National Instruments NI cDAQ-9172 User Manual

USER GUIDE AND SPECIFICATIONS

NI cDAQ-9172

Français |

Deutsch |

|

ni.com/manuals |

Contents

Introduction............................................................................................. |

4 |

Safety Guidelines .................................................................................... |

5 |

Safety Guidelines for Hazardous Voltages...................................... |

5 |

Related Documentation........................................................................... |

6 |

Device Documentation and Specifications ...................................... |

9 |

Training Courses.............................................................................. |

9 |

Technical Support on the Web......................................................... |

9 |

Installing the Software ............................................................................ |

10 |

Installing NI-DAQmx ...................................................................... |

10 |

Installing Other Software................................................................. |

10 |

Installing the NI cDAQ-9172.................................................................. |

11 |

Mounting the NI cDAQ-9172.......................................................... |

12 |

NI 9901 Desktop Mounting Kit................................................ |

12 |

NI 9910 DIN-Rail Kit............................................................... |

13 |

NI 9905 Panel Mount Kit ......................................................... |

13 |

Setting Up the NI cDAQ-9172................................................................ |

15 |

Understanding LED Indications.............................................................. |

17 |

Active LED ...................................................................................... |

17 |

Ready LED ...................................................................................... |

17 |

Using the NI cDAQ-9172 ....................................................................... |

18 |

C Series I/O Modules....................................................................... |

18 |

Correlated vs. Static DIO Modules........................................... |

19 |

cDAQ Module Interface .................................................................. |

19 |

USB-STC2 ....................................................................................... |

19 |

AI and AO Sample Timing....................................................... |

19 |

Triggering Modes ..................................................................... |

19 |

Independent Data Streams ........................................................ |

19 |

PFI Signals................................................................................ |

20 |

Flexible Counter/Timers........................................................... |

20 |

Analog Input ............................................................................................ |

20 |

Analog Input Triggering................................................................... |

20 |

AI Start Trigger Signal.............................................................. |

21 |

AI Reference Trigger Signal ..................................................... |

22 |

AI Pause Trigger Signal ............................................................ |

24 |

Analog Input Timing Signals ........................................................... |

24 |

AI Sample Clock ....................................................................... |

24 |

AI Sample Clock Timebase....................................................... |

25 |

Convert Behavior For Analog Input Modules........................... |

25 |

Getting Started with AI Applications in Software ........................... |

28 |

Analog Output ......................................................................................... |

28 |

Analog Output Data Generation Methods........................................ |

28 |

Software-Timed Generations .................................................... |

29 |

Hardware-Timed Generations ................................................... |

29 |

Analog Output Triggering ................................................................ |

30 |

Analog Output Timing Signals......................................................... |

31 |

AO Sample Clock...................................................................... |

31 |

AO Start Trigger Signal ............................................................ |

31 |

AO Pause Trigger Signal........................................................... |

33 |

Minimizing Glitches on the Output Signal....................................... |

34 |

Getting Started with AO Applications in Software.......................... |

34 |

Digital I/O................................................................................................ |

35 |

Correlated vs. Static DIO Modules .................................................. |

35 |

Static DIO......................................................................................... |

36 |

Digital Waveform Acquisition (Correlated Input) ........................... |

36 |

DI Sample Clock Signal............................................................ |

36 |

Digital Waveform Generation (Correlated Output) ......................... |

37 |

Buffered Digital Waveform Generation.................................... |

38 |

Change Detection Event ................................................................... |

39 |

Routing Change Detection Event to an Output Terminal ......... |

39 |

Change Detection Acquisition.......................................................... |

39 |

Digital Input/Output Configuration for NI 9401 .............................. |

39 |

PFI ........................................................................................................... |

40 |

Counters................................................................................................... |

40 |

Counter Input Applications .............................................................. |

42 |

Counting Edges ......................................................................... |

42 |

Pulse-Width Measurement ........................................................ |

44 |

Period Measurement.................................................................. |

46 |

Semi-Period Measurement ........................................................ |

48 |

Frequency Measurement ........................................................... |

49 |

Position Measurement ............................................................... |

54 |

Two-Signal Edge-Separation Measurement.............................. |

57 |

Counter Output Applications............................................................ |

59 |

Simple Pulse Generation ........................................................... |

59 |

Pulse Train Generation.............................................................. |

61 |

Frequency Generation ............................................................... |

62 |

Frequency Division ................................................................... |

63 |

NI cDAQ-9172 User Guide and Specifications |

2 |

ni.com |

Counter Timing Signals ................................................................... |

63 |

Counter n Source Signal ........................................................... |

64 |

Counter n Gate Signal............................................................... |

65 |

Counter n Aux Signal ............................................................... |

65 |

Counter n A, Counter n B, and Counter n Z Signals ................ |

66 |

Counter n Up_Down Signal ..................................................... |

66 |

Counter n HW Arm Signal ....................................................... |

66 |

Counter n Internal Output and Counter n TC Signals .............. |

67 |

Frequency Output Signal .......................................................... |

67 |

Default Counter/Timer Routing....................................................... |

68 |

Counter Triggering .......................................................................... |

68 |

Other Counter Features.................................................................... |

69 |

Cascading Counters .................................................................. |

69 |

Counter Filters .......................................................................... |

69 |

Prescaling.................................................................................. |

70 |

Duplicate Count Prevention...................................................... |

71 |

Synchronization Modes ............................................................ |

73 |

Digital Routing and Clock Generation.................................................... |

75 |

Clock Routing .................................................................................. |

76 |

80 MHz Timebase .................................................................... |

76 |

20 MHz Timebase .................................................................... |

76 |

100 kHz Timebase .................................................................... |

76 |

Specifications .......................................................................................... |

77 |

Analog Input .................................................................................... |

77 |

Analog Output.................................................................................. |

77 |

Digital Waveform Characteristics (Slots 1 through 4 Only) ........... |

78 |

PFI Characteristics (Slots 5 and 6 Only) ......................................... |

78 |

General-Purpose Counter/Timers (Slots 5 and 6 Only)................... |

79 |

Frequency Generator (Slots 5 and 6 Only) ...................................... |

80 |

External Digital Triggers (Slots 5 and 6 or with Some |

|

AI Modules) .................................................................................. |

80 |

Module I/O States ............................................................................ |

80 |

Power Requirements ........................................................................ |

80 |

Bus Interface .................................................................................... |

81 |

Physical Characteristics ................................................................... |

