Teledyne 200EH-EM User Manual

INSTRUCTION MANUAL

MODEL 200EH/EM

NITROGEN OXIDES ANALYZER

© TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

9480 CARROLL PARK DRIVE SAN DIEGO, CA 92121-5201 USA

Toll-free Phone: |

800-324-5190 |

Phone: |

858-657-9800 |

Fax: |

858-657-9816 |

Email: |

api-sales@teledyne.com |

Website: |

http://www.teledyne-api.com/ |

|

04521 |

|

Rev. C |

|

DCN 5731 |

Copyright 2007-2010 |

14 May 2010 |

Teledyne Advanced Pollution Instrumentation |

|

Teledyne API - Model 200EH/EM Operation Manual |

Safety Messages |

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is associated with a safety alert symbol. These symbols are found in the manual and inside the instrument. The definition of these symbols is described below:

GENERAL SAFETY HAZARD: Refer to the instructions for details on the specific hazard.

CAUTION: Hot Surface Warning.

CAUTION: Electrical Shock Hazard.

TECHNICIAN SYMBOL: All operations marked with this symbol are to be performed by qualified maintenance personnel only.

CAUTION

The analyzer should only be used for the purpose and in the manner described in this manual. If you use the analyzer in a manner other than that for which it was intended, unpredictable behavior could ensue with possible hazardous consequences.

NOTE

Technical Assistance regarding the use and maintenance of the Model 200EH/EM NOx Analyzer or any other Teledyne Instruments product

can be obtained by:

Contacting Teledyne Instruments’ Customer Service Department at 800-324-5190

or

Via the internet at http://www.teledyne-api.com/inquiries.asp

i

04521C (DCN5731)

This page intentionally left blank.

ii

04521C (DCN5731)

Teledyne API - Model 200EH/EM Operation Manual |

Table of Contents |

TABLE OF CONTENTS |

|

1. M200EH/EM Documentation.................................................................................................................................................... |

1 |

1.1. Using This Manual............................................................................................................................................................ |

1 |

2. Specifications, Approvals and Warranty................................................................................................................................... |

3 |

2.1. M200EH/EM Operating Specifications ............................................................................................................................. |

3 |

2.2. CE Mark Compliance ....................................................................................................................................................... |

4 |

2.3. Warranty........................................................................................................................................................................... |

4 |

3. Getting Started ......................................................................................................................................................................... |

7 |

3.1. Unpacking and Initial Setup.............................................................................................................................................. |

7 |

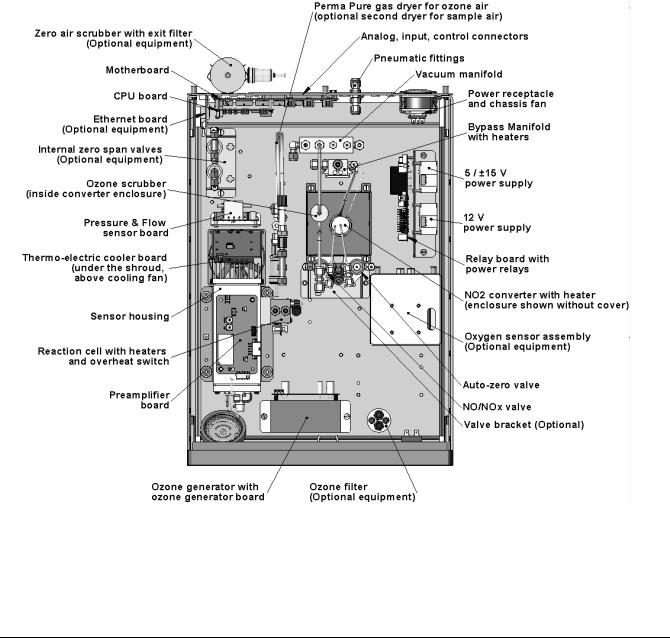

3.1.1. M200EH/EM Layout.................................................................................................................................................. |

8 |

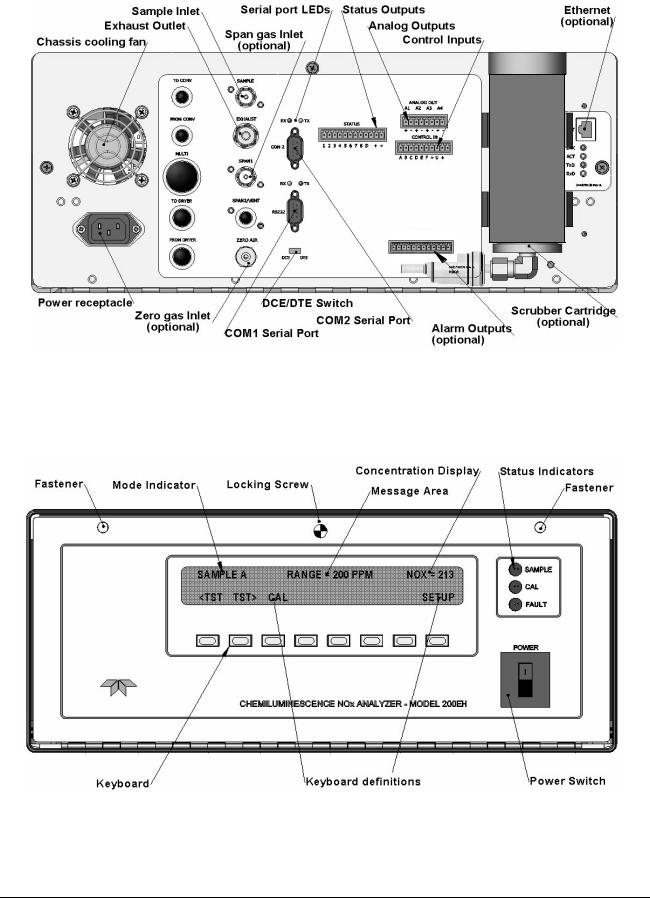

3.1.2. Electrical Connections ............................................................................................................................................ |

10 |

3.1.2.1. Power Connection........................................................................................................................................... |

10 |

3.1.2.2. Analog Output Connections ............................................................................................................................ |

11 |

3.1.2.3. Connecting the Status Outputs ....................................................................................................................... |

