Panasonic MDDDT5540, MDDDT3530P, MDDDT5540P User Manual

AC Servo Motor Driver

MINAS S-series

Operating Manual

Be sure give this instruction manual to the user.

•Thank you very much for your buying Panasonic AC Servo Motor Driver,A-series.

•Before use, read through this manual to ensure proper use. Keep this manual at an easily accessible place so as to be referred anytime as necessary.

Table of Contents

Before Use

Safety Precautions •••••4

Introduction •••••••••••••8

After Opening the Package•••••••••••••••• 8 Check the Model Number of Amplifier •••••••••••••••••• 8 Check the Model Number of Motor••••••••••••••••••• 9 Check the Combination of Amplifier and Motor ••••••••••••••••••••• 10

Parts Description •••••••••••12

Amplifier ••••••••••••••••••••••••••••••••••••• 12 Motor ••••••••••••••••••••••••••••••••••••••••• 13

Installation •••••••••••••••••14

Amplifier ••••••••••••••••••••••••••••••••••••• 14 Motor ••••••••••••••••••••••••••••••••••••••••• 16

Preparations

and Adjustments

System Configuration and Wiring••••• 1 8

General Wiring Diagram ••••••••••••••••••••••• 18 List of Available Components •••••••••••••••••• 20 Main Circuits ••••••••••••••••••••••••••••••• 22 CN SIG Connector

For Encoder ••••••••••••••••••••••••••••• 23 CN SER Connector ••••••••••••••••••••••• 24 CN I/F Connector

For Controller •••••••••••••••••••••••••••• 25 CN MON Connector ••••••••••••••••••• 35

Parameter Setting •••••••••••36

Overview •••••••••••••••••••••••••••••••••••• 36 Parameter Groups and Listing ••••••••••••••• 36 Setting the Parameters••••••••••••••••••• 41 Overview of PANATERM“ ••••••••••••••• 41 How to Connect •••••••••••••••••••••••••••• 41

Trial Run •••••••••••••••••••44

Inspections before Trial Run ••••••••••••••••••• 44 Operation with

CN I/F Connected •••••••••••••••••• 45

Adjustments •••••••••••••••50

Purposes of Gain Adjustments ••••••••••••••• 50 Types of Gain Adjustments •••••••••••••• 50 How to Adjust Gain•••••••••••••••••••••••• 52 How to Use

"Normal Auto-Gain" Tuning •••••••••• 53 How to Use "Real Time

Auto-Gain" Tuning •••••••••••••••• 54 How to Adjust Gain Manually ••••••••••••••• 55 Gain Tuning Using

Gain Adjustment Rotary Switch ••••••••• 58 To reduce the mechanincal

resonance ••••••••••••••••••••••••••• 59

- 2 -

Important Information

Protective Functions ••••••••••• 60 Maintenance and Inspections ••••••••••• 6 6

Troubleshooting

••••••••••••••••••••••••••••••68

After-Sale Service

•••••••••••••••••••••• Back cover

Appendixes

Conformance to EC Directives and UL Standards ••••••••••• App. 2 Holding Brake ••••••••••••••••••••••••• App. 6 Dynamic Brake •••••••••••••••••••••••• App. 8 Timing Chart ••••••••••••••••••••••••• App. 10 Acceptable Loads on Output Shaft ••••••••••••••• App. 14 Homing Operation (Precautions) •••••••••••••• App. 15

Details of Parameters ••••••••••••• App. 16 Optional Parts ••••••••••••••••••••••• App. 38 Recommended Parts •••••••••••••• App. 47 Dimensions •••••••••••••••••••••••••• App. 48 Characteristics •••••••••••••••••••••• App. 53 Specifications ••••••••••••••••••••••• App. 54

- 3 -

Safety Precautions |

(Important) |

Observe the following precautions in order to avoid injuries of operators and other persons, and mechanical damages.

The following DANGER and CAUTION symbols are used according to the level of dangers possibly occurring if you fail to observe the instructions or precautions indicated.

The following DANGER and CAUTION symbols are used according to the level of dangers possibly occurring if you fail to observe the instructions or precautions indicated.

DANGER |

Indicates a potentially hazardous situation which, if not |

|

avoided, will result in death or serious injury. |

Indicates a potentially hazardous situation which, if not avoided, CAUTION will result in minor or moderate injury and physical damage.

The following symbols indicate what you are not allowed to do, or what you must observe.

The following symbols indicate what you are not allowed to do, or what you must observe.

This symbol indicates that the operation is prohibited.

This symbol indicates that the operation must be performed without fail.

DANGER

DANGER

An over-current protection, earth leakage breaker, over-temperature protection and emergency stop should be installed.

Failure to observe this

instruction could result in electric shocks, injuries and/or fire.

Don't insert your hands in the amplifier.

Failure to observe this instruction could result in burns and/or electric shocks.

Install the amplifier securely to prevent fire hazard and personal injury resulting from earthquake.

Failure to observe this

instruction could result in electric shocks, injuries and/or fire.

Be sure to check safety after occurrence of earthquake.

Failure to observe this

instruction could result in electric shocks, injuries and/or fire.

-4-

DANGER

DANGER

Don't touch the rotating part of the motor in motion.

Rotating part

Failure to observe this instruction could result in injuries.

Don't subject the product to w a t e r s p l a s h , c o r r o s i v e gases, flammable gases and combustible things.

Failure to observe this instruction could result in fire.

Do not expose the cables to s h a r p e d g e s , e x c e s s i v e p r e s s i n g f o r c e s , h e a v y loads or pinching forces.

Failure to observe this instruction could result in electric shocks,

m a l f u n c t i o n a n d / o r damages.

Perform the transportation, wiring and inspection at least 10 minutes after the power off.

Failure to observe this instruction could result in electric shocks.

Always ask to an electrical engineer for wiring.

Ground the earth terminal of the amplifier.

Failure to observe this instruction could result in electric shocks.

Install an external emergency stop device so that you can shut off the power in any emergency cases.

Failure to observe this instruction could result in injuries, electric shocks, fire, malfunction and/or mechanical damages.

Use Before

-5-

Safety Precautions |

(Important) |

Caution

Caution

Use the motor and amplifier in the specified combination.

Failure to observe this instruction could result in fire.

Execute the trial operations with the motor fixed but without motor load connected. Connecting a load to the motor is possible only after successful trial operation.

Failure to observe this instruction could result in injuries.