81 |

Safety ............................................................................................... |

81 |

Environmental.................................................................................. |

82 |

Shock and Vibration ........................................................................ |

82 |

Electromagnetic Compatibility ........................................................ |

83 |

CE Compliance ................................................................................ |

83 |

Environmental Management............................................................ |

83 |

Where to Go for Support......................................................................... |

84 |

© National Instruments Corporation |

3 |

NI cDAQ-9172 User Guide and Specifications |

Introduction

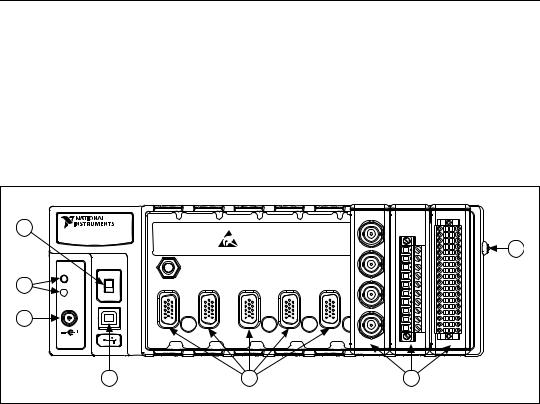

This user guide describes how to use the National Instruments cDAQ-9172 chassis and lists specifications. For an interactive demonstration of how to install the NI cDAQ-9172, go to ni.com/info and enter daqinstall.

The NI cDAQ-9172 is an eight-slot USB chassis designed for use with C Series I/O modules. The NI cDAQ-9172 chassis is capable of

measuring a broad range of analog and digital I/O signals and sensors using a Hi-Speed USB 2.0 interface. For module specifications, refer to the documentation included with your C Series I/O module(s) or go to ni.com/manuals.

1 |

|

|

|

|

|

NI cDAQ-9172 |

|

|

|

|

|

|

|

|

|

|

7 |

ON |

|

|

|

|

|

Ready |

1 |

2 |

3 |

4 |

5 |

2 |

|||||

Active |

|

|

|

|

|

OFF |

|

|

|

|

|

3 |

|

|

|

|

|

11-30 VDC |

|

|

|

|

|

15 W |

|

|

|

|

|

4 |

|

|

5 |

|

6 |

1 |

Power Switch |

5 |

Empty Module Slots |

2 |

Ready/Active LEDs |

6 |

Installed C Series I/O Modules |

3 |

Power Connector |

7 |

Screw for Ground Connection |

4 |

USB Connector |

|

|

|

|

|

|

Figure 1. NI cDAQ-9172 Chassis

NI cDAQ-9172 User Guide and Specifications |

4 |

ni.com |

Safety Guidelines

Operate the NI cDAQ-9172 chassis only as described in this user guide.

Note Because some C Series I/O modules may have more stringent certification standards than the NI cDAQ-9172 chassis, the combined system may be limited by individual component restrictions. Refer to the Using the NI cDAQ-9172 section of this document for more details.

Caution The NI cDAQ-9172 chassis is not certified for use in hazardous locations.

Hot Surface This icon denotes that the component may be hot. Touching this component may result in bodily injury.

Safety Guidelines for Hazardous Voltages

If hazardous voltages are connected to the module, take the following precautions. A hazardous voltage is a voltage greater than 42.4 Vpk or 60 VDC to earth ground.

Caution Ensure that hazardous voltage wiring is performed only by qualified personnel adhering to local electrical standards.

Caution Do not mix hazardous voltage circuits and human-accessible circuits on the same module.

Caution Make sure that chassis and circuits connected to the module are properly insulated from human contact.

Caution The NI cDAQ-9172 chassis provides no isolation, but some modules offer isolation. Follow the safety guidelines for each module when using hazardous voltage.

© National Instruments Corporation |

5 |

NI cDAQ-9172 User Guide and Specifications |

Related Documentation

Each application software package and driver includes information about writing applications for taking measurements and controlling measurement devices. Check ni.com/manuals for the most recent hardware documentation, and refer to Table 1 for a list of locations for driver and application software documentation. The following document location references assume you have NI-DAQmx 8.8 or later, and where applicable, version 7.1 or later of the NI application software.

Table 1. NI Driver and Application Software Documentation

Software |

Document/Description |

Location/Topic |

|

|

|

|

|

|

NI-DAQmx for Windows |

DAQ Getting Started |

Start»Programs» |

|

Guide—describes how to |

National Instruments» |

|

install and use the |

NI-DAQ»DAQ Getting Started |

|

NI-DAQmx driver software |

Guide |

|

for Windows and your data |

|

|

acquisition (DAQ) device, |

|

|

how to confirm the device is |

|

|

operating properly, and how |

|

|

to take an NI-DAQmx |

|

|

measurement. |

|

|

|

|

|

NI-DAQ Readme—includes |

Start»Programs» |

|

information about |

National Instruments» |

|

NI-DAQmx and Traditional |

NI-DAQ»NI-DAQ Readme |

|

NI-DAQ (Legacy). |

|

|

Describes how to choose |

|

|

the API to use, new |

|

|

features, and a list of known |

|

|

issues, supported devices, |

|

|

and devices not supported. |

|

|

Also provides details about |

|

|

system requirements. |

|

|

|

|

|

NI-DAQmx Help—explains |

Start»Programs» |

|

how to get started in your |

National Instruments» |

|

OS and ADE; provides an |

NI-DAQ»NI-DAQmx Help |

|

NI-DAQmx overview; |

|

|

includes information about |

|

|

programming the most |

|

|

common measurement |

|

|

tasks with references to |

|

|

examples in CVI/C, C++, |

|

|

.NET. |

|

|

|

|

NI cDAQ-9172 User Guide and Specifications |

6 |

ni.com |

Table 1. NI Driver and Application Software Documentation (Continued)

