Toshiba LF654, LF620F User Manual

|

|

|

|

|

Field Intelligent Device – Mount Anywhere Series - Flanged |

LF654 /LF620 |

|

|

|||

|

LF654 /LF622 |

||

|

Electromagnetic Flowmeter |

|

|

|

1/2" to 18" (15 to 450 mm) |

||

|

|

|

|

|

|

|

|

Introduction

The electromagnetic flowmeter uses Faraday’s Law of electromagnetic induction to measure the process flow. The device consists of two units: a detector, through which the fluid to be measured flows and in which low-level signals proportional to flow rates are obtained; and a converter, which supplies excitation current to the detector, and amplifies the signals from the detector and then processes and converts the signals into the 4–20 mAdc current signal or communication signal. The meter features a Mount-Anywhere magnetic field distribution technology, the meter is highly immune to upstream flow disturbances. Combined with a multi-functional converter LF620 (combined type) or LF622 (separate type) equipped with its patented Noise-Sentry original noisesuppression circuit and advanced algorithms. The LF654 has a very high tolerance to noise, giving the unit a very stable output even for slurry fluid measurement. IR (Infrared) switches enable parameter setting of the converter without removing the cover. Flow direction can be set in either way, and its unique 128 x 128 dot matrix LCD display allows the LCD to be rotated electronically to 90, 180 and 270 degrees without opening the cover.

*HART protocol (Highway Addressable Remote Transducer) is a communication protocol for industrial sensors recommended by the HCF (HART Communication Foundation).

**DevComm2000 Smart Device Communicator available through TIC for performing HART device configurations on PC or laptop.

*PROFIBUS is the communications protocol for factory and process automation that the PROFIBUS Organization recommends. Instead of analog control with a conventional analog signal (4-20 mA), it is fieldbus which digitizes all signals. Flowmeters support PROFIBUS-PA.

*Modbus is the communication protocol that Modicon Inc. developed. Physical layer is RS485.

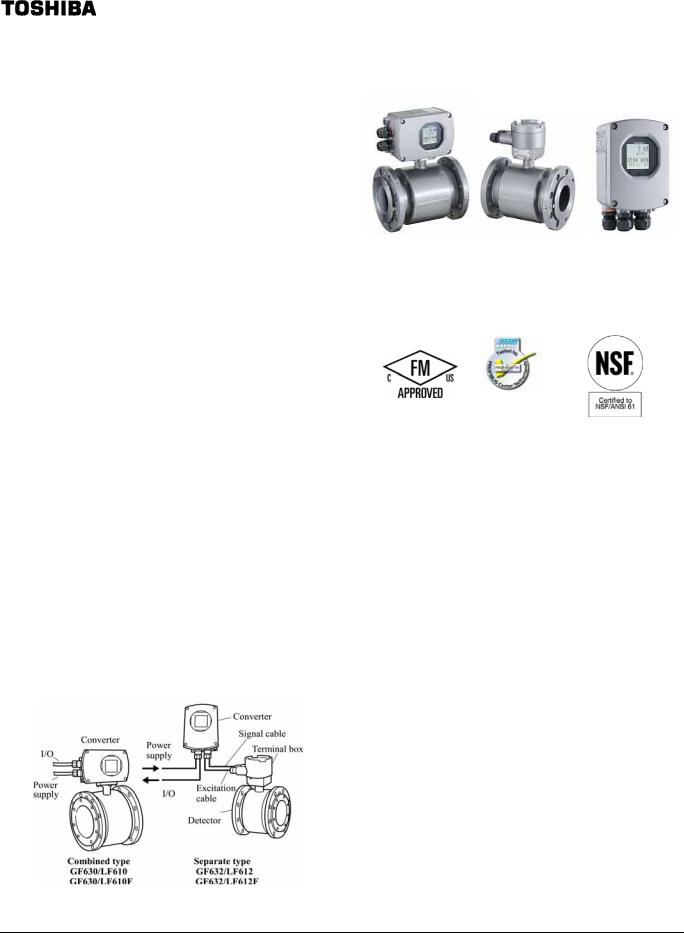

LF654/LF620F |

LF654 |

LF622F |

Figure2. LF654 Mount-Anywhere Series

Flowmeters

Certification

No. Z01207

For PU and

HR lined flowmeter

Specifications

Overall Specifications

Measurement range in terms of flow velocity:

0 –1.0 ft/s to 0 – 39.4ft/s (0 – 0.3 m/s to 0 –12 m/s).

