Siemens ERTEC200 User Manual

.

ERTEC 200

Enhanced Real-Time Ethernet Controller

Manual

Copyright © Siemens AG 2007. All rights reserved. |

Page 1 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

Edition (04/2007)

Disclaimer of Liability

We have checked the contents of this manual for agreement with the hardware and software described. Since deviations cannot be precluded entirely, we cannot guarantee full agreement. However, the data in this manual are reviewed regularly. Necessary corrections are included in subsequent editions. Suggestions for improvement are welcomed.

Copyright

© Siemens AG 2006. All rights reserved

The reproduction, transmission or use of this document or its contents is not permitted without express written authority. Offenders will be liable for damages. All rights, including rights created by patent grant or registration of a utility model or design, are reserved.

All product and system names are registered trademarks of their respective owner and must be treated as such.

Technical data subject to change.

Copyright © Siemens AG 2007. All rights reserved. |

Page 2 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

Preface

Target Audience of this Manual

This manual is intended for hardware developers who want to use the ERTEC 200 for new products. Experience working with processors and designing embedded systems and knowledge of Ethernet are required for this. It described all ERTEC function groups in details and provides information that you must take into account when configuring your own PROFINET IO device hardware.

The manual serves as a reference for software developers. The address areas and register contents are described in detail for all function groups.

Structure of this Manual

o Section 1 Overview of the architecture and the individual function groups of the ERTEC 200. o Section 2 ARM946E-S processor systems.

o Section 3 Bus system of the ERTEC 200. o Section 4 I/O of the ERTEC 200.

o Section 5 General hardware functions.

o Section 6 External memory interface (EMIF). o Section 7 Local bus unit (LBU).

o Section 8 DMA controller o Section 9 Ethernet PHYs

o Section 10 Memory partitioning of the ERTEC 200. o Section 11 HW tools for test, trace, and debugging. o Section 12 List of terms and references

Scope of the Manual

This manual applies to the following product:

ERTEC 200 Version 01 and higher

Copyright © Siemens AG 2007. All rights reserved. |

Page 3 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

This manual will be updated as required. You can find the current version of the manual on the Internet at http://www.siemens.com/comdec.

Guide

To help you quickly find the information you need, this manual contains the following aids:

oA complete table of contents as well as a list of all figures and tables in the manual are provided at the beginning of the manual.

o A glossary containing definitions of important terms used in the manual is located following the appendices.

oReferences to other documents are indicated by the document reference number enclosed in slashes (/No./). The complete title of the document can be obtained from the list of references at the end of the manual.

Additional Support

If you have questions regarding use of the described block that are not addressed in the documentation, please contact your Siemens representative.

Please send your written questions, comments, and suggestions regarding the manual to the hotline via the e- mail address indicated above.

In addition, you can receive general information, current product information, FAQs, and downloads pertaining to your application on the Internet at:

http://www.siemens.com/comdec

Technical Contacts for Germany / Worldwide

Siemens AG |

Phone: |

0911/750-2736 |

Automation & |

Phone: |

0911/750-2080 |

Drives |

Fax: |

0911/750-2100 |

E-mail: ComDeC@siemens.com |

||

ComDeC |

|

|

Street address: |

Mailing address: |

|

Würzburgerstr.121 |

P.O. Box 2355 |

|

90766 Fürth |

90713 Fürth |

|

Federal Republic of |

Federal Republic of Germany |

|

Germany |

|

|

Technical Contacts for USA |

|

|

PROFI Interface Center: |

Fax: |

(423)- 2622103 |

One Internet Plaza |

Phone: |

(423)- 2622576 |

PO Box 4991 |

E-mail: profibus.sea@siemens.com |

|

Johnson City, TN 37602-4991 |

|

|

Copyright © Siemens AG 2007. All rights reserved. |

Page 4 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

Contents

1 |

Introduction ............................................................................................................................ |

9 |

||

1.1 |

Applications of the ERTEC 200.............................................................................................................. |

9 |

||

1.2 |

Features of the ERTEC 200 ................................................................................................................... |

9 |

||

1.3 |

Structure of the ERTEC 200................................................................................................................... |

10 |

||

1.4 |

ERTEC 200 Package ............................................................................................................................. |

11 |

||

1.5 |

Signal Function Description.................................................................................................................... |

12 |

||

1.5.1 |

GPIO 0 to 31 and Alternative Functions......................................................................................... |

12 |

||

1.5.2 |

JTAG and Debug ........................................................................................................................... |

13 |

||

1.5.3 |

Trace Port ...................................................................................................................................... |

13 |

||

1.5.4 |

Clock and Reset ............................................................................................................................ |

14 |

||

1.5.5 |

Test Pins........................................................................................................................................ |

14 |

||

1.5.6 |

EMIF (External Memory Interface)................................................................................................. |

14 |

||

1.5.7 |

LBU, MII Interface or ETM Trace Interface .................................................................................... |

16 |

||

1.5.8 |

Ethernet PHY1 and PHY2.............................................................................................................. |

18 |

||

1.5.9 |

Power Supply................................................................................................................................. |

19 |

||

2 |

ARM946E-S Processor .......................................................................................................... |

21 |

||

2.1 |

Structure of ARM946E-S........................................................................................................................ |

21 |

||

2.2 |

Description of ARM946E-S .................................................................................................................... |

22 |

||

2.3 |

Operating Frequency of ARM946E-S..................................................................................................... |

22 |

||

2.4 |

Cache Structure of ARM946E-S............................................................................................................. |

22 |

||

2.5 |

Tightly Coupled Memory (TCM) ............................................................................................................. |

22 |

||

2.6 |

Memory Protection Unit (MPU) .............................................................................................................. |

23 |

||

2.7 |

Bus Interface of ARM946E-S ................................................................................................................. |

23 |

||

2.8 |

ARM946E-S Embedded Trace Macrocell (ETM9).................................................................................. |

23 |

||

2.9 |

ARM Interrupt Controller (ICU)............................................................................................................... |

23 |

||

2.9.1 |

Prioritization of Interrupts ............................................................................................................... |

24 |

||

2.9.2 |

Trigger Modes................................................................................................................................ |

24 |

||

2.9.3 |

Masking the Interrupt Inputs .......................................................................................................... |

24 |

||

2.9.4 |

Software Interrupts for IRQ ............................................................................................................ |

24 |

||

2.9.5 |

Nested Interrupt Structure.............................................................................................................. |

24 |

||

2.9.6 |

EOI End-Of-Interrupt...................................................................................................................... |

24 |

||

2.9.7 |

IRQ Interrupt Sources .................................................................................................................... |

25 |

||

2.9.8 |

FIQ Interrupt Sources .................................................................................................................... |

25 |

||

2.9.9 |

IRQ Interrupts as FIQ Interrupt Sources ........................................................................................ |

26 |

||

2.9.10 |

Interrupt Control Register............................................................................................................... |

26 |

||

2.9.11 |

ICU Register Description ............................................................................................................... |

27 |

||

2.10 ARM946E-S Register ............................................................................................................................. |

31 |

|||

3 |

Bus System of the ERTEC 200.............................................................................................. |

32 |

||

3.1 |

“Multilayer AHB” Communication Bus .................................................................................................... |

32 |

||

3.1.1 |

AHB Arbiter.................................................................................................................................... |

32 |

||

3.1.2 |

AHB Master-Slave Coupling .......................................................................................................... |

32 |

||

3.2 |

APB I/O Bus ........................................................................................................................................... |

32 |

||

4 |

I/O on APB bus ....................................................................................................................... |

33 |

||

4.1 |

BOOT ROM............................................................................................................................................ |

33 |

||

4.1.1 |

Booting from External ROM ........................................................................................................... |

34 |

||

4.1.2 |

Booting via SPI .............................................................................................................................. |

34 |

||

4.1.3 |

Booting via UART .......................................................................................................................... |