Software |

Document/Description |

Location/Topic |

|

|

|

|

|

|

LabVIEW |

Getting Started with |

Start»All Programs» |

|

LabVIEW—describes the |

National Instruments» |

|

LabVIEW graphical |

LabVIEW»LabVIEW Manuals or |

|

programming environment |

navigate to the labview\manuals |

|

and the basic LabVIEW |

directory and opening |

|

features you use to build |

LV_Getting_Started.pdf |

|

data acquisition and |

|

|

instrument control |

|

|

application. |

|

|

|

|

|

LabVIEW Help—provides |

Help»Search the LabVIEW Help |

|

information about |

|

|

LabVIEW programming |

|

|

concepts, step-by-step |

|

|

instructions for using |

|

|

LabVIEW, and reference |

|

|

information about |

|

|

LabVIEW VIs, functions, |

|

|

palettes, menus, and tools. |

|

|

|

|

|

LabVIEW Help Topics Specific to NI-DAQmx |

|

|

|

|

|

Includes overview |

From the Contents tab, Getting |

|

information and a tutorial to |

Started»Getting Started with DAQ |

|

learn how to take an |

|

|

NI-DAQmx measurement |

|

|

in LabVIEW using the |

|

|

DAQ Assistant. |

|

|

|

|

|

Describes the LabVIEW |

From the Contents tab, VI and |

|

NI-DAQmx VIs and |

Function Reference» |

|

properties. |

Measurement I/O VIs and |

|

|

Functions |

|

|

|

|

Contains the conceptual |

From the Contents tab, Taking |

|

and how-to information you |

Measurements |

|

need to acquire and analyze |

|

|

measurement data in |

|

|

LabVIEW, including |

|

|

common measurements, |

|

|

measurement |

|

|

fundamentals, NI-DAQmx |

|

|

key concepts, and device |

|

|

considerations. |

|

|

|

|

© National Instruments Corporation |

7 |

NI cDAQ-9172 User Guide and Specifications |

Table 1. NI Driver and Application Software Documentation (Continued)

Software |

Document/Description |

Location/Topic |

|

|

|

|

|

|

LabWindows™/CVI™ |

LabWindows/CVI Help |

Help»Contents, then select Using |

|

Data Acquisition |

LabWindows/CVI» |

|

book—contains |

Data Acquisition»Taking an |

|

NI-DAQmx measurement |

NI-DAQmx Measurement in |

|

concepts and step-by-step |

LabWindows/CVI |

|

instructions about creating |

|

|

a measurement task using |

|

|

the DAQ Assistant. |

|

|

|

|

|

LabWindows/CVI Help |

LibraryReference» |

|

NI-DAQmx Library |

NI-DAQmx Library |

|

book—contains |

|

|

NI-DAQmx API overviews |

|

|

and function reference. |

|

|

|

|

Measurement |

Microsoft Visual Studio |

Measurement Studio» |

Studio/Microsoft Visual |

.NET Help/NI |

NI Measurement Studio Help and |

Studio .NET |

Measurement Studio |

select NI-DAQmx .NET Class |

|

Help—contains |

Library or NI-DAQmx Visual C++ |

|

NI-DAQmx methods and |

Class Library |

|

properties. |

|

|

|

|

ANSI C without |

NI-DAQmx Help |

Start»All Programs» |

NI Application Software |

|

National Instruments» |

|

|

NI-DAQ»NI-DAQmx Help |

|

|

|

|

NI-DAQmx C Reference |

Start»All Programs» |

|

Help—describes the |

National Instruments» |

|

NI-DAQmx Library |

NI-DAQ»NI-DAQmx C Reference |

|

functions. |

Help |

|

|

|

NI cDAQ-9172 User Guide and Specifications |

8 |

ni.com |

Table 1. NI Driver and Application Software Documentation (Continued)

Software |

Document/Description |

Location/Topic |

|

|

|

|

|

|

.NET Languages without |

NI-DAQmx .NET |

Start»All Programs» |

NI Application Software* |

Help—contains conceptual |

National Instruments» |

|

topics for using NI-DAQmx |

NI-DAQ»NI-DAQmx .NET |

|

with Visual C# and Visual |

Reference Help. Expand |

|

Basic .NET. |

NI Measurement Studio Help» |

|

|

NI Measurement Studio .NET |

|

|

Class Library»Reference to view |

|

|

the function reference. Expand |

|

|

NI Measurement Studio Help» |

|

|

NI Measurement Studio .NET |

|

|

Class Library»Using the |

|

|

Measurement Studio .NET Class |

|

|

Libraries |

|

|

|

|

Visual Studio .NET |

Help»Contents. Select |

|

Help—contains conceptual |

Measurement Studio from the |

|

topics for using NI-DAQmx |

Filtered By drop-down list and |

|

with Visual C# and Visual |

follow the location instructions for |

|

Basic .NET. |

the NI-DAQmx .NET Help. |

|

|

|

* With the Microsoft .NET Framework version 1.1 or later, you can use NI-DAQmx to create applications using Visual C# and Visual Basic .NET without Measurement Studio. You need Microsoft Visual Studio .NET 2003 or Microsoft Visual Studio 2005 for the API documentation to be installed.

Device Documentation and Specifications

Check ni.com/manuals for the most recent device and software documentation. If you do not have Web access, NI-DAQmx includes a Documentation CD that includes documentation available when NI-DAQmx released.

Training Courses

If you need more help getting started developing an application with NI products, NI offers training courses. To enroll in a course or obtain a detailed course outline, refer to ni.com/training.

Technical Support on the Web

For additional support, refer to ni.com/support or zone.ni.com.

© National Instruments Corporation |

9 |

NI cDAQ-9172 User Guide and Specifications |

Installing the Software

Installing NI-DAQmx

The DAQ Getting Started Guide, which you can download at ni.com/ manuals, offers NI-DAQmx users step-by-step instructions for installing software and hardware, configuring channels and tasks, and getting started developing an application.

Installing Other Software

If you are using other software, refer to the installation instructions that accompany your software.

NI cDAQ-9172 User Guide and Specifications |

10 |

ni.com |

Installing the NI cDAQ-9172

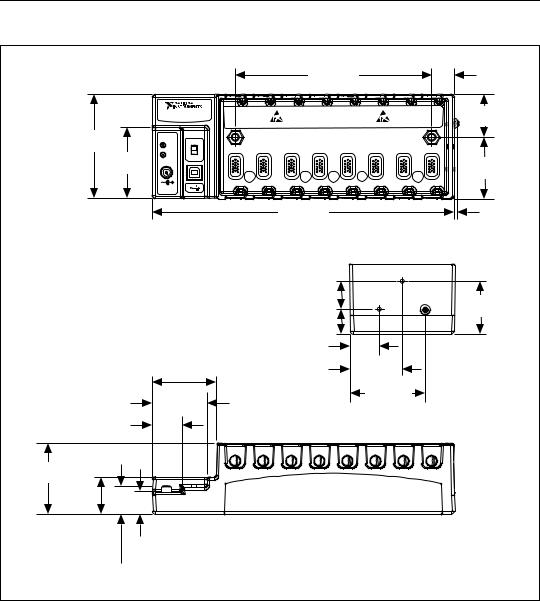

Figure 2 shows the dimensions of the NI cDAQ-9172 chassis.

