MTD E660G, E610E, E640F User Manual

OPERATOR’S MANUAL

SNOW

THROWERS

Models

E600E, E610E

E640F, E660G

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forestcovered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. |

FORM NO. 770-8782A |

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL BEFORE ATTEMPTING TO OPERATE YOUR SNOW THROWER. FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY. WHEN YOU SEE THIS SYMBOL-HEED ITS WARNING.

WARNING: The Engine Exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

DANGER: Your snow thrower was built to be operated according to the rules for safe operation in this manual. As with any type of power equipment, carelessness or error on the part of the operator can result in serious injury. If you violate any of these rules, you may cause serious injury to yourself or others.

1. TRAINING

•Read this operator's manual carefully in its entirety before attempting to assemble or operate this machine. Be completely familiar with the controls and the proper use of this machine before operating it. Keep this manual in a safe place for future and regular reference and for ordering replacement parts.

•Never allow children under 14 years old to operate a snow thrower. Children 14 years old and over should only operate snow thrower under close parental supervision. Only persons well acquainted with these rules of safe operation should be allowed to use your snow thrower.

•No one should operate this unit while intoxicated or while taking medication that impairs the senses or reactions.

•Keep the area of operation clear of all persons, especially small children and pets.

•Exercise caution to avoid slipping or falling, especially when operating in reverse.

2.PREPARATION

•Thoroughly inspect the area where the equipment is to be used and remove all door mats, sleds, boards, wires and other foreign objects.

•Disengage all clutches and shift into neutral before starting engine.

•Do not operate equipment without wearing adequate winter outer garments. Do not wear jewelry, long scarfs or other loose clothing which could become entangled in moving parts. Wear footwear which will improve footing on slippery surfaces.

•Before working with gasoline, extinguish all cigarettes and other sources of ignition. Check the fuel before starting the engine. Gasoline is an extremely flammable fuel. Do not fill the gasoline tank indoors, while the engine is running, or until engine has been allowed to cool at least two minutes. Replace gasoline cap securely and wipe off any spilled gasoline before starting the engine as it may cause a fire or explosion.

•Use a grounded three wire plug-in for all units with electric drive motors or electric starting motors.

•Adjust collector housing height to clear gravel or crushed rock surface.

•Never attempt to make any adjustments while engine is running (except where specifically recommended by manufacturer).

•Let engine and machine adjust to outdoor temperature before starting to clear snow.

•Always wear safety glasses or eye shields during operation or while performing an adjustment or repair, to protect eyes from foreign objects that may be thrown from the machine in any direction.

3.OPERATION

•Do not put hands or feet near or under rotating parts. Keep clear of discharge opening and auger at all times.

•Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards or traffic. Do not carry passengers.

•After striking a foreign object, stop the engine, remove wire from spark plug, and thoroughly inspect the snow thrower for any damage. Repair the damage before restarting and operating the snow thrower.

2

•If the snow thrower should start to vibrate abnormally, stop the engine and check immediately for the cause. Vibration is generally a warning of trouble.

•Stop engine whenever you leave the operating position, before unclogging the collector/impeller housing or discharge guide, and making any repairs, adjustments, or inspections. Never place your hand in the discharge or collector openings. Use a stick or wooden broom handle to unclog the discharge opening.

•Take all possible precautions when leaving the unit unattended. Disengage the collector/impeller, shift into neutral, stop the engine, and remove the key.

•When cleaning, repairing, or inspecting, make certain collector/impeller and all moving parts have stopped. Disconnect spark plug wire and keep away from plug to prevent accidental starting.

•Do not run engine indoors, except when starting engine and transporting snow thrower in or out of building. Open doors. Exhaust fumes are dangerous.

•Do not clear snow across the face of slopes. Exercise extreme caution when changing direction on slopes. Do not attempt to clear steep slopes.

•Never operate snow thrower without guards, plates, or other safety protection devices in place.

•Never operate snow thrower near glass enclosure, automobiles, window wells, drop off, etc., without proper adjustments of snow thrower discharge angle. Keep children and pets away.

•Do not overload machine capacity by attempting to clear snow at too fast a rate.

•Never operate the machine at high transport speeds on slippery surfaces. Look behind and use care when backing.

