Sears 233.52152, 233.52059, 233.52153, 233.52057, 233.52157 User Manual

...

8! 8

OWNER'S

MAN UAL

Model Nos.

233.52052002

233.52053002

233.52057002

233.52059002

233.52152002

233.52153002

233.52157002

233.52159002

Caution:

Read and follow

all Safety Rules and

Operating Instructions

before first use of this

Product.

RANGE

HOOD

• Safety Instructions

. Installation Instructions

• Maintenance

• Replacement Parts List

• Warranty

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

IMPORTANT SAFETY

INSTRUCTIONS

WARNING

WARNING -TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

II_LIRYTO PERSONS, OBSERVETHE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock service panel to prevent power from being switched on

accidentally. When the service disconnecting means cannot be

locked,securely fasten a prominent warning device,such as a tag,

to the service panel. .

3. Installation work and electrical wiring must be done by a quali-

fied person(s) in accordance with all applicable codes and stan-

dards, including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to

prevent backdrafting. Follow the heating equipment

manufacturer's guideline and safety standards such as those pub-

lished by the National Fire Protection Association (NFPA), and

the American Society for Heating, Refrigeration and Air Condi-

tioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage elec-

trical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. To reduce the risk of fire, use only metal ductwork.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. J3oilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat .or when cook-

ing flaming foods.

3. Clean ventilating fans frequently. Grease should not be allowed

to accumulate on fan or filter.

4. Use proper pan size.Always uSe cookware appropriate for the

size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT

OFA RANGETOP GREASE FIRE, OBSERVETHE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFULTO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN -You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - a vio-

lent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ARC extinguisher, and you al-

ready know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

• Based on _Kitchen Fir_safetyTips _ published by NFPA.

IMPORTANT SAFETY

INSTRUCTIONS

CAUTION

1. For general ventilating use only.Do not use to exhaust hazardous

or explosive materials and vapors.

2. To reduce the risk of Rre or electrical shock,this range hood should

not be used with an additional speed control device.

3. To reduce the risk of shock, disconnect power before servicing.

4. To reduce the risk of fire and to properly exhaust air, be sure to

duct air outside.

PLAN THE INSTALLATION

Recommended mounting height is 18 _to 24 _from the bottom of the

range hood to the top of the cooking surface.

The hood should be mounted to the bottom of a standard wall cabi-

net. If the hood must be mounted directly to a wall, secure the hood

to wall studs.

All wiring must comply with local codes and the unit must be prop-

erly grounded.The hood is connected to a 110-120vAC lighting cir-

cuit (15 amp) in the circuit breaker or fuse box.

This range hood is "Convertible'- it may be installed as a ducted or as

a non-ducted unit.

IFTHE RANGE HOOD ISTO BE NON-DUCTF, D:

• Purchase nonMucted (duct-free) charcoal filter Model BPQTE

IFTHE RANGE HOOD ISTO BE DUCTED:

• Ductwork can be installed vertically or horizontally.

• Duct runs should Be as short as possible.

• Avoid the use of elbows.

• Use duct tape at all joints.

• Do not use duct smaller than the discharge on the hood.

• For 7" round ductwork installation, use 7 _round damper, Model

BP87 (purchased separately).

