Siemens MAG 5100 W User Manual

INSTRUCTIONS

SITRANS F M MAGFLO

Electromagnetic flowmeter

type MAG 5100 W

ENGLISH

083R9166

SFIDK.PI.026.V1.52

Siemens Flow Instruments SITRANS F M MAGFLO

electromagnetic flowmeters consist of a

sensor and a transmitter. These instructions only describe the sensor installation. For further

information on the transmitter installation, please refer to the SITRANS F M MAGFLO

handbook.

Introduction

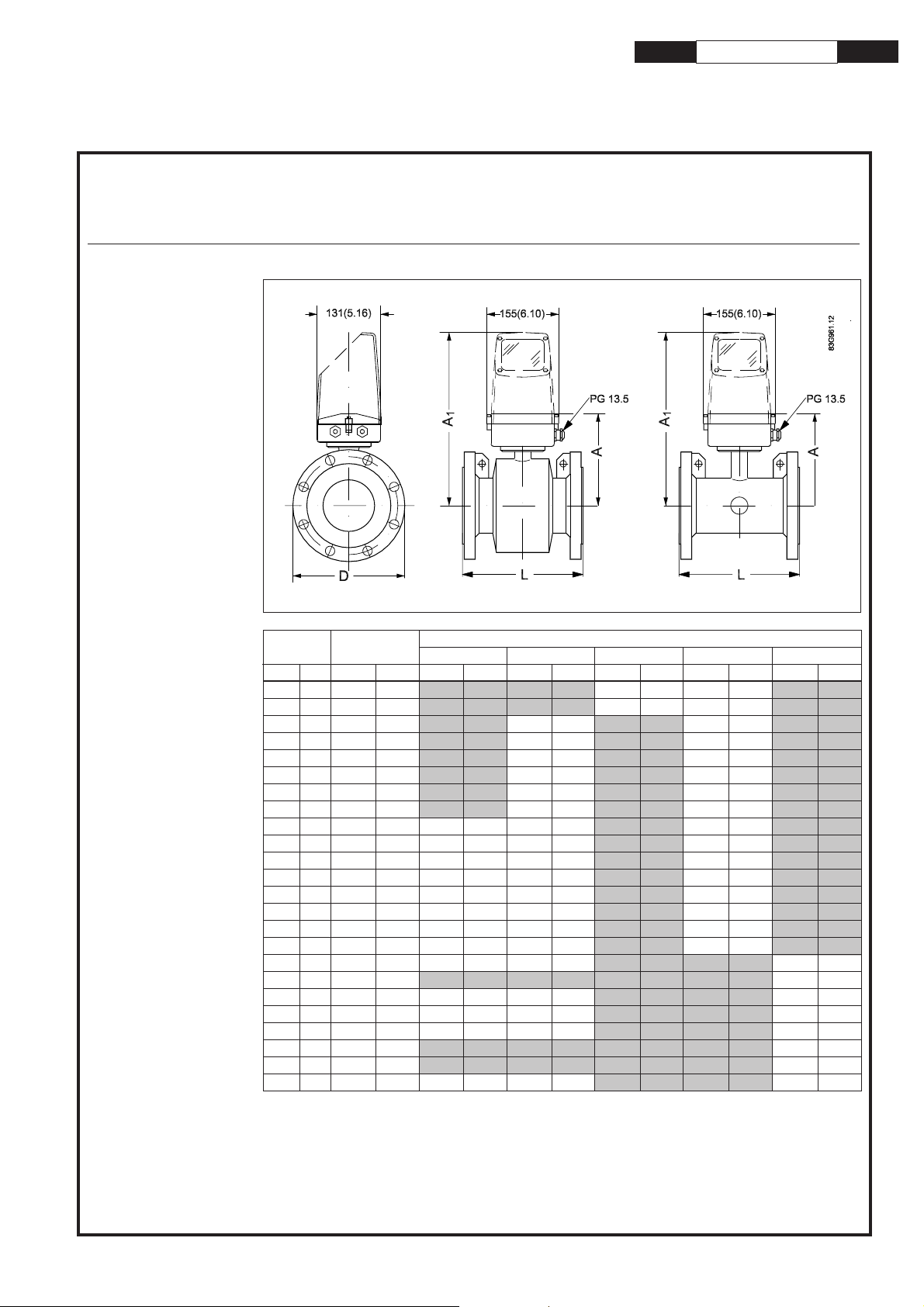

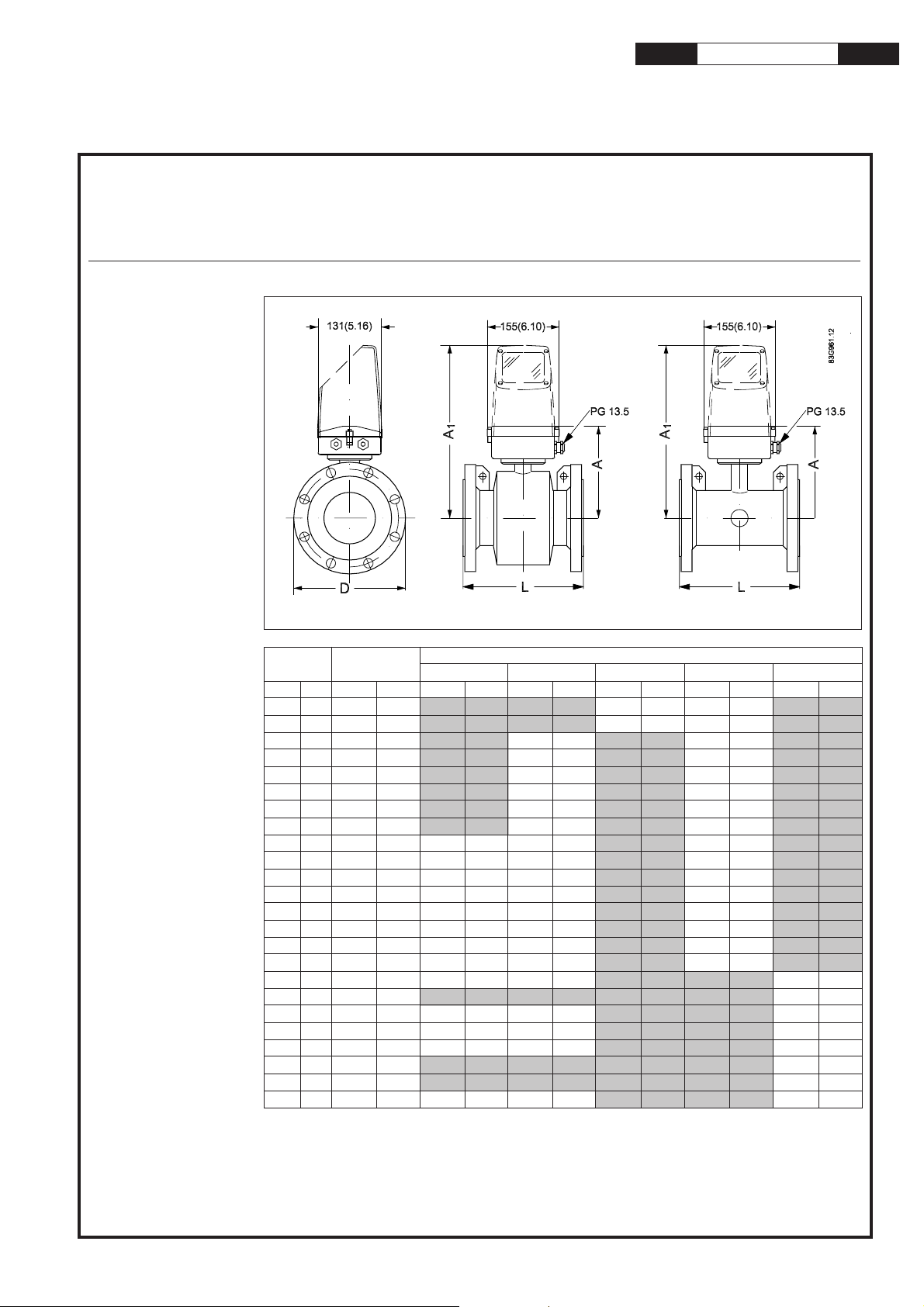

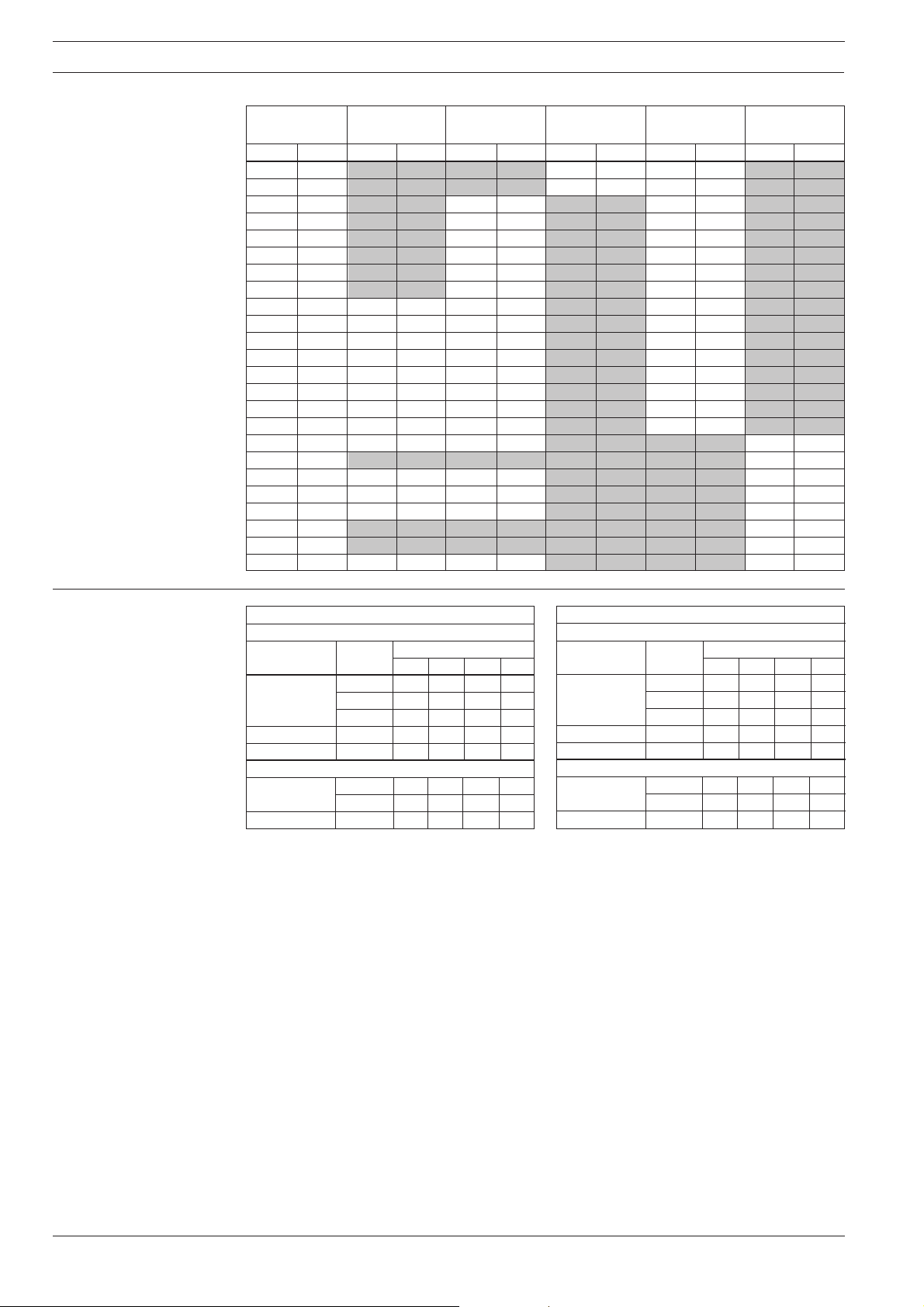

MAG 5100 W, compact/separate

Dimensions and

weight

mm inch mm inch mm inch mm inch mm inch mm inch mm inch

25 1" 187 7.4 N/A N/A N/A N/A 200 7.9 200 7.9 N/A N/A

40 1½” 197 7.8 N/A N/A N/A N/A 200 7.9 200 7.9 N/A N/A

50 2" 188 7.4 N/A N/A 200 7.9 N/A N/A 200 7.9 N/A N/A

65 2½” 194 7.6 N/A N/A 200 7.9 N/A N/A 200 7.9 N/A N/A

80 3" 200 7.9 N/A N/A 200 7.9 N/A N/A 200 7.9 N/A N/A

100 4" 207 8.1 N/A N/A 250 9.8 N/A N/A 250 9.8 N/A N/A

125 5" 217 8.5 N/A N/A 250 9.8 N/A N/A 250 9.8 N/A N/A

150 6" 232 9.1 N/A N/A 300 11.8 N/A N/A 300 11.8 N/A N/A

200 8" 257 10.1 350 13.8 350 13.8 N/A N/A 350 13.8 N/A N/A

