Omega CNiS8DH, CNiS8DV, CNiS16D, CNiS32, CNiS8C User Manual

...

MADE IN |

User’sGuide |

|

|

USA |

|

Shop on line at

®

®

®

omega.com e-mail: info@omega.com iSeries info: omega.com/specs/iseries For latest product manuals omegamanual.info

Process/Strain Gauge Controller Manual

CNiS8, CNiS8C,

CNiS8DH, CNiS8DV,

CNiS16, CNiS16D, CNiS32

|

|

|

|

® |

|

|

® |

|

|

|

|

|

|

|

|

OMEGAnet® On-Line Service |

|

Internet e-mail |

|

|

|

www.omega.com |

|

info@omega.com |

|

|

|

|

|

|

|

Servicing North America: |

||

USA: |

One Omega Drive, P.O. Box 4047 |

|||

ISO 9001 Certified |

Stamford CT 06907-0047 |

|

||

|

|

TEL: (203) 359-1660 |

FAX: (203) 359-7700 |

|

|

|

e-mail: info@omega.com |

|

|

Canada: |

976 Bergar |

|

||

|

|

Laval (Quebec) H7L 5A1 |

|

|

|

|

TEL: (514) 856-6928 |

FAX: (514) 856-6886 |

|

|

|

e-mail: info@omega.ca |

|

|

For immediate technical or application assistance:

USA and Canada: Sales Service: 1-800-826-6342 / 1-800-TC-OMEGA® Customer Service: 1-800-622-2378 / 1-800-622-BEST® Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN®

Mexico and |

TEL: (001) 203-359-7803 |

FAX: (001) 203-359-7807 |

Latin America: |

e-mail: espanol@omega.com |

|

Servicing Europe:

Benelux: |

TEL: +31 20 3472121 |

FAX: +31 20 6434643 |

|

Toll Free in Benelux: 0800 0993344 |

|

|

e-mail: sales@omegaeng.nl |

|

Czech Republic: |

Frystatska 184, 733 01 Karviná |

|

|

TEL: +420 59 6311899 |

FAX: +420 59 6311114 |

|

e-mail: info@omegashop.cz |

|

France: |

TEL: +33 1 61 37 29 00 |

FAX: +33 1 30 57 54 27 |

|

Toll Free in France: 0800 466 342 |

|

|

e-mail: sales@omega.fr |

|

Germany/Austria: |

Daimlerstrasse 26, D-75392 Deckenpfronn, Germany |

|

|

TEL: +49 7056 9398-0 |

FAX: +49 7056 9398-29 |

|

Toll Free in Germany: 0800 639 7678 |

|

|

e-mail: info@omega.de |

|

United Kingdom: |

One Omega Drive |

|

ISO 9001 Certified |

River Bend Technology Centre |

|

|

Northbank, Irlam Manchester M44 5BD United Kingdom |

|

|

TEL: +44 161 777 6611 |

FAX: +44 161 777 6622 |

|

Toll Free in England: 0800 488 488 |

|

|

e-mail: sales@omega.co.uk |

|

It is the policy of OMEGA to comply with all worldwide safety and EMC/EMI regulations that apply.

OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.

The information contained in this document is believed to be correct but OMEGA Engineering, Inc. accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.

WARNING: These products are not designed for use in, and should not be used for, patient connected applications.

!This device is marked with the international caution symbol. It is important to read the Setup Guide before installing or commissioning this device as it contains important information relating to safety and EMC.

TABLE OF CONTENTS

Part 1: Introduction............................................................................................ |

|

2 |

1.1 |

Description ................................................................................. |

2 |

1.2 |

Safety Considerations ............................................................... |

3 |

1.3 |

Before You Begin ....................................................................... |

4 |

Part 2: Setup |

|

5 |

2.1 ................................................................................. |

Front Panel |

5 |

2.2 ............................................................ |

Rear Panel Connections |

5 |

2.3 ................................................................. |

Electrical Installation |

7 |

........................................................ |

Power Connections |

7 |

............................................................. |

Process Current |

8 |

.............................................................. |

Process Voltage |

8 |

................................................................... |

Strain Gauge |

9 |

................................. |

Wiring Outputs - Wiring Hookup |

10 |

Part 3: Operation: .........................................................Configuration Mode |

13 |

|

3.1 .............................................................................. |

Introduction |

13 |

|

Turning your Instrument On for the First Time |

|

|

Buttons Functions in Configuration Mode |

|

3.2 ................................................................ |

Menu Configuration |

14 |

..................................................................... |

ID Number |

15 |

........................................................... |

Set Points Menu |

16 |

.................................................... |

Configuration Menu |

17 |

........................................................... |

Input Type Menu |

17 |

..................................... |

Reading Configuration Menu |

19 |

.................... |

Input/Reading (Scale and Offset) Menu |

22 |

................................................................ |

Alarm 1 Menu |

26 |

...................... |

Analog Output (Retransmission) Menu |

30 |

................................................................ |

Alarm 2 Menu |

33 |

................................................ |

Loop Break Time Menu |

34 |

.............................................................. |

Output 1 Menu |

36 |

.............................................................. |

Output 2 Menu |

43 |

.................................................. |

Ramp and Soak Menu |

46 |

............................................................... |

ID Code Menu |

48 |

..................................... |

Communication Option Menu |

50 |

..................................... |

3.2.16 Display Color Selection Menu |

56 |

Part 4: Specifications ...................................................................................... |