34 |

||

4.1.4 |

Booting via LBU ............................................................................................................................. |

34 |

||

4.1.5 |

Memory Swapping ......................................................................................................................... |

34 |

||

4.2 |

General Purpose I/O (GPIO) .................................................................................................................. |

35 |

||

4.2.1 |

Address Assignment of GPIO Registers ........................................................................................ |

36 |

||

4.2.2 |

GPIO Register Description............................................................................................................. |

36 |

||

4.3 |

Timer 0/1/2 ............................................................................................................................................. |

38 |

||

4.3.1 |

Timer 0 and Timer 1....................................................................................................................... |

38 |

||

|

4.3.1.1 |

Timer 0/1 Interrupts............................................................................................................... |

39 |

|

|

4.3.1.2 |

Timer 0/1 Prescaler............................................................................................................... |

39 |

|

|

4.3.1.3 |

Cascading of Timers 0/1 ....................................................................................................... |

39 |

|

4.3.2 |

Timer 2........................................................................................................................................... |

39 |

||

4.3.3 |

Address Assignment of Timer Registers........................................................................................ |

40 |

||

4.3.4 |

Timer Register Description ............................................................................................................ |

40 |

||

4.4 |

F-Timer Function.................................................................................................................................... |

43 |

||

4.4.1 |

Address Assignment of F-Timer Registers .................................................................................... |

44 |

||

Copyright © Siemens AG 2007. All rights reserved. |

Page 5 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

4.4.2 |

F-Timer Register Description ......................................................................................................... |

44 |

|

4.5 |

Watchdog Timers ................................................................................................................................... |

45 |

|

4.5.1 |

Watchdog Timer 0.......................................................................................................................... |

45 |

|

4.5.2 |

Watchdog Timer 1.......................................................................................................................... |

45 |

|

4.5.3 |

Watchdog Interrupt ........................................................................................................................ |

45 |

|

4.5.4 |

WDOUT0_N................................................................................................................................... |

45 |

|

4.5.5 |

WDOUT1_N................................................................................................................................... |

45 |

|

4.5.6 |

Watchdog Registers....................................................................................................................... |

46 |

|

4.5.7 |

Address Assignment of Watchdog Registers................................................................................. |

46 |

|

4.5.8 |

Watchdog Register Description ..................................................................................................... |

46 |

|

4.6 |

UART Interface....................................................................................................................................... |

48 |

|

4.6.1 |

Address Assignment of UART Registers ....................................................................................... |

49 |

|

4.6.2 |

UART Register Description............................................................................................................ |

50 |

|

4.7 |

Synchronous Interface SPI..................................................................................................................... |

54 |

|

4.7.1 |

Address Assignment of SPI Register ............................................................................................. |

55 |

|

4.7.2 |

SPI Register Description................................................................................................................ |

56 |

|

4.8 |

System control register........................................................................................................................... |

58 |

|

4.8.1 |

Address Assignment of System Control Registers ........................................................................ |

58 |

|

4.8.2 |

System Control Register Description ............................................................................................. |

59 |

|

5 |

General Hardware Functions ................................................................................................ |

64 |

|

5.1 |

Clock Generation and Clock Supply....................................................................................................... |

64 |

|

5.1.1 |

Clock Supply in ERTEC 200 .......................................................................................................... |

64 |

|

5.1.2 |

JTAG Clock Supply........................................................................................................................ |

65 |

|

5.1.3 |

Clock Supply for PHYs and Ethernet MACs .................................................................................. |

65 |

|

5.2 |

Reset Logic of the ERTEC 200 .............................................................................................................. |

65 |

|

5.2.1 |

PowerOn reset............................................................................................................................... |

65 |

|

5.2.2 |

Hardware Reset............................................................................................................................. |

66 |

|

5.2.3 |

Watchdog Reset ............................................................................................................................ |

66 |

|

5.2.4 |

Software reset................................................................................................................................ |

66 |

|

5.2.5 |

IRT Switch Reset ........................................................................................................................... |

66 |

|

5.3 |

Address Space and Timeout Monitoring ................................................................................................ |

67 |

|

5.3.1 |

AHB Bus Monitoring....................................................................................................................... |

67 |

|

5.3.2 |

APB Bus Monitoring....................................................................................................................... |

67 |

|

5.3.3 |

EMIF Monitoring ............................................................................................................................ |

67 |

|

5.4 |

Configuration Options on the ERTEC 200.............................................................................................. |

67 |

|

6 |

External Memory Interface (EMIF) ........................................................................................ |

69 |

|

6.1 |

Address Assignment of EMIF Registers................................................................................................. |

70 |

|

6.2 |

EMIF Register Description ..................................................................................................................... |

70 |

|

7 |

Local Bus Unit (LBU). ............................................................................................................ |

74 |

|

7.1 |

Page Range Setting ............................................................................................................................... |

76 |

|

7.2 |

Page Offset Setting ................................................................................................................................ |

76 |

|

7.3 |

LBU Address Mapping ........................................................................................................................... |

77 |

|

7.4 |

Page Control Setting .............................................................................................................................. |

78 |

|

7.5 |

Host Access to the ERTEC200 .............................................................................................................. |

78 |

|

7.5.1 |

LBU Read from ERTEC 200 with separate Read/Write line (LBU_RDY_N active low) ................. |

79 |

|

7.5.2 |

LBU Write to ERTEC 200 with separate Read/Write line (LBU_RDY_N active low)...................... |

80 |

|

7.5.3 |

LBU Read from ERTEC 200 with common Read/Write line (LBU_RDY_N active low) ................. |

81 |

|

7.5.4 |

LBU Write to ERTEC 200 with common Read/Write line (LBU_RDY_N active low)...................... |

82 |

|

7.6 |

Host Interrupt Handling: ......................................................................................................................... |

82 |

|

7.7 |

Address Assignment of LBU Registers .................................................................................................. |

83 |

|

7.8 |

LBU Register Description ....................................................................................................................... |

83 |

|

8 |

DMA-Controller....................................................................................................................... |

85 |

|

8.1 |

DMA Register Address Assignment ....................................................................................................... |

86 |

|

8.2 |

Description of DMA Registers ................................................................................................................ |

86 |

|

9 |

Multiport Ethernet PHY.......................................................................................................... |

88 |

|

10 |

Memory Description............................................................................................................... |

91 |

|

10.1 |

Memory Partitioning of the ERTEC 200 ................................................................................................. |

91 |

|

10.2 |

Detailed Memory Description ................................................................................................................. |

92 |

|

11 |

Test and Debugging............................................................................................................... |

94 |

|

11.1 ETM9 Embedded Trace Macrocell ......................................................................................................... |

94 |

||

11.1.1 |

Trace Modes.................................................................................................................................. |

94 |

|

11.1.2 |

Features of the ETM9 Module ....................................................................................................... |

94 |

|

Copyright © Siemens AG 2007. All rights reserved. |

Page 6 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

11.1.3 ETM9 Registers ............................................................................................................................. |

94 |

|

11.2 |

Trace Interface ....................................................................................................................................... |

95 |

11.3 |

JTAG Interface ....................................................................................................................................... |

95 |

11.4 Debugging via UART.............................................................................................................................. |

95 |

|

12 |

Miscellaneous......................................................................................................................... |

96 |

12.1 |

Acronyms/Glossary: ............................................................................................................................... |

96 |

12.2 |

References:............................................................................................................................................ |

97 |

Copyright © Siemens AG 2007. All rights reserved. |

Page 7 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

List of Figures |

|

Figure 1: ERTEC 200 Block Diagram .................................................................................................................... |

10 |

Figure 2: ERTEC 200 Package Description .......................................................................................................... |

