Mitsubishi Electronics FX2N-8AD User Manual

USER’S MANUAL

FX2N-8AD Analog input block

FX2N-8AD Analog input block

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the correct installation

and operation of the FX

install or use the unit.

-8AD Analog input block. It should be read and understood before attempting to

2N

• Further information can be found in the FX

/FX1N/FX2N/FX

0N

Series Hardware Manual for connecting main

2NC

unit, and the FX Series Programming Manual(ΙΙ).

• If in doubt at any stage of the installation of FX

-8AD Analog input block always consult a professional

2N

electrical engineer who is qualified and trained to the local and national standards that applies to the

installation site.

• If in doubt about the operation or use of FX2N-8AD Analog input block please consult the nearest Mitsubishi

Electric distributor.

• This manual is subject to change without notice.

FX2N-8AD Analog input block

FX

2N

-8AD Analog input block

USER’S MANUAL

Manual number : JY992D86001

Manual revision : C

Date : April 2003

FX2N-8AD Analog input block

ii

FX2N-8AD Analog input block

Guidelines for the Safety of the User and Protection of the FX2N-8AD Analog

input block.

This manual provides information for the use of the FX2N-8AD Analog input block. The manual

has been written to be used by trained and competent personnel. The definition of such a

person or persons is as follows:

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual, should be of a competent

nature, trained and qualified to the local and national standards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for said product. All

maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment (see Note) should be trained to use this

product in a safe manner in compliance to established safety practices. The operators

should also be familiar with documentation which is associated with the actual operation

of the completed equipment.

Note :

The term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

iii

FX2N-8AD Analog input block

Notes on the Symbols Used in this Manual

At various times throughout this manual certain symbols will be used to highlight points which

are intended to ensure the users personal safety and protect the integrity of equipment.

Whenever any of the following symbols are encountered its associated note must be read and

understood. Each of the symbols used will now be listed with a brief description of its meaning.

Hardware Warnings

1) Indicates that the identified danger

2) Indicates that the identified danger could

damage.

3) Indicates a point of further interest or further explanation.

Software Warnings

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point which the user of the associate software element should

be aware.

6) Indicates a point of interest or further explanation.

WILL

cause physical and property damage.

POSSIBLY

cause physical and property

iv

FX2N-8AD Analog input block

• Under no circumstances will Mitsubishi Electric be liable responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to understanding

the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

use of the product based on these illustrative examples.

• Please contact a Mitsubishi Electric distributor for more information concerning applications

in life critical situations or high reliability.

v

FX2N-8AD Analog input block

vi

FX2N-8AD Analog input block Contents.

Guideline................................................................... .........................................................iii

1. Introduction .........................................................................................1-1

2. External Dimensions...........................................................................2-1

3. Part Name...........................................................................................3-1

4. Installation...........................................................................................4-1

5. Connection to PLC..............................................................................5-1

6. Wiring..................................................................................................6-1

6.1 Caution.............................................................................................................6-1

7. Specifications......................................................................................7-1

8. Buffer Memory (BFM).........................................................................8-1

8.1 Buffer Memories (BFM) lists ............................................................................8-3

8.2 Details of buffer memories.............................................................................8-13

8.2.1 BFM #0, #1: Specifies input mode. ...................................................................8-13

8.2.2 BFM #2 to BFM #9: Number of times of averaging...........................................8-15

8.2.3 BFM #10 to BFM #17: Channel data.................................................................8-17

8.2.4 BMF #19: Disables setting change....................................................................8-17

8.2.5 BFM #20: Initializes functions............................................................................8-17

8.2.6 BFM #21: Writes I/O characteristics..................................................................8-18

8.2.7 BFM #22: Sets convenient functions.................................................................8-19

8.2.8 BFM #24: Specifies high-speed conversion channel ........................................8-20

8.2.9 BFM #26: Upper/lower limit value error status..................................................8-21

8.2.10 BFM #27: A/D data sudden change detection status........................................8-22

8.2.11 BFM #28: Scale over status..............................................................................8-23

8.2.12 BFM #29: Error status.......................................................................................8-25

8.2.13 BFM #30: Model code.......................................................................................8-26

vii

FX2N-8AD Analog input block Contents.