•Never direct discharge at bystanders or allow anyone in front of unit.

•Disengage power to collector/impeller when transporting or not in use.

•Use only attachments and accessories approved by the manufacturer of snow thrower (such as wheel weights, counter weights, cabs, etc.).

•Never operate the snow thrower without good visibility or light. Always be sure of your footing and keep a firm hold on the handles. Walk, never run.

•Muffler and engine become hot and can cause a burn. Do not touch.

4.MAINTENANCE AND STORAGE

•Check shear bolts, engine mounting bolts, etc., at frequent intervals for proper tightness to be sure equipment is in safe working condition.

•Never store the machine with fuel in the fuel tank inside a building where ignition sources are present, such as hot water and space heaters, clothes dryers, and the like. Allow engine to cool before storing in any enclosure.

•Always refer to operator's manual instructions for important details if snow thrower is to be stored for an extended period.

•Run machine a few minutes after throwing snow to prevent freeze up of collector/impeller.

•Check clutch controls periodically to verify they engage and disengage properly and readjust if necessary. Refer to operator's manual for adjustment instructions.

WARNING - YOUR RESPONSIBILITY: Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in this manual and on the machine.

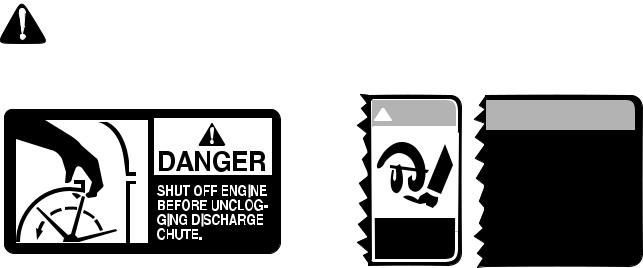

DANGER

DANGER

AVOID INJURY FROM

ROTATING AUGER -

KEEP HANDS, FEET

ANDCLOTHINGAWAY.

Figure 1

WARNING

WARNING

1.STOP ENGINE BEFORE REMOVING DEBRIS AND SERVICING UNIT

2.KEEP CLEAR OF IMPELLER WHILE ENGINE IS RUNNING

3.NEVER DIRECT DISCHARGE AT BYSTANDERS OR WINDOWS OR ALLOW ANYONE IN FRONT OF UNIT

4.THOROUGHLY INSPECT THE AREA WHERE THE EQUIPMENT IS TO BE USED AND REMOVE ALL DOOR MATS, SLEDS, BOARDS, WIRES AND OTHER FOREIGN OBJECTS

5.REFER TO OWNERS MANUAL FOR FULL INSTRUCTIONS

3396MW

3

SECTION 2: FINDING YOUR MODEL NUMBER

This Operator’s Manual is an important part of your new snow thrower. It will help you assemble, prepare and maintain your snow thrower. Please read and understand what it says.

Before you start to prepare your snow thrower for its first use, please locate the model plate and copy the information from it in this Operator’s Manual. The information on the model plate is very important if you need help from your dealer or the MTD customer support department.

•Every snow thrower has a model plate. You can locate it by standing behind the unit in the operating position and looking down at the rear frame below the engine.

•The model plate will look like Figure 2.

|

|

|

|

|

|

This is where your model number will be. |

||||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

XXX-X-XXX-X-XXX XXXXXXXXXXX |

|

|

|

|

|

|

|||

|

|

|

|

|

|

This is where your serial number will be. |

||||

|

|

|

|

|

|

|||||

|

|

|

|

|

Copy the model number here: |

|||||

|

|

MTD PRODUCTS INC |

Copy the serial number here: |

|

|

|

|

|||

|

|

CLEVELAND, OHIO 44136 |

|

|

||||||

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 2 |

|||||

SECTION 3: CALLING CUSTOMER SUPPORT

If you are having difficulty assembling this product or if you have any question regarding the controls, operation or maintenance of this snow thrower, please call the Customer Support Department. You can reach them by calling:

1-800-800-7310

Before you call, make sure that you have both your model and serial number ready. By having the model and serial number ready, you help the Customer Support Representative give you faster service. To find your units model and serial number, see SECTION 2: FINDING YOUR MODEL NUMBER.