12 |

3.1.2.4. Connecting the Control Inputs......................................................................................................................... |

13 |

3.1.2.5. Connecting the Serial Ports ............................................................................................................................ |

14 |

3.1.2.6. Connecting to a LAN or the Internet................................................................................................................ |

14 |

3.1.2.7. Connecting to a Multidrop Network ................................................................................................................. |

14 |

3.1.3. Pneumatic Connections.......................................................................................................................................... |

15 |

3.1.3.1. Calibration Gases ........................................................................................................................................... |

16 |

3.1.3.2. Pneumatic Connections to M200EH/EM Basic Configuration:........................................................................ |

18 |

3.1.3.3. Connections with Internal Valve Options Installed .......................................................................................... |

19 |

3.2. Initial Operation .............................................................................................................................................................. |

20 |

3.2.1. Startup .................................................................................................................................................................... |

20 |

3.2.2. Warm-Up ................................................................................................................................................................ |

22 |

3.2.3. Warning Messages ................................................................................................................................................. |

22 |

3.2.4. Functional Check.................................................................................................................................................... |

24 |

3.3. Calibration ...................................................................................................................................................................... |

25 |

3.3.1. Basic NOx Calibration Procedure............................................................................................................................ |

25 |

3.3.2. Basic O2 Sensor Calibration Procedure.................................................................................................................. |

28 |

3.3.2.1. O2 Calibration Setup ....................................................................................................................................... |

28 |

3.3.2.2. O2 Calibration Method .................................................................................................................................... |

28 |

3.3.3. Interferences for NOX Measurements ..................................................................................................................... |

31 |

4. Frequently Asked Questions & Glossary................................................................................................................................ |

33 |

4.1. Frequently Asked Questions .......................................................................................................................................... |

33 |

4.2. Glossary ......................................................................................................................................................................... |

34 |

5. Optional Hardware and Software ........................................................................................................................................... |

37 |

5.1. External Pumps (OPT 10) .............................................................................................................................................. |

37 |

5.2. Rack Mount Kits (OPTs 20-23)....................................................................................................................................... |

37 |

5.3. Carrying Strap Handle (OPT 29) .................................................................................................................................... |

38 |

5.4. Current Loop Analog Outputs (OPT 41) ......................................................................................................................... |

39 |

5.4.1. Converting Current Loop Analog Outputs to Standard Voltage Outputs................................................................. |

39 |

5.5. Particulate Filter Kit (OPT 42A) ...................................................................................................................................... |

40 |

5.6. Ozone Supply Filter (OPT 49) ........................................................................................................................................ |

40 |

5.7. Calibration Valve Options ............................................................................................................................................... |

40 |

5.7.1. Zero/Span Valves (OPT 50) ................................................................................................................................... |

40 |

5.7.2. Second Range span Valve (OPT 52)...................................................................................................................... |

42 |

5.8. Oxygen Sensor (OPT 65) ............................................................................................................................................... |

45 |

5.8.1. Theory of Operation................................................................................................................................................ |

45 |

5.8.1.1. Paramagnetic measurement of O2 .................................................................................................................. |

45 |

5.8.1.2. Operation Within the M200EH/EM Analyzer ................................................................................................... |

46 |

5.8.1.3. Pneumatic Operation of the O2 Sensor........................................................................................................... |

46 |

5.8.2. Zero Air Scrubber (OPT 64B) ................................................................................................................................. |

48 |

5.8.3. Zero Air Scrubber Maintenance Kit (OPT 43) ......................................................................................................... |

48 |

5.8.4. M200EH/EM Expendables Kit (OPT 42)................................................................................................................. |

48 |

5.8.5. M200EH/EM Spare Parts Kit (OPT 43)................................................................................................................... |

48 |

5.9. Communication Options ................................................................................................................................................. |

48 |

5.9.1. RS232 Modem Cables (OPTs 60 and 60A)............................................................................................................ |

48 |

5.9.2. RS-232 Multidrop (OPT 62) .................................................................................................................................... |

49 |

5.9.3. Ethernet (OPT 63) .................................................................................................................................................. |

49 |

5.10. Sample Gas Conditioners (OPTs 86 & 88)................................................................................................................... |

50 |

|

iii |

04521C (DCN5731)

5.11. Alarm Relay Option (OPT 67)....................................................................................................................................... |

51 |

5.12. Special Software Features ........................................................................................................................................... |

53 |

5.12.1. Maintenance Mode Switch.................................................................................................................................... |

53 |

5.12.2. Second Language Switch ..................................................................................................................................... |

53 |

5.12.3. Dilution Ratio Option............................................................................................................................................. |

53 |

5.13. Additional Manual (OPT 70) ......................................................................................................................................... |

53 |

5.14. Extended Warranty (OPTs 92 & 93)............................................................................................................................. |

54 |

6. Operating Instructions ............................................................................................................................................................ |

55 |

6.1. Overview of Operating Modes ........................................................................................................................................ |

55 |

6.2. Sample Mode ................................................................................................................................................................. |

57 |

6.2.1. Test Functions ........................................................................................................................................................ |

57 |

6.2.2. Warning Messages ................................................................................................................................................. |

59 |

6.3. Calibration Mode ............................................................................................................................................................ |

60 |

6.3.1. Calibration Functions .............................................................................................................................................. |

60 |

6.4. SETUP MODE................................................................................................................................................................ |

61 |

6.5. SETUP CFG: Viewing the Analyzer’s Configuration Information ............................................................................... |

62 |

6.6. SETUP ACAL: Automatic Calibration......................................................................................................................... |

62 |

6.7. SETUP DAS - Using the Data Acquisition System (iDAS) ........................................................................................ |

63 |

6.7.1. iDAS Structure........................................................................................................................................................ |

64 |

6.7.1.1. iDAS Channels................................................................................................................................................ |

64 |

6.7.1.2. iDAS Parameters ............................................................................................................................................ |

65 |

6.7.1.3. iDAS Triggering Events................................................................................................................................... |

65 |

6.7.2. Default iDAS Channels ........................................................................................................................................... |

66 |

6.7.2.1. Viewing iDAS Data and Settings..................................................................................................................... |

68 |

6.7.2.2. Editing iDAS Data Channels ........................................................................................................................... |