|

|

|

|

|

165.1 mm |

|

|

19.0 mm |

|

|

|

|

|

|

(6.50 in.) |

|

|

(0.75 in.) |

|

|

NI cDAQ-9172 |

|

|

|

|

|

|

|

36.4 mm |

|

|

|

|

|

|

|

|

|

(1.43 in.) |

88.1 mm |

|

|

|

|

|

|

|

|

|

(3.50 in.) |

ON |

|

|

|

|

|

|

|

|

Ready |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

|

|||||||||

|

|

||||||||

59.6 mm |

Active |

|

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

51.7 mm |

|

(2.35 in.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(2.04 in.) |

|

|

|

|

|

|

|

|

|

|

|

|

11-30 VDC |

|

|

|

|

|

|

|

|

|

15 W |

|

|

|

|

|

|

|

|

|

|

|

|

254.0 mm |

|

|

|

4.10 mm |

|

|

|

|

|

|

|

|

(0.16 in.) |

||

|

|

|

|

(10.00 in.) |

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

23.7 mm |

|

|

|

|

|

|

|

|

|

(0.94 in.) |

|

|

|

44.1 mm |

|

|

|

|

|

20.3 mm |

|

|

|

(1.74 in.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(0.80 in.) |

|

|

|

|

|

|

|

|

|

25.0 mm |

|

|

|

|

|

|

|

|

|

(0.98 in.) |

|

|

|

|

|

53.8 mm |

|

|

|

44.1 mm |

|

|

|

|

|

(2.12 in.) |

|

|

|

(1.74 in.) |

|

|

|

|

|

|

|

|

|

|

|

63.1 mm |

|

|

46.0 mm |

|

|

|

|

|

|

(2.49 in.) |

|

|

(1.81 in.) |

|

|

|

|

|

|

|

|

|

24.8 mm |

|

|

|

|

|

|

|

|

|

(0.98 in.) |

|

|

|

|

|

|

|

|

|

58.9 mm |

|

|

|

|

|

|

|

|

|

(2.32 in.) |

|

|

|

|

|

|

|

|

|

31.7 mm |

|

|

|

|

|

|

|

|

|

(1.25 in.) |

|

|

|

|

|

|

|

|

|

19.1 mm |

|

|

|

|

|

|

|

|

|

(0.75 in.) |

|

|

|

|

|

|

|

|

|

23.2 mm |

|

|

|

|

|

|

|

|

|

(0.91 in.) |

|

|

|

|

|

|

|

|

|

Figure 2. NI cDAQ-9172 with Dimensions in Millimeters (Inches)

© National Instruments Corporation |

11 |

NI cDAQ-9172 User Guide and Specifications |

Mounting the NI cDAQ-9172

You can mount the NI cDAQ-9172 chassis using a desktop, a 35 mm DIN-Rail, or a panel mount accessory kit. For accessory ordering information, refer to ni.com.

Caution Your installation must meet the following requirements:

•Allows 25.4 mm (1 in.) of clearance above and below the NI cDAQ-9172 chassis for air circulation.

•Allows at least 50.8 mm (2 in.) of clearance in front of the modules for common connector cabling such as the 10-terminal detachable screw terminal connector and, as needed, up to 88.9 mm (3.5 in.) of clearance in front of the modules for other types of cabling. For more information about mechanical dimensions, refer to ni.com/ info and enter the info code cDAQMechanical. For more information about cable dimensions, refer to ni.com/info and enter the info code cDAQCable.

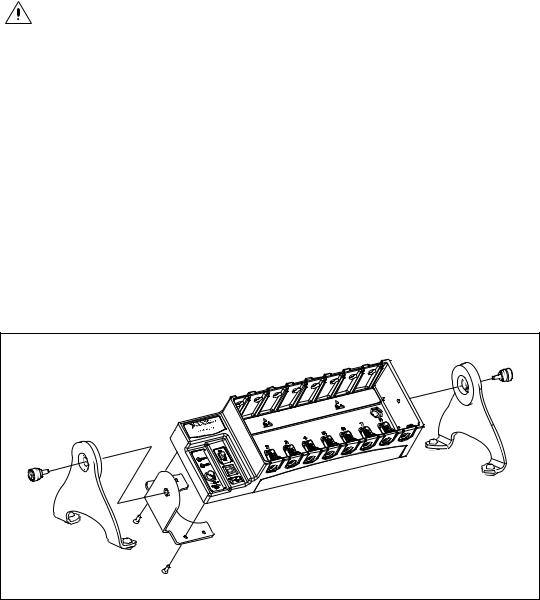

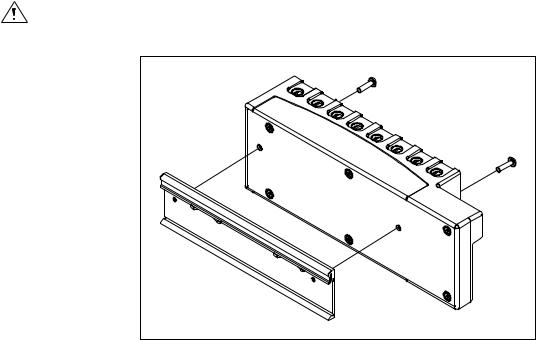

NI 9901 Desktop Mounting Kit

The NI 9901 Desktop Mounting Kit includes two metal feet you can install on the sides of the NI cDAQ-9172 chassis for desktop use. With this kit, you can tilt the NI cDAQ-9172 chassis for convenient access to the I/O module connectors. When you install the two metal feet, the two existing screws on the power switch side of the chassis must be removed. After removing the screws, replace them with the two longer screws included in the NI 9901 Desktop Mounting Kit.

