Porter-Cable NS100A User Manual

|

|

FRANÇAISE : PAGE 11 |

|

|

ESPAÑOL: PÁGINA 23 |

Instruction |

NARROW CROWN |

|

manual |

STAPLER |

|

To learn more about Porter-Cable visit our website at:

http://www.porter-cable.com

Copyright © 2005 Porter-Cable

IMPORTANT

Please make certain that the person who is to use this equipment carefully reads and understands these instructions before starting operations.

The Model and Serial No. plate is located on the main housing of the tool. Record these numbers in the spaces below and retain for future reference.

Model No.______________________________________

Type ___________________________________________

Serial No. ______________________________________

894885-004 - 07-11-06

PORTER CABLE

Porter-Cable Corporation

4825 Highway 45 North

Jackson, TN 38305

GB ENGLISH EC-DECLARATION OF CONFORMITY

W e d e c l a r e u n d e r o u r s o l e

r e s p o n s i b i l i t y t h a t t h i s p r o d u c t i s i n c o n f o r m i t y w i t h t h e r e g u l a t i o n s

E N 2 9 2 - 2 : s e c t i o n 3 o f 1 9 9 2 E N 2 9 2 - 1 : s e c t i o n 5 o f 1 9 9 2 E N 1 0 5 0 : 1 9 9 3

E N 7 9 2 1 3 : 2 0 0 0

E ESPANOL DECLARACION DE CONFORMIDAD ”CE”

D e c l a r a m o s b a j o n u e s t r a s o l a

r e s p o n s a b i l i d a d q u e e s t e p r o d u c t o e s t á e n c o n f o r m i d a d c o n l a s r e g u l a c i o n e s

E N 2 9 2 - 2 : s e c t i o n 3 o f 1 9 9 2 E N 2 9 2 - 1 : s e c t i o n 5 o f 1 9 9 2 E N 1 0 5 0 : 1 9 9 3

E N 7 9 2 1 3 : 2 0 0 0

F FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

N o u s d e c l a r o n s s o u s n o t r e p r o p r e

r e s p o n s a b i l i t e q u e c e p r o d u i t e s t c o n f o r m e a u x r e g l e m e n t a t i o n s

E N 2 9 2 - 2 : s e c t i o n 3 o f 1 9 9 2 E N 2 9 2 - 1 : s e c t i o n 5 o f 1 9 9 2 E N 1 0 5 0 : 1 9 9 3

E N 7 9 2 1 3 : 2 0 0 0

Date of Manufacture:___________________________

Fecha de fabricación:, Date de fabrication:

Serial No:______________________________________

Número de serie:, Nombre d'ordre

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using pneumatic tools, basic safety precautions should always be followed to reduce the risk of personal injury, including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

There are certain applications for which this tool was designed. Porter-Cable strongly recommends that this tool NOT be modified and/or used for any application other than for which it was designed. If you have any questions relative to its application DO NOT use the tool until you have written PorterCable and we have advised you.

1. USE SAFETY GLASSES. To prevent eye injuries, the tool operator and all persons in the work area must wear safety glasses with permanently attached, rigid, plastic side shields.These safety glasses must conform to ANSI Z87.1 requirements (approved glasses have “Z87” printed or stamped on them). Fig. 1.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

P. O. Box 2468

Jackson, TN 38302-2468

Fig. 1

2.WEAR EAR PROTECTION to safeguard against possible hearing loss. Fig. 1.

3.USE CLEAN, DRY, REGULATED compressed air at 70 to 120 PSI. Fig. 2.

4.DO NOT CONNECT TOOL TO pressure which potentially exceeds 200 PSI (13.7 BAR).

5.ONLY USE AIR HOSE THAT IS RATED for a minimum working pressure of 150 PSI or 150% of the maximum system pressure, which ever is greater.

6.NEVER USE OXYGEN, CARBON DIOXIDE, combustible gases or any other bottled gas as a power source for this tool: explosion and serious personal injury could result. Fig. 3.

7.CONNECT TOOL TO AIR SUPPLY HOSE with a coupling that removes all pressure from the tool when the coupling is disconnected. Fig. 4.

Fig. 2

Fig. 3

Fig. 4

2

8. DISCONNECT TOOL FROM AIR SUPPLY HOSE before doing tool maintenance, clearing a jammed fastener, leaving work area, moving tool to another location, or handing the tool to another person. Fig. 5.