4

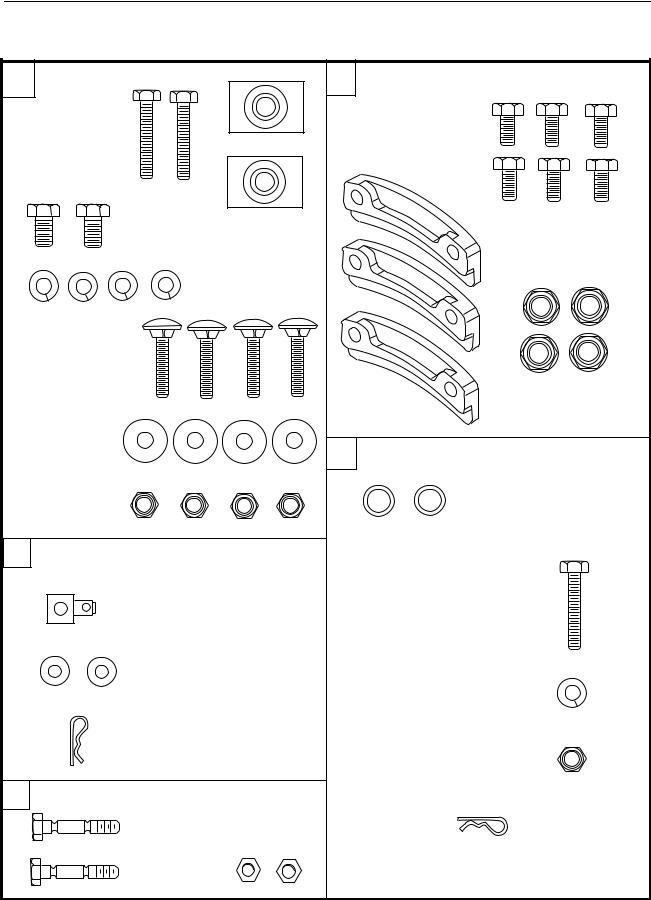

SECTION 4: CONTENTS OF HARDWARE PACK

Lay out the hardware according to the illustration for identification purposes. Part numbers are shown in parentheses. (Hardware pack may contain extra items which are not used on your unit.)

A ATTACHING THE HANDLES |

|

B ATTACHING THE CHUTE ASSEMBLY |

|

Hex Bolts (A) |

|

Hex Bolts |

|

5/16-18 x 1-3/4” Long |

|

1/4-20 x 3/4” Long |

|

(710-3180) |

|

(710-3015) |

|

Hex Bolts |

|

|

|

5/16-18 x 3/4” Long |

Handle Tabs |

Chute Flange |

|

(710-3008) |

|||

(784-5599) |

Keepers |

||

|

|||

Lock Washers |

(731-0851) |

||

|

|||

5/16” I.D. |

|

||

(736-0119) |

|

||

Carriage Bolts |

|

|

|

5/16-18 x 1-1/2” Long |

|

|

|

(710-0262) |

|

|

|

|

|

Hex Lock Nuts |

|

|

|

1/4-20 Thread |

|

Cupped Washers |

|

(712-3027) |

|

|

|

||

5/16” I.D. |

|

C ATTACHING THE CHUTE CRANK ASSEMBLY |

|

(736-0242) |

|

||

Hex Nuts |

|

Flat Washers |

|

5/16” Thread |

|

3/8” I.D. x 5/8” O.D. |

|

(712-3010) |

|

(736-0185) |

|

ATTACHING THE SHIFT ROD |

|

|

|

D AND CLUTCH CABLES |

|

|

|

Ferrule |

|

Hex Bolt |

|

|

5/16-18 x 1-1/2” Long |

||

(711-0677) |

|

(710-0442) |

|

Flat Washers |

|

||

3/8” I.D. x 5/8” O.D. |

Lock Washers |

||

(736-0185) |

|

||

|

|

5/16” I.D. |

|

|

|

(736-0119) |

|

Hair Pin Clip |

|

Hex Nut |

|

(714-0104) |

|

||

|

5/16” Thread |

||

|

|

||

F AUGER SHEAR BOLTS (SPARES) |

|

(712-3010) |

|

Hex Lock Nuts |

|

||

|

|

||

|

5/16” Thread |

|

|

Shear Bolts |

(712-0429) |

Hair Pin Clip |

|

(710-0890A) |

|

||

|

|

(714-0104) |

|

Note: Parts are not to actual size.