69 |

6.7.2.3. Trigger Events................................................................................................................................................. |

70 |

6.7.2.4. Editing iDAS Parameters ................................................................................................................................ |

71 |

6.7.2.5. Sample Period and Report Period .................................................................................................................. |

73 |

6.7.2.6. Number of Records......................................................................................................................................... |

75 |

6.7.2.7. RS-232 Report Function ................................................................................................................................. |

76 |

6.7.2.8. Compact Report.............................................................................................................................................. |

76 |

6.7.2.9. Starting Date................................................................................................................................................... |

76 |

6.7.2.10. Disabling/Enabling Data Channels................................................................................................................ |

77 |

6.7.2.11. HOLDOFF Feature ....................................................................................................................................... |

77 |

6.7.3. Remote iDAS Configuration.................................................................................................................................... |

78 |

6.8. SETUP RNGE: Range Units and Dilution Configuration............................................................................................ |

80 |

6.8.1. Range Units............................................................................................................................................................ |

80 |

6.8.2. Dilution Ratio .......................................................................................................................................................... |

81 |

6.9. SETUP PASS: Password Feature ............................................................................................................................. |

82 |

6.10. SETUP CLK: Setting the Internal Time-of-Day Clock .............................................................................................. |

84 |

6.11. SETUP MORE COMM: Setting Up the Analyser’s Communication Ports ........................................................... |

86 |

6.11.1. Analyzer ID ........................................................................................................................................................... |

86 |

6.11.2. COM Port Default Settings ................................................................................................................................... |

87 |

6.11.3. RS-232 COM Port Cable Connections ................................................................................................................. |

87 |

6.11.4. RS-485 Configuration of COM2............................................................................................................................ |

89 |

6.11.5. DTE and DCE Communication ............................................................................................................................. |

90 |

6.11.6. Ethernet Card Configuration ................................................................................................................................. |

91 |

6.11.6.1. Ethernet Card COM2 Communication Modes and Baud Rate...................................................................... |

91 |

6.11.6.2. Configuring the Ethernet Interface Option using DHCP ................................................................................ |

91 |

6.11.6.3. Manually Configuring the Network IP Addresses .......................................................................................... |

94 |

6.11.6.4. Changing the Analyzer’s HOSTNAME.......................................................................................................... |

96 |

6.11.7. Multidrop RS-232 Set Up...................................................................................................................................... |

97 |

6.11.8. COM Port Communication Modes ........................................................................................................................ |

99 |

6.11.9. COM Port Baud Rate.......................................................................................................................................... |

101 |

6.11.10. COM Port Testing ............................................................................................................................................. |

102 |

6.12. SETUP MORE VARS: Internal Variables (VARS) ............................................................................................. |

103 |

6.12.1. Setting the Gas Measurement Mode .................................................................................................................. |

105 |

6.13. SETUP MORE DIAG: Diagnostics MENU ........................................................................................................ |

106 |

6.13.1. Accessing the Diagnostic Features..................................................................................................................... |

107 |

6.13.2. Signal I/O............................................................................................................................................................ |

108 |

6.13.3. Analog Output Step Test .................................................................................................................................... |

109 |

6.13.4. ANALOG OUTPUTS and Reporting Ranges...................................................................................................... |

110 |

6.13.4.1. Analog Output Signals Available on the M200EH/EM................................................................................. |

110 |

6.13.4.2. Physical Range versus Analog Output Reporting Ranges.......................................................................... |

111 |

6.13.5. ANALOG I/O CONFIGURATION........................................................................................................................ |

113 |

iv |

|

|

04521C (DCN5731) |

Teledyne API - Model 200EH/EM Operation Manual |

Table of Contents |

6.13.5.1. The Analog I/O Configuration Submenu. .................................................................................................... |

113 |

6.13.5.2. Analog Output Signal Type and Range Selection....................................................................................... |

115 |

6.13.5.3. Turning the Analog Output Over-Range Feature ON/OFF.......................................................................... |

116 |

6.13.5.4. Adding a Recorder Offset to an Analog Output........................................................................................... |

117 |

6.13.5.5. Assigning an iDAS parameter to an Analog Output Channel...................................................................... |

118 |

Reporting Gas Concentrations via the M200EH/EM Analog Output Channels ........................................ |

118 |

6.13.5.6. Setting the Reporting Range Scale for an Analog Output........................................................................... |

121 |

6.13.5.7. Setting Data Update Rate for an Analog Output ......................................................................................... |

123 |

6.13.5.8. Turning an Analog Output On or Off ........................................................................................................... |

124 |

6.13.6. ANALOG OUTPUT CALIBRATION .................................................................................................................... |

125 |

6.13.6.1. Automatic Analog Output Calibration .......................................................................................................... |

126 |

6.13.6.2. Manual Calibration of Analog Output configured for Voltage Ranges......................................................... |

127 |

6.13.6.3. Manual Calibration of Analog Outputs configured for Current Loop Ranges .............................................. |

128 |

6.13.6.4. AIN Calibration............................................................................................................................................ |

131 |

6.13.7. OTHER DIAG MENU FUNCTIONS .................................................................................................................... |

132 |

6.13.7.1. Display Sequence Configuration................................................................................................................. |

132 |

6.13.7.2. Optic Test ................................................................................................................................................... |

135 |

6.13.7.3. Electrical Test ............................................................................................................................................. |

136 |

6.13.7.4. Ozone Generator Override ......................................................................................................................... |

137 |

6.13.7.5. Flow Calibration .......................................................................................................................................... |

138 |

6.14. SETUP – ALRM: Using the optional Gas Concentration Alarms (OPT 67) ................................................................ |

139 |

6.15. REMOTE OPERATION OF THE ANALYZER ............................................................................................................ |

140 |

6.15.1. Remote Operation Using the External Digital I/O ............................................................................................... |

140 |

6.15.1.1. Status Outputs ............................................................................................................................................ |

140 |

6.15.1.2. Control Inputs.............................................................................................................................................. |

141 |

6.15.2. Remote Operation Using the External Serial I/O ................................................................................................ |

142 |

6.15.2.1. Terminal Operating Modes ......................................................................................................................... |

142 |

6.15.2.2. Help Commands in Terminal Mode............................................................................................................. |

143 |

6.15.2.3. Command Syntax ....................................................................................................................................... |