11 |

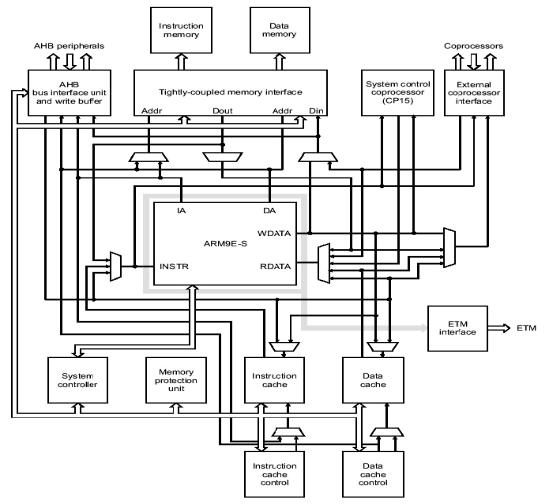

Figure 3: Structure of ARM946E-S Processor System .......................................................................................... |

21 |

Figure 4: GPIO Cell on GPIO Port [31:0] of the ERTEC 200................................................................................. |

35 |

Figure 5: Block Diagram of F-Counter ................................................................................................................... |

43 |

Figure 6: Watchdog Timing.................................................................................................................................... |

45 |

Figure 7: Block Diagram of UART ......................................................................................................................... |

48 |

Figure 8: Block Diagram of SPI ............................................................................................................................. |

54 |

Figure 9: Clock Generation in ERTEC 200............................................................................................................ |

64 |

Figure 10: Clock Supply of Ethernet Interface ....................................................................................................... |

65 |

Figure 11: Power-Up Phase of the PLL ................................................................................................................. |

66 |

Figure 12: Interconnection of Addresses between Host and ERTEC 200 LBU ..................................................... |

77 |

Figure 13: LBU-Read-Sequence with separate RD/WR line ................................................................................. |

79 |

Figure 14: LBU-Write-Sequence with separate RD/WR line.................................................................................. |

80 |

Figure 15: LBU-Read-Sequence with common RD/WR line.................................................................................. |

81 |

Figure 16: LBU-Write-Sequence with common RD/WR line.................................................................................. |

82 |

List of Tables |

|

Table 1: ERTEC 200 Pin Assignment and Signal Description............................................................................... |

19 |

Table 2: Overview of IRQ Interrupts ...................................................................................................................... |

25 |

Table 3: Overview of FIQ Interrupts....................................................................................................................... |

25 |

Table 4: Overview of Interrupt Control Register..................................................................................................... |

27 |

Table 5: CP15 Registers - Overview ..................................................................................................................... |

31 |

Table 6: Overview of AHB Master-Slave Access................................................................................................... |

32 |

Table 7: Access Type and Data Width of the I/O................................................................................................... |

33 |

Table 8: Selection of Download Source................................................................................................................. |

34 |

Table 9: Overview of GPIO Registers.................................................................................................................... |

36 |

Table 10: Overview of Timer Registers ................................................................................................................. |

40 |

Table 11: Overview of F-Timer Registers .............................................................................................................. |

44 |

Table 12: Overview of WD Registers..................................................................................................................... |

46 |

Table 13: Baud Rates for UART at FUARTCLK=50 MHz ........................................................................................... |

49 |

Table 14: Overview of UART Registers................................................................................................................. |

49 |

Table 15: Overview of SPI Registers..................................................................................................................... |

55 |

Table 16: Overview of System Control Registers .................................................................................................. |

59 |

Table 17: Overview of ERTEC 200 Clocks............................................................................................................ |

64 |

Table 18: Configurations for ERTEC 200 .............................................................................................................. |

68 |

Table 19: Overview of EMIF Registers .................................................................................................................. |

70 |

Table 20: Setting of Various Page Sizes ............................................................................................................... |

76 |

Table 21: Setting of Various Offset Areas ............................................................................................................. |

76 |

Table 22: Address Mapping from the Perspective of an External Host Processor on the LBU Port ...................... |

77 |

Table 23: Summary of Accesses to Address Areas of ERTEC 200....................................................................... |

78 |

Table 24: Host Access to Address Areas of ERTEC 200 ...................................................................................... |

78 |

Table 25: LBU Read access timing with seperate Read/Write line........................................................................ |

79 |

Table 26: LBU Write access timing with seperate Read/Write line........................................................................ |

80 |

Table 27: LBU Read access timing with common Read/Write line........................................................................ |

81 |

Table 28: LBU Write access timing with common Read/Write line ........................................................................ |

82 |

Table 29: Overview of LBU Registers.................................................................................................................... |

83 |

Table 30: DMA Transfer Modes............................................................................................................................. |

85 |

Table 31: I/O Synchronization Signals................................................................................................................... |

85 |

Table 32: Overview of DMA Registers................................................................................................................... |

86 |

Table 33: Partitioning of Memory Areas ................................................................................................................ |

91 |

Table 34: Detailed Description of Memory Segments............................................................................................ |

93 |

Table 35: Pin Assignment of JTAG Interface......................................................................................................... |

95 |

Copyright © Siemens AG 2007. All rights reserved. |

Page 8 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

1 Introduction

The ERTEC 200 is intended for the implementation of PROFINET devices with RT and IRT functionality. With its integrated ARM946 processor and 2-port Ethernet switch with integrated PHYs and the option to connect an external host processor system to a local bus interface, it meets all the requirements for implementing PROFINET devices with integrated switch functionality.

1.1 Applications of the ERTEC 200

Interface connection for high-precision drive control, including for PC-based systemsDistributed I/O with real-time Ethernet interfacing

PROFINET RT and IRT functionality

1.2 Features of the ERTEC 200

The ERTEC 200 is a high-performance Ethernet controller with the following integrated function groups:

•High-performance ARM 946 processor with D-cache, I-cache, D-TCM memory

•Multilayer AHB bus master/slave with AHB arbiter

•IRT switch with 64-Kbyte communication RAM

•2 Ethernet channels with integrated PHYs

•Local Bus Unit (LBU) for connecting an external host processor (with boot capability)

•SDRAM controller

•SRAM controller

•DMA controller, 1-channel

•45 IO, with assignable parameters

•UART (with boot capability)

•SPI (with boot capability)