250 10" 284 11.2 450 17.7 450 17.7 N/A N/A 450 17.7 N/A N/A

300 12" 310 12.2 500 19.7 500 19.7 N/A N/A 500 19.7 N/A N/A

350 14" 362 14.3 550 21.7 550 21.7 N/A N/A 550 21.7 N/A N/A

400 16" 387 15.2 600 23.6 600 23.6 N/A N/A 600 23.6 N/A N/A

450 18" 418 16.5 600 23.6 600 23.6 N/A N/A 600 23.6 N/A N/A

500 20" 443 17.4 625 24.6 625 24.6 N/A N/A 680 26.8 N/A N/A

600 24" 494 19.4 750 29.5 750 29.5 N/A N/A 820 32.3 N/A N/A

700 28" 544 21.4 875 34.4 875 34.4 N/A N/A N/A N/A 875 34.4

750 30" 571 22.5 N/A N/A N/A N/A N/A N/A N/A N/A 937 36.9

800 32" 606 23.9 1000 39.4 1000 39.4 N/A N/A N/A N/A 1000 39.4

900 36" 653 25.7 1125 44.3 1125 44.3 N/A N/A N/A N/A 1125 44.3

1000 40" 704 27.7 1250 49.2 1250 49.2 N/A N/A N/A N/A 1250 49.2

42" 704 27.7 N/A N/A N/A N/A N/A N/A N/A N/A 1250 49.2

1100 44" 755 29.7 N/A N/A N/A N/A N/A N/A N/A N/A 1375 54.1

1200 48" 810 31.9 1500 59.1 1500 59.1 N/A N/A N/A N/A 1500 59.1

AWWA

Nominal

size

A

L

PN 10

PN 16 PN 40 Class 150

Dimensions

s

Order no.: FDK:521H1190

2

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

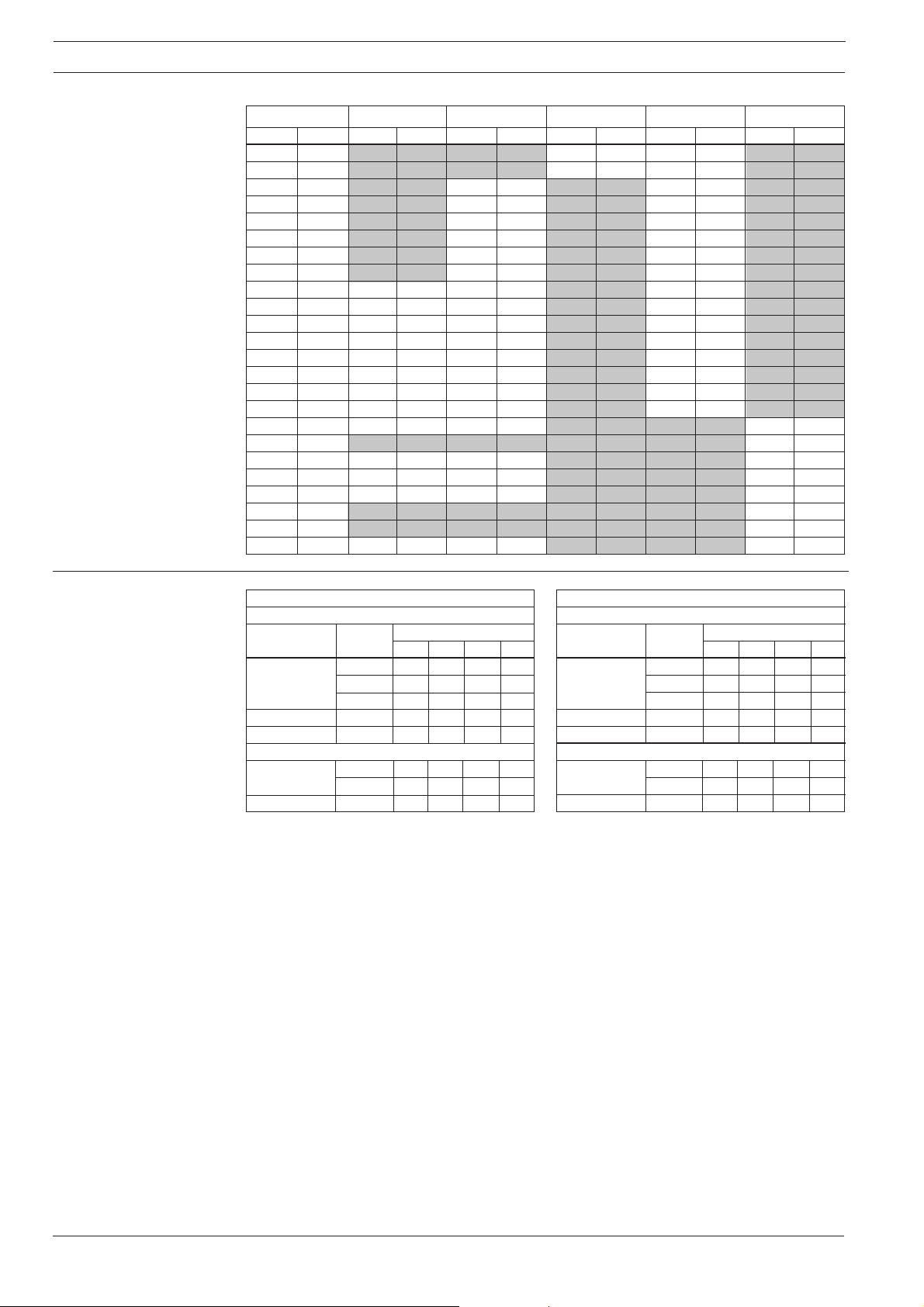

mm inch kgs lbs kgs lbs kgs lbs kgs lbs kgs lbs

25 1" N/A N/A N/A N/A 4 9 4 9 N/A N/A

40 1½" N/A N/A N/A N/A 7 15 6 13 N/A N/A