59 |

|

Part 5: Factory .........................................................................Preset Values |

62 |

|

CE APPROVAL .......................................................................INFORMATION |

64 |

|

i

|

LIST OF FIGURES: |

|

Figure 2.1 |

Front Panel Display ..................................................................... |

5 |

Figure 2.2 |

Rear Panel Power and Output Connections ............................. |

5 |

Figure 2.3 |

Rear Panel Input Connections ................................................... |

6 |

Figure 2.4 |

Main Power Connections............................................................ |

7 |

Figure 2.5 |

Process Current Wiring Hookup ................................................ |

8 |

|

Process Voltage |

|

Figure 2.6 |

a) Process Voltage with Sensor Excitation ........................... |

8 |

|

b) Process Voltage without Sensor Excitation ..................... |

8 |

|

Strain Gauge |

|

Figure 2.7 |

a) 4-Wire Voltage Input with Internal Excitation.................... |

9 |

|

b) 4-Wire Bridge Input with External Excitation.................... |

9 |

Figure 2.8 |

a) 6-Wire Voltage Input with Internal Excitation.................... |

9 |

|

b) 6-Wire Bridge Input with External Excitation.................... |

9 |

Figure 2.9 |

4-Wire Voltage Input with Internal Excitation.......................... |

10 |

|

Wiring Outputs |

|

Figure 2.10 |

a) Mechanical Relay and SSR Outputs Wiring Hookup ..... |

10 |

|

b) Pulse and Analog Outputs Wiring Hookup ..................... |

10 |

Figure 2.11 |

Snubber Circuits Wiring Hookup ............................................. |

10 |

Figure 2.12 |

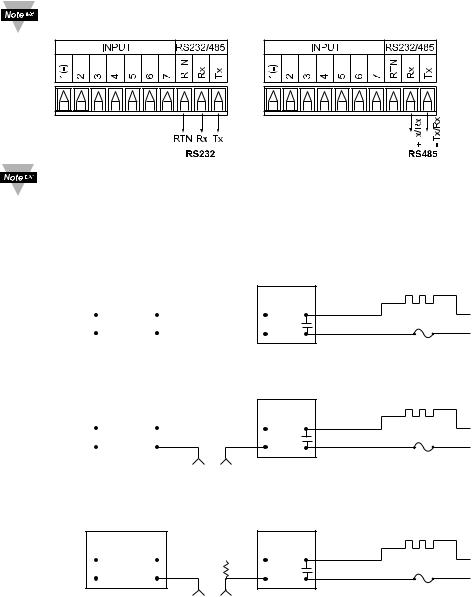

a) RS-232 Output Wiring Hookup ......................................... |

11 |

|

b) RS-485 Outputs Wiring Hookup ....................................... |

11 |

Figure 2.13 |

Typical Applications .................................................................. |

12 |

Figure 2.14 |

a) Excitation Outputs ............................................................ |

12 |

|

b) Top View Location of S2 ................................................... |

12 |

|

c) Top View Location of S2 on 1/8 DIN Compact Unit ........... |

12 |

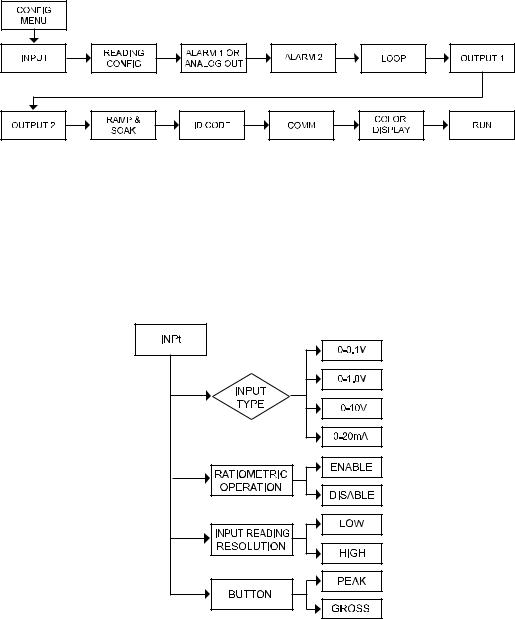

Figure 3.1 |

Flow Chart for ID and Setpoints Menu .................................... |

14 |

Figure 3.2 |

Flow Chart for Configuration Menu ......................................... |

17 |

Figure 3.3 |

Flow Chart for Input Type Menu............................................... |

17 |

Figure 3.4 |

Flow Chart for Reading Configuration Menu .......................... |

19 |

Figure 3.5 |

Flow Chart for Alarm 1 Menu.................................................... |

26 |

Figure 3.6 |

Flow Chart for Analog Output (Retransmission) Menu.......... |

30 |

Figure 3.7 |

Flow Chart for Alarm 2 Menu.................................................... |

33 |

Figure 3.8 |

Flow Chart for Loop Break Time Menu.................................... |

34 |

Figure 3.9 |

Flow Chart for Output 1 Menu .................................................. |

36 |

Figure 3.10 |

Flow Chart for Output 2 Menu .................................................. |

43 |

Figure 3.11 |

Flow Chart for Ramp and Soak Menu...................................... |

46 |

Figure 3.12 |

Flow Chart for ID Code Menu ................................................... |