•3 timers

•F-timer

•Watchdog

•IRQ and FIQ interrupt controller

•PLL with clock generator

•8 Kbytes of BOOT ROM

•304-pin FBGA housing

•Different test functions

•JTAG debug and trace interface

Copyright © Siemens AG 2007. All rights reserved. |

Page 9 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

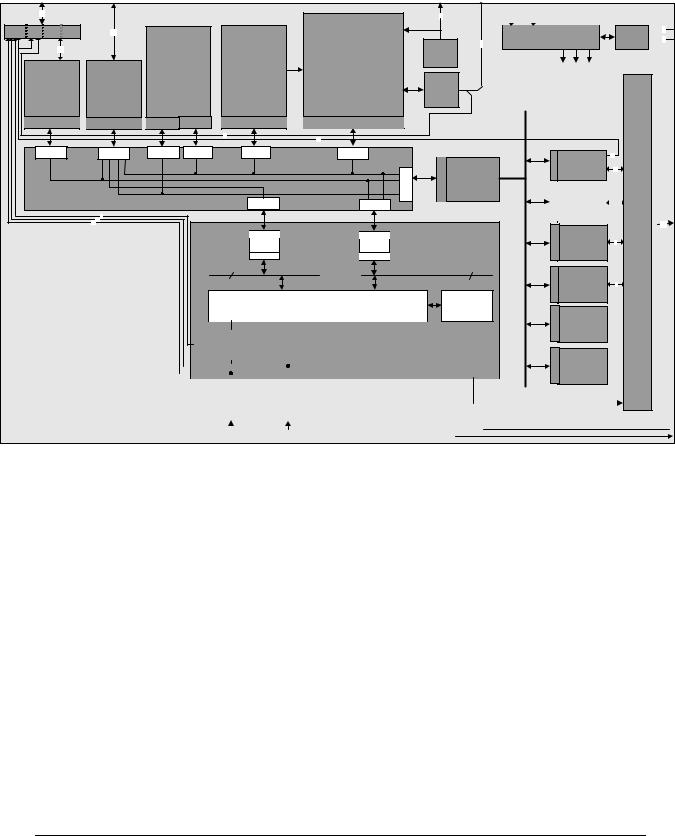

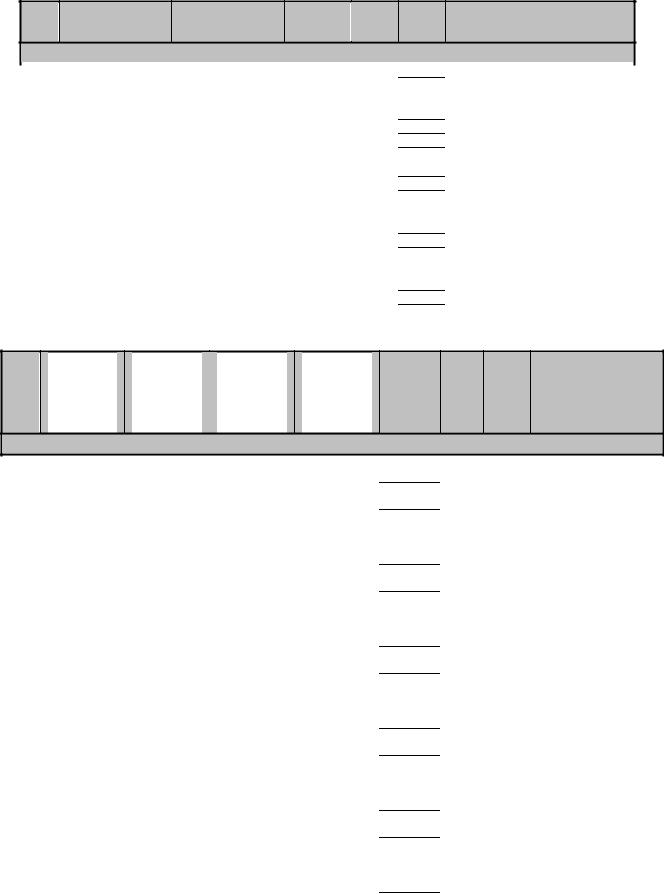

1.3Structure of the ERTEC 200

The figure below shows the function groups with the common communication paths.

LBU / MII + SMI / |

External |

|

|

|

JTAG / Debug |

TRACE_ |

ETM / GPIO |

Memory Interface |

|

|

|

||

|

|

|

CLK |

|||

48 |

|

|

|

|

7 |

|

|

|

|

|

ARM946ES |

|

|

MUX |

74 |

|

|

|

1 |

|

|

|

|

|

|

||

48 |

|

|

ARM- |

with |

BS- |

|

|

|

DMA- |

TAP |

|

||

Local |

|

Interrupt- |

I-Cache (8kByte), |

|

|

|

Memory- |

Controller |

|

|

|||

Bus Unit |

Controller |

D-Cache (4kByte), |

ETM |

|

||

Controller |

|

|

||||

16 Bit |

(EMIF) |

|

|

D-TCM (4kByte) |

Interface |

|

(LBU) |

|

|

|

|

|

|

Master |

Slave |

Master Slave |

Slave |

Master |

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

13 |

|

|

|

Input |

MUX/Arb. |

Input |

Decode |

Decode |

Input |

|

|

|

stage |

stage |

stage |

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

MUX/Arb. |

AHB/APB |

Master |

|

|

|

|

|

|

Slave |

Bridge |

||

|

|

|

|

|

|

|

|

|

Multi-Layer-AHB |

|

|

Input |

MUX/Arb. |

|

|

|

|

50 MHz/32Bit |

|

|

|

stage |

|

|

|

|

|

|

|

|

|

|

|

||

|

3 |

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

|

|

Master |

Slave |

|

|

|

|

|

|

|

AHB- |

AHB- |

|

|

|

|

|

|

|

Wrapper |

Wrapper |

|

|

|

|

|

|

|

Slave |

Master |

|

|

|

|

|

|

|

32 Bit |

MC-Bus (50MHz) |

SC-Bus (50MHz) |

32 Bit |

|

|

|

|

|

|

Switch Control |

K-SRAM |

|

|

|

|

|

|

|

|

64 kByte |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet- |

|

Ethernet- |

|

|

|||

|

|

|

SMI |

|

|

2-Port Switch |

|||||||

|

|

|

|

Port1 |

|

Port2 |

|||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MII-1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MII-0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REF_ |

F_CLK |

|

|

|

|

25MHz |

||||||

CLK |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

1 |

|

||

|

1 |

|

|

1 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Clock-Unit PLL

ARM9 clock |

50MHz |

100MHz |

APB

50MHz / 32 Bit

Slave |

|

13 |

GPIO |

32 |

|

|

|

P |

Slave |

1 x UART |

|

|

|

P |

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Slave |

SPI1 |

o |

|

8 |

|||

Interface |

|||

|

r |

||

|

|

||

Slave |

3 x Timer, |

t |

|

Watchdog, |

|||

2 |

|||

|

F-Timer |

s |

|

|

|

||

Slave |

System |

|

|

Control |

|

||

|

|

Slave |

Boot- |

ROM |

(8 kByte)