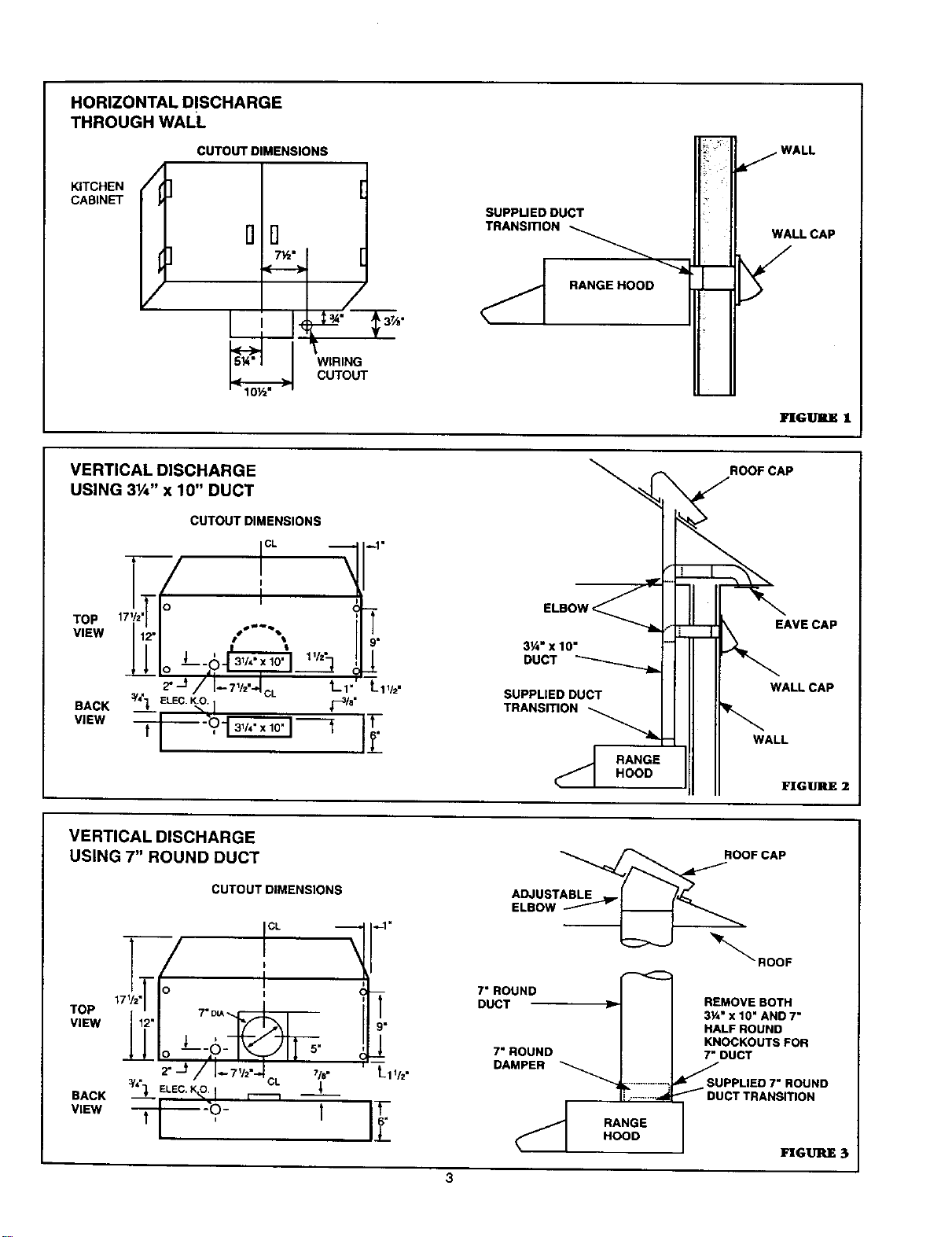

HORIZONTAL DISCHARGE

THROUGH WALL

CUTOUT DIMENSIONS

KITCHEN

CABINET

/

5¼"

DD

7½"

__ w_&

SUPPUED DUCT

TRANSmON

RANGEHOOD

/ WALL

WALL CAP

In[G_ I

VERTICAL DISCHARGE

USING 3V4" x 10" DUCT

TOP

VIEW

BACK

VIEW

CUTOUT DIMENSIONS

_'J/I--_"="I_L L,.

a!'{] ELEC.K.O._ r--3/_"

-- ",.I _ T

T

9"

1

t-11/2"

3Y4"X 10"

DUCT

SUPPLIED DUCT

TRANSITION

RANGE

HOOD

ROOF CAP

WALL

EAVE CAP

WALL CAP

VERTICAL DISCHARGE

USING 7" ROUND DUCT

TOP

VIEW

BACK

VIEW

CUTOUT DIMENSIONS

CL

17 = TDL_

_.J/'l-_,,,:: ,,..

X_- ,o- I

J

9"

Lll/2 .