50 2" N/A N/A 9 20 N/A N/A 8 20 N/A N/A

65 2½" N/A N/A 10.7 24 N/A N/A 11 24 N/A N/A

80 3" N/A N/A 11.6 26 N/A N/A 13 28 N/A N/A

100 4" N/A N/A 15.2 33 N/A N/A 19 41 N/A N/A

125 5" N/A N/A 20.4 45 N/A N/A 24 52 N/A N/A

150 6" N/A N/A 26 57 N/A N/A 29 64 N/A N/A

200 8" 48 106 48 106 N/A N/A 56 124 N/A N/A

250 10" 64 141 69 152 N/A N/A 79 174 N/A N/A

300 12" 76 167 86 189 N/A N/A 110 243 N/A N/A

350 14" 100 220 116 255 N/A N/A 131 289 N/A N/A

400 16" 127 280 144 317 N/A N/A 165 364 N/A N/A

450 18" 152 335 178 393 N/A N/A 176 388 N/A N/A

500 20" 184 405 232 512 N/A N/A 235 518 N/A N/A

600 24" 258 568 343 736 N/A N/A 345 761 N/A N/A

700 28" 315 693 350 772 N/A N/A N/A N/A 309 681

750 30" N/A N/A N/A N/A N/A N/A N/A N/A 480 1058

800 32" 410 904 442 975 N/A N/A N/A N/A 421 928

900 36" 512 1129 550 1213 N/A N/A N/A N/A 539 1188

1000 40" 650 1433 732 1614 N/A N/A N/A N/A 670 1477

42" N/A N/A N/A N/A N/A N/A N/A N/A 700 1544

1100 44" N/A N/A N/A N/A N/A N/A N/A N/A 1100 2426

1200 48" 990 2183 1106 2439 N/A N/A N/A N/A 1030 2271

AWWA

Nominal size

PN 10 PN 16 PN 40 Class 150

Weight

The effect of temperature

on working pressure

Metric (Pressures in bar)