143 |

6.15.2.4. Data Types.................................................................................................................................................. |

144 |

6.15.2.5. Status Reporting ......................................................................................................................................... |

145 |

6.15.2.6. Remote Access by Modem ......................................................................................................................... |

145 |

6.15.2.7. COM Port Password Security ..................................................................................................................... |

147 |

6.15.2.8. APICOM Remote Control Program ............................................................................................................. |

148 |

6.15.3. Additional Communications Documentation ....................................................................................................... |

148 |

6.15.4. Using the M200EH/EM with a Hessen Protocol Network.................................................................................... |

149 |

6.15.4.1. General Overview of Hessen Protocol ........................................................................................................ |

149 |

6.15.4.2. Hessen COMM Port Configuration.............................................................................................................. |

149 |

6.15.4.3. Selecting a Hessen Protocol Type .............................................................................................................. |

150 |

6.15.4.4. Setting The Hessen Protocol Response Mode ........................................................................................... |

151 |

6.15.4.5. Hessen Protocol Gas ID ............................................................................................................................. |

152 |

6.15.4.6. Setting Hessen Protocol Status Flags......................................................................................................... |

153 |

6.15.4.7. Instrument ID Code..................................................................................................................................... |

154 |

7. Calibration Procedures......................................................................................................................................................... |

155 |

7.1. Calibration Preparations ............................................................................................................................................... |

155 |

7.1.1. Required Equipment, Supplies, and Expendables................................................................................................ |

155 |

7.1.2. Zero Air................................................................................................................................................................. |

155 |

7.1.3. Span Calibration Gas Standards & Traceability.................................................................................................... |

156 |

7.1.3.1. Traceability ................................................................................................................................................... |

156 |

7.1.4. Data Recording Devices ....................................................................................................................................... |

157 |

7.1.5. NO2 Conversion Efficiency ................................................................................................................................... |

157 |

7.1.5.1. Determining / Updating the NO2 Converter Efficiency................................................................................... |

157 |

7.2. Manual Calibration ....................................................................................................................................................... |

160 |

7.3. Calibration Checks ....................................................................................................................................................... |

163 |

7.4. Manual Calibration with Zero/Span Valves................................................................................................................... |

164 |

7.5. Calibration Checks with Zero/Span Valves................................................................................................................... |

167 |

7.6. Calibration With Remote Contact Closures .................................................................................................................. |

168 |

7.7. Automatic Calibration (AutoCal) ................................................................................................................................... |

169 |

7.8. Calibration Quality Analysis.......................................................................................................................................... |

172 |

8. EPA Protocol Calibration...................................................................................................................................................... |

173 |

9. Instrument Maintenance....................................................................................................................................................... |

175 |

9.1. Maintenance Schedule................................................................................................................................................. |

175 |

9.2. Predictive Diagnostics .................................................................................................................................................. |

177 |

9.3. Maintenance Procedures.............................................................................................................................................. |

177 |

9.3.1. Changing the Sample Particulate Filter ................................................................................................................ |

178 |

|

v |

04521C (DCN5731)

9.3.2. Changing the O3 Dryer Particulate Filter............................................................................................................... |

179 |

9.3.3. Maintaining the External Sample Pump................................................................................................................ |

180 |

9.3.3.1. Rebuilding the Pump..................................................................................................................................... |

180 |

9.3.3.2. Changing the Inline Exhaust Scrubber.......................................................................................................... |

180 |

9.3.4. Changing the Pump and IZS Dust Filters ............................................................................................................. |

180 |

9.3.5. Changing the External Zero Air Scrubber ............................................................................................................. |

182 |

9.3.6. Changing the NO2 converter................................................................................................................................. |

183 |

9.3.7. Cleaning the Reaction Cell ................................................................................................................................... |

184 |

9.3.8. Changing Critical Flow Orifices............................................................................................................................. |

185 |

9.3.9. Checking for Light Leaks ...................................................................................................................................... |

186 |

10. Theory of Operation ........................................................................................................................................................... |

189 |

10.1. Measurement Principle............................................................................................................................................... |

189 |

10.1.1. Chemiluminescence ........................................................................................................................................... |

189 |

10.1.2. NOX and NO2 Determination ............................................................................................................................... |

190 |

10.2. Chemiluminescence Detection ................................................................................................................................... |

191 |

10.2.1. The Photo Multiplier Tube................................................................................................................................... |

191 |

10.2.2. Optical Filter ....................................................................................................................................................... |

192 |

10.2.3. Auto Zero............................................................................................................................................................ |

192 |

10.2.4. Measurement Interferences................................................................................................................................ |

193 |

10.2.4.1. Direct Interference ...................................................................................................................................... |

193 |

10.2.4.2. Third Body Quenching ................................................................................................................................ |

193 |

10.2.4.3. Light Leaks.................................................................................................................................................. |

194 |

10.3. Pneumatic Operation.................................................................................................................................................. |

195 |

10.3.1. Pump and Exhaust Manifold............................................................................................................................... |

195 |

10.3.2. Sample Gas Flow ............................................................................................................................................... |

196 |

10.3.2.1. NO/NOx and AutoZero cycles ..................................................................................................................... |

196 |

10.3.3. Flow Rate Control - Critical Flow Orifices ........................................................................................................... |

197 |

10.3.3.1. Critical Flow Orifice ..................................................................................................................................... |

199 |

10.3.4. Sample Particulate Filter..................................................................................................................................... |

201 |

10.3.5. Ozone Gas Air Flow............................................................................................................................................ |

201 |

10.3.6. O3 Generator...................................................................................................................................................... |

202 |

10.3.7. Perma Pure® Dryer ............................................................................................................................................. |

203 |

10.3.8. Ozone Supply Air Filter....................................................................................................................................... |

205 |

10.3.9. Ozone Scrubber ................................................................................................................................................. |

205 |

10.3.10. Pneumatic Sensors........................................................................................................................................... |

206 |

10.3.10.1. Vacuum Manifold ...................................................................................................................................... |

206 |

10.3.10.2. Sample Pressure Sensor .......................................................................................................................... |

206 |

10.3.10.3. Vacuum Pressure Sensor ......................................................................................................................... |