IF_

ROOFCAP

ADJUSTABLE

ELBOW

_""ROOF

7"ROUND

DUCT

RANGE

HOOD

7"ROUND

DAMPER

REMOVE BOTH

3½" x 10" AND7"

HALF ROUND

KNOCKOUTS FOR

7" DUCT

_UPPLIED 7" ROUND

DUCT TRANSITION

_GtrBLE 3

PREPARATION

1. Use the dimensional drawings (Refer to FIGURES 1 - 3) to lay

out the range hood's mounting holes, vin'ing access and ductwork

by marking the cabinet bottom and drywall where applicable.

2. Make cutouts for wiring and ductwork.

3. If the hood is to be ducted,install the ductwork so that is flush to

the range hood's mounting surface.

Refer to FIGURE 1 if the range hood is to be installed with a

horizontal discharge.

Refer to FIGURE 2 and FIGURE 3 if the range hood is to be

installed with a vertical discharge.

4. Run two-conductor wire (with ground) from a power source to

the hood location.B(mg approximately 12"of wiring through wir-

ing hole in cabinet.

5. DriU four 3/32" diameter pilot holes at points where mounting

holes are marked in cabinet bottom.

6. Insert four (4) mounting screws, leaving approximately ¼" of

thread exposed.

7. Remove and retain the mounting screws securing the 3¼"x 10"

and 7 _ duct transitions to the hood. Install the appropriate duct

transition as described in the installation section.