Figure 3. NI 9901 Desktop Mounting Kit

NI cDAQ-9172 User Guide and Specifications |

12 |

ni.com |

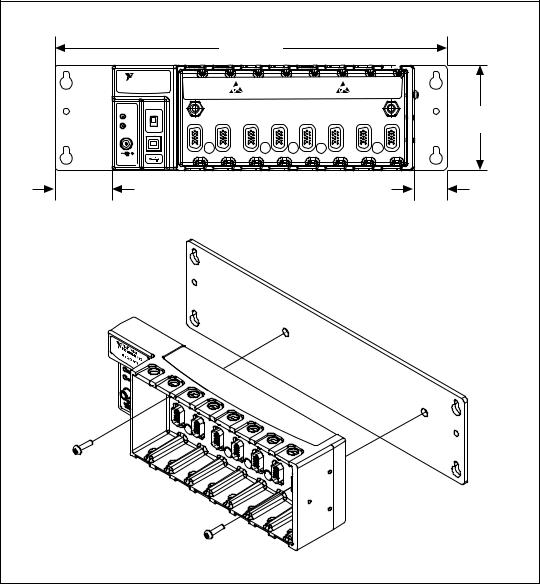

NI 9910 DIN-Rail Kit

The NI 9910 DIN-Rail Kit contains one clip for mounting the chassis on a standard 35 mm DIN-Rail. To mount the chassis on a DIN-Rail, fasten the DIN-Rail clip to the chassis using a number 2 Phillips screwdriver and two M4 × 17 screws. The screws are included in the DIN-Rail kit. Make sure the DIN-Rail kit is installed as illustrated in Figure 4, with the larger lip of the DIN-RAIL positioned up. When the DIN-Rail kit is properly installed, the NI cDAQ-9172 chassis is centered on the DIN-Rail.

Caution Remove the I/O modules before removing the chassis from the DIN-Rail.

Figure 4. DIN-Rail Installation on the NI cDAQ-9172

NI 9905 Panel Mount Kit

To mount the chassis on a panel, align the chassis on the panel mount accessory. Attach the chassis to the panel mount kit using two M4 × 17 screws (as shown in Figure 5). National Instruments provides these screws with the panel mount kit. You must use these screws because they are the correct depth and thread for the panel. These slots in the panel mount kit

© National Instruments Corporation |

13 |

NI cDAQ-9172 User Guide and Specifications |

can be used with M4, M5, No. 8, or No.10 panhead screws. Figure 5 illustrates the panel dimensions and installation on the NI cDAQ-9172 chassis. Refer to the documentation included with the NI 9905 Panel Mount Kit for more detailed dimensions.

|

|

330.2 mm |

|

|

|

|

|

|

|

|

(13.00 in.) |

|

|

|

|

|

|

NATIONAL |

|

|

|

|

|

|

|

|

INSTRUMENTS |

|

|

|

|

|

|

|

|

NI cDAQ-9172 |

|

|

|

|

|

|

|

|

ON |

|

|

|

|

|

|

|

88.1 mm |

Ready |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

1 |

(3.47 in.) |

|||||||

Active |

|

|

|

|

|

|

|

|

OFF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11-30 VDC |

|

|

|

|

|

|

|

|

15 W |

|

|

|

|

|

|

|

|

48.1 mm |

|

|

|

|

|

28.1 mm |

|

|

(1.90 in.) |

|

|

|

|

|

(1.11 in.) |

|

|

Figure 5. Panel Mount Dimensions and Installation on the NI cDAQ-9172

NI cDAQ-9172 User Guide and Specifications |

14 |

ni.com |

Setting Up the NI cDAQ-9172

Complete the following steps to prepare the NI cDAQ-9172 chassis for use:

1.Before connecting the hardware, install the NI-DAQmx software. Refer to the DAQ Getting Started Guide for more information about software installation.

Note The NI-DAQmx software is included on the CD shipped with your kit and is available for download at ni.com/support. The DAQ Getting Started Guide is available after installation from Start»All Programs»National Instruments»NI-DAQ»DAQ Getting Started Guide. Other NI documentation is available from ni.com/manuals.

2.If you are not using any mounting accessories, attach the provided rubber standoffs to the back of the NI cDAQ-9172 chassis.

3.Make sure the NI cDAQ-9172 chassis power switch is turned off.

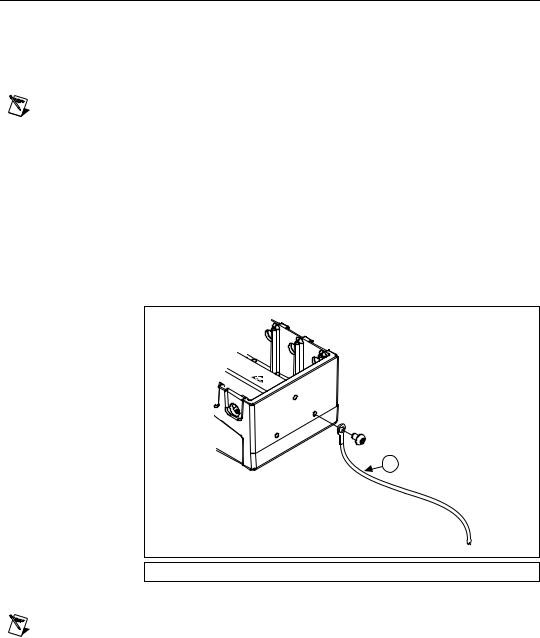

4.Attach a ring lug to a 14 AWG (1.6 mm) wire. Connect the ring lug to the ground terminal on the side of the chassis using the ground screw. Attach the other end of the wire to the system safety ground.

1

1 Attached to System Ground

Figure 6. Ring Lug Attached to Ground Terminal

Note Additionally, attach a wire with a ring lug to all other C Series I/O module cable shields. You must connect this wire to the ground terminal of the chassis using the ground screw.

5.Remove the plastic cover from the connector in any empty module slot.

© National Instruments Corporation |

15 |

NI cDAQ-9172 User Guide and Specifications |

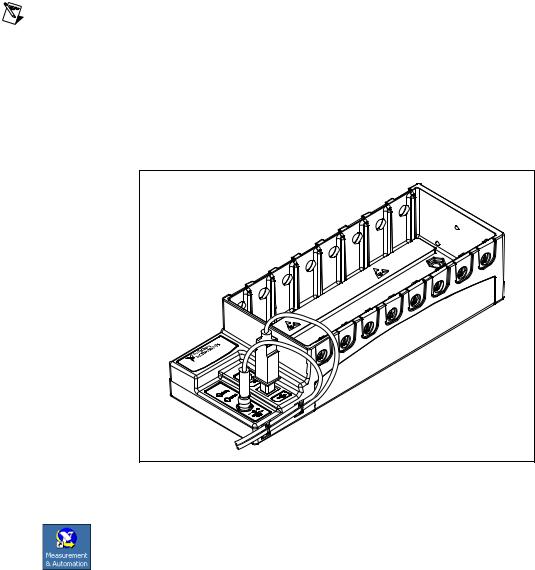

6.Squeeze both C Series I/O module latches, insert the I/O module into the module slot, and press until both latches lock the module in place.