PHY |

|

PHY |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

7 |

|

|

||||||

|

|

|

|

MC-PLL Signals |

|||||||||

(Port 1) |

|

(Port 2) |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 Reset

1 Reset

4 Test

4 Test

GPIO,

UART,  32 SPI,

32 SPI,

Timer,

Watchdog,

PHY2

PHY2

PHY1

ERTEC200

Figure 1: ERTEC 200 Block Diagram

Copyright © Siemens AG 2007. All rights reserved. |

Page 10 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

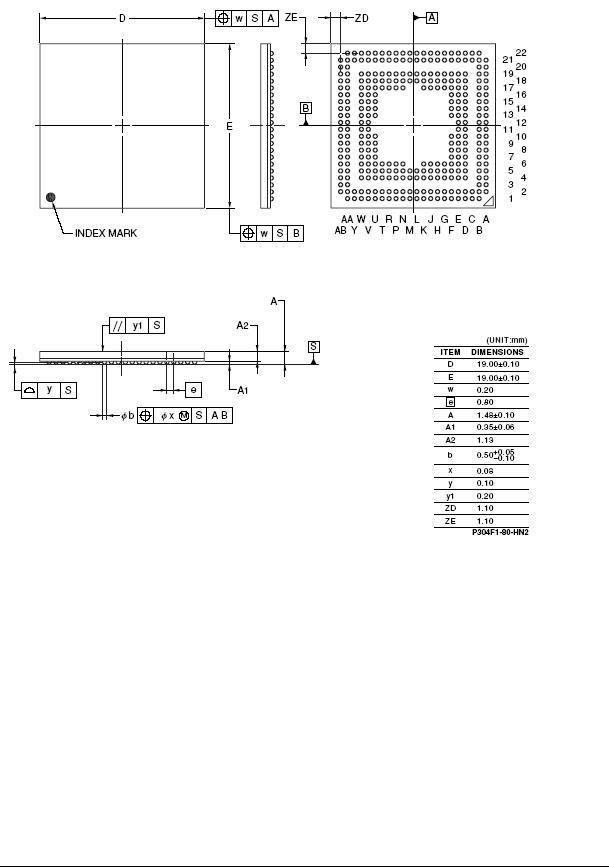

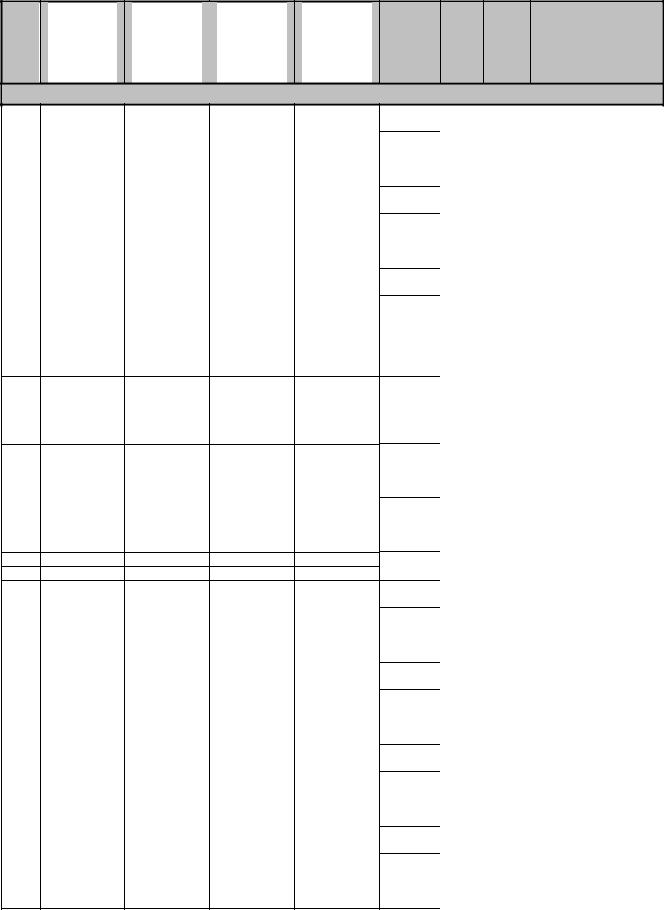

1.4ERTEC 200 Package

The ERTEC 200 is supplied in an FBGA package with 304 pins. The distance between the pins is 0.8 mm. The package dimensions are 19 mm x 19 mm.

Figure 2: ERTEC 200 Package Description

Soldering instructions for the ERTEC 200 can be found in the following documents: /10/ Soldering instructions for lead-based block.

/11/ Soldering instructions for lead-free block. /12/ Code description for soldering.

When working with modules, always take precautionary measures against electrostatic charge (ESD – Electrostatic Sensitive Devices).

Copyright © Siemens AG 2007. All rights reserved. |

Page 11 |

Technical data subject to change |

|

ERTEC 200 Manual

Version 1.1.0

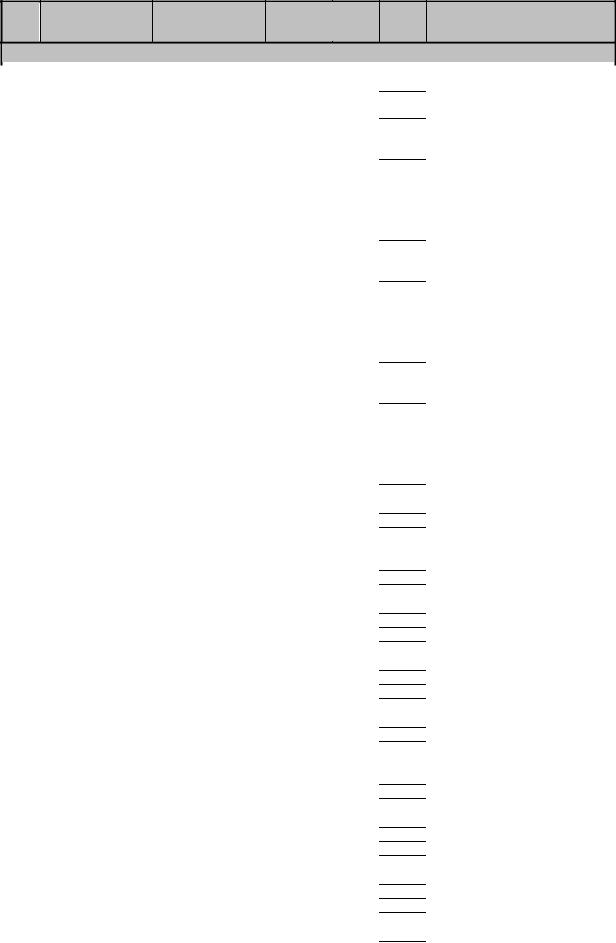

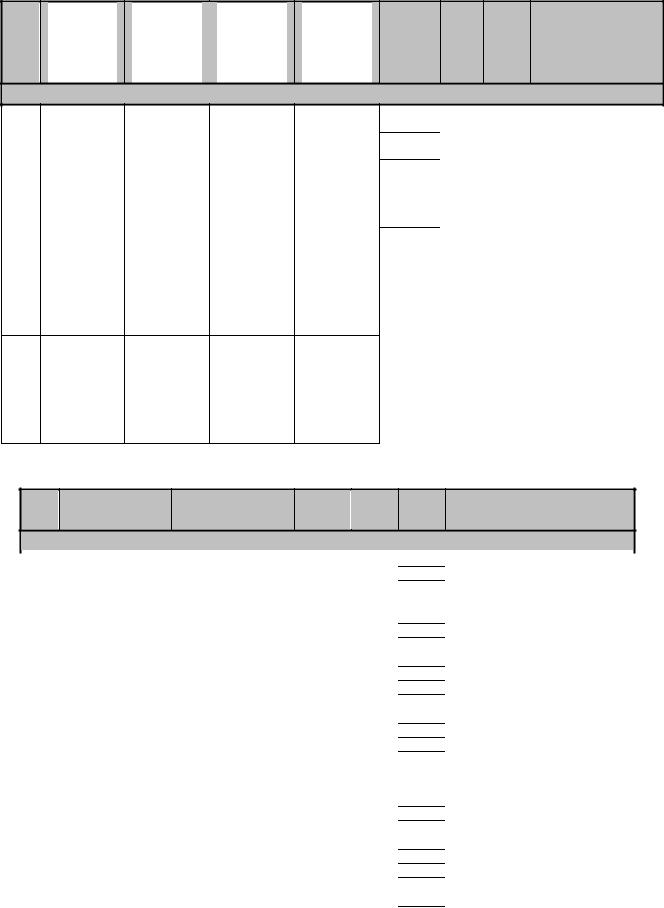

1.5Signal Function Description

ERTEC 200 Pin Description

The ERTEC 200 Ethernet communication block is available in a 304-pin FBGA package. The signal names of the ERTEC 200 are described in this section.

1.5.1GPIO 0 to 31 and Alternative Functions

Various signals are multiplexed on the same pin. These multiplexed signals can contain up to four different functions. The alternative functions are assigned in GPIO registers GPIO_PORT_MODE_L and GPIO_PORT_MODE_H (see Section 4.2.2). The table describes all signals with their different functions and associated pin numbers.