IN STALLATIO N

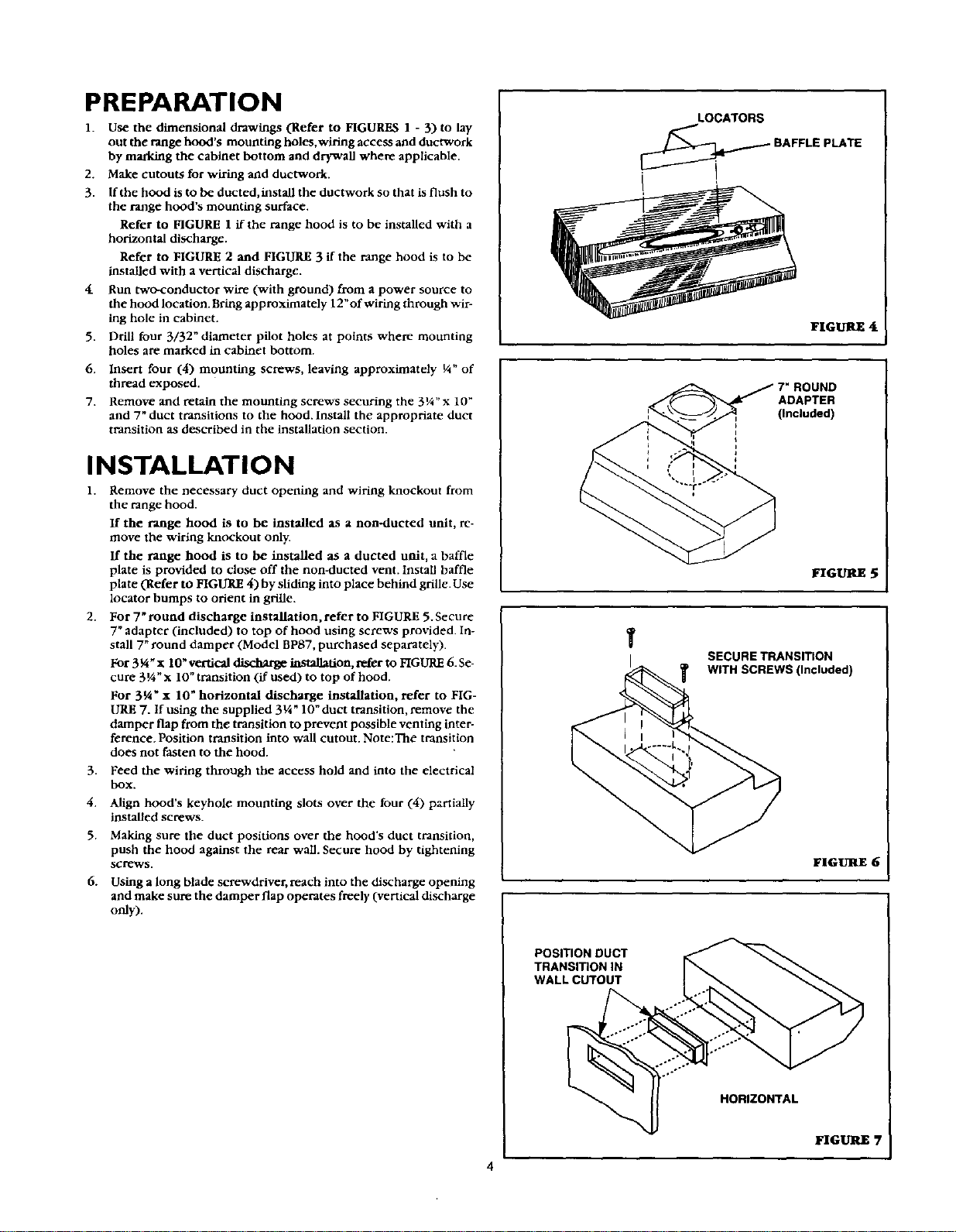

1. Remove the necessary duct opening and wiring knockout from

the range hood.

If the range hood is to be installed as a non-ducted unit, re-

move the wiring knockout only.

If the range hood is to be installed as a dueted unit, a baffle

plate is provided to close off the nonMucted vent. InstaB baffle

plate (Refer to FIGURE 4) by sliding into place behind grille. Use

locator bumps to orient in grille.

2. For 7" round discharge installation, refer to FIGURE 5. Secure

7" adapter (included) to top of hood using screws provided, in-

stall 7" round damper (Model BPg7, purchased separately).

For 3V_x 10" vertical _ installation, refer to FIGURE 6. Se-

cure 3¼" x 10" transition (if used) to top of hood.

For 3_i" x 10" horizontal discharge installation, refer to FIG-

URE 7. If using the supplied 3¼ _ 10" duct transition, remove the

damper flap from the transition to prevent possible venting inter-

ference. Position transition into wall cutout. Note:The transition

does not fasten to the hood.

3. Feed the wiring through the access hold and into the electrical

box.

4. Align hood's keyhole mounting slots over the four (4) partially

installed screws.

5. Making sure the duct positions over the hood's duct transition,

push the hood against the rear wail. Secure hood by tightening

SCreWS.

6. Using a long blade screwdriver, reach into the discharge opening

and make sure the damper flap operates freely (vertical discharge

only).

LOCATORS

_ BAFFLE PLATE

FIGURE 4

ADAPTER

(Included)

FIGURE 5

SECURE TRANSITION

T WITH SCREWS (Included)