48 |

Figure 3.13 |

Flow Chart for Communication Option Menu ......................... |

50 |

Figure 3.14 |

Flow Chart for Display Color Selection Menu......................... |

56 |

|

LIST OF TABLES: |

|

Table 2.1 |

Front Panel Display ..................................................................... |

5 |

Table 2.2 |

Rear Panel Connector ................................................................. |

6 |

Table 2.3 |

Fuse Requirements ..................................................................... |

7 |

Table 2.4 |

Jumper Connections................................................................. |

12 |

Table 3.1 |

Button Function in Configuration Mode.................................. |

13 |

Table 3.2 |

Conversion Table....................................................................... |

23 |

Table 3.3 |

Input Resolution Multiplier ....................................................... |

23 |

Table 5.1 |

Factory Preset Values ............................................................... |

62 |

ii

NOTES, WARNINGS and CAUTIONS

Information that is especially important to note is identified by following labels:

•NOTE

•WARNING or CAUTION

•IMPORTANT

•TIP

NOTE: Provides you with information that is important to successfully setup and use the Programmable Digital Meter.

CAUTION or WARNING: Tells you about the risk of electrical shock.

CAUTION, WARNING or IMPORTANT: Tells you of circumstances or practices that can effect the instrument’s functionality and must refer to accompanying documents.

TIP: Provides you helpful hints.

1

PART 1

INTRODUCTION

1.1 Description

This device can be purchased as monitor (read process value only) or as

acontroller.

•The i Series Strain and Process controllers can measure a wide variety of DC voltage and current inputs for all common load cells, pressure transducers and strain gauge type of transducer. It offers unparalleled flexibility in process control. The voltage /current inputs are fully scaleable to virtually all engineering units, with selectable decimal point, perfect for use with pressure, flow or other process input.

•The process control can be achieved by using on/off or PID control strategy. Control can be optimized with an Auto Tune feature. The controller offers a ramp to set point with timed soak period before switching off the output.

•The i Series controller features a large, three color programmable display with capability to change a color every time when Alarm is triggered. The standard features include dual outputs with relay, SSR, DC pulse, analog voltage or current, built-in excitation for transducers, selectable as

10V @ 60 mA or 5 V @ 40 mA. Analog output is fully scaleable and may be configured as a proportional controller or retransmission to follow your display. Universal power supply accepts 90 to 240. Low voltage power option accepts 24 Vac or 12 to 36 Vdc.

•Options include programmable RS-232 or RS-485 serial communication and ethernet with an embedded web server.

2

1.2 Safety Considerations

This device is marked with the international caution symbol. It is important to read this manual before installing or commissioning this device as it contains important information relating to Safety and EMC (Electromagnetic Compatibility).

This instrument is a panel mount device protected in accordance with EN 61010-1:2001, electrical safety requirements for electrical equipment for measurement, control and laboratory. Installation of this instrument should be done by qualified personnel. In order to ensure safe operation, the following instructions should be followed.

This instrument has no power-on switch. An external switch or circuitbreaker shall be included in the building installation as a disconnecting device. It shall be marked to indicate this function, and it shall be in close proximity to the equipment within easy reach of the operator. The switch or circuit-breaker shall not interrupt the Protective Conductor (Earth wire), and it shall meet the relevant requirements of IEC 947–1 and IEC 947-3 (International Electrotechnical Commission). The switch shall not be incorporated in the main supply cord.

Furthermore, to provide protection against excessive energy being drawn from the main supply in case of a fault in the equipment, an overcurrent protection device shall be installed.

•Do not exceed voltage rating on the label located on the top of the instrument housing.

•Always disconnect power before changing signal and power connections.

•Do not use this instrument on a work bench without its case for safety reasons.

•Do not operate this instrument in flammable or explosive atmospheres.

•Do not expose this instrument to rain or moisture.

•Unit mounting should allow for adequate ventilation to ensure instrument does not exceed operating temperature rating.

•Use electrical wires with adequate size to handle mechanical strain and power requirements. Install without exposing bare wire outside the connector to minimize electrical shock hazards.

EMC Considerations

•Whenever EMC is an issue, always use shielded cables.

•Never run signal and power wires in the same conduit.

•Use signal wire connections with twisted-pair cables.

•Install Ferrite Bead(s) on signal wires close to the instrument if EMC problems persist.

Failure to follow all instructions and warnings may result in injury!

3

1.3 Before You Begin

Inspecting Your Shipment:

Remove the packing slip and verify that you have received everything listed. Inspect the container and equipment for signs of damage as soon as you receive the shipment. Note any evidence of rough handling in transit. Immediately report any damage to the shipping agent. The carrier will not honor damage claims unless all shipping material is saved for inspection. After examining and removing the contents, save the packing material and carton in the event reshipment is necessary.

Customer Service:

If you need assistance, please call the nearest Customer Service Department, listed in this manual.

Manuals, Software:

The latest Operation and Communication Manual as well as free configuration software and ActiveX controls are available at the website listed on the cover page of this manual or on the CD-ROM enclosed with your shipment.

For first-time users: Refer to the QuickStart Manual for basic operation and set-up instructions.

If you have the Serial Communications/Ethernet Option you can easily configure the controller on your computer or on-line.

To Disable Outputs:

To ensure that menu changes are properly stored, Standby Mode should be used during setup of the instrument. During Standby Mode, the instrument remains in a ready condition, but all outputs are disabled. Standby Mode is useful when maintenence of the system is necessary.