0 – 0.3 ft/s to 0 – 1.0 ft/s (0 – 0.1 m/s to 0 – 0.3 m/s) range is available optionally.

Accuracy:

< 1/2" to 18" ( 15mm to 450mm) >

±0.2 % of Rate*

*This pulse output error result is established under standard operating conditions at Toshiba admitted flow calibration facility. (NIST Traceable)

*Individual meter measurement error may vary up to ±0.5% of Rate at 1.64 ft/s (0.5m/s) or more and ±0.3% of rate ±0.039 inch/s (1mm/s) at 1.64 ft/s or less.

*Current output: plus ± 8µA (0.05% of span.)

*Refer to individual calibration data for each individual meter's measurement error.

Combined type |

|

Separate type |

|

|

|

Figure1. Configuration

TIC-LF654L

TIC-LF654L

Fluid conductivity:

3µS/cm minimum

Fluid temperature:

-4 to 248 °F (-20 to +120 °C): PFA lined flowmeter

-4 to 140 °F (-20 to +60 °C): Polyurethane lined flowmeter

23 to 176 °F (- 5to +80 °C): Hard Rubber lined flowmeter

Ambient temperature:

-40 to 140 °F (-40 to +60 °C): PFA lined flowmeter

-4 to 140 °F (-20 to +60 °C):

PU lined and HR lined flowmeters

Structure:

Standard — IP 67 and NEMA 4X Watertight

Option — IP68 and NEMA 6P Submersible type allows for accidental submergence up to 15m for 48 hours. This option is only available when PU or HR liners are selected.

Power consumption:

Standard:10W(14VA)

at AC100V and Excitation current:0.2A MAX:15W (22VA)

MAX:17W(24VA) with PROFIBUS

Approved hazardous location certifications:

Model: LF654/LF620F and LF654/LF622F cFMus Nonincendive for use in

hazardous (classified) locations:

Class I, II, III, Division 2, Groups A-G

Detector and converter combination:

LF650/LF620: Combined type for standard specification.

LF650/LF622: Separate type for standard specification.

LF654/LF620F: Combined type with Ex approval of Class I, II, III, Division 2 (cFMus).

LF654/LF622F: Separate type with Ex approval of Class I, II, III, Division 2 (cFMus).

Mount-Anywhere Technology:

With TOSHIBA’s unique magnetic field distribution technology the meter is highly immune to upstream flow disturbances.

A minimum of 1D (one diameter) length of upstream straight pipe from the flange is required to maintain the specification performance.

Note: The test results were obtained and demonstrated at TOSHIBA's flow calibration facility, Fuchu Japan.

Drinking water approvals:

PU and HR liner: NSF certified

Model LF654 Detector

Mounting style: Flange connection type

Fluid pressure:

-15 psi or -1.0 bar (-0.1 MPa) to the nominal pressure of the connection flange.

Note: Before shipping from the manufacturer, each detector unit is tested by the following test condition. Pressure… twice of the pressure index number

(ex. 300 psi in case of ASME B 16.5 class 150 flange) Time… 15 minutes

Connection flange standards:

ASME B16.5 class 150, ASME B16.5 class 300 EN1092-1 PN10, EN1092-1 PN16

JIS B 2220 10K, JIS B 2220 20K

Principal materials: Case — carbon steel

Flange material — carbon steel Linings —

1/2” to 18” (15 to 450mm): PFA 1/2” to 18” (15 to 450mm): PU

4” to 18” (100 to 450mm): HR

Note: PFA liners are mechanically retained for full vacuum service (65 to 450 mm).