5

SECTION 5: ASSEMBLY INSTRUCTIONS

IMPORTANT: After assembly, service engine with gasoline, and check oil level as instructed in the separate engine manual packed with your unit.

NOTE: All references to right or left side of the snow thrower are determined from behind the unit in the operating position.

UNPACKING

•Remove staples or break glue on the top flaps of the carton. Remove any loose parts included with unit (i.e., Operator’s Manual, etc).

•Cut along dotted lines and lay end of carton down flat. Remove packing material.

•Roll unit out of carton. Check carton thoroughly for loose parts before discarding.

TOOLS REQUIRED FOR ASSEMBLY

•(1) 3/8" Wrench

•(2) 7/16" Wrench*

•(2) 1/2" Wrench*

•9/16” Wrench

•Pair of pliers

*or adjustable wrench

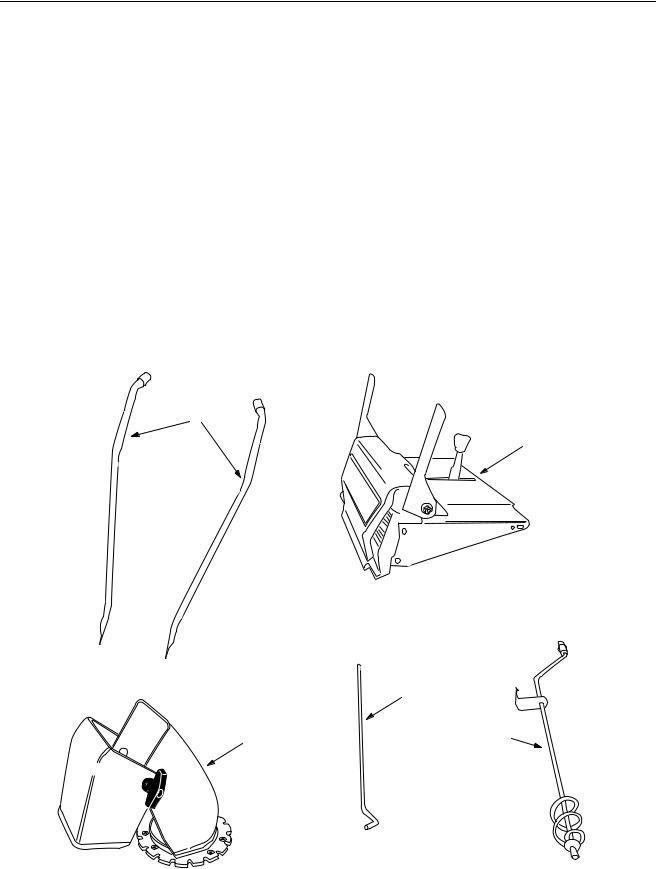

LOOSE PARTS IN CARTON See Figure 3

A(2) Handles (Right and Left)

B(1) Handle Panel Assembly

C(1) Chute Assembly

D(1) Chute Crank Assembly w/ Upper Mounting Bracket

E(1) Shift Rod

(1)Hardware Pack (not illustrated)

A

B

E

C D

Figure 3

6

Lock

Washers

Cable |

|

|

Roller |

Handle |

Hex Bolt |

Guide |

3/4” Long |

|

|

Tab |

|

Hex

Bolt 1-3/4”