207 |

10.3.10.4. O3 Supply Air Flow Sensor........................................................................................................................ |

207 |

10.3.11. Dilution Manifold ............................................................................................................................................... |

207 |

10.4. Electronic Operation................................................................................................................................................... |

209 |

10.4.1. CPU .................................................................................................................................................................... |

210 |

10.4.1.1. Disk On Chip............................................................................................................................................... |

211 |

10.4.1.2. Flash Chip................................................................................................................................................... |

211 |

10.4.2. Sensor Module, Reaction Cell ............................................................................................................................ |

211 |

10.4.2.1. Reaction Cell Heating Circuit ...................................................................................................................... |

211 |

10.4.3. Photo Multiplier Tube (PMT)............................................................................................................................... |

212 |

10.4.4. PMT Cooling System. ......................................................................................................................................... |

213 |

10.4.4.1. TEC Control Board...................................................................................................................................... |

213 |

10.4.5. PMT Preamplifier ................................................................................................................................................ |

214 |

10.4.6. Pneumatic Sensor Board.................................................................................................................................... |

215 |

10.4.7. Relay Board........................................................................................................................................................ |

215 |

10.4.7.1. Relay PCA Location and Layout ................................................................................................................. |

215 |

10.4.7.2. Heater Control............................................................................................................................................. |

215 |

10.4.7.3. Thermocouple Inputs and Configuration Jumper (JP5)............................................................................... |

216 |

10.4.7.4. Valve Control .............................................................................................................................................. |

217 |

10.4.8. Status LEDs & Watch Dog Circuitry.................................................................................................................... |

218 |

10.4.8.1. Watchdog Indicator (D1) ............................................................................................................................. |

218 |

10.4.9. Motherboard ....................................................................................................................................................... |

219 |

10.4.9.1. A to D Conversion....................................................................................................................................... |

219 |

10.4.9.2. Sensor Inputs.............................................................................................................................................. |

219 |

10.4.9.3. Thermistor Interface.................................................................................................................................... |

220 |

10.4.10. Analog Outputs................................................................................................................................................. |

220 |

10.4.11. External Digital I/O............................................................................................................................................ |

221 |

10.4.12. I2C Data Bus ..................................................................................................................................................... |

221 |

vi |

|

|

04521C (DCN5731) |

Teledyne API - Model 200EH/EM Operation Manual |

Table of Contents |

10.4.13. Power-up Circuit ............................................................................................................................................... |

221 |

10.5. Power Distribution &Circuit Breaker ........................................................................................................................... |

222 |

10.6. Communications Interface.......................................................................................................................................... |

223 |

10.6.1. Front Panel Interface .......................................................................................................................................... |

224 |

10.6.1.1. Analyzer Status LED’s ................................................................................................................................ |

224 |

10.6.1.2. Keyboard .................................................................................................................................................... |

224 |

10.6.1.3. Display ........................................................................................................................................................ |

225 |

10.6.1.4. Keyboard/Display Interface Electronics ...................................................................................................... |

225 |

10.7. Software Operation .................................................................................................................................................... |

227 |

10.7.1. Adaptive Filter..................................................................................................................................................... |

228 |

10.7.2. Calibration - Slope and Offset............................................................................................................................. |

228 |

10.7.3. Temperature/Pressure Compensation (TPC) ..................................................................................................... |

229 |

10.7.4. NO2 Converter Efficiency Compensation............................................................................................................ |

230 |

10.7.5. Internal Data Acquisition System (iDAS) ............................................................................................................ |

230 |

11. Troubleshooting & Repair .................................................................................................................................................. |

231 |

11.1. General Troubleshooting ............................................................................................................................................ |

231 |

11.1.1. Warning Messages ............................................................................................................................................. |

232 |

11.1.2. Fault Diagnosis with Test Functions ................................................................................................................... |

232 |

11.1.3. Using the Diagnostic Signal I/O Function ........................................................................................................... |

233 |

11.1.4. Status LED’s....................................................................................................................................................... |

235 |

11.1.4.1. Motherboard Status Indicator (Watchdog) .................................................................................................. |

235 |

11.1.4.2. CPU Status Indicator .................................................................................................................................. |

235 |

11.1.4.3. Relay Board and Status LEDs .................................................................................................................... |

235 |

11.2. Gas Flow Problems .................................................................................................................................................... |

238 |

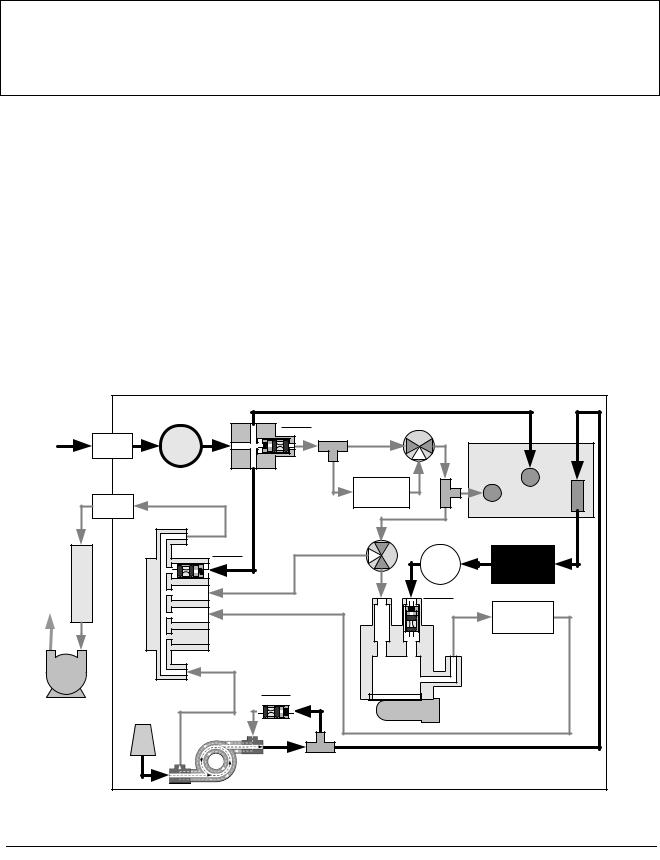

11.2.1. M200EH Internal Gas Flow Diagrams ................................................................................................................ |

