Omega LV800 User Manual

User’sGuide

User’sGuide

online at

omega.com

info@omega.com product manuals: omegamanual.info

LV800 SERIES

Capacitance Point Level Sensors

|

|

|

|

|

|

OMEGAnet® Online Service |

|

Internet e-mail |

|

|

|

omega.com |

|

info@omega.com |

|

|

Servicing North America: |

||

U.S.A.: |

One Omega Drive, P.O. Box 4047 |

|

||

ISO 9001 Certified |

Stamford, CT 06907-0047 |

|

||

|

|

TEL: (203) 359-1660 |

FAX: (203) 359-7700 |

|

Canada: |

e-mail: info@omega.com |

|

||

976 Bergar |

|

|||

|

|

Laval (Quebec) H7L 5A1, Canada |

|

|

|

|

TEL: (514) 856-6928 |

FAX: (514) 856-6886 |

|

|

|

e-mail: info@omega.ca |

|

|

For immediate technical or application assistance: |

||

U.S.A. and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA® |

||

|

Customer Service: 1-800-622-2378 / 1-800-622-BEST® |

|

|

Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN® |

|

|

TELEX: 996404 EASYLINK: 62968934 |

CABLE: OMEGA |

Mexico: |

En Espan˜ol: (001) 203-359-7803 |

e-mail: espanol@omega.com |

|

FAX: (001) 203-359-7807 |

info@omega.com.mx |

|

Servicing Europe: |

|

Benelux: |

Postbus 8034, 1180 LA Amstelveen, The Netherlands |

|

|

TEL: +31 (0)20 3472121 |

FAX: +31 (0)20 6434643 |

|

Toll Free in Benelux: 0800 0993344 |

|

Czech Republic: |

e-mail: sales@omegaeng.nl |

|

Frystatska 184, 733 01 Karviná, Czech Republic |

||

|

TEL: +420 (0)59 6311899 |

FAX: +420 (0)59 6311114 |

France: |

Toll Free: 0800-1-66342 |

e-mail: info@omegashop.cz |

11, rue Jacques Cartier, 78280 Guyancourt, France |

||

|

TEL: +33 (0)1 61 37 2900 |

FAX: +33 (0)1 30 57 5427 |

|

Toll Free in France: 0800 466 342 |

|

Germany/Austria: |

e-mail: sales@omega.fr |

|

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany |

||

|

TEL: +49 (0)7056 9398-0 |

FAX: +49 (0)7056 9398-29 |

|

Toll Free in Germany: 0800 639 7678 |

|

United Kingdom: |

e-mail: info@omega.de |

|

One Omega Drive, River Bend Technology Centre |

||

ISO 9002 Certified |

Northbank, Irlam, Manchester |

|

|

M44 5BD United Kingdom |

|

|

TEL: +44 (0)161 777 6611 |

FAX: +44 (0)161 777 6622 |

|

Toll Free in United Kingdom: 0800-488-488 |

|

|

e-mail: sales@omega.co.uk |

|

It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, human applications.

1

LV 8 0 0 S E R I E S

This manual contains the information necessary to ensure a safe and successful installation. Please read and comply with the section on page 9 of this manual pertaining to SAFETY. Doing so will ensure proper operation of the equipment and the safety of all personnel.

Before discarding shipping container, please inspect it thoroughly and verify that all parts ordered are accounted for. Sometimes smaller parts become stuck under carton flaps and other packaging materials.

2

P R E - I N S TA L L AT I O N C O N S I D E R AT I O N S

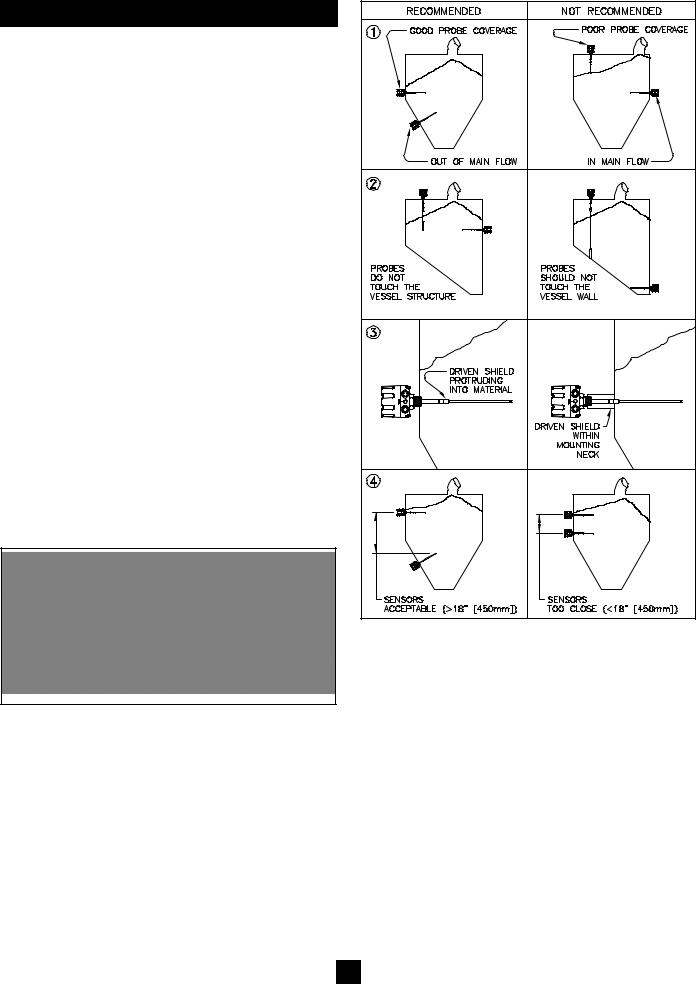

Choosing a Location: (See Figure 2)

1)Material Flow - When selecting a location for the LV800, choose a point in the vessel where the probe will be out of

the direct flow of incoming and outgoing material to prevent any mechanical damage that may be caused by the pressure of the flow. The LV800 must be positioned at a point where incoming material will reach and cover the probe in its normal flow, and when receding, will flow away from the probe in an even manner. For best results, choose a position where a majority of the probe, not just the tip, will be covered. This is particularly important when detecting materials with low relative dielectric constants and low product densities. The unit will not operate as a “tip sensitive” device. For extended length models, allow for at least 8 to 12 inches (203-305 mm) of probe coverage. When sensing highly conductive materials, or those with a high dielectric constant, the LV800 can perform as a “tip sensitive” sensor.

2)Vessel Contact - Select an area where the probe can not contact any internal structure elements of the vessel.

3)Driven Shield Penetration - Select a location which ensures that the driven shield section protrudes into the vessel and is not recessed in the mounting neck.

4)Multiple Probe Proximity - If more than one sensor is

mounted in the vessel, do not place the sensors closer than 18 inches (457 mm) from one another.

Cover Removal: (See Figure 1)

Before loosening the cover, loosen or remove the cover lock screw. Spanner slots are incorporated on the top of the cover which should be used to loosen the cover from the housing. Use a flat bar for initial loosening. DO NOT use a strap or chain type wrench. Keep hands clear of threads on the cover and housing to avoid contact with the thread lubricant.

Figure 2

Figure 1

3

Loading...

Loading...