If an error occurs, |

Don't touch the motor, |

remove the causes for |

amplifier or its |

the error and secure the |

regenerative discharge |

safety before restarting |

resistor, since they |

the operation. |

become hot. |

Failure to observe this instruction could result in injuries.

Failure to observe this instruction could result in burns.

Avoid extreme adjustment or change. Avoid an operation which causes unstable action.

Failure to observe this instruction could result in injuries.

Don't modify, dismantle or repair the amplifier.

Failure to observe this instruction could result in fire, electric shocks and/or injuries.

-6-

Caution

Caution

Don't |

hold the cables or |

After recovery from the |

|

motor |

shaft |

when |

power failure, the |

transporting |

the motor. |

equipment may restart |

|

|

|

|

suddenly. Don't approach |

|

|

|

the equipment |

|

|

|

Failure to observe this |

|

Failure to observe this |

instruction could result in |

|

|

instruction could result |

injuries. |

|

|

in injuries. |

*Provide appropriate settings as a preparedness against |

|

|

|

|

|

|

|

|

the accidental restart of the machine in order to ensure |

|

|

|

the safety of personnel. |

Don't block the heat |

Observe the voltage |

||

dissipation hole or insert |

specified. |

||

foreign |

matters in it. |

|

|

Use Before

Failure to observe this instruction could result in electric shocks, injuries and/or fire.

Failure to observe this instruction could result in electric shocks,

injuries and/or fire.

Make sure that the wirings are made correctly.

Failure to observe this

instruction could result in

electric shocks, injuries.

This equipment should be treated as an industrial waste when it is disposed of.

Do not turn on/off the main power frequently. Failure to observe this instruction could result in malfunctions.

-7-

Introduction

After Opening the Package

•Make sure that the product is what you have ordered.

•Check whether the product has been damaged or not during transportation.

If the product is not correct, or it has been damaged, contact dealer or sales agent.

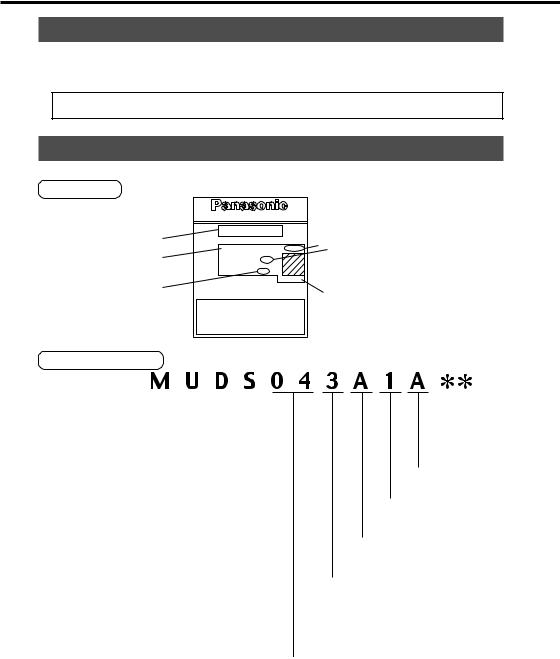

Check the Model of Amplifier

Name plate

Model

Rated input voltage

Rated motor output

AC SERVO DRIVER

Model No. |

MUDS3A1A1A |

|

|

|

INPUT |

OUTPUT |

ENCODER |

Voltage |

100-115V |

32V |

2500P/R |

Phase |

1ø |

3ø |

|

F.L.C |

1.0A |

1.0A |

|

Freq. |

50/60Hz |

0~333.3Hz |

|

Power |

|

30W |

|

60/75 Wire Only

Use Copper Conductors Only

Refer to Manual for Wiring and Wire Size Refer to Manual for Over Load Protection

Number of pulses of the encoder(resolution)

Rated output current

Serial Number

Model Designation

|

|

1~3 |

|

|

4 |

|

5~6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Symbol |

Applicable motors |

|

|

|

|

||

MUD |

MUMÅiExtra low inertiaÅj |

|

|

|

|

||

|

|

|

|

|

|

|

|

Series symbol

S: S-series

7 |

8 |

9 |

10 |

|

|

|

11~12 |

|

|||||

|

|

|

|

|

|

|

Custom specification

Custom specification 2 (A, B, C...)

A: Standard Custom specification 1 (1, 2, 3...)

1: Standard

Rotary encoder (see Table 1-b)

Power supply

1:Single-phase, 100V

2:Single-phase, 200V

3:Three-phase, 200V

5: Three-phase/Single-phase, 200V (common phase)

Rated motor output (see Table 1-a)

-8-

Check the Model of Motor

Name plate

Type

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONT. TORQUE 0.64 |

Nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

Rated output |

|

|

|

AC SERVO MOTOR |

RATING |

|

|

S1 |

|

|

|

|

Serial No |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

Model No. MUMS042A1A |

INS. CLASS B (TÜV) A (UL) |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

|

Revolution rating |

|

|

INPUT 3ØAC |

|

92 |

V |

IP65 |

00010001 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

RATED OUTPUT |

0.2 |

kW |

SER No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.6 |

A |

CONNECTION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

RATED FREQ. |

200 |

Hz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

RATED REV. |

3000 |

r/min |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MatsushitaElectric Industrial Co..Ltd. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Made in Japan |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Model Designation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1~3 |

|

|

|

|

4 |

|

|

5~6 |

|

|

|

|

|

7 |

|

8 |

|

9 |

|

|

10 |

11~12 |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Custom specification 2 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

|

Type |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Motor structure |

|

|||||||||||||||

|

|

|

|

MUM |

Super low inertia |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(see Table 1-c) |

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Custom specification 1 |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1: Standard |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rotary encoder |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Series symbol |

|

|

|

|

|

|

|

|

|

(see Table 1-b) |

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

S: S-series |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated output |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(see Table 1-a) |

Voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1: 100V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2: 200V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z: 100/200V |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Table 1-a |

|

|

Rated |

Motor |

Output |

|

|

|

Table 1-b |

|

|

Rotary Encoder |

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Symbol |

Rated output |

|

Symbol |

Rated output |

|

|

Symbol |

|

|

|

|

|

|

|

|

|

Specifications |

|

|

|

|||||||||||||||||||||||||

3A |

|

|

30W |

|

02 |

|

200W |

|

|

|

|

|

|

|

|

|

|

Type |

|

No. of pulses |

Resolution |

Lead wire |

|

||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

5A |

|

|

50W |

|

04 |

|

400W |

|

|

|

|

|

|

|

A |

|

|

|

Incremental |

|

2500P/r |

10000 |

|

11-wire |

|

||||||||||||||||||||

01 |

|

|

100W |

|

08 |

|

750W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

Table 1-c |

|

Motor |

Structure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil seal |

|

Brake |

|

|

|

Shaft |

|

|

|

|

|

|

|

|

|

∑ Specifications with the shaft |

|

||||||||||||||||||||||||||||

|

S t r a i g h t |

|

|

|

|

Key |

way |

|

|

provided with key way are standard. |

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

None |

|

None |

|

|

A |

|

|

|

|

|

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

Yes |

|

|

B |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Yes |

|

None |

|

|

C |

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Yes |

|

|

D |

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Use Before

-9-

Introduction

Check the Combination of Amplifier and Motor

The amplifier has been designed for use in combination with the specified motors only. Check the specifications (Series symbol, output rating, voltage rating and encoder type) of the motor you want to use.

-10-

With the incremental type encoder: 2500P/r

Power |

|

Amplifier |

|

|

M o t o r |

|

|

|

|

supply for |

Amplifier |

Series |

|

|

|

Output |

Revolution |

Encoder |

|

type |

Motor type |

Voltage |

|

||||||

amplifier |

|

||||||||

|

symbol |

|

rating |

rating |

type |

||||

|

|

|

|||||||

1-phase, |

MUDS3A1A1A |

Type1 |

MUMS |

MUMS3AZ**** |

|

|

30W |

|

|

|

|

|

|

|

|

|

|

|

|

100V |

MUDS5A1A1A |

|

Super |

MUMS5AZ**** |

|

|

50W |

|

|

|

|

|

|

|

|

|

|

||

|

MUDS011A1A |

|

Low |

MUMS011A**** |

100V |

|

100W |

|

|

|

|

|

|

|

|

|

|

||

|

MUDS021A1A |

Type2 |

inertia |

MUMS021A**** |

|

|

200W |

|

|

|

|

|

|

|

|

|

|

||

|

MUDS041A1A |

Type3 |

|

MUMS041A**** |

|

|

400W |

|

|

|

|

|

|

|

|

|

|

|

|

1-phase, |

MUDS022A1A |

Type2 |

|

MUMS022A**** |

|

|

200W |

|

|

|

|

|

|

|

|

|

|

|

|

200V |

MUDS042A1A |

Type3 |

|

MUMS042A**** |

|

|

400W |

|

Incremental |

|

|

|

|

|

|

|

|

|

|

3-phase/1- |

MUDS3A5A1A |

Type1 |

|

MUMS3AZA**** |

200V |

|

30W |

3000r/min |

2500P/r, 11 |

|

|

|

|

|

|

|

|

|

|

phase, |

MUDS5A5A1A |

|

|

MUMS5AZA**** |

|

|

50W |

|

wires |

|

|

|

|

|

|

|

|

|

|

200V |

MUDS015A1A |

|

|

MUMS012A**** |

|

|

100W |

|

|

|

|

|

|

|

|

|

|

|

|

3-phase, |

MUDS023A1A |

|

|

MUMS022A**** |

|

|

200W |

|

|

|

|

|

|

|

|

|

|

|

|

200V |

MUDS043A1A |

Type2 |

|

MUMS042A**** |

|

|

400W |

|

|

|

|

|

|

|

|

|

|

|

|

|

MUDS083A1A |

Type3 |

|

MUMS082A**** |

|

|

750W |

|

|

|

|

|

|

|

|

|

|

|

|

Use Before

-11-

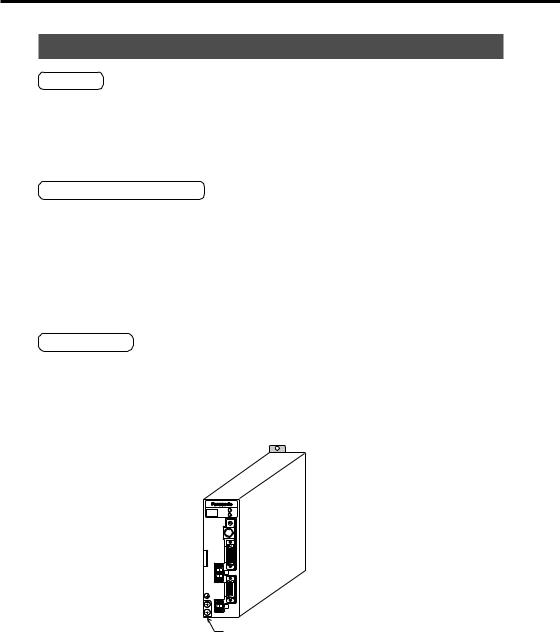

Parts Description

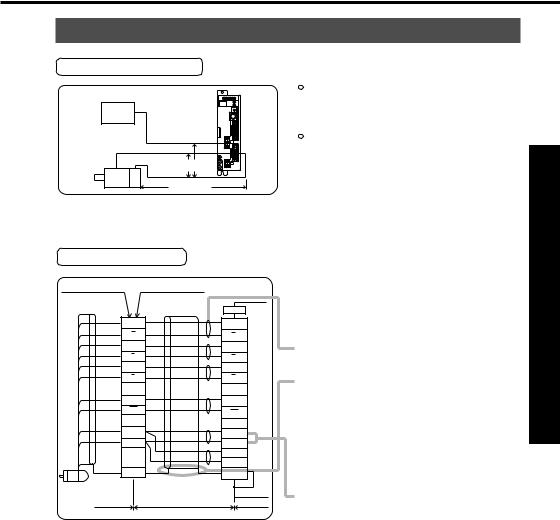

Amplifier

Example: MUDS023A1A |

Example: MUDS042A1A |

(3-phase, 200V 200W: Type 1) |

(1-phase, 200V 400W: Type 3) |

Main power input connector (L1, L2, L3,P, B)

Motor connection (U, V, W, E)

Earth connections

MSDS STATUS

ALM CODE

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

Communication connector

CN SER

Controller connection (CN I/F)

Encoder connection (CN SIG)

MSDS STATUS

ALM CODE

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

CN

MON

Status LED Alarm code LED

Rotary switch for gain (GAIN) tuning

Check pins (CN MON)

CN MON

Check pins (CN MON)

<Notes>

For detailed information for each of motor types, see the drawings in the Appendix

(App.50 to 52).