7.Connect the NI cDAQ-9172 chassis with the supplied USB cable to any available USB port on your computer.

8.Connect the power source to the NI cDAQ-9172 chassis. The

NI cDAQ-9172 chassis requires an external power supply that meets the specifications in the Power Requirements section.

Note The NI cDAQ-9172 chassis uses a DC input jack with a locking ring. Use only this connector with the NI cDAQ-9172 chassis. Refer to the Specifications section for more information about the connector.

9.Secure the power supply and USB cables, as depicted in Figure 7, using the two tie wraps and adhesive tie wrap mounts included in the shipping kit. The tie wraps and adhesive mounts help secure the non-latching USB connection. They can also be used to route the cables to a desirable position.

-9172 |

cDAQ |

NI |

Figure 7. cDAQ Chassis With Secured Cables

10.Power on the NI cDAQ-9172 chassis.

11.Double-click the Measurement & Automation icon, shown at left, on the desktop to open MAX.

12.Expand Devices and Interfaces, and then expand NI-DAQmx Devices.

NI cDAQ-9172 User Guide and Specifications |

16 |

ni.com |

13.Check that your device appears under Devices and Interfaces. If your device does not appear, press <F5> to refresh the view in MAX. If your device is still not recognized, refer to ni.com/support/install for troubleshooting information.

14.Right-click your device and select Self-Test.

If you need help during the self-test, select Help»Help Topics» NI-DAQmx and click MAX Help for NI-DAQmx.

When the self-test finishes, a message indicates successful verification or an error. If an error occurs, refer to ni.com/support/install for troubleshooting information.

Note When in use, the NI cDAQ-9172 chassis may become warm to the touch. This is normal.

Understanding LED Indications

Active LED

The Active LED indicates whether the NI cDAQ-9172 chassis is communicating over the USB bus.

|

Table 2. Active LED |

|

|

LED |

Definition |

|

|

|

|

Amber |

Power is applied, but USB connection is not |

|

established |

|

|

Green |

USB traffic present |

|

|

Off |

No USB traffic present |

|

|

Ready LED

The Ready LED is lit when the NI cDAQ-9172 chassis is ready for use. The color indicates whether the USB connection is Full-Speed or Hi-Speed.

|

Table 3. Ready LED |

|

|

LED |

Definition |

|

|

|

|

Amber |

Hi-Speed (480 Mbit/sec) |

|

|

Green |

Full-Speed (12 Mbit/sec) |

|

|

Off |

USB connection is not established |

|

|

© National Instruments Corporation |

17 |

NI cDAQ-9172 User Guide and Specifications |

Using the NI cDAQ-9172

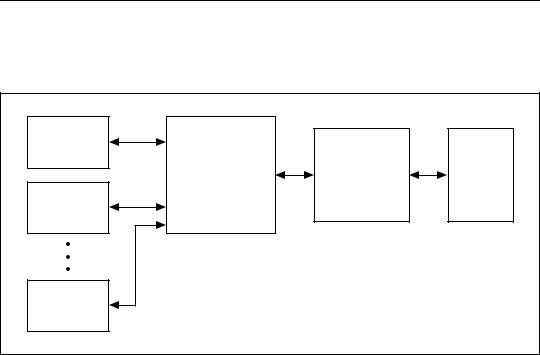

The cDAQ system consists of three parts: C Series I/O modules, the cDAQ module interface, and the USB-STC2. These components digitize signals, perform D/A conversions to generate analog output signals, measure and control digital I/O signals, and provide signal conditioning.

C Series |

|

|

I/O Module |

|

|

cDAQ Module |

USB- |

USB |

Interface |

STC2 |

2.0 |

C Series |

|

|

I/O Module |

|

|

C Series |

|

|

I/O Module |

|

|

Figure 8. NI cDAQ-9172 Block Diagram

C Series I/O Modules

National Instruments C Series I/O modules provide built-in signal conditioning and screw terminal, spring terminal, BNC, D-SUB, or RJ-50 connectors. A wide variety of I/O types are available, allowing you to customize the cDAQ system to meet your application needs.

C Series I/O modules are hot-swappable and automatically detected by the NI cDAQ-9172 chassis. I/O channels are accessible using the NI-DAQmx driver software.

Because the modules contain built-in signal conditioning for extended voltage ranges or industrial signal types, you can usually make your wiring connections directly from the C Series I/O modules to your sensors/actuators. In most cases, the C Series I/O modules provide isolation from channel-to-earth ground.

For more information about which C Series I/O modules are compatible with the NI cDAQ-9172 chassis, refer to the KnowledgeBase document,

C Series Modules Supported in the NI cDAQ-9172 CompactDAQ.

NI cDAQ-9172 User Guide and Specifications |

18 |

ni.com |

To access this KnowledgeBase, go to ni.com/info and enter the info code rdcdaq.

Correlated vs. Static DIO Modules

Digital I/O module capabilities are determined by the type of digital signals that the module is capable of measuring or generating. Static digital I/O modules are designed for signals that change slowly and are accessed by software-timed reads and writes. Correlated digital I/O modules are for signals that change rapidly and are updated by either software-timed or hardware-timed reads and writes. For more information about Digital I/O modules, refer to the Digital I/O section.

cDAQ Module Interface

The cDAQ Module Interface manages data transfers between the USB-STC2 and the C Series I/O modules. The interface also handles autodetection, signal routing, and synchronization.

USB-STC2

The USB-STC2 features independent high-speed data streams; flexible AI and AO sample timing; triggering; PFI signals for multi-device synchronization; flexible counter/timers with hardware gating; digital waveform acquisition and generation; and static DIO.

AI and AO Sample Timing

The USB-STC2 contains advanced analog input and analog output timing engines. A wide range of timing and synchronization signals are available through the PFI lines. Refer to the Analog Input Timing Signals and Analog Output Timing Signals sections for more information about the configuration of these signals.

Triggering Modes

The NI cDAQ-9172 supports different trigger modes, such as start trigger, reference trigger, and pause trigger with analog, digital, or software sources. Refer to the Analog Input Triggering and Analog Output Triggering sections for more information.