Electrodes —

Type-Super smooth, polished with self cleaning finish, and non stick shape

316L stainless steel (std.) in case of PU and HR lining

Hastelloy C equivalent (std.) … in case of PFA lining

Note: Electrodes are mechanically buffed and electro-chemically polished.

Grounding rings — 316 stainless steel (std.)

Note: See Table 4 for optional materials and other related information.

Measuring tube material — 304 stainless steel Terminal box material — ADC12(Aluminum

alloy die casting) Coating: Polyurethane resin coating (std.) gray colored

Dimensions and weights: See Figure 3, 4, 5 and 6.

Cable connection port: for separate type detectors.

Cable gland —

LF650: Provided as standard, G 1/2 male screws. LF654(with cFMus):Not provided, 3/4–14NPT

male screws are required.

Applicable diameter —

0.433 to 0.512 inch (11 to 13mm)

2

TIC-LF654L

Model LF620 and LF622 converters

Input signals

Analog signal — the voltage signal from detector, proportional to process flow rate (for LF622 separate type converter).

Digital input DI

Signal type: 20 to 30Vdc voltage signal Input resistance: 2.7k

Number of inputs: one point

Note: DI cannot be used with the Modbus communication.

DI function — One of the following functions can be assigned to the DI signal.

Range switching — Selects either the higher or lower range in the unidirectional or bidirectional 2-range setting.

Totalizer control — ‘Starts and stops’ or ‘Rest and start’ the built-in totalizer.

Fixed-value outputs —Outputs fixed-values for current and pulse outputs for loop check.

Zero adjustment — Executes zero adjustment (on-stream at zero flow rate).

Output signals Current output:

4–20mAdc (load resistance 0 to 750 )

Note: The current output cannot be used with the PROFIBUS-PA communication.

(Refer table 6 for details)

Digital outputs — Two points are available as follows.

Digital output DO1:

Output type: Transistor open collector Number of outputs: One point

Output capacity: 30Vdc, 200mA maximum

Note: DO1 cannot be used if Modbus communication connection is 3 lines. (Refer table 6 for details)

Digital output DO2 :

Output type:

Solid-state relay output (non polarity) Number of outputs: One point

Output capacity: 150Vdc, 150mA maximum or 150Vac (peak to peak), 100mA maximum

Note: DO2 cannot be used with the Modbus communication. (Refer table 6 for details)

DO1 and DO2 functions — One of the following functions can be assigned to DO1 and/or DO2 .

•Pulse output (available only for DO1, DO2)

Pulse rate: MAX 10kHz (10000pps)(DO1) MAX 100Hz (100pps)(DO2)

(Over 1kpps, auto-setting)

Pulse width: 0.5 to 500ms (but less than half of the period for 100% flow rate)

Note: The same and simultaneous pulse is not available between DO1 and DO2.)

•Multi-range selection outputs (Note 1)

•High, High high, Low, and/or Low low alarm outputs (Note 2)

•Empty pipe alarm output (Note 2)

•Preset count output

•Converter failure alarm output

Note 1: Two outputs (DO1 and DO2) are needed for 4-range switching and forward/reverse 2-range switching.

Note 2: Normal Open (default set) or Normal Close is selected for alarm outputs when programming.

When power failure occurs, unit will be fault to Normal Open.

Communications output:

• HART (std.) — Digital signal is superimposed on 4–20mAdc current signal as follows:

Conforms to HART protocol Load resistance: 240 to 750

Load capacitance: 0.25µF maximum Load inductance: 4mH maximum

• PROFIBUS (opt.)

Protocol: PROFIBUS-PA Baud rate: 31.25kbps Bus voltage: 9-30VDC

Consumption electric current of bus: less than 16mA

Manufacture Ident-No.: 093BHEX Standard Ident-No.: 9740HEX

Slave address: 0-126 (Default address is 126)

Profile: Profile Ver.3.01 for Process Control Devices

Function blocks: AI(Flow)×1 , Totalizer×1

• MODBUS (opt.)