When the instrument is in "RUN" Mode, push d twice to disable all outputs and alarms. It is now in "STANDBY" Mode. Push d once more to resume "RUN" Mode.

PUSH d TWICE to disable the system during an EMERGENCY.

To Reset the Meter:

When the controller is in the "MENU" Mode, push c once to direct controller one step backward of the top menu item.

Push c twice to reset controller, prior to resuming "Run" Mode except after "Alarms", that will go to the "Run" Mode without resetting the controller.

4

PART 2

SETUP

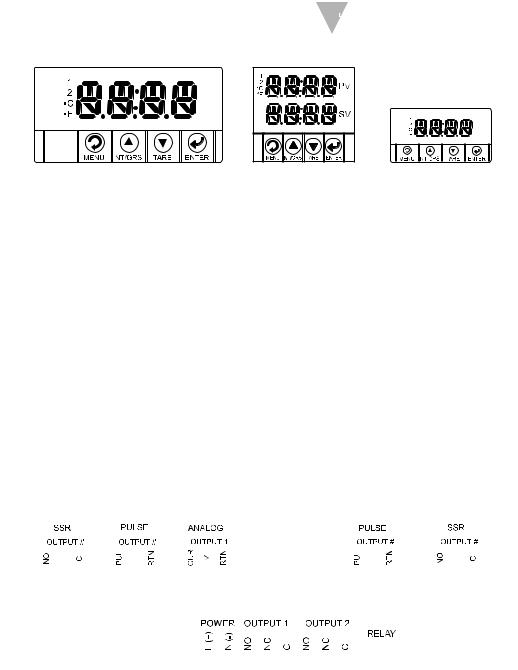

2.1 Front Panel

1/8 DIN

Refer to the Quick Start  Guide for assembly and

Guide for assembly and

disassembly instructions.

1/16 DIN |

1/32 DIN |

|

Figure 2.1 Front Panel Display |

Table 2.1 Front Panel Annunciators |

|

|

|

1 |

Output 1/Setpoint 1/ Alarm 1 indicator |

2 |

Output 2/Setpoint 2/ Alarm 2 indicator |

a/MENU |

Changes display to Configuration Mode and advances |

|

through menu items* |

b/PK/GRS |

Used in Program Mode and Peak or Gross Recall* |

c/TARE |

Used in Program Mode and to tare your reading* |

d/ENTER |

Accesses submenus in Configuration Mode and stores |

|

selected values* |

*See Part 3 Operation: Configuration Mode

2.2Rear Panel Connections

The rear panel connections are shown in Figures 2.2 and 2.3.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

5 |

4 |

|

6 |

|

5 |

4 |

|

6 |

5 |

4 |

|

|

|

|

|

|

|

|

|

3 |

|

2 |

1 |

|

|

3 |

2 |

1 |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 7 6 5 4 3 2 1

Figure 2.2 Rear Panel Power and Output Connections

5

Figure 2.3 Rear Panel Input Connections

Table 2.2 Rear Panel Connector

POWER AC/DC Power Connector: All models

INPUT Input Connector:

All models PR (Process) / ST (Strain)

OUTPUT 1 Based on one of the following models: Relay SPDT

Solid State Relay Pulse

Analog Output (Voltage and Current)

OUTPUT 2 Based on one of the following models: Relay SPDT

Solid State Relay Pulse

OPTION Based on one of the following models: RS-232C or RS-485 programmable Excitation

6

2.3 Electrical Installation

2.3.1Power Connections

Caution: Do not connect power to your device until you have completed all input and output connections. Failure to do so may result in injury!

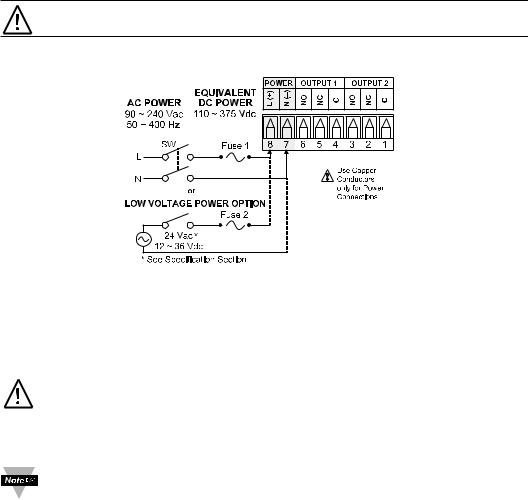

Connect the main power connections as shown in Figure 2.4.

Figure 2.4 Main Power Connections

Table 2.3 Fuse Requirements

FUSE |

Connector |

Output Type |

For 115 Vac |

For 230 Vac |

DC |

FUSE 1 |

Power * |

N/A |

100 mA(T) |

100 mA(T) |

100 mA(T) |

FUSE 2 |

Power * |

N/A |

N/A |

N/A |

400 mA(T) |

For the low voltage power option, in order to maintain the same degree of protection as the standard high voltage input power units (90 - 240 Vac), always use a Safety Agency Approved DC or AC source with the same Overvoltage Category and pollution degree as the standard AC unit (90 - 240 Vac).