Independent Data Streams

The NI cDAQ-9172 supports four independent high-speed data streams; allowing for up to four simultaneous hardware timed tasks, such as analog input, analog output, buffered counter/timers, and correlated digital input/output.

© National Instruments Corporation |

19 |

NI cDAQ-9172 User Guide and Specifications |

PFI Signals

The PFI signals, available through correlated digital input and output modules installed in slots 5 and/or 6, provide access to advanced features such as triggering, synchronization, and counter/timers. Refer to the PFI section for more information.

The PFI pins have a digital filter circuit at the inputs that is configurable on a per-line basis. The filters allow the rejection of noise caused by noisy environments, bounces on switches, and so on.

Flexible Counter/Timers

The NI cDAQ-9172 includes two general-purpose 32-bit counter/timers that can be used to count edges, measure pulse-widths, measure periods and frequencies, and perform position measurements (encoding). In addition, the counter/timers can generate pulses, pulse trains, and square waves with adjustable frequencies. You can access the counter inputs and outputs using correlated digital I/O modules in slots 5 and/or 6. Refer to the Counters section for more information.

Analog Input

To perform analog input measurements, insert a supported analog input C Series I/O module into any slot on the cDAQ chassis. The measurement specifications, such as number of channels, channel configuration, sample rate, and gain, are determined by the type of C Series I/O module used. For more information and wiring diagrams, refer to the documentation included with your C Series I/O modules.

The NI cDAQ-9172 has one AI timing engine, which means that only one analog input task can be running at a time on a chassis. However, the analog input task can include channels from multiple analog input modules.

Analog Input Triggering

A trigger is a signal that causes an action, such as starting or stopping the acquisition of data. When you configure a trigger, you must decide how you want to produce the trigger and the action you want the trigger to cause. The NI cDAQ-9172 chassis supports internal software, external digital triggering, and analog triggering.

Three triggers are available: start trigger, reference trigger, and pause trigger. An analog or digital trigger can initiate these three trigger actions. Any C Series correlated digital input module can supply a digital trigger when installed in slots 5 or 6, and some C Series analog modules can supply an analog or digital trigger in any slot. The start, reference, and pause

NI cDAQ-9172 User Guide and Specifications |

20 |

ni.com |

triggers can come from three separate modules if desired. To find your module triggering options, refer to the documentation included with your C Series I/O modules. For more information about using digital modules for triggering, refer to the Digital I/O section.

AI Start Trigger Signal

Use the AI Start Trigger (ai/StartTrigger) signal to begin a measurement acquisition. A measurement acquisition consists of one or more samples. If you do not use triggers, begin a measurement with a software command. Once the acquisition begins, configure the acquisition to stop in one of the following ways:

•When a certain number of points is sampled (in finite mode)

•After a hardware reference trigger (in finite mode)

•With a software command (in continuous mode)

An acquisition that uses a start trigger (but not a reference trigger) is sometimes referred to as a posttriggered acquisition. That is, samples are measured only after the trigger.

When you are using an internal sample clock, you can specify a delay from the start trigger to the first sample.

Using a Digital Source

To use ai/StartTrigger with a digital source, specify a source and an edge. Use the following signals as the source:

•Any PFI terminal.

•Counter n Internal Output

The source also can be one of several other internal signals on your

NI cDAQ-9172 chassis. Refer to the Device Routing in MAX topic in the NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help. To view the LabVIEW Help, in version 8.0 or later, select Help» Search the LabVIEW Help in LabVIEW. Alternately, to download the LabVIEW Help, go to ni.com/manuals.

You also can specify whether the measurement acquisition begins on the rising edge or falling edge of ai/StartTrigger.

© National Instruments Corporation |

21 |

NI cDAQ-9172 User Guide and Specifications |

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog signal. In NI-DAQmx, this is called the Analog Comparison Event. When you use an analog trigger source for ai/StartTrigger, the acquisition begins on the first rising edge of the Analog Comparison Event signal.

Routing AI Start Trigger to an Output Terminal

You can route ai/StartTrigger to any output PFI terminal. The output is an active high pulse.

AI Reference Trigger Signal

Use a reference trigger (ai/ReferenceTrigger) signal to stop a measurement acquisition. To use a reference trigger, specify a buffer of finite size and a number of pretrigger samples (samples that occur before the reference trigger). The number of posttrigger samples (samples that occur after the reference trigger) desired is the buffer size minus the number of pretrigger samples.

Once the acquisition begins, the NI cDAQ-9172 chassis writes samples to the buffer. After the NI cDAQ-9172 chassis captures the specified number of pretrigger samples, the NI cDAQ-9172 chassis begins to look for the reference trigger condition. If the reference trigger condition occurs before the NI cDAQ-9172 captures the specified number of pretrigger samples, the NI cDAQ-9172 ignores the condition.

If the buffer becomes full, the NI cDAQ-9172 continuously discards the oldest samples in the buffer to make space for the next sample. This data can be accessed (with some limitations) before the NI cDAQ-9172 chassis discards it. Refer to the KnowledgeBase document, Can a Pretriggered Acquisition be Continuous?, for more information. To access this KnowledgeBase, go to ni.com/info and enter the info code rdcanq.

NI cDAQ-9172 User Guide and Specifications |

22 |

ni.com |

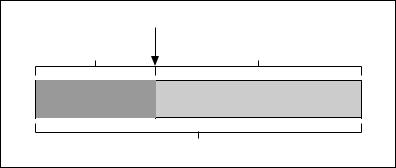

When the reference trigger occurs, the NI cDAQ-9172 continues to write samples to the buffer until the buffer contains the number of posttrigger samples desired. Figure 9 shows the final buffer.

Reference Trigger |

|

Pretrigger Samples |

Posttrigger Samples |

|

Complete Buffer |

Figure 9. Reference Trigger Final Buffer

Using a Digital Source

To use ai/ReferenceTrigger with a digital source, specify a source and an edge. Either PFI or one of several internal signals on the NI cDAQ-9172 chassis can provide the source. Refer to the Device Routing in MAX topic in the NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help. To view the LabVIEW Help, in version 8.0 or later, select Help» Search the LabVIEW Help in LabVIEW. Alternately, to download the LabVIEW Help, go to ni.com/manuals.

You also can specify whether the measurement acquisition stops on the rising edge or falling edge of ai/ReferenceTrigger.