9.NEVER USE A TOOL that is leaking air, has missing or damaged parts, or requires repair. Make sure all screws and caps are securely tightened. Fig. 5.

10.NEVER USE TOOL IF SAFETY, trigger or springs are inoperable, missing or damaged. Do not alter or remove safety, trigger, or springs. Make daily inspections for free movement of trigger and safety mechanism. Fig. 5.

Fig. 5

Fig. 6

11.DO NOT USETOOLWITHOUT SAFETY WARNING LABEL. If label is missing, damaged or unreadable, contact your PorterCable Service Center for a replacement. Fig.

12.ONLY USE PARTS, FASTENERS, AND ACCESSORIES recommended by PorterCable. Fig. 7.

13.CONNECT TOOL TO AIR SUPPLY BEFORE loading fasteners, to prevent a fastener from being fired during connection. The tool driving mechanism may cycle when tool is connected to the air supply. Fig. 8.

14.ALWAYS ASSUME THE TOOL CONTAINS FASTENERS. Keep the tool pointed away from yourself and others at all

times. No horseplay. Respect the tool as a working implement.

15. DO NOT LOAD FASTENERS with trigger or safety depressed, to prevent unintentional firing of a fastener. Fig. 9.

Fig. 7

Fig. 8

Fig. 9

3

Fig. 10

16. REMOVE FINGER FROM TRIGGER when not driving fasteners. Never carry tool with finger on trigger: tool may fire a fastener if safety is bumped while trigger is depressed. Fig. 10.

17.DON’T OVERREACH. Keep proper footing and balance at all times when using or handling the tool. Fig. 11.

18.FIRE FASTENERS INTO WORK SURFACE ONLY: never into materials too

hard to penetrate. Fig. 12.

19.GRIP TOOL FIRMLY TO MAINTAIN CONTROL WHILE allowing tool to recoil away from work surface as fastener is driven. If safety element is allowed to recontact work surface before trigger is released, an unwanted fastener may be fired.

20.DO NOT DRIVE FASTENERS on top of other fasteners, or with the tool at too steep

an angle: the fasteners can ricochet causing personal injury. Fig. 13.

21.DO NOT DRIVE FASTENERS CLOSE to the edge of the workpiece. The workpiece is likely to split allowing the fastener to fly free or ricochet causing personal injury. Fig. 13.

22.KEEP HANDS AND BODY PARTS away from area shown in Fig. 13A, to avoid injury.

23.DO NOT USE ON SCAFFOLDINGS OR

LADDERS or for tasks in which changing location involves the use of scaffoldings, stairs, ladders, and the like. Do not use for specific tasks such as closing boxes or crates or fitting transportation safety systems on vehicles and wagons. Fig. 13B.

Fig. 11

Fig. 12

Fig. 13

Fig. 13A

Fig. 13B

4

TECHNICAL SPECIFICATIONS

Noise level |

|

Typical Mean |

|

A - Weighted sound impulse |

effective Acceleration . . . . . . . |

2.5 m/s2 |

|

power level . . . . . . . . . |

101 dBA |

|

|

P - Emission sound |

|

|

|

pressure level . . . . . . . . |

88 dBA |

|

|

EMPLOYER’S RESPONSIBILITIES

Employer must enforce compliance with the safety warnings and all other instructions contained in this manual.

Keep this manual available for use by all people assigned to use this tool.

For personal safety and proper operation of this tool, read and follow all of these instructions carefully.

OPERATING INSTRUCTIONS

FOREWORD

Porter-Cable Model NS100A is a heavy duty pneumatic stapler. It is designed to install narrow crown (1/4" wide), 18 ga. wire staples of various lengths (from 1/2" to 1" long), see ACCESSORIES Listing in back of this manual.

CAUTION: Use approved Porter-Cable staples only (see ACCESSORIES Listing in back of this manual).

POWER SOURCE

This tool is designed to operate on clean, dry, compressed air at regulated pressures between 70 and 120 PSI (Pounds per Square Inch). The preferred system would include a filter, a pressure regulator, and an automatic oiler located as close to the tool as possible (within 15 feet is ideal).

All compressed air contains moisture and other contaminates that are detrimental to internal components of the tool. An air line filter will remove most of these contaminates and significantly prolong the life of the tool. If an in-line oiler is not available: place five or six drops of Porter-Cable Air Tool Oil (see ACCESSORIES), into the tool’s air inlet at the beginning of each workday.