Sizes 25 mm, 40 mm & > 300 mm

Flange spec. Flange Temperature

°°

°°

°C

rating −5105090

EN 1092-1 PN 10 10.0 10.0 9.7 9.4

PN 16 16.0 16.0 15.5 15.1

PN 40 40.0 40.0 38.7 37.7

ANSI B16.45 150 lb 19.7 19.7 19.3 18.0

AWWA C-207 Class D 10.3 10.3 10.3 10.3

Sizes 50 mm to 300 mm

EN 1092-1 PN 10 10.0 10.0 10.0 8.2

PN 16 10.0 16.0 16.0 13.2

ANSI B16.45 150 lb 10.0 19.7 19.7 16.2

Imperial (Pressures in Psi)

Sizes 1", 1½", & > 12"

Flange spec. Flange Temperature

°°

°°

°F

rating 23 50 120 200

EN 1092-1 PN 10 145 145 141 136

PN 16 232 232 225 219

PN 40 580 580 561 547

ANSI B16.45 150 lb 286 286 280 261

AWWA C-207 Class D 150 150 150 150

Sizes 2" to 12"

EN 1092-1 PN 10 145 145 145 119

PN 16 145 232 232 191

ANSI B16.45 150 lb 145 286 286 235

3

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

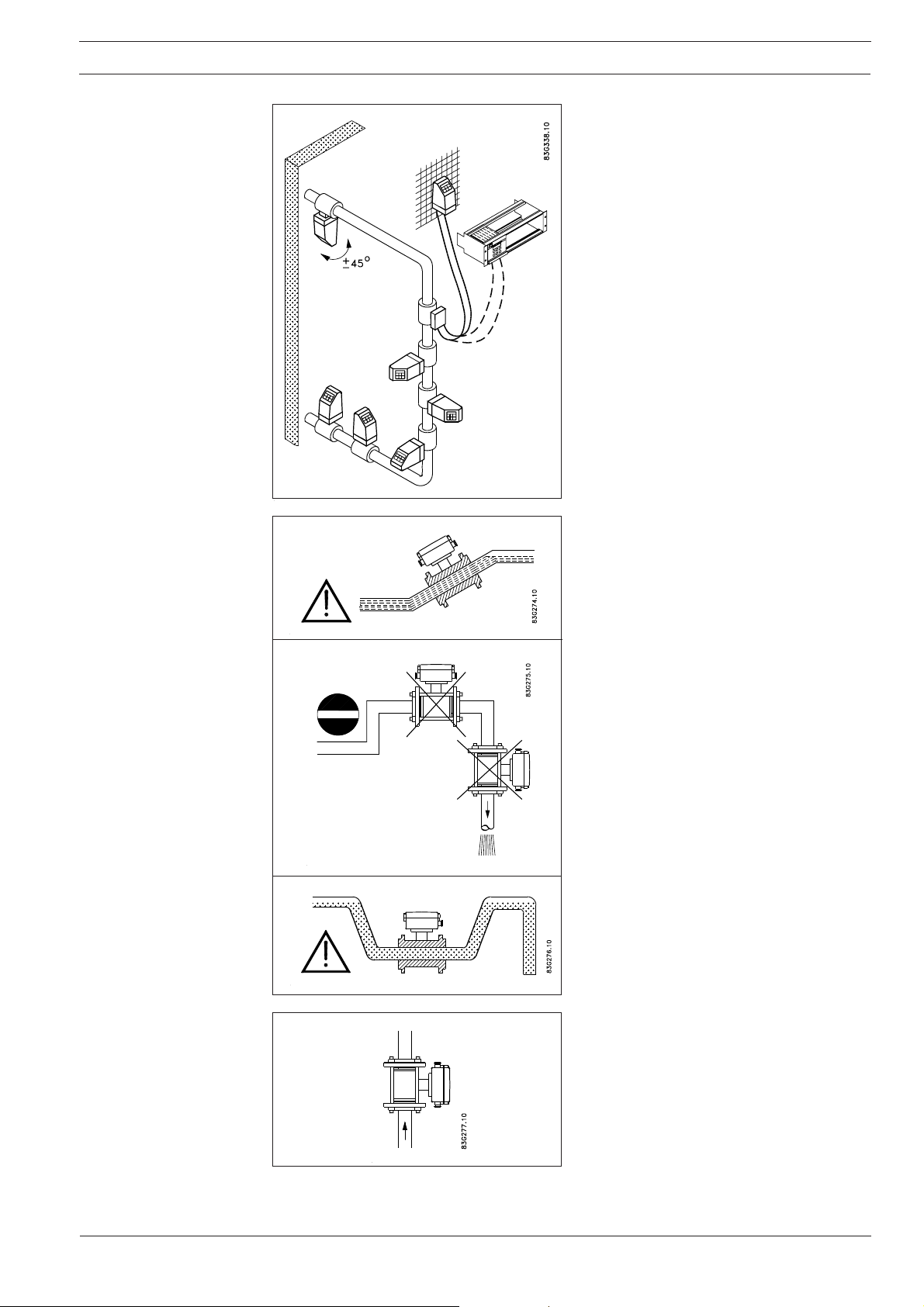

Installation, general

Reading and operating the flowmeter is possi-

ble under almost any installation conditions

because the display can be oriented in relation

to the sensor. To ensure optimum flow mea-

surement attention should be paid to the follow-

ing:

The sensor must always be completely full with

liquid.

Therefore avoid:

• Installation at the highest point in the pipe

system

• Installation in vertical pipes with free outlet

For partially filled pipes or pipes with downward

flow and free outlet the flowmeter should be

located in a U-tube.