The Safety European Standard EN61010-1 for measurement, control, and laboratory equipment requires that fuses must be specified based on IEC127. This standard specifies for a Time-lag fuse, the letter code “T”. The above recommended fuses are of the type IEC127-2-sheet III. Be aware that there are significant differences between the requirements listed in the UL 248-14/CSA 248.14 and the IEC 127 fuse standards. As a result, no single fuse can carry all approval listings. A 1.0 Amp IEC fuse is approximately equivalent to a 1.4 Amp UL/CSA fuse. It is advised to consult the manufacturer’s data sheets for a cross-reference.

7

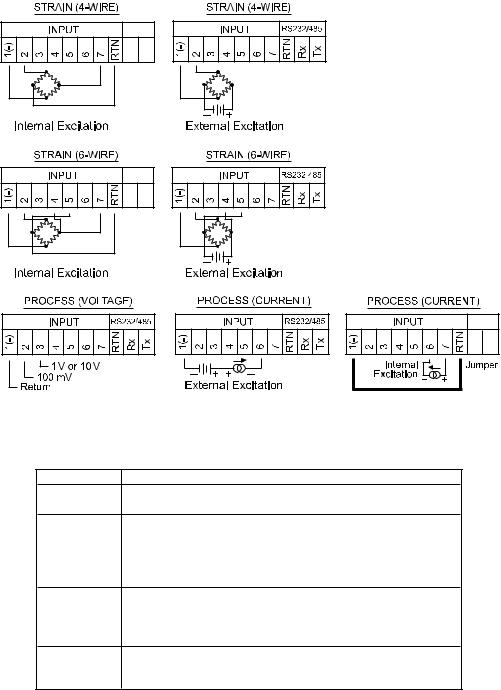

2.3.2 Process Current

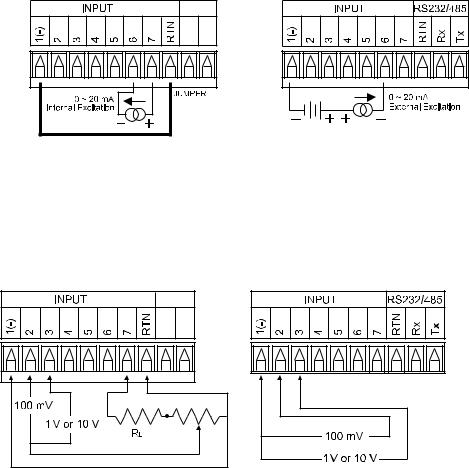

The figure below shows the wiring hookup for Process Current 0 – 20 mA.

Figure 2.5 Process Current Wiring Hookup

(Internal and External Excitation)

2.3.3 Process Voltage

The figure below shows the wiring hookup for Process Voltage 0 – 100 mV, 0 – 1 V, 0 – 10 V.

Figure 2.6

a)Process Voltage Wiring Hookup with Sensor Excitation

b)Process Voltage Wiring Hookup without Sensor Excitation

RL - Voltage limited resistor, which allows to convert 24 Vdc internal excitation voltage to the appropriate process input value. For instance: if the potentiometer value is equal to 10 kΩ, the minimum RL is 14 kΩ for 10 V process input.

When configuring your instrument, select Process Type in the Input Type Menu (see Part 3).

8

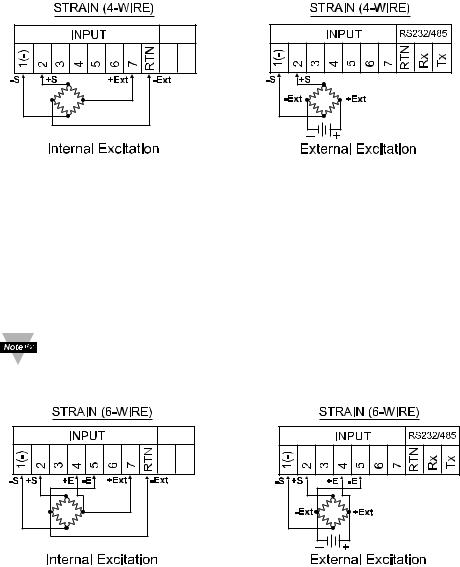

2.3.4 Strain Gauge

The figure below shows the wiring hookup for 4-wire bridge input.

Figure 2.7

a)4-Wire Voltage/Bridge Input with Internal Excitation Wiring Hookup

b)4-Wire Bridge Input with External Excitation Wiring Hookup

In 4-Wire connections the voltage drop across long excitation lead wires of strain gauge bridge may cause measurement errors. The output of a strain gauge bridge also depends on the stability of excitation voltage. To correct for voltage drop and changes in excitation voltage, 6-wire input configuration and ratio measurement are used.

In order for the Ratiometric to work properly, the External Excitation should not drop below 4.6 Vdc.

The figure below shows 6-wire hookup for 6-wire bridge input.

Figure 2.8

a)6-Wire Bridge Input with Internal Excitation and Ratio Measurement Wiring Hookup

b) 6-Wire Bridge Input with External Excitation and Ratio Measurement Wiring Hookup

9

2.3.4 Strain Gauge (continued)

The figure below shows Voltage (bridge with amplified output) input with internal excitation.

Where:

+S: signal plus -S: signal return

+Ext: excitation plus -Ext: excitation return +E: plus excitation sense

-E: minus excitation sense.

2.3.5 Wiring Outputs

Figure 2.9

4-Wire Voltage Input (Bridge

withAmplified Output)

with Internal Excitation.