FIGURE 6

POSITION DUCT

TRANSITION iN

WALL CUTOUT

÷,°

HORIZONTAL

FIGUILE7

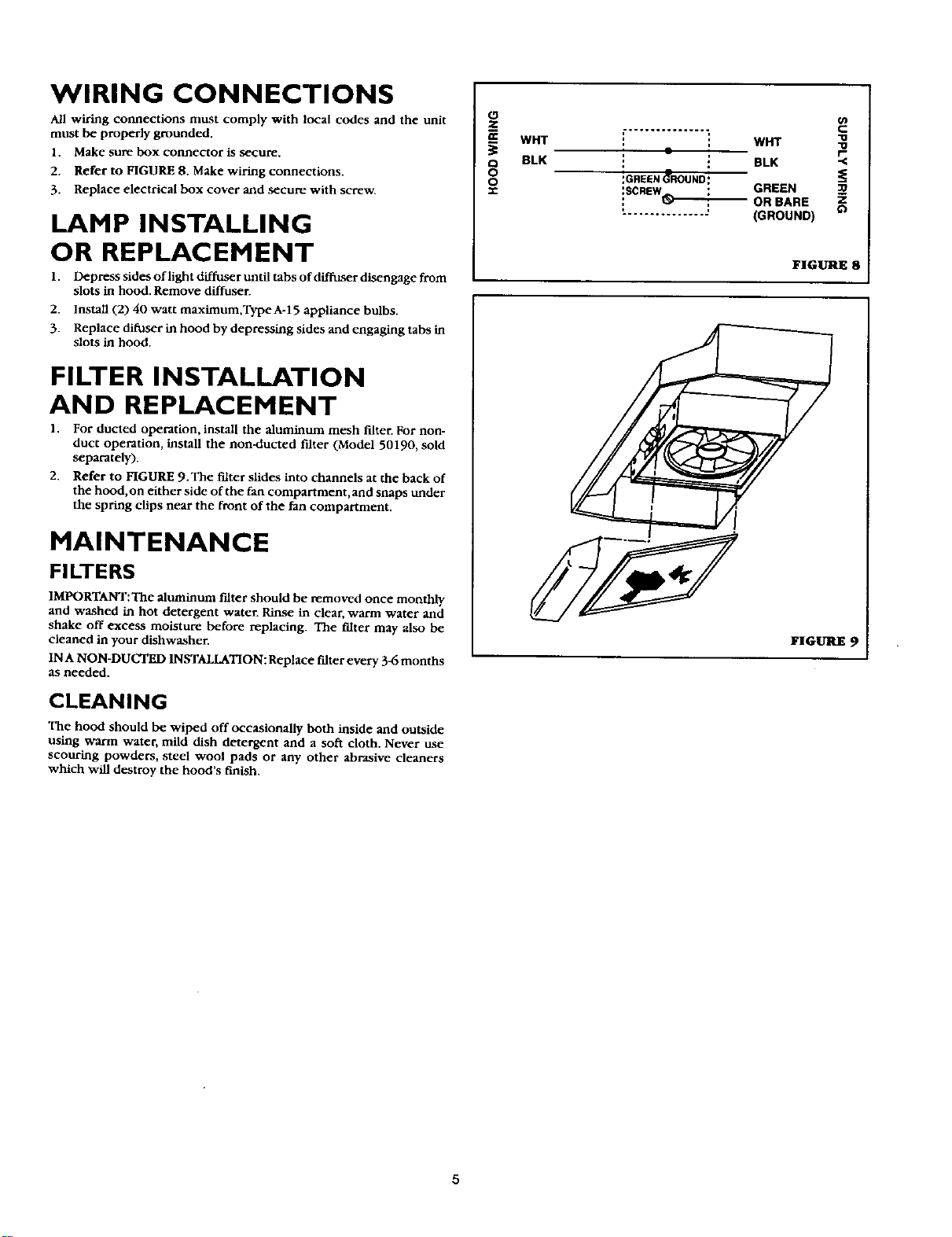

WIRING CONNECTIONS

All wiring connections must comply with local codes and the unit

must be properly grounded.

1. Make sure box connector is secure.

2. Refer to FIGURE 8. Make wiring connections.

3. Replace electrical box cover and secure with screw.

LAMP INSTALLING

OR REPLACEMENT

1. Depress sides of light diffuser until tabs of diShlser disengage from

slots in hood. Remove diffuser.

2. Install (2) 40 watt maximum,Type A-15 appliance bulbs.

3. Replace difuser in hood by depressing sides and engaging tabs in

slots in hood.

FILTER INSTALLATION

AND REPLACEMENT

1. For ducted operation, install the aluminum mesh filter. For non-

duct operation, install the non-ducted filter (Model 50190, sold

separately).

2. Refer to FIGURE 9. The filter slides into channels at the back of

the hood,on either side of the fan compartment,and snaps under

the spring clips near the front of the fan compartment.

MAINTENANCE

FILTERS

IMPORTANT:The aluminum filter should be removed once monthly

and washed in hot detergent water. Rinse in clear, warm water and

shake off excess moisture before replacing. The fdter may also be

cleaned in your dishwasher.

INA NON-DUCTED INSTALLATION:Replace filter every 3_ months

as needed.

CLEANING

The hood should be wiped off occasionally both inside and outside

using warm water, mild dish detergent and a soft cloth. Never use

scouring powders, steel wool pads or any other abrasive cleaners

which will destroy the hood's finish.

O

WHT

BLK

O

O

0'J

' i WHT

• . BLK

:GREEN_ROUND:

:SCREW : GREEN

: _-"_OR BARE

.............. : (GROUND) O

FIGURE8

FIGURE 9

5

Loading...

Loading...