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog signal. In NI-DAQmx, this is called the Analog Comparison Event.

When you use an analog trigger source, the acquisition stops on the first rising or falling edge of the Analog Comparison Event signal, depending on the trigger properties.

Routing AI Reference Trigger Signal to an Output Terminal

You can route ai/ReferenceTrigger to any output PFI terminal.

© National Instruments Corporation |

23 |

NI cDAQ-9172 User Guide and Specifications |

AI Pause Trigger Signal

You can use the AI Pause Trigger (ai/PauseTrigger) signal to pause and resume a measurement acquisition. The internal sample clock pauses while the external trigger signal is active and resumes when the signal is inactive. You can program the active level of the pause trigger to be high or low.

Using a Digital Source

To use ai/PauseTrigger, specify a source and a polarity. The source can be either from PFI or one of several other internal signals on

your NI cDAQ-9172 chassis. Refer to the Device Routing in MAX topic in the NI-DAQmx Help or the LabVIEW Help in version 8.0 or later for more information.

The NI-DAQmx Help is available after installation from Start»

All Programs»National Instruments»NI-DAQ»NI-DAQmx Help. To view the LabVIEW Help, in version 8.0 or later, select Help» Search the LabVIEW Help in LabVIEW. Alternately, to download the LabVIEW Help, go to ni.com/manuals.

Using an Analog Source

Some C Series I/O modules can generate a trigger based on an analog signal. In NI-DAQmx, this is called the Analog Comparison Event.

When you use an analog trigger source, the internal sample clock pauses when the Analog Comparison Event signal is low and resumes when the signal goes high (or vice versa).

Note Pause triggers are only sensitive to the level of the source, not the edge.

Analog Input Timing Signals

AI Sample Clock

A sample consists of one reading from each channel in the AI task. ai/SampleClock signals the start of a sample of all analog input channels in the task. ai/SampleClock can be generated from external or internal sources.

NI cDAQ-9172 User Guide and Specifications |

24 |

ni.com |

|

|

|

|

|

PFI |

|

|

|

|||

|

|

|

|

|

|

||||||

|

|

|

|

Analog Comparison Event |

|

|

|

||||

|

|

|

|

|

|

||||||

|

|

|

|

|

Ctr n Internal Output |

|

|

||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

ai/SampleClock |

PFI |

|

|

Sigma-Delta Module Internal Output |

||||||||

|

|

ai/SampleClock |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Analog Comparison |

|

|

|

|

|

|

|

|

|

|

|

|

|

Timebase |

|

Programmable |

|

|

|

|

|

|

|

Event |

|

|

|

|

|||||||

|

|

|

|

Clock |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 MHz Timebase |

|

|

|

|

Divider |

|

|||||

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

100 kHz Timebase

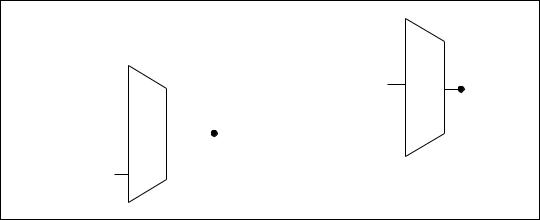

Figure 10. Sample Clock Timing Options

Routing AI Sample Clock to an Output Terminal

You can route ai/SampleClock to any output PFI terminal.

AI Sample Clock Timebase

The AI Sample Clock Timebase (ai/SampleClockTimebase) signal is divided down to provide a source for ai/SampleClock. ai/SampleClock Timebase can be generated from external or internal sources. ai/SampleClockTimebase is not available as an output from the chassis.

Convert Behavior For Analog Input Modules

Scanned

Scanned C Series analog input modules contain a single A/D converter and a multiplexer to select between multiple input channels. When the cDAQ Module Interface receives a Sample Clock pulse, it begins generating a Convert Clock for each scanned module in the current task. Each Convert Clock signals the acquisition of a single channel from that module. The Convert Clock rate depends on the module being used, the number of channels used on that module, and the system Sample Clock rate.

The driver chooses the fastest conversion rate possible based on the speed of the A/D converter for each module and adds 10 µs of padding between each channel to allow for adequate settling time. This scheme enables the channels to approximate simultaneous sampling. If the AI Sample Clock rate is too fast to allow for 10 µs of padding, NI-DAQmx selects a conversion rate that spaces the AI Convert Clock pulses evenly throughout the sample. NI-DAQmx uses the same amount of padding for all the modules in the task. To explicitly specify the conversion rate, use the

© National Instruments Corporation |

25 |

NI cDAQ-9172 User Guide and Specifications |

ActiveDevs and AI Convert Clock Rate properties using the DAQmx Timing property node or functions.

Simultaneous Sample-and-Hold

Simultaneous sample-and-hold (SSH) C Series analog input modules contain multiple A/D converters or circuitry that allows all the input channels to be sampled at the same time. These modules sample their inputs on every Sample Clock pulse.

Sigma-Delta

Sigma-delta C Series analog input modules function much like SSH modules, but use A/D converters that require a high-frequency oversample clock to produce accurate, synchronized data. Sigma-delta modules in the cDAQ chassis automatically share a single oversample clock to synchronize data from all sigma-delta modules.

This clock is used as the AI Sample Clock Timebase. While most modules supply a common oversample clock frequency (12.8 MHz), some modules, such as the NI 9234, supply a different frequency. When sigma-delta modules with different oversample clock frequencies are used in an analog input task, the AI Sample Clock Timebase can use any of the available frequencies; by default, the fastest available is used. The sampling

rate of all modules in the system is an integer divisor of the frequency of the AI Sample Clock Timebase.

When one or more sigma-delta modules are in an analog input task, the sigma-delta modules also provide the signal used as the AI Sample Clock. This signal is used to cause A/D conversion for other modules in the system, just as the AI Sample Clock does when a sigma-delta module is not being used.

When sigma-delta modules are in an AI task, the chassis automatically issues a synchronization pulse to each sigma-delta modules that resets their ADCs at the same time. Both the synchronization pulse and the oversample clock can be routed from or to any PFI line to allow synchronization between multiple chassis. Because of the filtering used in sigma-delta A/D converters, these modules usually exhibit a fixed input delay relative to non-sigma-delta modules in the system. This input delay is specified in the C Series I/O module documentation.

NI cDAQ-9172 User Guide and Specifications |

26 |

ni.com |

Loading...

Loading...