-12-

Motor

Example: Super Low-Inertia Motor (MUMS Series, 400W)

Encoder cable

Motor cable

Encoder

Brake cable

(Motor with electromagFrame

netic brake only )

Mounting bolt holes (4)

Flange

<Notes>

For detailed information for each of motor types, see the drawings in the Appendix

(App.48 & 49).

Use Before

-13-

Installation

The amplifier and motor should be properly installed to avoid failures, mechanical damages and injuries.

Amplifier

Location

•Indoors, where the amplifier is not subjected to rain water and direct sun beams. Note that the amplifier is not a waterproof structure.

•Avoid the place where the amplifier is subjected to corrosive gases, flammable gases, grinding liquids, oil mists, iron powders and cutting particles.

•Place in a well-ventilated, and humidand dust-free space.

•Place in a vibration-free space.

Environmental Conditions

I t e m |

Conditions |

Ambient temperature |

0 to 55˚C (free from freezing) |

Ambient humidity |

Not greater than 90%RH (free from condensation) |

Storage temperature |

-20 to 80˚C (free from condensation) |

Storage humidity |

Not greater than 90%RH (free from condensation) |

Vibration |

Not greater than 5.9m/s2 (0.6G) at 10 to 60 Hz |

Altitude |

Not greater than 1000 m |

How to Install

•This is a rack-mount type.

Place the amplifier vertically. Allow enough space surrounding for ventilation. Front panel mount type (recessed)

MSDS STATUS

ALM CODE

ALM CODE

GAIN

CN

SER

CN

I/F

CN

POWER

CN

SIG

CN

MOTOR

Earth connection (M4 screw) tightening torque shall not exceed 0.39 ~ 0.59 N·mU.U

-14-

Mounting Direction and Space Requirements

•Allow enough space to ensure enough cooling.

•Install fans to provide a uniform distribution of temperature in the control box.

The airflow of fan is more than 0.43m3/min. And it should be located 10 cm away from the amplifier.

•Observe the environmental requirements for the control box, mentioned in the previous page.

|

|

Fan |

|

|

|

Fan |

|

|

min. |

|

|

|

|

|

|

|

|

|

100mm |

MSDS |

STATUS |

MSDS |

STATUS |

MSDS |

STATUS |

|

MSDS |

STATUS |

|

|

ALM CODE |

|

ALM CODE |

|

ALM CODE |

|

|

ALM CODE |

|

|

GAIN |

|

GAIN |

|

GAIN |

|

|

GAIN |

|

|

CN |

|

CN |

|

CN |

|

|

CN |

|

|

SER |

|

SER |

|

SER |

|

|

SER |

|

|

CN |

|

CN |

|

CN |

|

|

CN |

|

|

I/F |

|

I/F |

|

I/F |

|

|

I/F |

|

|

CN |

|

CN |

|

CN |

|

|

CN |

|

|

POWER |

|

POWER |

|

POWER |

|

|

POWER |

|

min. |

|

min. |

|

min. |

|

min. |

|

|

min. |

40mm |

CN |

10mm |

CN |

10mm |

CN |

10mm |

|

CN |

40mm |

|

SIG |

|

SIG |

|

SIG |

|

|

SIG |

|

|

CN |

|

CN |

|

CN |

|

|

CN |

|

|

MOTOR |

|

MOTOR |

|

MOTOR |

|

|

MOTOR |

|

|

|

|

|

|

|

|

|

|

min. |

|

|

|

|

|

|

|

|

|

100mm |

Use Before

-15-

Installation

Motor

Location

•Indoors, where the amplifier is not subjected to rain water and direct sun beams.

•Avoid the place where the amplifier is subjected to corrosive gases, flammable gases, grinding liquids, oil mists, iron powders and cutting particles.

•Place in a well-ventilated, and humidand dust-free space.

•Easy maintenance, inspections and cleaning is also important.

Environmental Conditions

I t e m |

|

|

Conditions |

Ambient temperature |

|

|

0 to 40˚C (free from freezing) |

Ambient humidity |

|

Not greater than 85%RH (free from condensation) |

|

Storage temperature |

|

|

-20 to 80˚C (free from freezing) |

Storage humidity |

|

Not greater than 85%RH (free from condensation) |

|

Vibration |

Motor only |

|

49 m/s2 (5G) or less at rotation, 24.5 m/s2 (2.5G) or less at rest |

|

With gear |

|

High precision and normal type: 24 m/s2 (2G) or less |

|

|

|

|

|

(At rotation) |

|

Standard type: 49 m/s2 (5G) or less |

|

|

|

|

Shock |

Motor only |

|

98 m/s2 (10G) or less |

|

|

|

|

|

With gear |

|

High precision and normal type: 98 m/s2 (10G) or less |

|

|

|

|

|

|

|

Standard type: 24 m/s2 (2G) or less |

|

|

|

|

How to Install

The motor can be installed either vertically or horizontally. Observe the following notes.

•Horizontal mounting

•Place the motor with the cable outlet facing down to prevent the entry of oil and water.

•Vertical mounting

•If a motor is coupled with a reduction gear, use a motor equipped with oil seal so that oil in the reduction gear may not enter into the motor.

Oil and Water Protections

•This motor(IP65 rating) can be used where it is subjected to water and/or oil drops, but is not water - or oil - proof. Therefore, the motors should not be placed or used in such environment.

•If the motor is coupled with a reduction gear, use the motor with oil seals to prevent the reduction gear oil from entering into the motor.

•Don't use the motor with the cables being immersed in oil or water.

-16-

Cable

Motor

Oil and water

Cable: Stress Relieving |

Before |

|

• Make sure that the cables are not subjected to moments or vertical loads due to external |

||

|

||

bending forces or self-weight at the cable outlets or connections. |

|

|

• In case the motor is movable, secure the cable (proper one supplied together with the |

Use |

|

motor) to a stationery part (e.g. floor), and it should be extended with an additional cable |

||

|

which should be housed in a cable bearer so that bending stresses can be minimized.

• Make the bending radius of cables as large as possible. (Minimum bend radius: 20 mm)

Permissible Shaft Load

•Make sure that both of radial and thrust load to be applied to the motor shaft during installation and running, are within the specified value of each model.

•Pay extra attention to installing a rigid coupling (especially an excess bending load which may cause the damages and/or wear of the shaft and bearings).