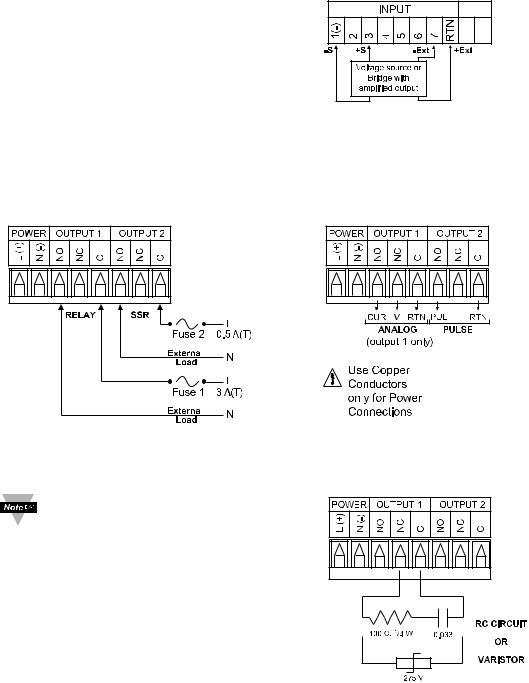

This meter has two, factory installed, outputs. The SPDT Mechanical Relay, SPST Solid State Relay, Pulse and Analog Output Connection are shown below.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2.10 a) Mechanical Relay and SSR |

b) Pulse and Analog |

||||||

|

Outputs Wiring Hookup |

Outputs Wiring Hookup |

|||||

|

|

|

|

|

|

|

|

This device has snubber circuits designed to protect the contacts of the

mechanical relays when it switches inductive loads (i.e. solenoids, relays). These snubbers are internally connected between the Common (C) and Normally Open (NO) relay contacts of Output 1 and Output 2.

If you have an inductive load connected between Common (C) and Normally Closed (NC) contacts of the mechanical relays and you want to protect them from the rush current during the switching period, you have to connect an external snubber circuit between Common

(C) and Normally Closed (NC) contacts as indicated in the figure below.

Figure 2.11 Snubber

Circuits Wiring Hookup

10

2.3.5 Wiring Outputs (continued)

This device may also have a programmable communication output. The RS-232 and RS-485 Output Connection are shown below.

If your meter has the communication option, the internal excitation is not available. Use external excitation for strain gauge meter.

External RS-232 connections are not available with -EI or C4EI options.

Figure 2.12

a) RS-232 Output Wiring Hookup b) RS-485 Output Wiring Hookup

dc CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH dc VOLTAGE SSR DRIVER OUTPUT

|

|

TEMPERATURE |

CONTROL |

dc INPUT |

LOAD |

|

|||

|

|

|

CONTROLLER |

|

SSR |

|

|||

|

|

|

|

|

SIDE |

4 |

1 |

SIDE |

HEATER |

Vac |

|

|

|

|

|

Vac |

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

3 |

2 |

|

|

|

|

|

|

|

0 or 5 Vdc, |

|

FAST BLOW |

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

TYPICALLY |

|

|

|

|

|

|

|

|

|

|

|

|

FUSE |

|

|

|

|

|

|

|

|

|

|

|

ac CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH MECHANICAL RELAY OUTPUT |

|||||||||

|

|

|

|

|

|

|

|

||

|

|

TEMPERATURE |

CONTROL |

ac INPUT |

LOAD |

|

|||

|

|

|

CONTROLLER |

|

|||||

|

|

|

|

SSR |

|

||||

|

|

|

|

|

SIDE |

|

SIDE |

HEATER |

|

|

|

|

|

|

4 |

1 |

|||

Vac |

|

|

|

|

|

Vac |

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

3 |

2 |

|

FAST BLOW |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vac |

|

|

|

FUSE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DRIVING |

|

|

|

|

|

|

|

|

|

SSR |

|

|

|

|

|

|

ac CONTROLLED SSR USED WITH TEMPERATURE CONTROLLER WITH TRIAC OUTPUT |

|||||||

|

|

TEMPERATURE |

CONTROL SIDE |

ac INPUT |

|

|

|||

|

|

LOAD |

LOAD |

|

|||||

|

|

|

CONTROLLER |

|

|||||

|

|

|

|

SSR |

|

||||

|

|

|

|

|

RESISTOR |

|

SIDE |

HEATER |

|

|

|

|

|

|

4 |

1 |

|||

Vac |

|

|

Vac |

||||||

|

|

|

|

||||||

|

|

|

|

|

|

3 |

2 |

|

FAST BLOW |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Vac |

FUSE |

DRIVING |

|

SSR |

|

Figure 2.13 Typical Applications

11

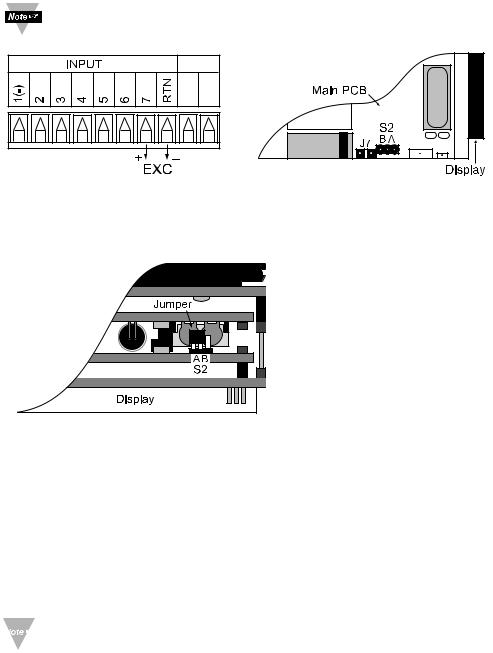

2.3.5 Wiring Outputs (continued)

This meter is capable of supplying 5 or 10 Vdc sensor excitation. The excitation output connection and location of S2 pin selection jumper are shown below.