The tool is equipped with a male “quick connector”. The tool must always be connected to the air supply with a coupling such that all pressure is removed from the tool when the coupling is disconnected.

CAUTION: All air line components (hoses, connectors, filters, regulators, etc.) must have a minimum working pressure rating of 150 PSI (10.3 BAR) or 150% of maximum system potential, whichever is higher.

Do not connect this tool to a system with maximum potential pressure greater than 200 PSI (13.7 BAR).

Only connect tool to air supply with a coupling that will release all pressure from the tool when disconnected.

Disconnect tool from air supply before performing maintenance, clearing a jammed fastener, leaving work area, moving tool to another location, or handing the tool to another person.

5

Fig. 14 |

Fig. 15 |

B |

|

|

|

|

C |

|||

|

|

C |

|

|

|

|

|

B |

|

|

|

||||||

|

|

|

|

|

|

|

||

A |

|

|

|

|

A |

|||

|

|

|

|

|

|

|||

|

|

|

|

|

||||

Fig. 16 |

|

Fig. 17 |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PREPARING THE TOOL

1. After reading and understanding this entire manual, connect tool to air supply.

CAUTION: Keep tool pointed away from yourself and others at all times.

Always connect tool to air supply before loading fasteners. Do not load fasteners with trigger or safety depressed.

Only use approved Porter-Cable fasteners (see ACCESSORIES).

Always wear Z87 approved safety glasses, and hearing protection when preparing or operating the tool.

Never use a tool that leaks air or needs repair.

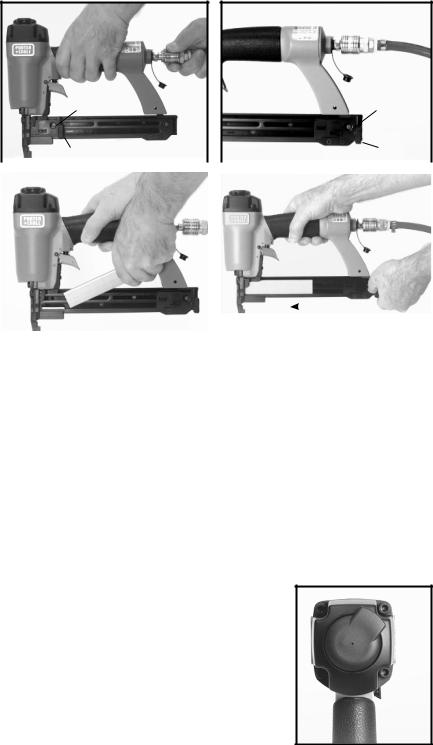

2.Pull fastener follower (A) Fig. 14, back until hole (B) Fig. 14, catches on latch (C) Fig. 14 and release fastener follower (see Fig. 15).

3.Insert a strip of approved fasteners, see Fig. 16.

4.While holding fastener follower (A) Fig. 14,

press latch (C) Fig. 14, and allow fastener follower |

|

|

to slide forward against fasteners (see Fig. 17). |

|

A |

5. Adjust directional exhaust deflector (A) Fig. 18, |

|

|

|

|

|

so that the exhaust air blast will be directed away |

|

|

from the operator. The exhaust deflector provides |

|

|

8 detented positions for directing the exhaust blast |

|

|

away from the operator. Grasp the deflector and |

|

|

rotate it to the desired position for the current |

|

|

application. |

Fig. 18 |

|

6

USING THE TOOL

Complete all steps of PREPARING THE TOOL before using the tool.

To fire, grip tool firmly, position nose of tool onto work surface, push forward on tool to depress safety, and squeeze trigger to fire a fastener. This “trigger fire” method provides the most accurate fastener placement. This tool is shipped from the factory with a “restrictive fire trigger” that only allows the tool to be fired this way and is less likely to fire an unwanted fastener.

An alternate “bottom fire trigger” is available. The “bottom fire” trigger allows the tool to be fired in two different ways.

1.The tool can be fired using the “trigger fire” method described above.

OR

2. Grip tool firmly, depress and hold trigger while pushing the tool firmly against work surface. The tool will fire a fastener each time the safety is depressed. This method is known as “bottom fire” and allows very fast repetitive fastener placement.

The “bottom fire trigger” is available free-of-charge by calling 1-800-321-9443 in the United States and Canada or 001-901-660-9374 outside the United States and Canada, and providing tool model and serial number. For identification purposes: the Bottom Fire Trigger is black and the Restrictive Fire Trigger is red.