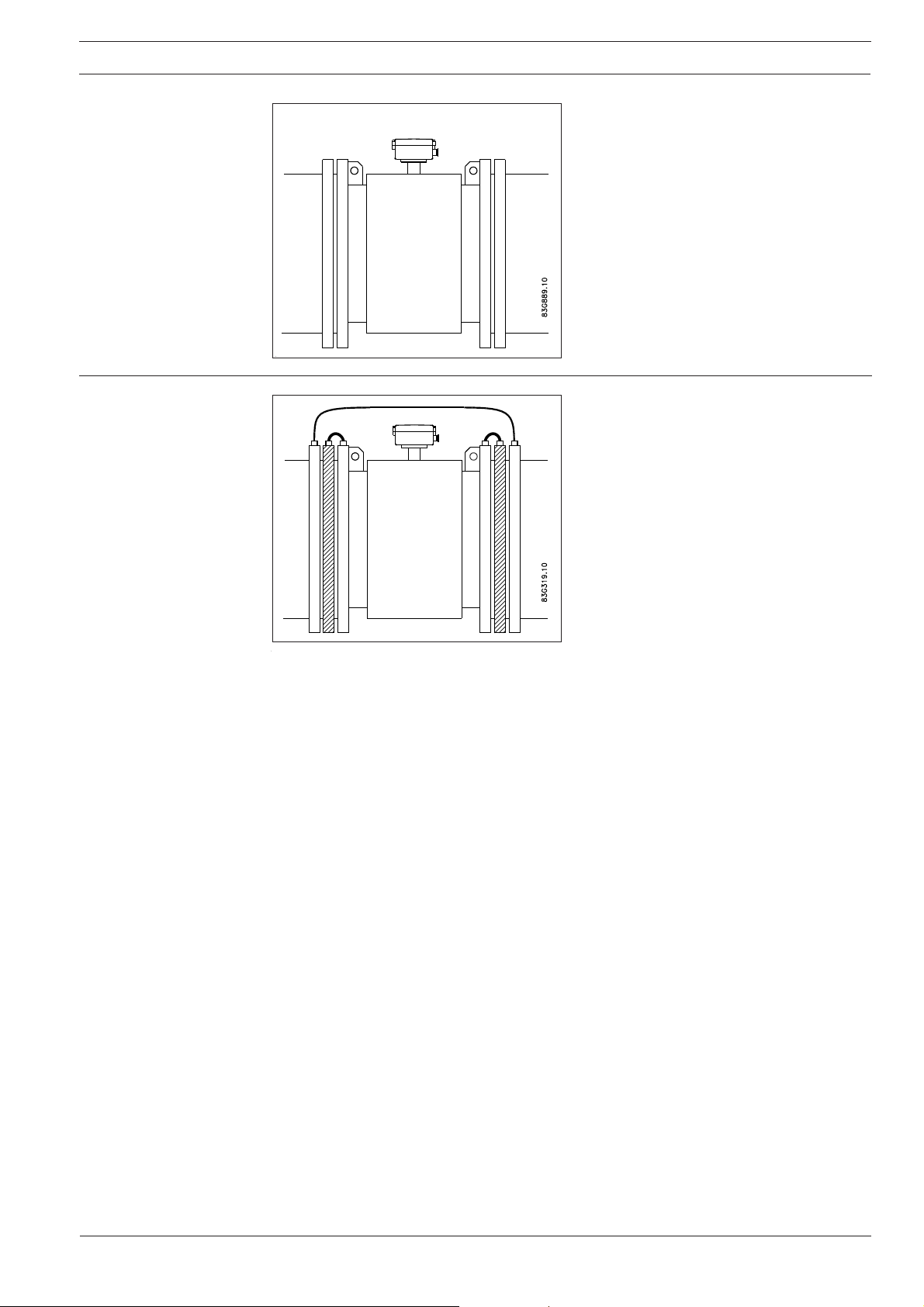

Installation in vertical pipes

Recommended flow direction: upwards. This

minimizes the effect on the measurement of

any gas/air bubbles in the liquid.

4

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

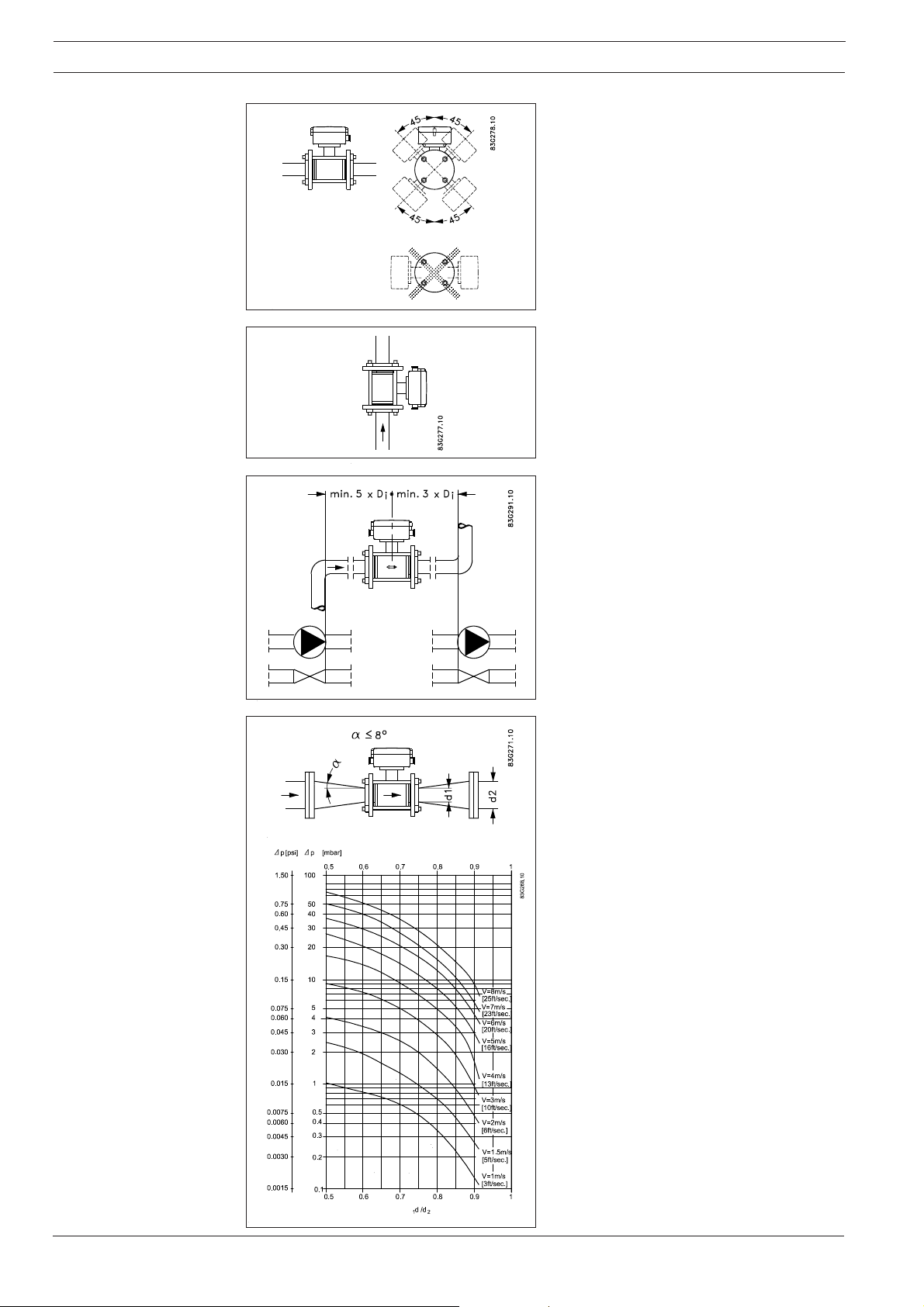

Installation in horizontal pipes

The sensor must be mounted as shown in the

upper figure. Do not mount the sensor as shown

in the lower figure. This will position the elec-

trodes at the top where there is possibility for air

bubbles and at the bottom where there is pos-

sibility for mud, sludge, sand etc.

If using empty pipe detection the sensor can be

tilted 45°, as shown in the upper figure.

Measuring abrasive liquids and liquids con-

taining particles

Recommended installation is in a vertical/in-

clined pipe to minimize the wear and deposits

in the sensor.

Inlet and outlet conditions

To achieve accurate flow measurement it is

essential to have straight lengths of inlet and

outlet pipes and a certain distance between

pumps and valves.

It is also important to centre the flowmeter in

relation to pipe flanges and gaskets.

Installation, general

(continued)

Installation in large pipes

The flowmeter can be installed between two

reducers (e.g. DIN 28545). Assuming that at 8°

the following pressure drop curve applies. The

curves are applicable to water.