Excitation is not available if Serial Communication (-C24) or Ethernet (-C4EI) or Low Voltage Power Supply (-DC) options are installed.

Figure 2.14 |

|

a) Excitation Output |

b) Top View Location of S2 |

c) Top View Location of S2 on 1/8 DIN Compact Unit

Install jumpers according to the table below.

Table 2.4 Jumper Connections

|

|

|

Excitation Output |

|

S2 |

|

|

|

|

|

A |

|

B |

|

|

|

|

|

||

|

|

|

10 V |

Close |

|

Open |

|

|

|

5 V |

Open |

|

Close |

|

|

|

|

|

|

|

|

Factory default is 10 V. |

|

|

|

||

|

|

|

|

|||

12

PART 3

OPERATION: CONFIGURATION MODE

3.1 Introduction

The instrument has two different modes of operation. The first, Run Mode, is used to display values for the Process Variable, and to display or clear Peak and Valley values. The other mode, Menu Configuration Mode, is used to navigate through the menu options and configure the controller. Part 3 of this manual will explain the Menu Configuration Mode. For your instrument to operate properly, the user must first "program" or configure the menu options.

Turning your Controller On for the First Time

The device becomes active as soon as it is connected to a power source. It has no On or Off switch. The device at first momentarily shows the software version number, followed by reset RST, and then proceeds to the Run Mode.

For first-time users: Refer to the QuickStart Manual for basic operation and set-up instructions.

If you have the Serial Communications/Ethernet Option you can easily configure the controller on your computer or on-line.

Table 3.1 Button Function in Configuration Mode

• To enter the Menu, the user must first press a button.

a• Use this button to advance/navigate to the next menu item. The user can navigate

through all the top level menus by pressing a.MENU

•While a parameter is being modified, press a to escape without saving the parameter.

•Press the up b button to scroll through “flashing” selections. When a numerical value is displayed press this key to increase value of a parameter that is currently

bbeing modified.

PK/GRS |

• Holding the b button down for approximately 3 seconds will speed up the rate at |

(UP) |

which the set point value increments. |

|

• In the Run Mode press b causes the display to flash the PEAK or GROSS value – |

|

|

press again to return to the Run Mode. |

|

|

• Press the down c button to go back to a previous Top Level Menu item. |

|

|

• Press this button twice to reset the controller to the Run Mode. |

|

c |

• When a numerical value is flashing (except set point value) press c to scroll digits |

|

from left to right allowing the user to select the desired digit to modify. |

||

TARE |

||

• When a setpoint value is displayed press c to decrease value of a setpoint that is |

||

(DOWN) |

||

currently being modified. Holding the c button down for approximately 3 seconds |

||

|

||

|

will speed up the rate at which the setpoint value is decremented. |

|

|

• In the Run Mode press c causes the display to flash the TARE value to tare your |

|

|

reading (zeroing). Press again to return to the Run Mode. |

|

|

• Press the enter d button to access the submenus from a Top Level Menu item. |

d• Press d to store a submenu selection or after entering a value — the display will

ENTER |

flash a STRD message to confirm your selection. |

•To reset flashing Peak or Valley press d.

•In the Run Mode, press d twice to enable Standby Mode with flashing STBY.

Reset: Except for Alarms, modifying any settings of the menu configuration will reset the instrument prior to resuming Run Mode.

13

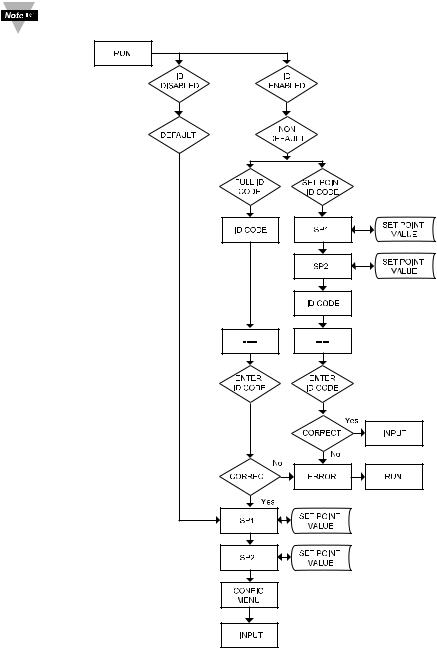

3.2 Menu Configuration

It is required that you put the controller in the Standby Mode for any configuration change other than Set Points & Alarms.

Figure 3.1 Flow Chart for ID and Set Points Menu

14

3.2.1 ID Number Menu

SEE ID MENU SELECTION IN CONFIGURATION SECTION FOR ENABLE/DISABLE OR CHANGE ID CODE.

If ID Code is Disabled or set as Default (0000) the menu will skip ID step to Set Point Menu.