No. |

|

Signal |

|

Alternative |

Alternative |

|

Alternative |

I/O |

Pull- |

PIN |

Comment |

|

|

Name |

|

Function 1 |

Function 2 |

|

Function 3 |

(Reset) |

|

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

General Purpose I/O / I/O |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

GPIO0 |

|

P1-DUBLEX- |

|

|

|

B/O/(I) |

up |

D19 |

GPIO (interrupt- |

|

|

|

LED_N |

|

|

|

|

|

|

capable) or PHY-LED |

|

|

|

|

|

|

|

|

|

|

|

|

(O) |

2 |

|

GPIO1 |

|

P2-DUBLEX- |

|

|

|

B/O/(I) |

up |

B20 |

GPIO (interrupt- |

|

|

|

LED_N |

|

|

|

|

|

|

capable) or PHY-LED |

|

|

|

|

|

|

|

|

|

|

|

|

(O) |

3 |

|

GPIO2 |

|

P1-SPEED_N- |

P1-SPEED- |

|

|

B/O/O/(I) |

up |

D17 |

GPIO or PHY-LED (O) |

|

|

|

100LED |

10LED_N |

|

|

|

|

|

|

|

|

|

|

|

(TX/FX) |

|

|

|

|

|

|

|

|

|

GPIO3 |

|

P2-SPEED- |

P2-SPEED- |

|

|

B/O/O/(I) |

up |

B19 |

GPIO or PHY-LED (O) |

4 |

|

|

|

100LED_N |

10LED_N |

|

|

|

|

|

|

|

|

|

|

(TX/FX) |

|

|

|

|

|

|

|

5 |

|

GPIO4 |

|

P1-LINK- |

|

|

|

B/O/(I) |

up |

A19 |

GPIO or PHY-LED (O) |

|

|

|

LED_N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

GPIO5 |

|

P2-LINK- |

|

|

|

B/O/(I) |

up |

D16 |

GPIO or PHY-LED (O) |

|

|

|

LED_N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

GPIO6 |

|

P1-RX-LED_N |

P1-TX-LED_N |

|

P1-ACTIVE- |

B/O/O/O/(I) |

up |

B18 |

GPIO or PHY-LED (O) |

|

|

|

|

|

|

LED_N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

|

GPIO7 |

|

P2-RX-LED_N |

P2-TX-LED_N |

|

P2-ACTIVE- |

B/O/O/O/(I) |

up |

D15 |

GPIO or PHY-LED (O) |

|

|

|

|

|

|

LED_N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

GPIO8 |

|

UART-TXD |

|

|

|

B/O/(I) |

up |

B17 |

GPIO or UART (O) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

GPIO9 |

|

UART-RXD |

|

|

|

B/I (I) |

up |

A17 |

GPIO or UART (I) |

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

GPIO10 |

|

UART-DCD_N |

|

|

|

B/I (I) |

up |

B16 |

GPIO or UART (I) |

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

GPIO11 |

|

UART-DSR_N |

|

|

|

B/I (I) |

up |

E16 |

GPIO or UART (I) |

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

GPIO12 |

|

UART-CTS_N |

|

|

|

B/I (I) |

up |

A16 |

GPIO or UART (I) |

|

|

|

|

|

|

|

|

|

|

|

|

14 |

|

GPIO13 |

|

Reserved |

|

|

|

B/O/(I) |

up |

B15 |

GPIO |

|

|

|

|

|

|

|

|

|

|

|

|

15 |

|

GPIO14 |

|

DBGACK |

|

|

|

B/O/(I) |

up |

E15 |

GPIO or DEBUG (O) |

|

|

|

|

|

|

|

|

|

|

|

|

16 |

|

GPIO15 |

|

WD_WDOUT0_ |

|

|

|

B/O/(I) |

up |

E14 |

GPIO or Watchdog (O) |

|

|

|

|

N |

|

|

|

|

|

|

|

17 |

|

GPIO16 |

|

SPI1_SSPCTL |

|

|

|

B/O/(I) |

up |

A13 |

GPIO or SPI1 (O) |

|

|

|

|

OE |

|

|

|

|

|

|

|

18 |

|

GPIO17 |

|

SPI1_SSPOE |

|

|

|

B/O/(I) |

up |

F14 |

GPIO or SPI1 (O) |

|

|

|

|

|

|

|

|

|

|

|

|

19 |

|

GPIO18 |

|

SPI1_SSPRXD |

|

|

|

B/I (I) |

up |

B12 |

GPIO or SPI1 (I) |

|

|

|

|

|

|

|

|

|

|

|

|

20 |

|

GPIO19 |

|

SPI1_SSPTXD |

|

|

|

B/O/(I) |

up |

D13 |

GPIO or SPI1 (O) |

|

|

|

|

|

|

|

|

|

|

|

|

21 |

|

GPIO20 |

|

SPI1_SCLKOU |

|

|

|

B/O/(I) |

up |

D11 |

GPIO or SPI1 (O) |

|

|

|

|

T |

|

|

|

|

|

|

|

22 |

|

GPIO21 |

|

SPI1_SFRMOU |

|

|

|

B/O/(I) |

up |

A11 |

GPIO or SPI1 (O) |

|

|

|

|

T |

|

|

|

|

|

|

|

Copyright © Siemens AG 2007. All rights reserved. |

12 |

ERTEC 200 Manual |

Technical data subject to change |

|

Version 1.1.0 |

No. |

Signal |

Alternative |

Alternative |

Alternative |

I/O |

Pull- |

PIN |

Comment |

|

Name |

Function 1 |

Function 2 |

Function 3 |

(Reset) |

|

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

General Purpose I/O / I/O |

|

|

|

||

|

|

|

|

|

|

|

|

|

23 |

GPIO22 |

SPI1_SFRMIN |

DBGACK |

|

B/I/O/(I) |

up |

F10 |

GPIO or SPI1 (I) or |

|

|

|

|

|

|

|

|

Debug (O) |

|

|

|

|

|

|

|

|

This GPIO is used as |

|

|

|

|

|

|

|

|

chip select when |

|

|

|

|

|

|

|

|

booting from Nand |

|

|

|

|

|

|

|

|

Flash or SPI ROM. |

24 |

GPIO23 |

SPI1_SCLKIN |

Reserved |

|

B/I/O/(I) |

up |

D10 |

GPIO or SPI1 (I) |

|

|

|

|

|

|

|

|

This GPIO is used as |

|

|

|

|

|

|

|

|

chip select when |

|

|

|

|

|

|

|

|

booting from SPI Flash |

|

|

|

|

|

|

|

|

or SPI EEPROM. |

25 |

GPIO24 |

PLL_EXT_IN_N |

|

|

B/I (I) |

up |

B11 |

GPIO or MC_PLL (I) |

26 |

GPIO25 |

TGEN_OUT1_N |

|

|

B/O/(I) |

up |

B9 |

GPIO or MC_PLL (O) |

|

|

*1 |

|

|

|

|

|

|

27 |

GPIO26 |

TGEN_OUT2_N |

|

|

B/O/(I) |

up |

A7 |

GPIO or MC_PLL (O) |

28 |

GPIO27 |

TGEN_OUT3_N |

|

|

B/O/(I) |

up |

B10 |

GPIO or MC_PLL (O) |

29 |

GPIO28 |

TGEN_OUT4_N |

|

|

B/O/(I) |

up |

F9 |

GPIO or MC_PLL (O) |

30 |

GPIO29 |

TGEN_OUT5_N |

|

|

B/O/(I) |

up |

E9 |

GPIO or MC_PLL (O) |

31 |

GPIO30 |

TGEN_OUT6_N |

|

|

B/O/(I) |

up |

B8 |

GPIO (interrupt- |

|

|

|

|

|

|

|

|

capable) or MC_PLL |

|

|

|

|

|

|

|

|

(O) |

32 |

GPIO31 |

DBGREQ |

|

|

B/I (I) |

up |

E8 |

GPIO (interrupt- |

|

|

|

|

|

|

|

|

capable) or DEBUG (I) |

*1 For an IRT application pin GPIO25 is default parameterized as alternate function1 (TGEN_OUT1_N). A synchronous clock is issued at this pin. During the certification process of a PROFINET IO DEVICE with IRT functionality this pin has to be accessible from outside (mandatory).

Different GPIO’s are used on the Evaluation Board EB200. See Dokument /14/ Table 6.