CAUTION: Remove finger from trigger when not driving fasteners. Never carry tool with finger on trigger: tool may fire a fastener if safety is bumped.

Keep tool pointed in a safe direction at all times.

Never attempt to drive a fastener into material that is too hard, or at too step an angle, or near the edge of the workpiece. The fastener can ricochet causing personal injury.

Disconnect tool from air supply before performing maintenance, clearing a jammed fastener, leaving work area, moving tool to another location, or handing the tool to another person.

Clean and inspect tool daily. Carefully check for proper operation of trigger and safety mechanism. Do Not use the tool unless both the trigger and the safety mechanism are functional, or if the tool is leaking air or needs any other repair.

The depth to which a fastener is driven is |

|

|

Fig. 19 |

|

|

|

|

controlled by the depth adjustment knob |

|

|

|

(A) Fig. 19. The depth of drive is factory |

|

|

|

adjusted to a nomimal setting. Test fire |

|

|

A |

a fastener and check depth. If a change |

|

|

|

|

|

|

|

is desired, rotate the adjustment knob |

|

|

|

(A) Fig. 19: the adjustment knob has |

|

|

|

detents every 1/4 turn. Rotate the knob |

|

|

|

clockwise (see Fig. 19), to increase |

|

|

|

the depth of drive, rotate the knob |

|

|

|

|

|

|

counterclockwise to decrease the depth of drive. Test fire another fastener and check depth. Repeat as necessary to achieve desired results. The amount of air pressure required will vary depending on the size of the fastener and the material being fastened. Experiment with the air pressure setting to determine the lowest setting that will consistently perform the job at hand. Air pressure in excess of that required can cause premature wear and/or damage to the tool.

7

Fig. 20 |

|

Fig. 21 |

|

|

|

CLEARING A JAMMED FASTENER

1.CAUTION: Disconnect tool from air supply.

2.Open magazine and remove any remaining fasteners.

CAUTION: Remove fasteners from tool before opening the fastener guide plate. Fasteners are under pressure and may shoot out of magazine which could cause injury.

3.Depress the quick release latch and open the fastener guide plate (see Fig. 20).

4.Remove the jammed fastener (see Fig. 21).

5.Depress the quick release latch, close the fastener guide plate, and release the latch.

NOSE CUSHION

This tool is equipped with a rubber nose cushion (A) Fig.22, that prevents marring of finished surfaces by the metal safety during normal operation. The nose cushion can be removed and stored in the rear area of the tool

(B) Fig. 22, when it is not required.

CAUTION: Disconnect tool from air supply before removing or reinstalling rubber nose cushion.

Fig. 22

MAINTENANCE

CLEAN AND INSPECT DAILY

A

B

CAUTION: Disconnect tool from air supply before cleaning and inspection.Correct all problems before placing the tool back in use.

Wipe tool clean and inspect for wear or damage. Use non-flammable cleaning solutions to wipe exterior of tool only if necessary. DO NOT SOAK tool with cleaning solutions. Such solutions can damage internal parts.

Inspect trigger and safety mechanism to assure system is complete and functional: no loose or missing parts, no binding or sticking parts.

Keep all screws tight. Loose screws can cause personal injury or damage tool.

8

If tool is used without an in-line oiler: place 5 or 6 drops of Porter-Cable Air Tool Oil into the air inlet of the tool at the beginning of each workday.

SERVICE AND REPAIRS

All quality tools eventually require servicing or replacement of parts due to wear from normal use. Some user serviceable components are described in the TROUBLESHOOTING Section. Complete product Service is available from either an AUTHORIZED PORTER-CABLE SERVICE STATION or a PORTERCABLE SERVICE CENTER. All repairs made by these agencies are fully guaranteed against defective material and workmanship. We cannot guarantee repairs made or attempted by anyone other than these agencies.

Should you have any questions about your tool, feel free to write us at any time. In any communications, please give all information shown on the nameplate of your tool (model number, type, serial number, etc.).

TROUBLESHOOTING

CAUTION: Disconnect tool from air supply before performing any Service Procedure.

SYMPTOM |

PROBLEMS |

SOLUTIONS |

1.Air leak near top of tool or in trigger area.