Example:

A flow velocity of 3 m/s (V) in a sensor with a

diameter reduction from DN 100 to DN 80

(d

1

/d

2

= 0.8) gives a pressure drop of 2.9 mbar.

5

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

Potential equalisation Potential equalisation is carried out with the

built-in earthing electrodes.

Special attention must be given to systems with

cathodic protection.

By compact mounting:

The transmitter must be supplied through an

isolation transformer. The terminal "PE" must

never be connected.

By remote mounting:

The screen must only be connected at the

sensor end via a 1.5 µF condensator. The

screen must never be connected at both ends.

By isolated sensor:

If above mentioned connections are unaccept-

able the sensor must be isolated from the pipe

work.

Cathodic protected

piping

With earthing electrodes

6

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

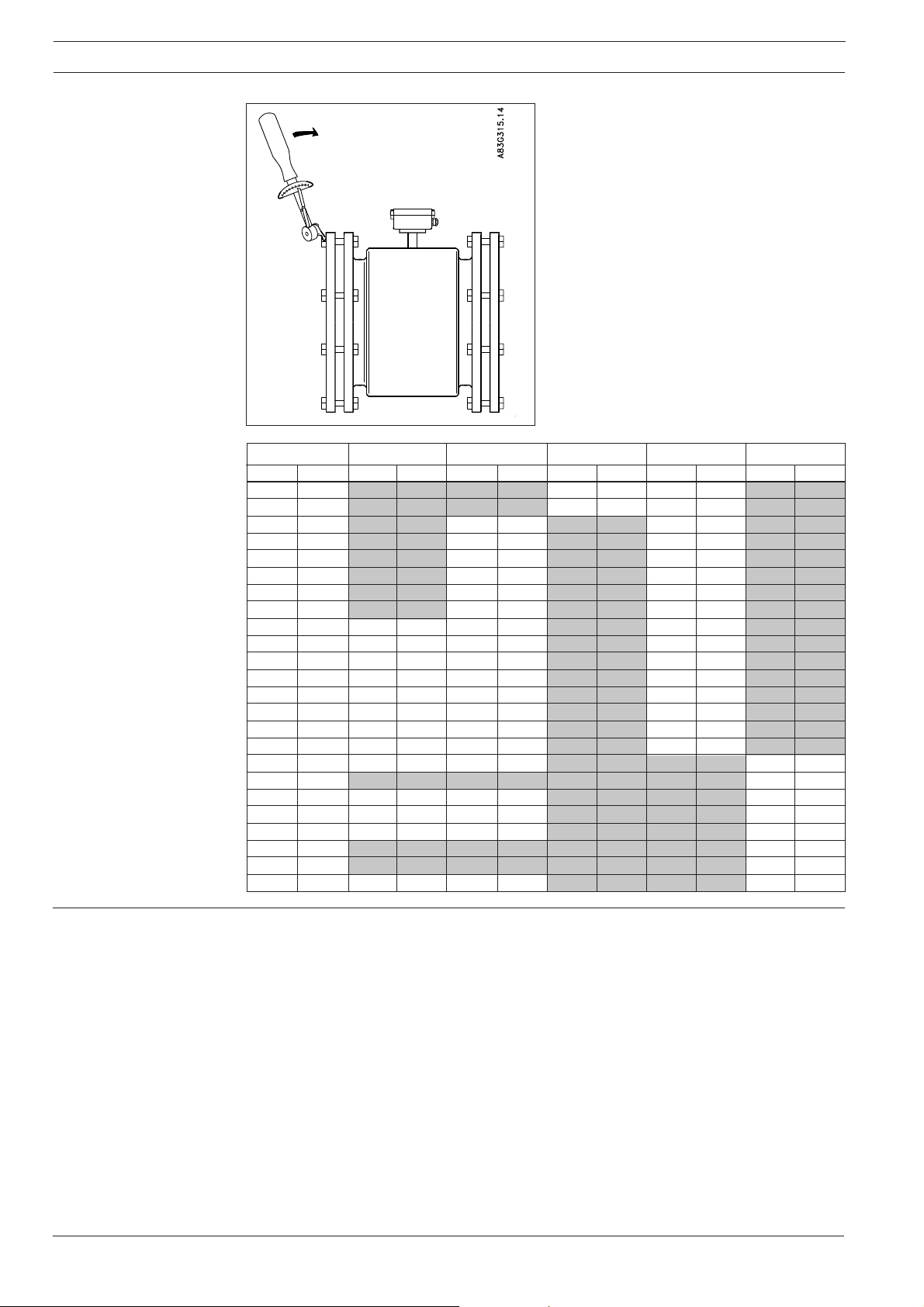

mm inch Nm f/lbs Nm f/lbs Nm f/lbs Nm f/lbs Nm f/lbs

25 1" N/A N/A N/A N/A 10 7 7 5 N/A N/A

40 1½" N/A N/A N/A N/A 16 12 9 7 N/A N/A

50 2" N/A N/A 25 18 N/A N/A 25 18 N/A N/A

65 2½" N/A N/A 25 18 N/A N/A 25 18 N/A N/A

80 3" N/A N/A 25 18 N/A N/A 34 25 N/A N/A

100 4" N/A N/A 25 18 N/A N/A 26 19 N/A N/A

125 5" N/A N/A 29 21 N/A N/A 42 31 N/A N/A

150 6" N/A N/A 50 37 N/A N/A 57 42 N/A N/A

200 8" 50 37 50 37 N/A N/A 88 65 N/A N/A

250 10" 50 37 82 61 N/A N/A 99 73 N/A N/A

300 12" 57 42 111 82 N/A N/A 132 97 N/A N/A

350 14" 60 44 120 89 N/A N/A 225 166 N/A N/A

400 16" 88 65 170 125 N/A N/A 210 155 N/A N/A

450 18" 92 68 170 125 N/A N/A 220 162 N/A N/A

500 20" 103 76 230 170 N/A N/A 200 148 N/A N/A

600 24" 161 119 350 258 N/A N/A 280 207 N/A N/A

700 28" 200 148 304 224 N/A N/A N/A N/A 200 148

750 30" N/A N/A N/A N/A N/A N/A N/A N/A 240 177

800 32" 274 202 386 285 N/A N/A N/A N/A 260 192

900 36" 288 213 408 301 N/A N/A N/A N/A 240 177

1000 40" 382 282 546 403 N/A N/A N/A N/A 280 207

42" N/A N/A N/A N/A N/A N/A N/A N/A 280 207

1100 44" N/A N/A N/A N/A N/A N/A N/A N/A 290 214

1200 48" 395 292 731 539 N/A N/A N/A N/A 310 229

AWWA

Nominal size

PN 10

PN 16 PN 40 Class 150

Maximum allowable

torques

All values are theoretical and are calculated making the following assumptions:

1) All bolts are new and material selection is according to EN 1515-1 table 2

2) Gasket material not exceeding 75 shore A durometer is used between the flowmeter and

mating flanges

3) All bolts are galvanized and adequately lubricated

4) The values are calculated for use with carbon steel flanges

5) Flowmeter and mating flanges are correctly aligned

Torque calculations

Standard bolts must be well lubricated and tight-

ened evenly around the gasket. Leakage/dam-

age to the flowmeter or piping may arise if bolts

are overtightened.