•Flexible coupling is recommended in order to keep the radial load smaller than the permissible value, which is designed exclusively for servo motors with high mechanical stiffness.

•For the permissible shaft load, see "Allowable Shaft Loads Listing" in Appendix.

Installation Notes

•Don't hit the shaft with a hammer directly while attaching/detaching the coupling to the motor shaft.(otherwise the encoder at the opposite end of the shaft will be damaged).

•Try perfect alignment between shafts (misalignment may cause vibration, and damages of the bearings).

Motor

-17-

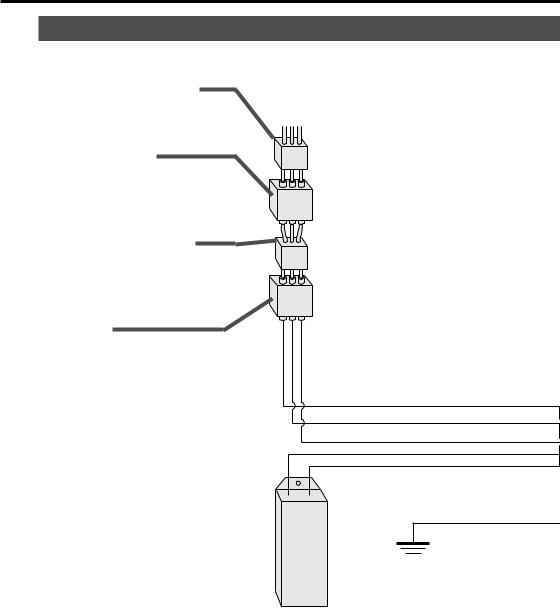

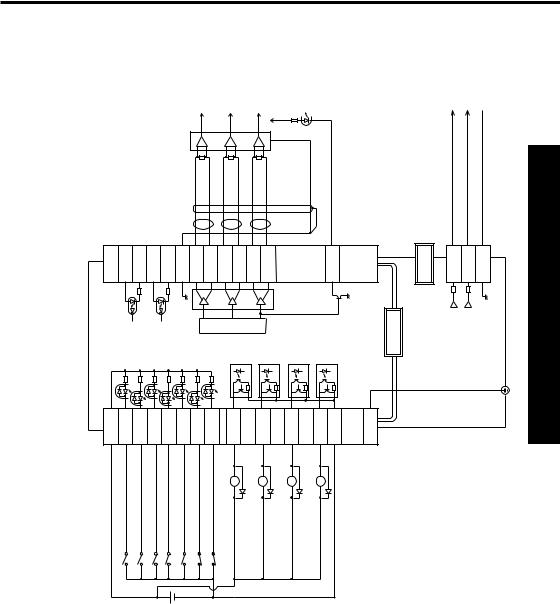

System Configuration and Wiring

General Wiring Diagram

• Main Circuits

Non-Fuse Breaker (NFB)

Used to protect the power lines: overcurrent will shut off the circuit.

Noise Filter (NF)

Prevents the external noise from the power line, and reduces the effect of the noises generated by the servo motor.

Magnetic Contactor (MC)

Turns on/off the main power of the servo motor.

Used together with a surge absorber.

Reactor (L)

Reduces the harmonic current in the main power.

Terminals P and B

•In case of use under large regenerative energy, connect an external regenerative discharge resistor to P and B terminals.

<Notes>

Where residual-current-operated protective device (RCD) is used for protection in case of direct or indirect contact. Only RCD of Type B is allowed on supply side of this Electronic Equipment (EE).

Ground

Regenerative discharge resistor

-18-

|

|

|

|

|

Personal computer |

STATUS |

|

|

|

Communication |

|

|

|

|

control software |

||

ALM CODE |

|

|

|

||

|

|

|

P A N A T E R M “ |

||

|

7 |

8 |

9 |

0 |

|

GAIN |

6 |

|

|

|

|

5 |

|

|

1 |

|

|

|

4 |

3 |

2 |

|

|

|

|

|

|||

CN |

|

|

|

|

|

SER |

|

|

|

|

|

|

|

|

|

|

CN SER |

CN |

|

|

|

|

(to connect a PC or |

I/F |

|

|

|

|

|

CN |

|

|

|

|

controller) |

POWER |

|

|

|

|

|

|

|

|

|

|

CN I/F |

|

|

|

|

|

(to connect a controller) |

CN |

|

|

|

|

|

SIG |

|

|

|

|

CN SIG |

CN |

|

|

|

|

|

MOTOR |

|

|

|

|

|

|

|

|

|

|

(to connect an encoder) |

|

|

|

|

|

Encoder cable |

1234 Hazardous Voltage

Others; Low Voltage circuit

Motor cable

Power supply for motor brake (24VDC)

-19-

Adjustments and parationsPre

System Configuration and Wiring

List of Available Components

Amplifier |

Required Power |

Circuit |

Noise |

Magnetic contactor |

Maincircuitwirediameter |

|||

|

|

|

breaker |

(L1, L2, L3, |

||||

Series |

Voltage |

Output |

(at the rated load) |

filter |

( c o n t a c t s ) |

|||

(rated current) |

U, V, W, E) |

|||||||

|

|

|

|

|

|

|||

|

|

30 ~ 50W |

Approx. 0.3kVA |

B K 2 5 1 |

D V O P 1 4 4 1 |

BMFT61041N |

|

|

|

1-phase, |

1 0 0 W |

Approx. 0.4kVA |

(5A) |

|

(3P+1a) |

|

|

|

100V |

2 0 0 W |

Approx. 0.5kVA |

|

|

|

|

|

|

|

4 0 0 W |

Approx. 1.0kVA |

B K 2 1 0 1 |

D V O P 1 4 4 2 |

BMFT61541N |

|

|

|

|

|

|

( 1 0 A ) |

|

(3P+1a) |

0.75mm2 |

|

|

*1-phase, |

30 ~ 50W |

Approx. 0.3kVA |

B K 3 5 1 |

D V O P 1 4 4 1 |

BMFT61541N |

~ 0.85mm2 |

|

|

200V |

1 0 0 W |

|

(5A) |

|

(3P+1a) |

AWG 18 |

|

MUDS |

1-phase, |

2 0 0 W |

Approx. 0.5kVA |

|

|

|

|

|

|

4 0 0 W |

Approx. 0.9kVA |

B K 3 1 0 1 |

D V O P 1 4 4 2 |

|

|

||

|

200V |

|

|

|||||

|

|

|

( 1 0 A ) |

|

|

|

||

|

|

|

|

|

|

|

||

|

*3-phase, |

30 ~ 50W |

Approx. 0.3kVA |

B K 3 5 1 |

D V O P 1 4 4 1 |

MMFT61042N |

|

|

|

200V |

1 0 0 W |

|

(5A) |

|

(3P+1a) |

|

|

|

|

2 0 0 W |

Approx. 0.5kVA |

|

|

|

|

|

|

3-phase, |

4 0 0 W |

Approx. 0.9kVA |

BK3101(10A) |

|

|

|

|

|

200V |

7 5 0 W |

Approx. 1.3kVA |

B K 3 1 5 1 |

D V O P 1 4 4 2 |

|

|

|

|

|

|

|

( 1 5 A ) |

|

|

|

|

As these models with * are used for both 1-phase 200V and 3-phase 200V, make a choice

according to the power source.

