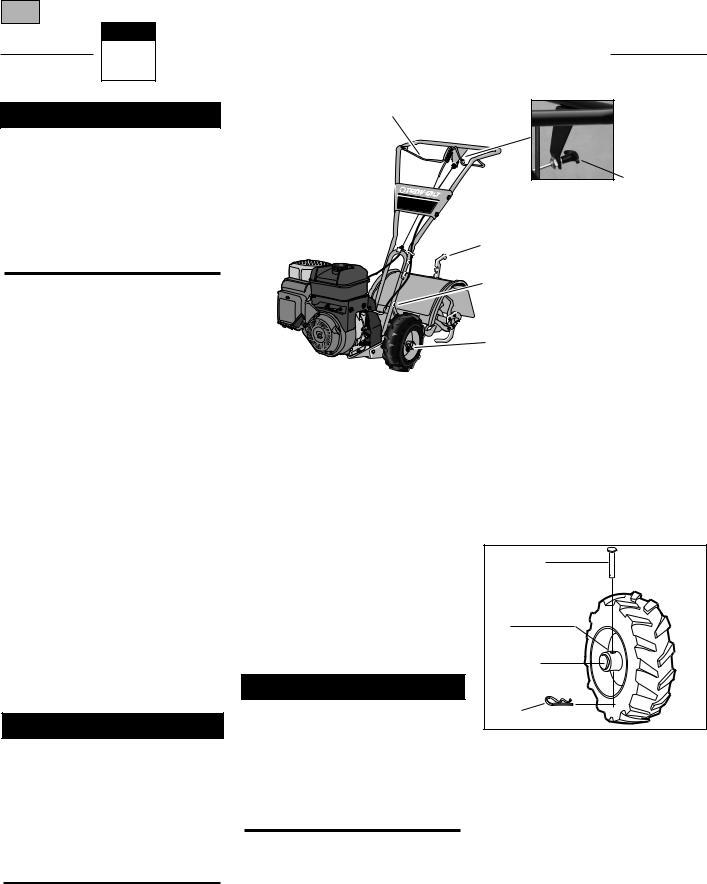

WHEEL DRIVE PINS

Each wheel is equipped with a wheel drive pin (A, Figures 3-2 and 3-3) that secures the wheel to the wheel shaft (B). The wheels can be positioned in either a WHEEL DRIVE or a FREEWHEEL mode.

WARNING

WARNING

Never allow either of the wheels to be in the FREEWHEEL position when the engine is running. Always put both wheels in the WHEEL DRIVE position before starting the engine.

Failure to comply could cause loss of tiller control, property damage, or personal injury.

Before starting the engine, put both wheels in the WHEEL DRIVE position by inserting the wheel drive pins through the wheel hubs and the wheel shaft. Doing so

“locks” the wheels to the wheel shaft, causing the wheels to turn when either the

Forward Clutch Bail

BRONCO

Reverse Clutch

Control (Models

12209/12210)

Depth Regulator

Handlebar Height

Adjustment

Wheel Drive Pin (on each wheel)

Figure 3-1: Tiller features and controls (5.5HP Model shown). See separate Engine Owner’s Manual to identify engine controls.

Forward Clutch Bail (all models) or the Reverse Clutch Control (Models 12209 and 12210) is engaged.

Use the FREEWHEEL mode only when the engine is not running. In FREEWHEEL, the wheel drive pins are placed only through the holes in the wheel shaft (not the wheel hubs), thus allowing the wheels to turn freely when you manually move the tiller.

To place the wheels in WHEEL DRIVE or FREEWHEEL:

1. Stop engine, disconnect spark plug wire from spark plug and allow engine to cool.

WARNING

WARNING

Do not place tiller on its side when changing wheel drive positions. Doing so could result in gasoline leaking from the fuel tank.

Failure to follow this instruction could result in personal injury or property damage.

2.Raise one wheel about one inch off the ground and place a sturdy support under the transmission.

3.Remove hairpin cotter (C, Figures 3-2 and 3-3) from wheel drive pin (A).

4.FOR WHEEL DRIVE MODE (Figure 3-2): Slide wheel outward and align holes in wheel hub (D, Figure 3-2) and wheel shaft

(B). Insert wheel drive pin (A) through

wheel hub (D) and wheel shaft (B). Secure wheel drive pin with hairpin cotter (C) by pushing hairpin cotter in as far as it will go. Repeat with the other wheel and then remove the support from beneath the transmission.

A

D

B

C

Figure 3-2: WHEEL DRIVE position.

5. FOR FREEWHEEL MODE (Figure 3-3): Slide the wheel inward and insert the wheel drive pin (A, Figure 3-3) only through the hole in the wheel shaft (B). Secure wheel drive pin with hairpin cotter

(C) by pushing hairpin cotter in as far as it will go. Repeat for the other wheel and then remove the support from beneath the transmission.

Loading...

Loading...