7

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

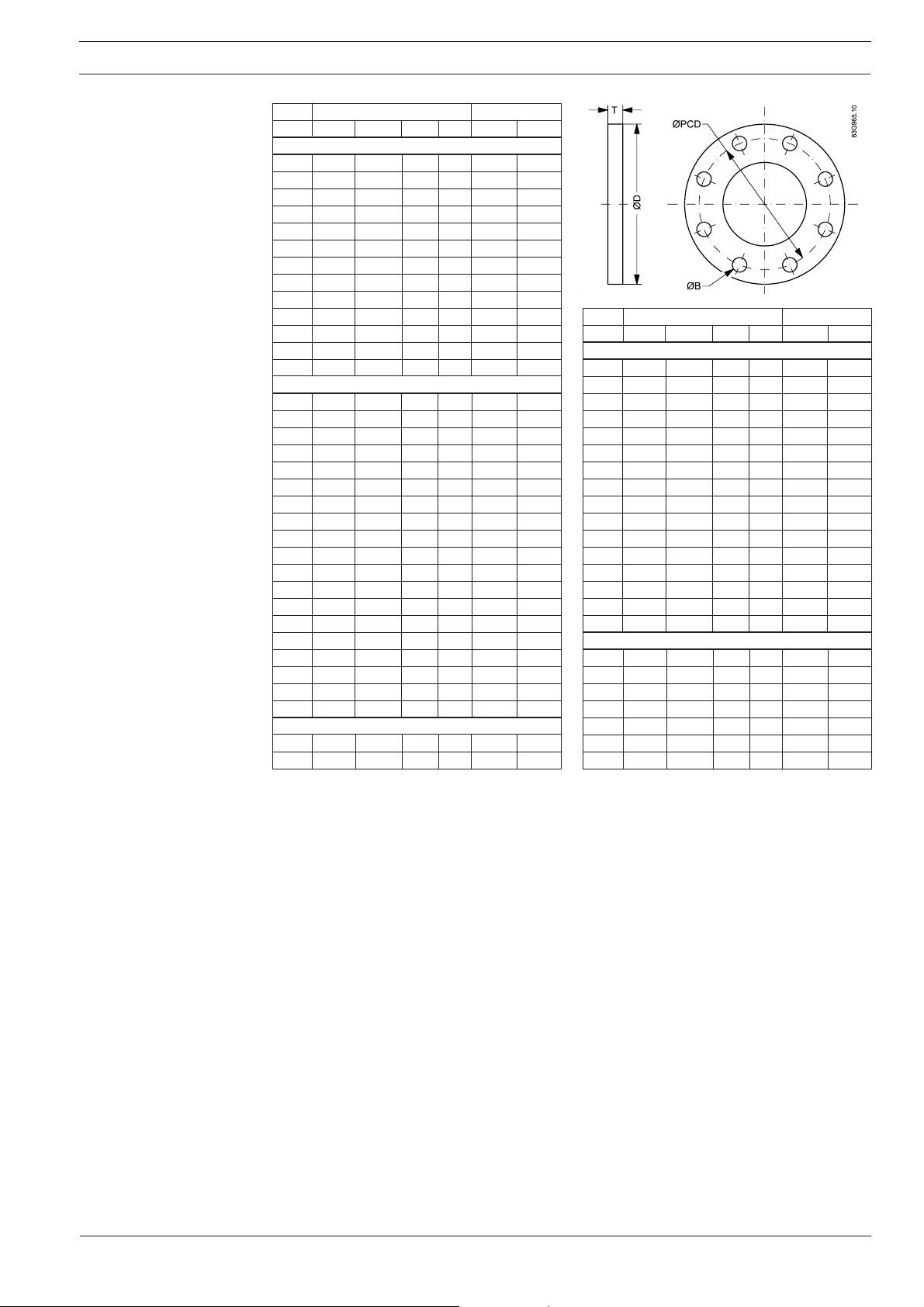

Flange mating dimen-

sions (Metric)

Dimensions mm Bolting

mm OD PCD T B Holes Bolts

PN 10

200 340 295 24 22 8 M20

250 395 350 26 22 12 M20

300 445 400 26 22 12 M20

350 505 460 28 22 16 M20

400 565 515 32 26 16 M24

450 615 565 36 26 20 M24

500 670 620 38 26 20 M24

600 780 725 42 30 20 M27

700 895 840 30 30 24 M27

800 1015 950 32 33 24 M30

900 1115 1050 34 33 28 M30

1000 1230 1160 34 36 28 M33

1200 1455 1380 38 39 32 M36

PN 16

50 165 125 19 18 4 M16

65 185 145 20 18 8 M16

80 200 160 20 18 8 M16

100 220 180 22 18 8 M16

125 250 210 22 18 8 M16

150 285 240 24 22 8 M20

200 340 295 26 22 12 M20

250 405 355 29 26 12 M24

300 460 410 32 26 12 M24

350 520 470 35 26 16 M24

400 580 525 38 30 16 M27

450 640 585 42 30 20 M27

500 715 650 46 33 20 M30

600 840 770 52 36 20 M33

700 910 840 36 36 24 M33

800 1025 950 38 39 24 M36

900 1125 1050 40 39 28 M36

1000 1255 1170 42 42 28 M39

1200 1485 1390 48 48 32 M45

PN 40

25 115 85 16 14 4 M12

40 150 110 18 18 4 M16

Dimensions mm Bolting

mm OD PCD T B Holes Bolts

150 lb

25 108 79 14 16 4 M14

40 127 98 18 16 4 M14

50 152 121 19 19 4 M16

65 178 140 22 19 4 M16

80 190 152 24 19 4 M16

100 229 191 24 19 8 M16

125 254 216 24 22 8 M20

150 279 241 25 22 8 M20

200 343 298 29 22 8 M20

250 406 362 30 25 12 M24

300 483 432 32 25 12 M24

350 533 476 35 28 12 M27

400 597 540 36.5 28 16 M27

450 635 578 40 32 16 M30

500 699 635 43 32 20 M30

600 813 749 48 35 20 M33

AWWA

700 927 864 33 35 28 M33

750 984 914 35 35 28 M33

800 1060 978 38 41 28 M39

900 1168 1086 41 41 32 M39

1000 1289 1200 41 41 36 M39

1050 1346 1257 44 41 36 M39

1200 1511 1422 48 41 44 M39

8

SITRANS F M MAGFLO

Electromagnetic flowmeter type MAG 5100 W

1. Responsibility for the choice of lining and electrode materials with regard to their abrasion and

corrosion resistance lies with the purchaser; the effect of any change in process medium during

the operating life of the flowmeter should be taken into account. Incorrect selection of lining

and/or electrode materials could lead to a failure of the flowmeter.

2. Stresses and loading caused by earthquakes, traffic, high winds and fire damage not taken

into account during flowmeter design.

3. Do not install flowmeter such that it acts as a focus for pipeline stresses. External loadings not

taken into account during flowmeter design.