Long

Figure 4

Cupped

Cupped

Washer Hex

Nut

|

NOTE: |

|

|

Place the CUPPED |

|

Carriage |

side against the |

|

handle panel. |

||

Bolt |

||

|

||

Figure 5 |

|

“Z” End

Hex Jam

Hex Jam

Nut

Nut

Cable is Straight

Figure 6

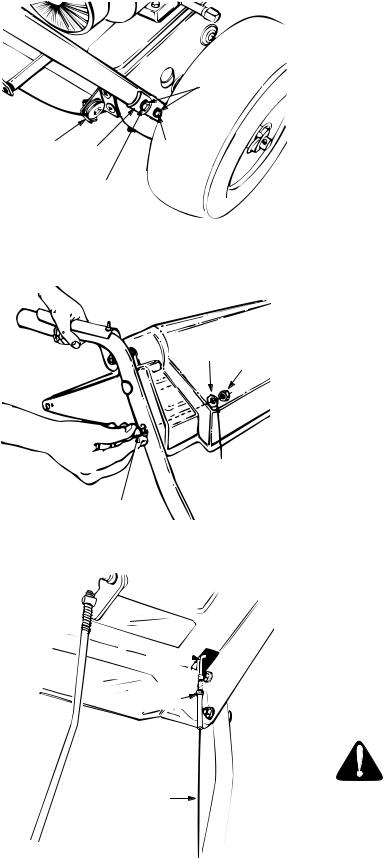

ATTACHING THE HANDLE ASSEMBLY

(Hardware A)

1.Place right handle (A) in position against the snow thrower so the flat side of the handle is against the snow thrower. Secure bottom hole in handle to snow thrower using hex bolt 3/4" long and lock washer. See Figure 4. Do not tighten at this time.

2.Place handle tab over the upper hole in handle so the curve in the handle tab matches the curve in the handle. Secure to the snow thrower using hex bolt 1-3/4" long and lock washer. Do not tighten at this time.

3.Attach the left handle (A) in the same manner. Do not tighten at this time.

4.Place the handle panel (B) in position between the handles. To hold the handle panel in place, depress both clutch grips against the handles. While continuing to hold the right hand grip, release the left hand grip (the auger clutch lock will keep left hand grip engaged). See Figure 4.

5.Fasten right side of the handle panel by inserting two carriage bolts through handle and handle panel (bolts must go through both the plastic and metal parts of the handle panel). Secure with cupped washers (cupped side against handle panel) and hex nuts. See Figure 5.

6.Secure the left side of the handle panel in the same manner.

7.Tighten the four hex bolts used to attach the bottom of the handles to the snow thrower frame.

ATTACHING THE CLUTCH CABLES

The “Z” end of the clutch cables are hooked into the clutch grips on each handle. Attach cables as follows.

1.Thread the hex jam nuts all the way up the threaded portion of the “Z” ends of the clutch cables.

2.Make certain all cables are in the grooves of the cable roller guides. The two roller guides are located in the lower rear of the unit, one on each side.

3.Thread the cable onto the threaded portion of the “Z” end until there is no slack in the cable, but the cable is NOT tight. Do not overtighten cable. See Figure 6.

WARNING: If cable is tightened so there is tension on the cable with the clutch grip released, the safety features of the snow thrower may be overridden.

4.When correct adjustment is reached, tighten the hex jam nut against the bottom portion of the cable to lock it in position.

7

Chute

Assembly

Hex Head

Screw

Chute |

Hex Lock |

|

Flange |

||

Nut |

||

Keeper |

||

|

Figure 7 |

|

|

Lock Washer |

|

|

Hex Nut |

|

Hex Bolt |

|

Upper

Chute

Crank

Bracket

Figure 8

Carriage Bolts

Hex Lock Nuts

Figure 9

Flat |

Chute |

Washers |

Crank |

Hairpin Clip

Lower

Chute Crank Plastic

Bracket Bushing

Figure 10

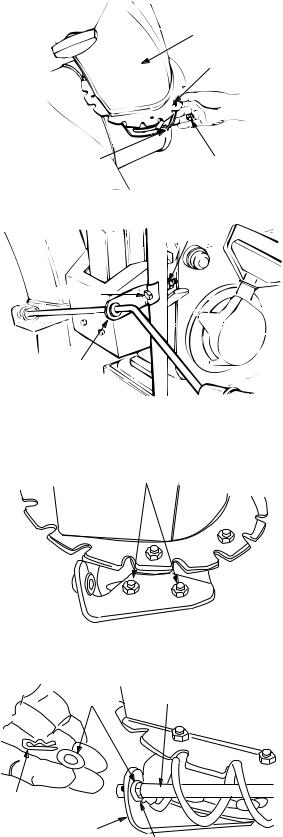

ATTACHING THE CHUTE ASSEMBLY

(Hardware B)

Place chute assembly (C) over chute opening, with the opening in the chute assembly facing the front of the unit. Place chute flange keepers beneath lip of chute assembly, with the flat side down. Secure with hex head screws and hex lock nuts as shown in Figure 7. Tighten with two 7/16" wrenches. Do not overtighten.