1.5.2JTAG and Debug

No. |

Signal |

I/O |

Pull- |

PIN |

Comment |

|

Name |

(Reset) |

|

No. |

|

|

|

|

|

|

|

|

|

Debug / JTAG (BOUNDARY SCAN) |

|||

|

|

|

|

|

|

33 |

TRST_N |

I (I) |

|

U10 |

JTAG Reset |

34 |

TCK |

I (I) |

up |

W7 |

JTAG Clock |

35 |

TDI |

I (I) |

up |

U9 |

JTAG Data In |

36 |

TMS |

I (I) |

up |

V7 |

JTAG Test Mode Select |

37 |

TDO |

O (O) |

|

V9 |

JTAG Data Out |

38 |

SRST_N |

B (O) |

up |

V8 |

Hardware Reset |

39 |

TAP_SEL |

I (I) |

up |

W8 |

Select TAP Controller: |

|

|

|

|

|

0: Boundary Scan TAP Controller |

|

|

|

|

|

selected |

|

|

|

|

|

1: ARM-TAP Controller selected |

|

|

|

|

|

or Scan Clock (Scan mode) |

1.5.3Trace Port

No. |

Signal |

I/O |

|

Pull- |

PIN |

Comment |

|

Name |

(Reset) |

|

|

No. |

|

|

|

|

|

|

|

|

|

|

|

Trace Port/Other |

|

||

|

|

|

|

|

|

|

40 |

TRACECLK |

B (O) |

|

|

AB4 |

ETM Trace Clock |

41 |

Reserved |

I (I) |

|

up |

U19 |

Connect pin to GND |

Copyright © Siemens AG 2007. All rights reserved. |

13 |

ERTEC 200 Manual |

Technical data subject to change |

|

Version 1.1.0 |

1.5.4Clock and Reset

|

No. |

|

|

Signal Name |

|

|

I/O |

|

|

Pull- |

|

|

PIN |

|

|

Comment |

|

|

|

|

|

|

|

|

(Reset) |

|

|

|

|

|

No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CLOCK / RESET GENERATION |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

42 |

|

CLKP_A |

|

I (I) |

|

|

|

|

B14 |

|

Quartz connection |

||||||

43 |

|

|

CLKP_B |

|

O |

|

|

|

|

D14 |

|

Quartz connection |

|||||

44 |

|

F_CLK |

|

I (I) |

|

|

|

|

B13 |

|

F_CLK for F-counter |

||||||

45 |

|

|

REF_CLK |

|

Dependent |

|

|

|

|

A15 |

|

Tristate or |

|||||

|

|

|

|

|

|

|

on PIN |

|

|

|

|

|

|

|

reference clock output, 25 MHz |

||

|

|

|

|

|

|

|

CONFIG[1] |

|

|

|

|

|

|

|

|

|

|

46 |

|

|

RESET_N |

|

I (I) |

|

up |

|

B7 |

|

PowerOn reset |

||||||

1.5.5Test Pins

No. |

Signal Name |

I/O |

Pull- |

PIN |

Comment |

|

|

|

|

(Reset) |

|

No. |

|

|

|

|

|

|

|

|

|

|

|

|

TEST |

|

|

|

|

|

|

|

|

|

47 |

TEST_N |

(3) |

I (I) |

up |

T5 |

Test mode |

48 |

TMC1 |

(3) |

I (I) |

|

G5 |

Test configuration |

49 |

TMC2 |

(3) |

I (I) |

|

H6 |

Test configuration |

50 |

TACT_N |

(3) |

I (I) |

dn |

J5 |

TESTACT-TAP reset |

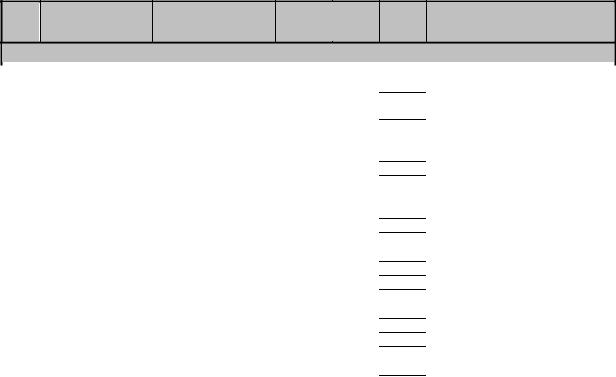

1.5.6EMIF (External Memory Interface)

No. |

Signal Name |

Alternative |

I/O |

Pull- |

PIN |

Comment |

|

|

Reset Function |

(Reset) |

|

No. |

|

EMIF (External Memory Interface)

51 |

DTR_N |

BOOT0 |

B (I) |

up |

E7 |

Direction signal for external driver |

|

|

|

|

|

|

or scan clock (Scan mode) |

|

|

|

|

|

|

ERTEC 200 boot mode (external |

|

|

|

|

|

|

PD may be necessary) |

|

|

|

|

|

D8 |

|

52 |

OE_DRIVER_N |

|

O (O) |

|

Enable signal for external driver |

|

|

|

|

|

|

B4 |

or scan clock (Scan mode) |

53 |

A0 |

|

O (O) |

|

Address bit 0 |

|

|

|

|

|

|

SDRAM: Bank address 0 |

|

|

|

|

|

|

A3 |

|

54 |

A1 |

|

O (O) |

|

Address bit 1 |

|

|

|

|

|

|

SDRAM: Bank address 1 |

|

|

|

|

|

|

B3 |

|

55 |

A2 |

|

O (O) |

|

Address bit 2 |

|

|

|

|

|

|

SDRAM: Address 0 |

|

|

|

|

|

|

B2 |

|

56 |

A3 |

|

O (O) |

|

Address bit 3 |

|

|

|

|

|

|

SDRAM: Address 1 |

|

|

|

|

|

|

D4 |

|

57 |

A4 |

|

O (O) |

|

Address bit 4 |

|

|

|

|

|

|

SDRAM: Address 2 |

|

|

|

|

|

|

C2 |

|

58 |

A5 |

|

O (O) |

|

Address bit 5 |

|

|

|

|

|

|

SDRAM: Address 3 |

|

|

|

|

|

|

C1 |

|

59 |

A6 |

|

O (O) |

|

Address bit 6 |

|

|

|

|

|

|

SDRAM: Address 4 |

|

|

|

|

|

|

D2 |

|

60 |

A7 |

|

O (O) |

|

Address bit 7 |

|

|

|

|

|

|

SDRAM: Address 5 |

|

|

|

|

|

|

D1 |

|

61 |

A8 |

|

O (O) |

|

Address bit 8 |

|

|

|

|

|

|

SDRAM: Address 6 |

|

|

|

|

|

|

E2 |

|

62 |

A9 |

|

O (O) |

|

Address bit 9 |

|

|

|

|

|

|

SDRAM: Address 7 |

|

|

|

|

|

|

E1 |

|

63 |

A10 |

|

O (O) |

|

Address bit 10 |

|

|

|

|

|

|

SDRAM: Address 8 |

|

|

|

|

|

|

F2 |

|

64 |

A11 |

|

O (O) |

|

Address bit 11 |

|

|

|

|

|

|

SDRAM: Address 9 |

|

|

|

|

|

|

F1 |

|

65 |

A12 |

|

O (O) |

|

Address bit 12 |

|

|

|

|

|

|

SDRAM: Address 10 |

|

|

|

|

|

|

|

Copyright © Siemens AG 2007. All rights reserved. |

14 |

ERTEC 200 Manual |

Technical data subject to change |

|

Version 1.1.0 |

No. |

Signal Name |

Alternative |

I/O |

Pull- |

PIN |

Comment |

|

|

Reset Function |

(Reset) |

|

No. |

|

EMIF (External Memory Interface)