Loose screws. |

Tighten screws. |

Worn or damaged |

Install “OVERHAUL” Maintenance Kit. |

o-rings or seals. |

|

2. Tool does nothing or |

Inadequate air supply. |

Verify adequate air supply. |

|

operates sluggishly. |

Inadequate lubrication. |

Put 5 or 6 drops of oil into air inlet. |

|

|

|

Worn or damaged |

Install |

“DRIVER” Maintenance Kit.

o-rings or seals.

3.Air leak near bottom of tool.

Loose screws. |

Tighten screws. |

Worn or damaged |

Install “OVERHAUL” Maintenance Kit. |

o-rings or bumper. |

|

4. |

Tool jams frequently. |

Incorrect fasteners. |

Verify approved fasteners of |

|

|

|

correct size. |

|

|

Damaged fasteners. |

Replace w/undamaged fasteners. |

|

|

Magazine or nose |

Tighten screws. |

|

|

screws loose. |

|

|

|

Magazine is dirty. |

Clean magazine. |

|

|

Driver is worn or damaged. |

Install “DRIVER” Maintenance Kit. |

|

|

|

|

5. |

Other. |

|

Contact a Porter-Cable |

|

|

|

Service Facility. |

9

ACCESSORIES

The testing of this tool has been accomplished with the following accessories. For safest operation, it is recommended that only these accessories be used with this product.

WARNING: Since accessories other than those listed have not been tested with this product, use of such accessories could be hazardous.

CATALOG NO. |

DESCRIPTION |

LENGTH |

GAUGE |

QUAN/BOX |

NS18050 |

Narrow Crown Staple |

1/2" |

18 |

5000 |

NS18063 |

Narrow Crown Staple |

5/8" |

18 |

5000 |

NS18075 |

Narrow Crown Staple |

3/4" |

18 |

5000 |

NS18088 |

Narrow Crown Staple |

7/8" |

18 |

5000 |

NS18088-1 |

1000 Pk. of NS18088 |

7/8" |

18 |

1000 |

NS18100 |

Narrow Crown Staple |

1" |

18 |

5000 |

NS18100-1 |

1000 Pk. of NS18100 |

1" |

18 |

1000 |

60061 |

“OVERHAUL” Maintenance Kit |

|

|

|

60064 |

“DRIVER” Maintenance Kit |

|

|

|

884293 |

Oil (for Air Tools) |

|

|

|

893579 |

Safety Glasses |

|

|

|

893933 |

Bottom Fire Trigger |

|

|

|

PORTER-CABLE LIMITED

ONE YEAR WARRANTY

Porter-Cable warrants its nailing and stapling tools for a period of one year from the date of original purchase. We will repair or replace at our option, any part or parts of the product and accessories covered under this warranty which, after examination, proves to be defective in workmanship or material during the warranty period. For repair or replacement return the complete tool or accessory, transportation prepaid, to your nearest Porter-Cable Service Center or Authorized Service Station. Proof of purchase may be required. This warranty does not apply to O-rings and Driver Blades or to repair or replacement required due to misuse, abuse, normal wear and tear or repairs attempted or made by other than our Service Centers or Authorized Service Stations.

ANY IMPLIED WARRANTY, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WILL LAST ONLY FOR ONE (1) YEAR FROM THE DATE OF PURCHASE.

To obtain information on warranty performance please write to: PORTER-CABLE CORPORATION, 4825 Highway 45 North, P.O. Box 2468, Jackson, Tennessee 38302-2468; Attention: Product Service. THE FOREGOING OBLIGATION IS PORTER-CABLE’S SOLE LIABILITY UNDER THIS OR ANY IMPLIED WARRANTY AND UNDER NO CIRCUMSTANCES SHALL PORTER-CABLE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other legal rights which vary from state to state.

10

ENGLISH: PAGE 1 ESPAÑOL: PÁGINA 23

Manuel

d’utilisation AGRAFEUSE POUR AGRAFES ÉTROITES

Pour de plus amples renseignements concernant Porter-Cable, consultez notre Website à l’adresse suivante :

http://www.porter-cable.com

IMPORTANT

Veuillez vous assurer que la personne qui utilise cet outil lit attentivement et comprend ces instructions avant de commencer à utiliser l’outil.

La plaque des numéros de modèle et de série est située sur le boîtier principal de l’outil. Prenez note de ces numéros dans les espaces ci-après et conservezles pour référence future.

No. de modèle __________________________________

Type ___________________________________________

No. de série ____________________________________

No. de pièce 894885-004 - 07-11-06

Loading...

Loading...