If ID Code is set to Full Security Level and user attempts to enter the Main Menu, they will be prompted for an ID Code.

If ID Code is set to Setpoint/ID Security Level and user attempts to enter the Configuration Menu, they will be prompted for an ID Code.

ENTERING YOUR NON-DEFAULT FULL SECURITY ID NUMBER.

Press a 1) Display shows ID.

Press d 2) Display advances to ____.

Press b & c 3) Press b to increase digit 0-9. Press c to activate next digit (flashing). Continue to use b and c to enter your 4-digit ID code.

Press d 4) If the correct ID code is entered, the menu will advance to the Setpoint 1 Menu, otherwise an error message ERRo will be displayed and the instrument will return to the Run Mode.

To change ID Code, see ID Menu in the Configuration section.

ENTERING YOUR NON-DEFAULT SETPOINT/ID SECURITY ID NUMBER.

Press a |

5) |

Display shows SP1 Setpoint 1 Menu. |

|

Press |

a |

6) |

Display shows SP2 Setpoint 2 Menu. |

Press a |

7) |

Display shows ID ID Code Menu. |

|

Press |

d |

8) |

Display advances to ____. |

Press b & c 9) |

Use b and c to change your ID Code. |

||

Press |

d |

10) If correct ID Code is entered, the display will advance to the |

|

|

|

INPT Input Menu, otherwise the error message ERRo will be |

|

|

|

displayed and the controller will return to the Run Mode. |

|

To prevent unauthorized tampering with the setup parameters, the instrument provides protection by requiring the user to enter the ID Code before allowing access to subsequent menus. If the ID Code entered does not match the ID Code stored, the controller responds with an error message and access to subsequent menus will be denied.

Use numbers that are easy for you to remember. If the ID Code is

forgotten or lost, call customer service with your serial number to access and reset the default to 0000.

15

3.2.2 Set Points Menu

SETPOINT 1:

Press a 1) Press a, if necessary until SP1 prompt appears.

Press d 2) Display shows previous value of “Setpoint 1” with 1st digit flashing.

Press b & c 3) Press b and c to increase or decrease Setpoint 1 respectively.

Holding b & c buttons down for approximately 3 seconds will speed up the rate at which the set point value increments or decrements.

Press b & c 4) Continue to use b and c to enter your 4-digit Setpoint 1 value. Press d 5) Display shows STRD stored message momentarily and then advance to SP2 only, if a change was made, otherwise press a

to advance to SP2 Setpoint 2 Menu.

SETPOINT 2:

Press d 6) Display shows previous value of “Setpoint 2” with 1st digit flashing.

Press b & c 7) Press b and c to increase or decrease Setpoint 2 respectively.

Holding b & c buttons down for approximately 3 seconds will speed up the rate at which the setpoint value increments or decrements.

Press d 8) Display shows STRD stored message momentarily and then advances to CNFG only, if a change was made, otherwise press a to advance to CNFG Configuration Menu.

16

3.2.3 Configuration Menu

Figure 3.2 Flow Chart for Configuration Menu

Enter Configuration Menu:

Press a 1) Press a, if necessary, until CNFG prompt appear. Press d 2) Display advance to INPT Input Menu.

Press a 3) Press and release a to scroll through all available menus of Configuration section.

3.2.4 Input Type Menu

Figure 3.3 Flow Chart for Input Type Menu

17

ENTER INPUT TYPE MENU:

Press a 1) Press a, if necessary, until CNFG prompt appears.

Press d 2) Display advances to INPT Input Menu.

Press d 3) Display flashes 0-0.1, 0-1.0, 0-10 or 0-20 (0 to 100 mV, 0 to 1 V, 0 to 10 V or 0 to 20 mA).

INPUT TYPE MENU:

Press b 4) Scroll through the available selection of input ranges 0-0.1, 0-1.0, 0-10 or 0-20 to the selection of your choice.

Press d 5) Display shows STRD stored message momentarily and then advances to the RT1B Ratiometric Operation Submenu.

Input Types: |

100 mV |

1 V |

10 V |

0 – 20 mA |

Display: |

0-0.1 |

0-1.0 |

0-10 |

0-20 |

RATIOMETRIC OPERATION SUBMENU:

Press d 6) Display flashes previous selection of ENBL Enable or DSBL Disable.

Press b 7) Scroll through the available selection ENBL or DSBL (flashing).

Press d 8) Display shows STRD stored message momentarily and then advances to RESO Input/Reading Resolution Submenu.

The Ratiometric operations are typically used for Strain gauge controller. If your controller is configured as Process (Voltage and Current), set RTIB to DSBL disable Ratiometric operations.

If ENBL Ratiometric operations Enabled was selected, the changes to the excitation voltage will be compensated through Ratio measurement. If DSBL Ratiometric operation Disabled was selected, any changes to the excitation voltage will effect the output of strain gauge bridge and, as a result, a reading of the controller.

INPUT/READING RESOLUTION SUBMENU:

Press a 9) Display flashes previous selection of LO Low or HI High resolution.

Press d 10) Scroll through the available selection LO or HI (flashing). Press d 11) Display shows STRD stored message momentarily and then advances to BUTN Button Selection Submenu.

If LO Low Resolution was selected the resolution of the display is 10 µV. If HI High Resolution was selected the resolution of the display is 1 µV. In case of High Resolution, the maximum input signal is 10 mV.

18

Loading...

Loading...