•When these wires are used, wire length between circuit breaker and amplifier should be less than 3 m.

•The model numbers of circuit breaker and magnetic contactors shown in the above list are manufactured by Matsushita Electric Works, Ltd.

•Use the circuit breaker as shown in App.3 to meet relevant EC Directives.

•The model number of noise filters (options) shown in the above are manufactured by Okaya Electric Industries Co., Ltd.

<Notes>

•CN POWER, CN MOTOR and earth terminals

Wires should be copper conductors of a temperature rating of 60˚C or above.

•Earth wire diameter should be 2.0 mm2 (AWG14) or larger.

•Please also consider the electrochemical potentials between metal conductor including closed loop terminals. The electrochemical potentials shall be less than 0.6V.

-20 -

For 3-phase 200VAC

3-phase |

|

|

|

|

|

|

200V |

|

ON |

|

|

|

|

|

|

MC |

OFF |

|

MC |

|

|

|

|

|

|||

|

NFB |

MC |

L |

10 |

|

|

|

Noise filter |

|

L1 |

P |

||

|

|

|

|

8 |

||

|

|

|

|

L2 |

|

|

|

|

|

|

6 |

|

|

|

|

|

|

L3 |

N |

|

|

|

|

|

5 |

||

|

|

|

|

P |

P |

|

172167-1 |

172159-1 |

|

|

3 |

||

|

|

B |

N |

|||

tyco Electronics AMP |

tyco Electronics AMP |

|

|

|||

|

|

5557-10R-210 |

|

|

|

|

Red |

1 |

|

|

1 |

U |

|

|

|

|

|

|

||

White or yellow |

2 |

|

|

4 |

V |

|

|

|

|

6 |

|

||

Black |

3 |

|

|

W |

|

|

|

|

|

|

|

||

Green/yellow |

4 |

|

|

3 |

E |

|

|

|

|

|

|

||

|

|

5557-06R-210 |

|

|

|

|

Motor |

|

|

|

|

|

|

|

|

ALM |

|

9 |

ALM |

|

|

|

VDC |

|

|

|

|

12~24V |

13 COM – |

|

For 1-phase 100V/200V

Single-phase 100V or |

|

|

|

|

|

|

Single-phase 200V |

|

ON |

|

|

|

|

|

|

|

MC |

OFF |

|

MC |

|

|

|

|

|

||

|

NFB |

Noise filter |

MC |

L 10 |

L1 |

P |

|

|

|

|

6 |

L2 |

|

|

|

|

|

L3 |

N |

|

|

|

|

|

5 |

||

|

|

|

|

P |

P |

|

172167-1 |

172159-1 |

|

|

3 |

||

|

|

B |

N |

|||

tyco Electronics AMP |

tyco Electronics AMP |

5557-10R-210 |

||||

|

|

|

|

|

||

Red |

1 |

|

|

1 |

U |

|

|

|

|

|

|

||

White or yellow |

2 |

|

|

4 |

V |

|

|

|

|

6 |

|

||

Black |

3 |

|

|

W |

|

|

|

|

|

|

|

||

Green/yellow |

4 |

|

|

3 |

E |

|

|

|

|

|

|

||

|

|

|

5557-06R-210 |

|

|

|

Motor |

|

|

|

|

|

|

|

|

|

ALM |

9 |

ALM |

|

|

|

VDC |

|

|

|

|

12~24V |

13 COM – |

|

<Note>

• In case that alarm occurs, construct the circuits so that the main power is switched off.

Adjustments and Preparations

- 21 -

System Configuration and Wiring

Main Circuits

Always ask to an electric engineer for wiring.

Don't turn on the main power until the wiring and connectings are completed, to avoid electric shocks.

Wiring Instructions

•Make necessary connections.

For wire diameter, see List of Available Components (page 20).

•Securely insert connectors.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

See the nameplate of the amplifier to check |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the power specification. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Install a non-fuse breaker or leakage breaker. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The latter should be a special one intended for |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

inverters, i.e. with a countermeasure against |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

higher harmonics. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Install a noise filter without fail. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Install a surge absorber to the magnetic |

|

Power |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

contactor coil. |

|

|

NFB |

|

NF |

|

MC |

|

|

L |

|

|

|

|

|

|

Install an AC reactor. |

|

|||

supply |

|

|

|

|

|

|

|

|

|

|

|

For three-phase 200V,connect L1(10pin), L2(8pin), |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and L3(6pin). |

|

|

|

|

|

|

|

|

|

|

|

|

CN |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

5 |

POWER |

10 |

For single-phase 100V and |

200V, connect |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L1(10pin) and L3(6pin). |

|

D class ground: 100Ω max. |

|

|

|

|

P |

|

|

|

|

|

L1 |

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

L2 |

Connect to the grounding system of the facility. |

||||||||

|

|

|

|

B |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

For wire diameter, see page 20. |

|

|

|

|

|

|

|

|

|

|

Never fail to connect between the amplifier's |

||||||||

|

|

|

|

|

|

|

|

|

L3 |

||||||||||

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

1 |

|

|

|

|

|

6 |

protective earth terminal ( |

) and control |

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

CN |

board's protective earth terminal (ground plate) |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

3 MOTOR |

in order to avoid electric shocks. |

6 |

|

U |

|

|

Ensure to connect matching in color between |

Red |

1 |

|

the motor wires and terminals (U, V, W and E). |

|

|

|

|||

White or |

V |

1 |

4 |

Don't short circuit or ground. Don't connect to |

|

2 |

|

||

yellow |

|

|

the main power. |

|

W |

3 |

|

||

Black |

|

|

||

Green |

E |

4 |

|

|

yellow |

|

|

|

|

Motor

|

|

|

|

|

|

|

The electromagnetic brake is not polar-sensitive. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For power capacities, see the App. 7. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power supply for |