238 |

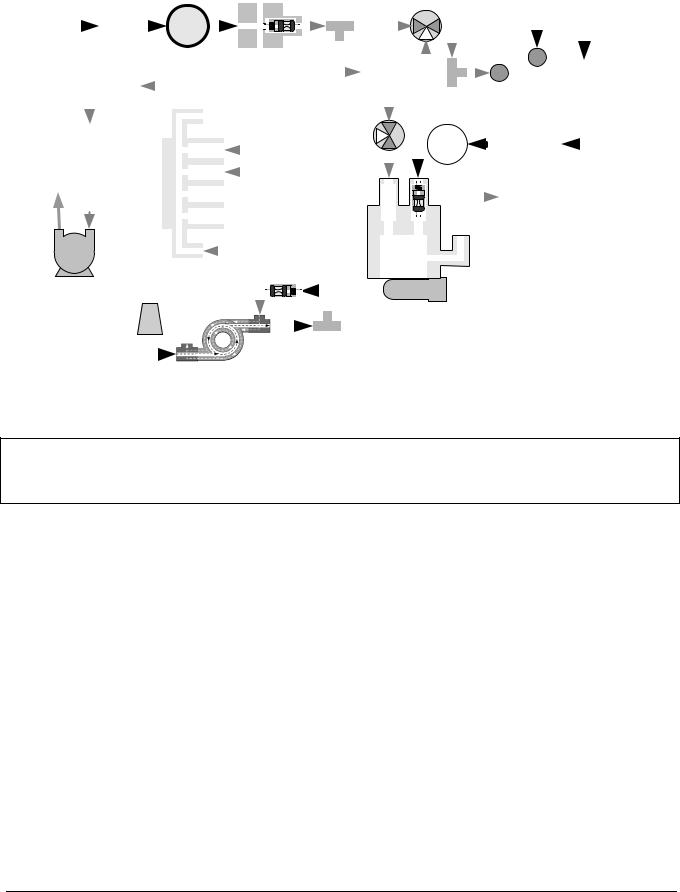

11.2.2. M200EM Internal Gas Flow Diagrams ................................................................................................................ |

241 |

11.2.3. Zero or Low Flow Problems................................................................................................................................ |

243 |

11.2.3.1. Sample Flow is Zero or Low........................................................................................................................ |

243 |

11.2.3.2. Ozone Flow is Zero or Low ......................................................................................................................... |

244 |

11.2.4. High Flow............................................................................................................................................................ |

245 |

11.2.5. Sample Flow is Zero or Low But Analyzer Reports Correct Flow ....................................................................... |

245 |

11.3. Calibration Problems .................................................................................................................................................. |

246 |

11.3.1. Negative Concentrations .................................................................................................................................... |

246 |

11.3.2. No Response...................................................................................................................................................... |

246 |

11.3.3. Unstable Zero and Span..................................................................................................................................... |

247 |

11.3.4. Inability to Span - No SPAN Key ........................................................................................................................ |

247 |

11.3.5. Inability to Zero - No ZERO Key ......................................................................................................................... |

248 |

11.3.6. Non-Linear Response......................................................................................................................................... |

248 |

11.3.7. Discrepancy Between Analog Output and Display ............................................................................................. |

249 |

11.3.8. Discrepancy between NO and NOX slopes......................................................................................................... |

249 |

11.4. Other Performance Problems..................................................................................................................................... |

249 |

11.4.1. Excessive noise.................................................................................................................................................. |

249 |

11.4.2. Slow Response................................................................................................................................................... |

249 |

11.4.3. Auto-zero Warnings ............................................................................................................................................ |

250 |

11.5. Subsystem Checkout.................................................................................................................................................. |

251 |

11.5.1. Simple Vacuum Leak and Pump Check ............................................................................................................. |

251 |

11.5.2. Detailed Pressure Leak Check ........................................................................................................................... |

251 |

11.5.3. Performing a Sample Flow Check ...................................................................................................................... |

252 |

11.5.4. AC Power Configuration ..................................................................................................................................... |

253 |

11.5.4.1. AC configuration – Internal Pump (JP7)...................................................................................................... |

254 |

11.5.4.2. AC Configuration – Standard Heaters (JP2) ............................................................................................... |

255 |

11.5.4.3. AC Configuration –Heaters for Option Packages (JP6) .............................................................................. |

256 |

11.5.5. DC Power Supply Test Points ............................................................................................................................ |

257 |

11.5.6. I2C Bus ............................................................................................................................................................... |

257 |

11.5.7. Keyboard / Display Interface............................................................................................................................... |

258 |

11.5.8. Genreal Relay Board Diagnostic ........................................................................................................................ |

258 |

11.5.9. Motherboard ....................................................................................................................................................... |

259 |

11.5.9.1. A/D functions............................................................................................................................................... |

259 |

11.5.9.2. Analog Output Voltages .............................................................................................................................. |

259 |

11.5.9.3. Status Outputs ............................................................................................................................................ |

260 |

11.5.9.4. Control Inputs.............................................................................................................................................. |

261 |

11.5.10. CPU .................................................................................................................................................................. |

261 |

11.5.11. RS-232 Communication.................................................................................................................................... |

262 |

11.5.11.1. General RS-232 Troubleshooting ............................................................................................................. |

262 |

11.5.11.2. Modem or Terminal Operation .................................................................................................................. |

262 |

|

vii |

04521C (DCN5731)

11.5.12. PMT Sensor...................................................................................................................................................... |

263 |

|

11.5.13. PMT Preamplifier Board ................................................................................................................................... |

263 |

|

11.5.14. High Voltage Power Supply .............................................................................................................................. |

263 |

|

11.5.15. Pneumatic Sensor Assembly............................................................................................................................ |

264 |

|

11.5.15.1. Reaction Cell Pressure ............................................................................................................................. |

264 |

|

11.5.15.2. Sample Pressure ...................................................................................................................................... |

264 |

|

11.5.15.3. Ozone Flow............................................................................................................................................... |

265 |

|

11.5.16. NO2 Converter .................................................................................................................................................. |

265 |

|

11.5.17. O3 Generator .................................................................................................................................................... |

266 |

|

11.5.18. Box Temperature.............................................................................................................................................. |

266 |

|

11.5.19. PMT Temperature............................................................................................................................................. |