|

66 |

A13 |

|

O (O) |

|

|

G2 |

Address bit 13 |

|

|

|

|

|

|

|

|

|

SDRAM: Address 11 |

|

|

|

|

|

|

|

|

|

|

G1 |

|

||

|

67 |

A14 |

|

O (O) |

|

|

Address bit 14 |

|

|

|

|

|

|

|

|

|

|

SDRAM: Address 12 |

|

|

|

|

|

|

|

|

|

|

H2 |

|

||

|

68 |

A15 |

BOOT1 |

B (I) |

|

dn |

Address bit 15 |

|

|

|

|

|

|

|

|

|

|

|

ERTEC 200 boot mode (ext. PU |

|

|

|

|

|

|

|

|

|

J2 |

may be necessary) |

|

|

|

69 |

A16 |

BOOT2 |

B (I) |

|

dn |

Address bit 16 / |

|

|

|

|

|

|

|

|

|

|

|

ERTEC 200 boot mode (ext. PU |

|

|

|

|

|

|

|

|

|

K2 |

may be necessary) |

|

|

|

70 |

A17 |

BOOT3 |

B (I) |

|

up |

Address bit 17 / |

|

|

|

|

|

|

|

|

|

|

|

ERTEC 200 boot mode (ext. PD |

|

|

|

|

|

|

|

|

|

K1 |

may be necessary) |

|

|

|

71 |

A18 |

CONFIG1 |

B (I) |

|

up |

Address bit 18 / ERTEC 200 |

|

|

|

|

|

|

|

|

|

|

|

system configuration (external PD |

|

|

|

|

|

|

|

|

|

E4 |

may be necessary) |

|

|

|

72 |

A19 |

CONFIG2 |

B (I) |

|

up |

Address bit 19 / ERTEC 200 |

|

|

|

|

|

|

|

|

|

|

|

system configuration (external PD |

|

|

|

|

|

|

|

|

|

F4 |

may be necessary) |

|

|

|

73 |

A20 |

CONFIG3 |

B (I) |

|

dn |

Address bit 20 / ERTEC 200 |

|

|

|

|

|

|

|

|

|

|

|

system configuration (external PU |

|

|

|

|

|

|

|

|

|

G4 |

may be necessary) |

|

|

|

74 |

A21 |

CONFIG4 |

B (I) |

|

up |

Address bit 21 / ERTEC 200 |

|

|

|

|

|

|

|

|

|

|

|

system configuration (external PD |

|

|

|

|

|

|

|

|

|

H5 |

may be necessary) |

|

|

|

75 |

A22 |

CONFIG5 |

B (I) |

|

dn |

Address bit 22 / ERTEC 200 |

|

|

|

|

|

|

|

|

|

|

|

system configuration (external PU |

|

|

|

|

|

|

|

|

|

H4 |

may be necessary) |

|

|

|

76 |

A23 |

CONFIG6 |

B (I) |

|

up |

Address bit 23 / ERTEC 200 |

|

|

|

|

|

|

|

|

|

|

|

system configuration (external PD |

|

|

|

|

|

|

|

|

|

M2 |

may be necessary) |

|

|

|

77 |

D0 |

|

B (I) |

|

up |

Data bit 0 |

|

|

|

|

78 |

D1 |

|

B (I) |

|

up |

N2 |

Data bit 1 |

|

|

|

79 |

D2 |

|

B (I) |

|

up |

P1 |

Data bit 2 |

|

|

|

80 |

D3 |

|

B (I) |

|

up |

P2 |

Data bit 3 |

|

|

|

81 |

D4 |

|

B (I) |

|

up |

R1 |

Data bit 4 |

|

|

|

82 |

D5 |

|

B (I) |

|

up |

T2 |

Data bit 5 |

|

|

|

83 |

D6 |

|

B (I) |

|

up |

U1 |

Data bit 6 |

|

|

|

84 |

D7 |

|

B (I) |

|

up |

U2 |

Data bit 7 |

|

|

|

85 |

D8 |

|

B (I) |

|

up |

V2 |

Data bit 8 |

|

|

|

86 |

D9 |

|

B (I) |

|

up |

W1 |

Data bit 9 |

|

|

|

87 |

D10 |

|

B (I) |

|

up |

W2 |

Data bit 10 |

|

|

|

88 |

D11 |

|

B (I) |

|

up |

Y2 |

Data bit 11 |

|

|

|

89 |

D12 |

|

B (I) |

|

up |

AA1 |

Data bit 12 |

|

|

|

90 |

D13 |

|

B (I) |

|

up |

AA2 |

Data bit 13 |

|

|

|

91 |

D14 |

|

B (I) |

|

up |

AB2 |

Data bit 14 |

|

|

|

92 |

D15 |

|

B (I) |

|

up |

AA3 |

Data bit 15 |

|

|

|

93 |

D16 |

|

B (I) |

|

up |

K4 |

Data bit 16 |

|

|

|

94 |

D17 |

|

B (I) |

|

up |

K5 |

Data bit 17 |

|

|

|

95 |

D18 |

|

B (I) |

|

up |

J6 |

Data bit 18 |

|

|

|

96 |

D19 |

|

B (I) |

|

up |

K6 |

Data bit 19 |

|

|

|

97 |

D20 |

|

B (I) |

|

up |

N5 |

Data bit 20 |

|

|

|

98 |

D21 |

|

B (I) |

|

up |

N6 |

Data bit 21 |

|

|

|

99 |

D22 |

|

B (I) |

|

up |

P6 |

Data bit 22 |

|

|

|

100 |

D23 |

|

B (I) |

|

up |

R5 |

Data bit 23 |

|

|

|

101 |

D24 |

|

B (I) |

|

up |

R6 |

Data bit 24 |

|

|

|

102 |

D25 |

|

B (I) |

|

up |

P4 |

Data bit 25 |

|

|

|

103 |

D26 |

|

B (I) |

|

up |

R4 |

Data bit 26 |

|

|

|

104 |

D27 |

|

B (I) |

|

up |

T4 |

Data bit 27 |

|

|

|

105 |

D28 |

|

B (I) |

|

up |

U4 |

Data bit 28 |

|

|

|

106 |

D29 |

|

B (I) |

|

up |

W4 |

Data bit 29 |

|

|

|

107 |

D30 |

|

B (I) |

|

up |

W5 |

Data bit 30 |

|

|

|

108 |

D31 |

|

B (I) |

|

up |

W6 |

Data bit 31 |

|

|

|

|

|

|

|

|

|

||||

|

Copyright © Siemens AG 2007. All rights reserved. |

|

15 |

|

|

ERTEC 200 Manual |

||||

|

Technical data subject to change |

|

|

|

|

Version 1.1.0 |

||||

No. |

Signal Name |

Alternative |

I/O |

Pull- |

PIN |

Comment |

|

|

Reset Function |

(Reset) |

|

No. |

|

EMIF (External Memory Interface)

109 |

WR_N |

|

O (O) |

|

A4 |

Write strobe |

110 |

RD_N |

|

O (O) |

|

B5 |

Read strobe |

111 |

CS_PER0_N |

|

O (O) |

|

D5 |

Chip Select Bank 1 (ROM); |

|

|

|

|

|

boot area |

|

|

|

|

|

|

A5 |

|

112 |

CS_PER1_N |

|

O (O) |

|

Chip select bank 2 |

|

113 |

CS_PER2_N |

|

O (O) |

|

A6 |

Chip select bank 3 |

114 |

CS_PER3_N |

|

O (O) |

|

B6 |

Chip select bank 4 |

115 |

BE0_DQM0_N |

|

O (O) |

|

N4 |

Byte enable 0 for D(7:0) |

116 |

BE1_DQM1_N |

|

O (O) |

|

V1 |

Byte enable 1 for D(15:8) |

117 |

BE2_DQM2_N |

|

O (O) |

|

J4 |

Byte enable 2 for D(23:16) |

118 |

BE3_DQM3_N |

|

O (O) |

|

P5 |

Byte enable 3 for D(31:24) |

119 |

RDY_PER_N |

|

I (I) |

up |

D7 |

Ready signal |

120 |

CLK_SDRAM |

|

B (O) |

|

M1 |

Clock for SDRAM |

121 |

CS_SDRAM_N |

|

O (O) |

|