For use of the brake, see "Holding Brake" in App. 6. |

|

|

|

|

|

DC |

||

|

|

|

|

|

|||

|

|

|

|

|

elector magnetic brake |

|

|

|

|

|

|

|

24V |

(Min, 0.5A) |

Install a surge absorber. |

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

- 22 -

CN SIG Connector (For Encoder)

Wiring Instructions

|

POWER |

Power |

ALARM |

RS232C |

|

|

GAIN |

|

CN |

|

I/F |

|

CN |

|

POWER |

|

CN |

Motor |

SIG |

Encoder min.30cm |

|

|

CN |

|

MOTOR |

|

max.20m |

Wiring Diagrams

172171-1 |

|

172163-1 |

|

|

|

tyco Electronics AMP |

|

tyco Electronics AMP |

|

|

|

|

|

|

|

CN SIG |

|

Yellow |

Z |

5 |

11 |

Z |

|

|

|

|

|||

Orange |

Z |

6 |

12 |

Z |

|

Yellow |

3 |

9 |

|||

Green |

B |

B |

|||

Blue |

4 |

10 |

|||

B |

B |

||||

Red |

1 |

7 |

|||

A |

A |

||||

Pink |

|

8 |

|||

A |

2 |

A |

|||

|

|

|

|||

Light |

|

11 |

17 |

|

|

Blue |

RX |

RX |

|||

Purple |

12 |

18 |

|||

RX |

RX |

||||

|

|

|

|||

|

|

|

|

||

White |

+5V |

13 |

3 |

+5V |

|

Black |

0V |

14 |

1 |

0V |

|

|

|

4 |

|||

|

|

|

+5V |

||

|

|

|

2 |

||

|

|

|

0V |

||

|

|

15 |

20 |

||

|

FG |

FG |

|||

|

|

|

|||

Moter side |

Connecting cable |

|

Driver side |

||

The cable length between the amplifier and motor should be max. 20 m. If you use a longer cable, contact the dealer or sales agent.

Separate these wiring min. 30 cm from the main circuit wires. Don't lay these wires in the same duct of the mains or bundle with them.

When you prepare your own connecting cables see the "Optional Parts" for connectors, and

1)Follow the wiring diagram and use the

2)Wire material: 0.18 mm2 (AWG24) or more, shielded twist-paired wire Å@with an enough bending durability,

3)Signal/power paired wires should be of a twist-paired type.

4)Shield:

•The shield at the amplifier side should be

connected to Pin 20 (FG) of CN SIG Connector.

•The shield at the motor side should be connected to: connector of 15 pins type

5)If the cable is longer than 10 m, the encoder power line (+5V and 0V) should be dual per the figure shown left.

6)Other terminals should be left unconnected.

Adjustment and Preparations

- 23 -

System Configuration and Wiring

CN SER Connector

For RC232C communications

Connect a personal computer to the amplifier with RS232C at 1:1, and use the communication control software "PANATERM“" (Option). Operate "PANATERM“" on the personal computer. Convenient functions of high operability can be obtained such as monitor and parameter setting and setting change and waveform graphic display.

Connection

MSDS STATUS

ALM CODE

GAIN

CN

SER

CN

I/F

Exclusive |

|

|

|

|

|

Insert and pull out connector |

|

Personal |

after cutting power to both |

||||

connection cable |

|

|||||

|

computer |

personal computer and |

||||

(Option) |

|

|||||

|

|

|

|

|

amplifier |

|

See App. 44. |

|

|

|

|

|

Securely tighten the fixing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

screw |

|

|

|

|

|

|

|

CN SER |

|

|

|

|

|

RS232C connector |

- 24 -

List of Available Components

CN I/F Connector (For Controller)

Wiring Instructions

max.3 m

Controller

min.30 cm

Power supply

Motor

COM+ |

1 |

|

2 |

|

GND |

VDC

Place the peripheral devices such as the controller max. 3 m away from the amplifier.

Separate these wiring min. 30 cm from the main circuit wires. Don't lay these wires in the same duct of the mains or bundle with them.

Thecontrolpower(VDC)betweenCOM+andCOM-should be supplied by the customer (recommended voltage: +12VDC to +24VDC).

Use a shielded twist-paired type for the wiring of pulse input, encoder signal output, etc.

Do not apply power higher than 24V or 50mA to control signal output terminal.

COM-

FG

CN I/F

If you directly activate a relay using the control signal,install a diode in parallel to the relay as shown in the left figure. Without a diode or with it but placed in the opposite direction, the amplifier will be damaged.

The Frame Ground (FG) is connected to an earth terminal in the amplifier.

• CN I/F Connector Specifications

Receptacle on the |

Connector to controller side |

|

Manufacturer |

|

amplifier side |

Part description |

Part No. |

|

|

|

|

|||

1 0 2 2 6 - 5 2 A 2 J L |

Solder type plug (Soldering type) |

1 0 1 2 6 - 3 0 0 0 V E |

Sumitomo |

|

|

Connector cover |

1 0 3 2 6 - 5 2 A 0 |

- 0 0 8 |

three M |

• The CN I/F pins assignment is shown in "Optional Parts" in Appendix.