266 |

|

11.6. Repair Procedures ..................................................................................................................................................... |

267 |

|

11.6.1. Disk-on-Chip Replacement................................................................................................................................. |

267 |

|

11.6.2. Flash Chip Replacement or Upgrade.................................................................................................................. |

268 |

|

11.6.3. O3 Generator Replacement ................................................................................................................................ |

268 |

|

11.6.4. Sample and Ozone Dryer Replacement ............................................................................................................. |

269 |

|

11.6.5. PMT Sensor Hardware Calibration ..................................................................................................................... |

270 |

|

11.6.6. Replacing the PMT, HVPS or TEC ..................................................................................................................... |

271 |

|

11.7. Removing / Replacing the Relay PCA from the Instrument ........................................................................................ |

274 |

|

11.8. Technical Assistance.................................................................................................................................................. |

275 |

|

12. A Primer on Electro-Static Discharge................................................................................................................................. |

277 |

|

12.1. How Static Charges are Created................................................................................................................................ |

277 |

|

12.2. How Electro-Static Charges Cause Damage.............................................................................................................. |

278 |

|

12.3. Common Myths About ESD Damage ......................................................................................................................... |

279 |

|

12.4. Basic Principles of Static Control................................................................................................................................ |

279 |

|

12.4.1. General Rules..................................................................................................................................................... |

280 |

|

12.4.2. Basic anti-ESD Procedures for Analyzer Repair and Maintenance .................................................................... |

281 |

|

12.4.2.1. Working at the Instrument Rack.................................................................................................................. |

281 |

|

12.4.2.2. Working at an Anti-ESD Work Bench.......................................................................................................... |

281 |

|

12.4.2.3. Transferring Components from Rack to Bench and Back ........................................................................... |

282 |

|

12.4.2.4. Opening Shipments from Teledyne Instruments Customer Service............................................................ |

282 |

|

12.4.2.5. Packing Components for Return to Teledyne Instruments Customer Service. ........................................... |

283 |

|

LIST OF FIGURES |

|

|

Figure 3-1: |

M200EH/EM Layout....................................................................................................................... |

8 |

Figure 3-2: |

M200EH/EM Rear Panel Layout.................................................................................................... |

9 |

Figure 3-3: |

M200EH/EM Front Panel Layout ................................................................................................... |

9 |

Figure 3-4: |

Analog Output Connector ............................................................................................................ |

11 |

Figure 3-5: |

Status Output Connector ............................................................................................................. |

12 |

Figure 3-6: |

Control Input Connector............................................................................................................... |

13 |

Figure 3-7: |

M200EH Internal Pneumatic Block Diagram - Standard Configuration....................................... |

15 |

Figure 3-8: |

M200EM Internal Pneumatic Block Diagram - Standard Configuration ...................................... |

16 |

Figure 3-9: |

Pneumatic Connections–Basic Configuration–Using Gas Dilution Calibrator............................. |

18 |

Figure 3-10: |

Pneumatic Connections–Basic Configuration–Using Bottled Span Gas..................................... |

18 |

Figure 3-11: |

Pneumatic Connections–With Zero/Span Valve Option (50) ...................................................... |

19 |

Figure 3-12: |

Pneumatic Connections–With 2-Span point Option (52) –Using Bottled Span Gas ................... |

20 |

Figure 3-13: |

Front Panel Display During Startup Sequence............................................................................ |

21 |

Figure 3-14: |

O2 Sensor Calibration Set Up ...................................................................................................... |

28 |

Figure 5-1: |

M200EH/EM with Carrying Strap Handle and Rack Mount Brackets.......................................... |

38 |

Figure 5-2: |

Current Loop Option Installed on the Motherboard ..................................................................... |

39 |

Figure 5-3: |

M200EH – Internal Pneumatics with Zero-Span Valve Option 50............................................... |

41 |

Figure 5-4: |

M200EM – Internal Pneumatics with Zero-Span Valve Option 50 .............................................. |

41 |

Figure 5-5: |

M200EH – Internal Pneumatics with Second Span Point Valve Option 52................................. |

44 |

Figure 5-6: |

M200EM – Internal Pneumatics with Second Span Point Valve Option 52 ................................ |

45 |

Figure 5-7: |

Oxygen Sensor - Principle of Operation ...................................................................................... |

46 |

Figure 5-8: |

M200EH – Internal Pneumatics with O2 Sensor Option 65 ......................................................... |

47 |

Figure 5-9: |

M200EM – Internal Pneumatics with O2 Sensor Option 65......................................................... |

47 |

Figure 5-10: |

M200EH/EM Multidrop Card........................................................................................................ |

49 |

viii |

|

|

|

04521C (DCN5731) |

|

Teledyne API - Model 200EH/EM Operation Manual |

List of Figures |

|

|||

Figure 5-11: |

M200EH/EM Ethernet Card ......................................................................................................... |

|

50 |

||

Figure 5-12: |

M200EH/EM Rear Panel with Ethernet Installed......................................................................... |

50 |

|||

Figure 5-13: |

Alarm Relay Output Pin Assignments.......................................................................................... |

|

52 |

||

Figure 6-6-1: |

Front Panel Display...................................................................................................................... |

|

55 |

||

Figure 6-6-2: |

Viewing M200EH/EM TEST Functions........................................................................................ |

|

58 |

||

Figure 6-6-3: |

Viewing and Clearing M200EH/EM WARNING Messages ......................................................... |

59 |

|||

Figure 6-6-4: |

APICOM Graphical User Interface for Configuring the iDAS ...................................................... |

78 |

|||

Figure 6-6-5: |

iDAS Configuration Through a Terminal Emulation Program...................................................... |

79 |

|||

Figure 6-6-6: |

Back Panel connector Pin-Outs for COM1 & COM2 in RS-232 mode........................................ |

87 |

|||

Figure 6-6-7: |

CPU connector Pin-Outs for COM1 & COM2 in RS-232 mode................................................... |

88 |

|||

Figure 6-6-8: |

CPU card Locations of RS-232/486 Switches, Connectors and Jumpers................................... |

89 |

|||

Figure 6-6-9: |

Back Panel connector Pin-Outs for COM2 in RS-485 mode....................................................... |