Physical layer : RS485 Protocol : Modbus Mode : RTU

Baudrate : 4800, 9600, 19200bps Data length : 8bit

Parity bit : None, Odd, Even Stop bit : 1bit, 2bit

Error check : CRC-16

Max. station number : 32(with Master device) Max. cable length : 1.2km (Note)

Note: This length is specification of 3 line connection.

3

TIC-LF654L

LCD display:

Full dot-matrix 128×128 dot LCD display (back–light provided)

A parameter change will rotate the display.

Parameter settings — Parameters can be set as follows:

•IR Switches: Three key switches are provided to set configuration parameters.

•Digital communication: HART, PROFIBUS or Modbus is needed to set parameters.

•Zero adjustment: Zero point adjustment can be started by pressing the switch in the converter.

•Damping: 0.1 to 60 seconds (selectable in one second increments)

“Field re-verification” Mag-Prover– Toshiba’s Zero span calibration tool allows unit to be re-calibrated and verified using an internal software program (For more information contact Toshiba International Corp.)

Conditions when power fails:

Parameter setting values are stored in non–volatile memory and the values will be restored when the power returns to normal condition. The outputs and display will remain as follows when power fails.

•Current output: 0mAdc

•Digital output: OFF

•LCD display: No display

• HART: |

No communication |

• PROFIBUS: |

No communication |

• Modbus: |

No communication |

Power supply:

One of the following can be selected:

•100 to 240Vac, 50/60Hz (allowable voltage 80 to 264Vac) 110Vdc

(allowable voltage 90 to 130Vdc)

•24Vdc (allowable voltage 18 to 36Vdc)

Surge protection:

Arresters are installed in the power supply and a current signal output circuit to help protect the meter from lightning and improve personnel safety.

Case: Aluminum alloy (equal to IP 67)

Coating:

Acrylic resin-baked coating, pearl–gray colored

Cable connection port: Cable glands —

LF620 and LF622 without cFMus Approval:

Provided as standard, outer diameter of cableφ 11~13mm

Material Nylon 66

G (PF) 1/2 male threads.

LF620F and LF622F with cFMus Approval:

Not provided, 1/2–14NPT male threads are required.

Applicable diameter —

0.433 to 0.512 inch (11 to 13mm)

Note: When PROFIBUS option is specified, cable gland size is φ6 8mm for signal cable, φ11 13mm for power cable

Vibration resistance:

No resonance to the following levels of vibration:

•10 to 150Hz with acceleration of 9.8m/s2

•Vibration of 30Hz with 29.4 m/s2 in 4h in each

direction will not cause any defect to unit.

Note: Avoid using the flowmeter in an environment with constant vibration.

Dimensions and Weights:

See Figure 7 (for Separate type)

MTBF:

Converter: 220,000 hours (25 years) at 77 °F (25 °C) based on strict military specification MIL-HDBK-217F

Detector: 350,000 hours (40 years) at 77 °F (25 °C) based on strict military specification MIL-HDBK-217F

4

TIC-LF654L

Installation

Dimensions

Unit: inch (mm)

Note1: Eye bolts are provided at the top for flowmeters sized 8" (200mm) or above, and further, a roll-prevention base is provided for flowmeters sized 10" (250mm) or larger.

Note2: Cable glands are not provided for LF654 of cFMus approved type. Refer to the cable connection port at converter.

ASME B 16.5 class 150 dimensions:

Meter size |

L1 |

L2 |

L3 |

No. of |

Weight |

(inch) |

(inch) |

(inch) |

(inch) |

bolts |

(lbs) |

1/2 |

5.51 |

8.07 |

9.84 |

4 |

approx. 11.0 |

1 |

6.30 |

8.31 |

10.43 |

4 |

approx. 16..0 |

1-1/4 |

7.87 |

8.62 |

10.94 |

4 |

approx. 20.0 |

1-1/2 |

6.69 |

8.66 |

11.18 |

4 |

approx. 20.0 |

2 |

7.09 |

9.09 |

12.09 |

4 |

approx. 29.0 |

2-1/2 |

7.87 |

9.29 |

12.80 |

4 |

approx. 38.0 |

3 |

9.06 |

9.69 |

13.43 |

4 |

approx. 45..0 |

4 |

9.45 |

10.28 |

14.80 |

8 |

approx. 64.0 |

5 |

9.84 |

10.71 |

15.71 |

8 |

approx. 73.0 |

6 |

10.24 |

11.34 |

16.85 |

8 |

approx. 93.0 |

8 |

11.81 |

12.24 |

19.02 |

8 |

approx. 139.0. |

10 |

13.78 |

13.15 |

21.14 |

12 |

approx. 207.0 |

12 |

15.75 |

14.65 |

24.13 |

12 |

approx. 315.0 |

14 |

17.72 |

14.88 |

25.39 |

12 |

approx. 403.0 |

16 |

19.69 |

15.79 |

27.20 |

16 |

approx. 509.0 |

18 |

21.65 |

16.69 |

29.21 |

16 |

approx. 617.0 |

EN 1092-1 PN 16 dimensions:

Meter size |

L1 |

L2 |

L3 |

No. of |

Weight |

(mm) |

(mm) |

(mm) |

(mm) |

bolts |

(kg) |

15 |

140 |

203 |

251 |

4 |

approx. 6.0 |

25 |

160 |

209 |

272 |

4 |

approx. 7.5 |

32 |

200 |

217 |

285 |

4 |

approx. 10.0 |

40 |

170 |

218 |

288 |

4 |

approx. 10.5 |

50 |

180 |

232 |

310 |

4 |

approx. 14.5 |

65 |

200 |

237 |

325 |

4 |

approx. 16.5 |

80 |

230 |

255 |

347 |

8 |

approx. 21.5 |

100 |

240 |

262 |

367 |

8 |

approx. 26.5 |

125 |

250 |

273 |

399 |

8 |

approx. 31.0 |

150 |

260 |

285 |

425 |

8 |

approx. 37.5 |

200 |

300 |

310 |

475 |

12 |

approx. 54.0 |

250 |

350 |

335 |

535 |

12 |

approx. 78.0 |

300 |

400 |

365 |

588 |

12 |

approx. 117.0 |

350 |

450 |

374 |

619 |

16 |

approx. 156.5 |

400 |

500 |

397 |

677 |

16 |

approx. 202.5 |

450 |

550 |

420 |

730 |

20 |

approx. 249.5 |

JIS B 2220 10K dimensions:

Meter size |

L1 |

L2 |

L3 |

No. of |

Weight |

(mm) |

(mm) |

(mm) |

(mm) |

bolts |

(kg) |

15 |

140 |

203 |

251 |

4 |

approx. 6.0 |

25 |

160 |

209 |

272 |

4 |

approx. 8.5 |

32 |

200 |

217 |

285 |

4 |

approx. 10.5 |

40 |

170 |

218 |

288 |

4 |

approx. 10.0 |

50 |

180 |

232 |

310 |

4 |

approx. 13.5 |

65 |

200 |

237 |

325 |

4 |

approx. 16.5 |

80 |

230 |

255 |

347 |

8 |

approx. 18.0 |

100 |

240 |

262 |

367 |

8 |

approx. 23.5 |

125 |

250 |

273 |

399 |

8 |

approx. 30.0 |

150 |

260 |

285 |

425 |

8 |

approx. 37.0 |

200 |

300 |

310 |

475 |

12 |

approx. 48.5 |

250 |

350 |

335 |

535 |

12 |

approx. 74.0 |

300 |

400 |

365 |

588 |

16 |

approx. 102.0 |

350 |

450 |

374 |

619 |

16 |

approx. 127.0 |

400 |

500 |

397 |

677 |

16 |

approx. 175.0 |

450 |

550 |

420 |

730 |

20 |

approx. 217.0 |

Note 3 : 1 inch = 25.4 mm

Figure 3. LF650/LF620 and LF654/LF620F combined type flowmeters Meter Sizes 1/2" (15) to 18" (450mm) for Toshiba lay length

5

Loading...

Loading...