NOTE: Locknuts cannot be threaded onto a bolt by hand. Tighten with 2 7/16” wrenches. This type of nut is used where vibration occurs.

ATTACHING THE CHUTE CRANK

(Hardware C)

1.Insert hex bolt 1-1/2" long through the upper chute crank bracket (D). See Figure 8.

2.Place the hex bolt into the hole provided in the left handle. Secure with lock washer and hex nut. Do not tighten until after attaching the other end of the chute crank.

3.To align the spiral on the chute crank, it may be necessary to loosen the carriage bolts and hex lock nuts which secure the lower chute crank bracket to the extension on the left side of the chute assembly. See Figure 9.

4.Place one flat washer on the end of the chute crank, then insert the end of the crank into the hole in the plastic bushing in the chute crank bracket. See Figure 10. Place another flat washer on the end of the chute crank, and insert hairpin clip into hole in the end of crank.

5.Adjust the chute bracket so that the spiral on the chute crank fully engages the teeth on the chute assembly. Tighten the nuts on the lower chute crank bracket securely. Tighten the hex bolt and nut on the upper chute crank bracket on the handle.

8

Traction

Drive  Shift Lever

Shift Lever

Clutch

Hairpin

Clip

Flat |

|

|

Washer |

Ferrule |

|

|

||

Shift |

Shift |

|

Arm |

||

Rod |

||

Assembly |

||

|

Figure 11

“Z” End

Hex Jam

Hex Jam

Nut

Nut

Cable is Straight

Figure 12

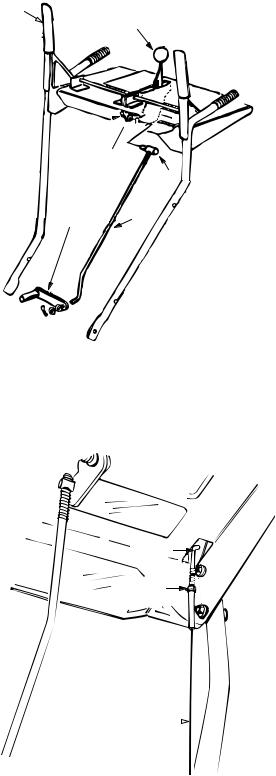

IMPORTANT: Attach the shift rod and clutch cables as follows. THEN CHECK THE ADJUSTMENTS AS INSTRUCTED, AND MAKE ANY FINAL ADJUSTMENTS NECESSARY BEFORE OPERATING YOUR SNOW THROWER. Failure to follow the instructions may cause damage to the snow thrower.

ATTACHING THE SHIFT ROD (Hardware D)

1.Place the shift lever (on the handle panel) in the sixth (6) speed position (all the way forward).

2.Place the bent end of the shift rod (E) into the hole in the shift arm assembly. See Figure 11. Secure with flat washer and hairpin clip.

3.Start threading the ferrule onto the other end of the shift rod. Push down on the shift rod (and shift arm assembly) as far as it will go.

4Thread the ferrule onto the shift rod until the ferrule lines up with the upper hole in the shift lever (beneath the handle panel). Insert the ferrule into the upper hole in the shift lever from the left side when adjustment is correct. Secure with flat washer and hairpin clip.

Make certain to check for correct adjustment of the shift rod as instructed in the Final Adjustment section before operating the snow thrower.

FINAL ADJUSTMENTS

Auger Drive Clutch

To check the adjustment of the auger drive clutch, push forward on the left hand clutch grip (depress the rubber bumper). There should be slack in the cable. Release the clutch grip. The cable should be straight. Make certain you can depress the auger drive clutch grip against the left handle completely.

If necessary, loosen the hex jam nut and thread the cable in (for less slack) or out (for more slack) as necessary. Refer to Figure 12. Recheck the adjustment. Tighten the jam nut against the cable when correct adjustment is reached.

9

Loading...

Loading...