90 |

|||

Figure 6-6-10: |

CPU connector Pin-Outs for COM2 in RS-485 mode.................................................................. |

90 |

|||

Figure 6-6-11: |

Location of JP2 on RS232-Multidrop PCA |

(option 62) ............................................................... |

97 |

||

Figure 6-6-12: |

RS232-Multidrop PCA Host/Analyzer Interconnect Diagram ...................................................... |

98 |

|||

Figure 6-6-13: |

Analog Output Connector Key .................................................................................................. |

|

110 |

||

Figure 6-6-14: |

Setup for Calibrating Analog Outputs ....................................................................................... |

|

127 |

||

Figure 6-6-15: |

Setup for Calibrating Current Outputs ...................................................................................... |

|

129 |

||

Figure 6-6-16: |

Alternative Setup for Calibrating Current Outputs .................................................................... |

129 |

|||

Figure 6-6-17: |

Status Output ConnectorTable 6-29: Status Output Pin Assignments..................................... |

140 |

|||

Table 6-29: |

Status Output Pin Assignments ................................................................................................ |

|

141 |

||

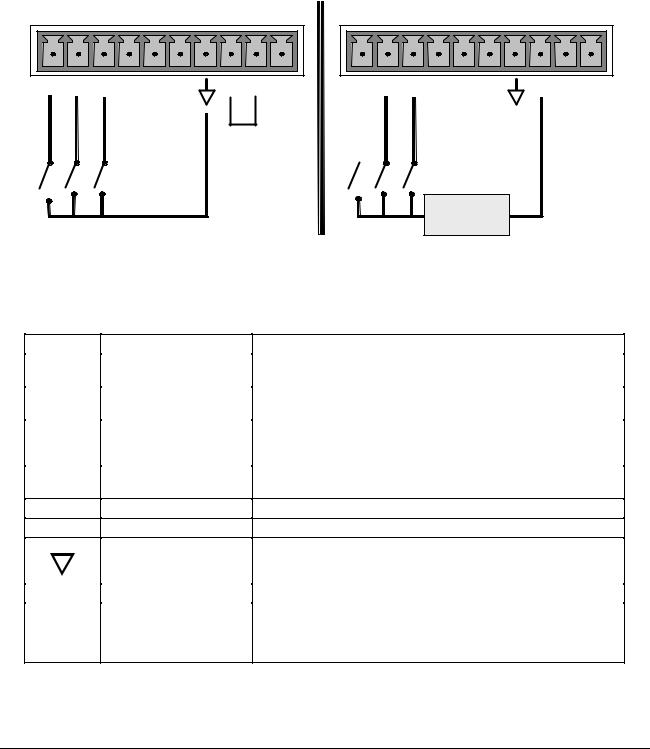

Figure 6-6-18: |

Control Inputs with local 5 V power supply............................................................................... |

|

142 |

||

Figure 6-6-19: |

Control Inputs with external 5 V power supply ......................................................................... |

142 |

|||

Figure 6-6-20: |

APICOM Remote Control Program Interface ........................................................................... |

148 |

|||

Figure 7-1: |

Gas Supply Setup for Determination of NO2 Conversion Efficiency......................................... |

157 |

|||

Figure 7-2: |

Pneumatic Connections–With Zero/Span Valve Option (50) ................................................... |

160 |

|||

Figure 7-3: |

Pneumatic Connections–With 2-Span point Option (52) –Using Bottled Span Gas ................ |

160 |

|||

Figure7-4: |

Pneumatic Connections–With Zero/Span Valve Option (50) ................................................... |

164 |

|||

Figure 9-1: |

Sample Particulate Filter Assembly.......................................................................................... |

|

178 |

||

Figure |

9-2: |

Particle Filter on O3 Supply Air Dryer ....................................................................................... |

|

179 |

|

Figure 9-3: |

Zero Air Scrubber Assembly..................................................................................................... |

|

182 |

||

Figure 9-4: |

NO2 Converter Assembly.......................................................................................................... |

|

183 |

||

Figure |

9-5: |

Reaction Cell Assembly............................................................................................................ |

|

184 |

|

Figure |

9-6: |

Critical Flow Orifice Assembly .................................................................................................. |

|

186 |

|

Figure 10-10-1: |

M200EH/EM Sensitivity Spectrum............................................................................................ |

|

190 |

||

Figure 10-10-2: |

NO2 Conversion Principle ......................................................................................................... |

|

191 |

||

Figure 10-10-3: |

Reaction Cell with PMT Tube ................................................................................................... |

|

192 |

||

Figure 10-10-4: |

Reaction Cell During the AutoZero Cycle................................................................................. |

|

193 |

||

Figure 10-10-5: |

External Pump Pack ................................................................................................................. |

|

195 |

||

Figure 10-10-6: |

Location of Gas Flow Control Assemblies for M200EH............................................................ |

197 |

|||

Figure 10-10-7: |

Location of Gas Flow Control Assemblies for M200EM ........................................................... |

198 |

|||

Figure 10-10-8: |

Location of Gas Flow Control Assemblies for M200EH with O2 sensor Option 65 .................. |

198 |

|||

Figure 10-10-9: |

Location of Gas Flow Control Assemblies for M200EH with Second Span Point Option 52 ... |

199 |

|||

Figure 10-10-10: |

Flow Control Assembly & Critical Flow Orifice ......................................................................... |

200 |

|||

Figure 10-10-11: |

Ozone Generator Principle ....................................................................................................... |

|

202 |

||

Figure 10-10-12: |

Semi-Permeable Membrane Drying Process ........................................................................... |

203 |

|||

Figure 10-10-13: |

M200EH/EM Perma Pure® Dryer.............................................................................................. |

|

204 |

||

Figure 10-10-14: |

Vacuum Manifold ...................................................................................................................... |

|

206 |

||

Figure 10-10-15: |

Dilution Manifold ....................................................................................................................... |

|

208 |

||

Figure 10-10-16: |

M200EH/EM Electronic Block Diagram .................................................................................... |

|

209 |

||

Figure 10-10-17: |

M200EH/EM CPU Board Annotated......................................................................................... |

|

210 |

||

Figure 10-10-18: |

PMT Housing Assembly ........................................................................................................... |

|

212 |

||

Figure 10-10-19: |