4. During operation do not exceed the pressure and/or temperature ratings indicated on the data

label or in the installation instructions.

5. It is recommended that all installations should include an appropriate safety valve and

adequate means for draining/venting.

6. Under the Pressure Equipment Directive this product is a pressure accessory, and not

approved for use as a safety accessory, as defined by the Pressure Equipment Directive.

7. Removal of the terminal box except by Siemens Flow Instruments or their approved agents will

invalidate the PED conformity of the product.

In accordance with the Pressure Equipment Directive (97/23/EC).

Manufacturer’s design

and safety statement

We have checked the contents of this manual for agreement with the hardware and

software described. Since deviations cannot be precluded entirely, we cannot guarantee

full agreement. However, the data in this manual are reviewed regularly and any

necessary corrections included in subsequent editions. Suggestions for improvement

are always welcomed.

Technical data subject to change without prior notice.

The reproduction, transmission or use of this document or its contents is not permitted without

express written authority.

Offenders will be liable for damages. All rights, including rights created by patent grant or

registration of a utility model or design, are reserved.

Copyright © Siemens AG 05.2004 All Rights Reserved

Siemens Flow Instruments A/S

Nordborgvej 81

DK-6430 Nordborg

Order no.: FDK:521H1190-01

Printed in: Denmark

INSTRUCTIONS

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser

Typ MAG 5100 W

DEUTSCH

083R9166

SFIDK.PI.026.V1.52

Siemens Flow Instruments SITRANS F M MAGFLO

magnetisch-induktive Durchflussmesser

bestehen aus einem Messaufnehmer und einem Messumformer. Diese Instruktion beschreibt nur

die Montage des Messaufnehmers. Für weitere Informationen über die Montage des Messumformers,

siehe bitte das SITRANS F M MAGFLO

Produkthandbuch.

Einführung

MAG 5100 W, kompakte/getrennte Montage

Abmessungen und

Gewichte

mm Zoll mm Zoll mm Zoll mm Zoll mm Zoll mm Zoll mm Zoll

25 1" 187 7,4 - - - - 200 7,9 200 7,9 - -

40 1½” 197 7,8 - - - - 200 7,9 200 7,9 - -

50 2" 188 7,4 - - 200 7,9 - - 200 7,9 - -

65 2½” 194 7,6 - - 200 7,9 - - 200 7,9 - -

80 3" 200 7,9 - - 200 7,9 - - 200 7,9 - -

100 4" 207 8,1 - - 250 9,8 - - 250 9,8 - -

125 5" 217 8,5 - - 250 9,8 - - 250 9,8 - -

150 6" 232 9,1 - - 300 11,8 - - 300 11,8 - -

200 8" 257 10,1 350 13,8 350 13,8 - - 350 13,8 - -

250 10" 284 11,2 450 17,7 450 17,7 - - 450 17,7 - -

300 12" 310 12,2 500 19,7 500 19,7 - - 500 19,7 - -

350 14" 362 14,3 550 21,7 550 21,7 - - 550 21,7 - -

400 16" 387 15,2 600 23,6 600 23,6 - - 600 23,6 - -

450 18" 418 16,5 600 23,6 600 23,6 - - 600 23,6 - -

500 20" 443 17,4 625 24,6 625 24,6 - - 680 26,8 - -

600 24" 494 19,4 750 29,5 750 29,5 - - 820 32,3 - -

700 28" 544 21,4 875 34,4 875 34,4 - - - - 875 34,4

750 30" 571 22,5 - - - - - - - - 937 36,9

800 32" 606 23,9 1000 39,4 1000 39,4 - - - - 1000 39,4

900 36" 653 25,7 1125 44,3 1125 44,3 - - - - 1125 44,3

1000 40" 704 27,7 1250 49,2 1250 49,2 - - - - 1250 49,2

42" 704 27,7 - - - - - - - - 1250 49,2

1100 44" 755 29,7 - - - - - - - - 1375 54,1

1200 48" 810 31,9 1500 59,1 1500 59,1 - - - - 1500 59,1

AWWA

Nennweite A

L

PN 10 PN 16 PN 40 Klasse 150

Abmessungen

s

Order no.: FDK:521H1190

10

SITRANS F M MAGFLO

Magnetisch-induktiver Durchflussmesser Typ MAG 5100 W

mmZollkglbkg lbkg lbkg lbkg lb

251"----49 49--

40 1½" - - - - 7 15 6 13 - -

50 2" - - 9 20 - - 8 20 - -

65 2½" - - 10,7 24 - - 11 24 - -

80 3" - - 11,6 26 - - 13 28 - -

100 4" - - 15,2 33 - - 19 41 - -

125 5" - - 20,4 45 - - 24 52 - -

150 6" - - 26 57 - - 29 64 - -

200 8" 48 106 48 106 - - 56 124 - -

250 10" 64 141 69 152 - - 79 174 - -

300 12" 76 167 86 189 - - 110 243 - -

350 14" 100 220 116 255 - - 131 289 - -

400 16" 127 280 144 317 - - 165 364 - -

450 18" 152 335 178 393 - - 176 388 - -

500 20" 184 405 232 512 - - 235 518 - -

600 24" 258 568 343 736 - - 345 761 - -

700 28" 315 693 350 772 - - - - 309 681

750 30" - - - - - - - - 480 1058

800 32" 410 904 442 975 - - - - 421 928

900 36" 512 1129 550 1213 - - - - 539 1188

1000 40" 650 1433 732 1614 - - - - 670 1477

42" - - - - - - - - 700 1544

1100 44" - - - - - - - - 1100 2426

1200 48" 990 2183 1106 2439 - - - - 1030 2271

AWWA

Nennweite

PN 10 PN 16 PN 40 Klasse 150

Gewicht

Auswirkung der

Temperatur auf den

Arbeitsdruck

Metrisch (Drücke in bar)

Nennweite 25 mm, 40 mm und > 300 mm

Flansch- Druck- Temperatur

°°

°°

°C

Spez. stufe −5105090

EN 1092-1 PN 10 10,0 10,0 9,7 9,4

PN 16 16,0 16,0 15,5 15,1

PN 40 40,0 40,0 38,7 37,7

ANSI B16.45 150 lb 19,7 19,7 19,3 18,0

AWWA C-207 Class D 10,3 10,3 10,3 10,3

Nennweite 50 mm bis 300 mm

EN 1092-1 PN 10 10,0 10,0 10,0 8,2

PN 16 10,0 16,0 16,0 13,2

ANSI B16.45 150 lb 10,0 19,7 19,7 16,2

Zollsystem (Drücke in psi)

Nennweite 1", 1½", und > 12"

Flansch- Druck- Temperatur

°°

°°

°F

Spez. stufe 23 50 120 200

EN 1092-1 PN 10 145 145 141 136

PN 16 232 232 225 219

PN 40 580 580 561 547

ANSI B16.45 150 lb 286 286 280 261

AWWA C-207 Class D 150 150 150 150

Nennweite 2" bis 12"

EN 1092-1 PN 10 145 145 145 119

PN 16 145 232 232 191

ANSI B16.45 150 lb 145 286 286 235

Loading...

Loading...