- 25 -

Adjustments and Preparations

System configutration and wiring

Circuits Available for Typical Control Modes

• CN I/F Wiring for Position Control

|

|

|

Command pulseinput |

|

|

|

A-phase |

output |

B-phase |

output |

Z-phase |

output |

|

|

anopencollectorI/F, |

inpage33. |

|

|

|

|

|

|

330Ω |

330Ω |

330Ω |

|

|||

Ifthisis |

seeP1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22 |

23 |

24 |

25 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

|

|

|

PULS1 |

PULS2 |

SIGN1 |

|

SIGN2 |

GND |

OA+ |

OA- |

OB+ |

OB- |

OZ+ |

OZ- |

|

|

|

|

Ω220 |

|

Ω220 |

|

|

|

|

|

|

|

||

|

Ω4.7k |

|

|

|

|

|

|

Scaler |

|

|

|

|

|

|

|

COM+ |

SRV-ON |

A-CLR |

CL |

|

GAIN |

DIV |

CWL |

CCWL |

|

ALM |

|

COIN |

BRKOFF |

|

1 |

2 |

3 |

4 |

|

5 |

6 |

7 |

8 |

9 |

10 |

11 |

||

|

|

Servo-ON |

Alarmclear |

Positionerrorcounterclear |

|

2ndgainswitching |

Commandpulsescalerswitch |

CWovertravelinhibit |

CCWovertravelinhibit |

Servoalarm |

In-position |

Mechanicalbrakerelease |

||

|

|

|

|

VDC |

12~24V |

|

|

|

|

|

|

|

|

|

- 26 -

21 Z-phase output (open collector)

CZ

CN I/F

WARN |

COM- |

FG |

12 |

13 |

26 |

Alarm |

(Pr09) |

CN MON

CN MON

Velocity monitor output Torque monitor output

Monitorpin |

Monitorpin |

|

1 |

2 |

3 |

SPM |

IM |

GND |

1K |

1K |

|

|

|

|

|

|

|

A-phase |

output |

B-phase output |

|

Z-phase |

output |

|

|

|

|

|

|

|

|

|

|

|

|

330Ω |

|

330Ω |

|

330Ω |

|

|

|

(opencollector) |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z-phaseoutput |

|

|

22 |

23 |

24 |

25 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

|

|

|

21 |

CNMON |

|

|

PULS1 |

PULS2 |

SIGN1 |

SIGN2 |

GND |

OA+ |

OA- |

OB+ |

OB- |

OZ+ |

OZ- |

|

|

|

CZ |

||

|

|

|

Ω220 |

Ω220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ω4.7k |

|

|

|

|

Scaler |

|

|

|

|

|

|

|

|

|

|

CNI/F |

COM+ |

SRV-ON |

A-CLR |

INTSPD2 |

ZEROSPD |

INTSPD1 |

CWL |

CCWL |

|

ALM |

|

COIN |

BRKOFF |

WARN |

COM- |

FG |

||

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

10 |

|

11 |

12 |

|

13 |

26 |

|

InternalforWiringVelocityControl |

Servo-ON |

Alarmclear |

Internalvel.cmnd.select2 |

VDC |

12~24V |

CWovertravelinhibit |

CCWovertravelinhibit |

Servoalarm |

|

At-speed |

|

Mechanicalbrakerelease |

Alarm |

(Pr09) |

|

||

|

|

|

|

Speedclampzero |

.cmnd.selectInternalvel1 |

|

|

|

|

|

|

|

|

|

|

|

|

•CNI/F |

|

|

|

|

|

|

|

|

|

|

|

|

- 27 - |

|

|

|

|

Velocitymonitor output |

Torquemonitor output |

|

Monitorpin |

Monitorpin |

1 |

2 |

3 |

SPM |

IM |

GND |

1K |

1K |

|

Adjustments and Preparations

System configuration and wiring

CN I/F Connector

Input Signals (Common) and their Functions

Signal |

Pin |

|

Symbol |

|

Function |

|

I / F |

||

No. |

|

|

circuit |

||||||

|

|

|

|

|

|||||

Control signal |

1 |

|

COMÅ{ |

• Connect to (+) of an external power supply(12VDC to 24VDC). |

Å\Å\ |

||||

power (+) |

|

|

|

• Use power supply of 12V±10%Å`24V±10% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Control signal |

1 3 |

|

C O M Å | |

• Connect to (-) of an external power supply(12VDC to 24VDC). |

|

|

|

|

|

power (-) |

|

|

|

•The required capacity depends on the I/O circuit configuration. |

|

|

|

|

|

|

|

|

|

|

0.5A or larger is recommended. |

|

|

|

|

Servo-ON |

2 |

|

SRV-ON |

• When this signal is connected to COM-, the dynamic brake will be |

|

|

|

|

|

|

|

SI |

|

||||||

|

<Notes> |

|

released and the amplifier is enabled. (Servo-ON). |

page 33 |

|||||

|

1. This signal becomes effective about two seconds after power on |

|

|

|

|

||||

|

(see the Timing chart). |

|

|

|

|

||||

|

2. Don't use this Servo-ON or Servo-OFF signal to turn on or off the |

|

|

|

|

||||

|

motor. (See App.8) |

|

|

|

|

||||

|

• Allow at least 100ms delay after the amplifier is enabled before any |

|

|

|

|

||||

|

command input is entered. |

|

|

|

|

||||

|

• By opening the connection to COM- , the amplifier will be disabled(Servo-OFF) and |

|

|

|

|

||||

|

the |

current flow to the motor will be inhibited. |

|

|

|

|

|||

|

• Operation of the dynamic brake and clearing action of the position error counter can be |

|

|

|

|

||||

|

selected using Pr69 (Sequence under Servo-OFF). |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alarm |

3 |

|

A-CLR |

• If the COMconnection is kept closed for more than 120 ms, |

|

SI |

|

||

clear |

|

|

|

|

the alarm status will be cleared. |

page 33 |

|||

|

|

|

|

• Some alarms cannot be cleared by this input. |

|

|

|

|

|

|

|

|

|

|

For details, see Protective Functions on page 60. |

|

|

|

|

|

|

|

|

|

|

|

|

||

Position error |

4 |

|

C L / |

The function differs depending on the control mode. |

|

SI |

|

|

|

counter |

|

|

INTSPD2 |

|

|

page 33 |

|||

clear/Internal |

|

|

|

|

|

|

|

|

|

|

|

Position |

|

• Clears the position error counter. Connect to COM- |

|

|

|||

command |

|

|

|

|

|

||||

|

|

control |

|

to clear the counter. |

|

|

|

|

|

velocity |

|

|

|

|

|

|

|

||

|

|

|

|

• Use Pr4D to select the clear mode (0 Default: level 1: Edge) |

|

|

|

|

|

selection 2 |

|

|

|

|

|

|

|

|

|

|

|

Internal |

|

• The internal velocity selection 2 (input) is valid. 4 kinds of |

|

|

|||

|

|

|

|

|

|

||||

|

|

|

velocity |

|

velocity settings are available by combination with DIV/ |

|

|

||

|

|

|

control |

|

INTSPD1 input. See control mode setting Pr02 (APP. 16). |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 28 -

Signal |

|

Pin |

Symbol |

|

|

|

Function |

|

I / F |

|

|

||||||||

|

No. |

|

|

|

circuit |

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|