8.2.14 BFM #32: Operating time ..................................................................................8-26

8.2.15 BFM#33 disconnection detection (Only goods: since V1.1 0)............................8-27

8.2.16 BFM #41 to BFM #48: Offset data

BFM #51 to BFM #58: Gain data.......................................................................8-28

8.2.17 BFM #61 to BFM #68: Addition data .................................................................8-30

8.2.18 BFM #71 to BFM #78: Lowe r limit, error set value

BFM #81 to BFM #88: Upper limit, error set value............................................8-31

8.2.19 BFM #91 to BFM #98: Sudden change detection set value..............................8-33

8.2.20 BFM #99: Clears upper/lower limit value error and sudden change detection error

..........................................................................................................................8-35

8.2.21 BFM #101 to BFM #108: Peak value (minimu m value)

BFM #111 to BFM #118: Peak value (maximum value)....................................8-36

8.2.22 BFM #109: Peak value reset flag (minimum value)

BFM #119: Peak value reset flag (maximum value)..........................................8- 37

8.2.23 BFM #198: Data history sampling time .............................................................8-38

8.2.24 BFM #199: Resets or stops data history...........................................................8-40

8.2.25 BFM #200 to BFM #3399: Data history.............................................................8-41

9. Adjustment of I/O Characteristics........................................................9-1

9.1 Standard I/O characteristics............................................................ ......... ........9-2

9.2 Adjustment of I/O characteristics.....................................................................9-7

10. Example program..............................................................................10-1

Appendix A

Associated Manuals List........................................................................... A -1

viii

FX2N-8AD Analog input block

1. Introduction

The FX2N-8AD analog input block (hereafter referred to as "FX2N-8AD") converts 8 points of

analog input values (voltage input, current input and temperature input) into digital values, and

transfers them to the PLC main unit.

Introduction 1

The FX

-8AD can be connected to FX0N, FX1N, FX2N and FX

2N

Series PLC.

2NC

1) Analog inputs can be selected from the voltage input, the current input and the thermocouple

input (temperature input) by the input mode setting by the TO instruction given by the PLC

main unit and the connection method.

At this time, a different analog input can be selected for each channel.

2) The voltage input can be selected within the range from -10 to +10 V. The current input can

be selected within the range from -20 to +20 mA and from +4 to +20 mA. The input

characteristics can be adjusted for each channel (except while the analog value direct

displa y is used).

The thermocouple input can be selected among the K type, J type and T type. (The input

characteristics cannot be adjusted when the thermocouple input is used.)

3) The resolution is 0.63 mV (20 V × 1/32,000) or 2.50 mV (20 V × 1/8,000) when the voltage

input is used, 2.50 µA (40 mA × 1/16,000) or 5.00 µA (40 mA × 1/8,000) when the current

input is used, and 0.1 °C when the thermocouple input is used.

1-1

FX2N-8AD Analog input block Introduction 1

4) Up to two FX2N-8AD units can be connected to FX0N main unit, FX0N extension unit, FX

main unit.

Up to eight FX

8AD units can be connected to one FX

(For connection to the FX

Data transfer with the PLC is performed to buffer memories of the FX

-8AD units can be connected to one FX2N Series PLC. Up to four FX2N-

2N

Series PLC.

2NC

Series PLC, an FX

2NC

-CNV-IF is required.)

2NC

-8AD by FROM/TO

2N

instructions.

1N

1-2

COM2

I8+

I4+

V3+

I3+

COM3COM1

COM5

COM8

I5+

24+ 24-

POWER

24V

V2+

I2+

V4+

V7+

V1+

I1+

COM4

V5+

V6+

I7+

I6+

COM6

COM7

V8+

7.5(0.30)

7.5(0.30)

105(4.13)

8(0.31)

75(2.95)

90(3.54)

67(2.64)

(installation dimension)

75(2.95)

8(0.31)

FX2N-8AD

98(3.86)

(installation dimension)

FX2N-8AD Analog input block

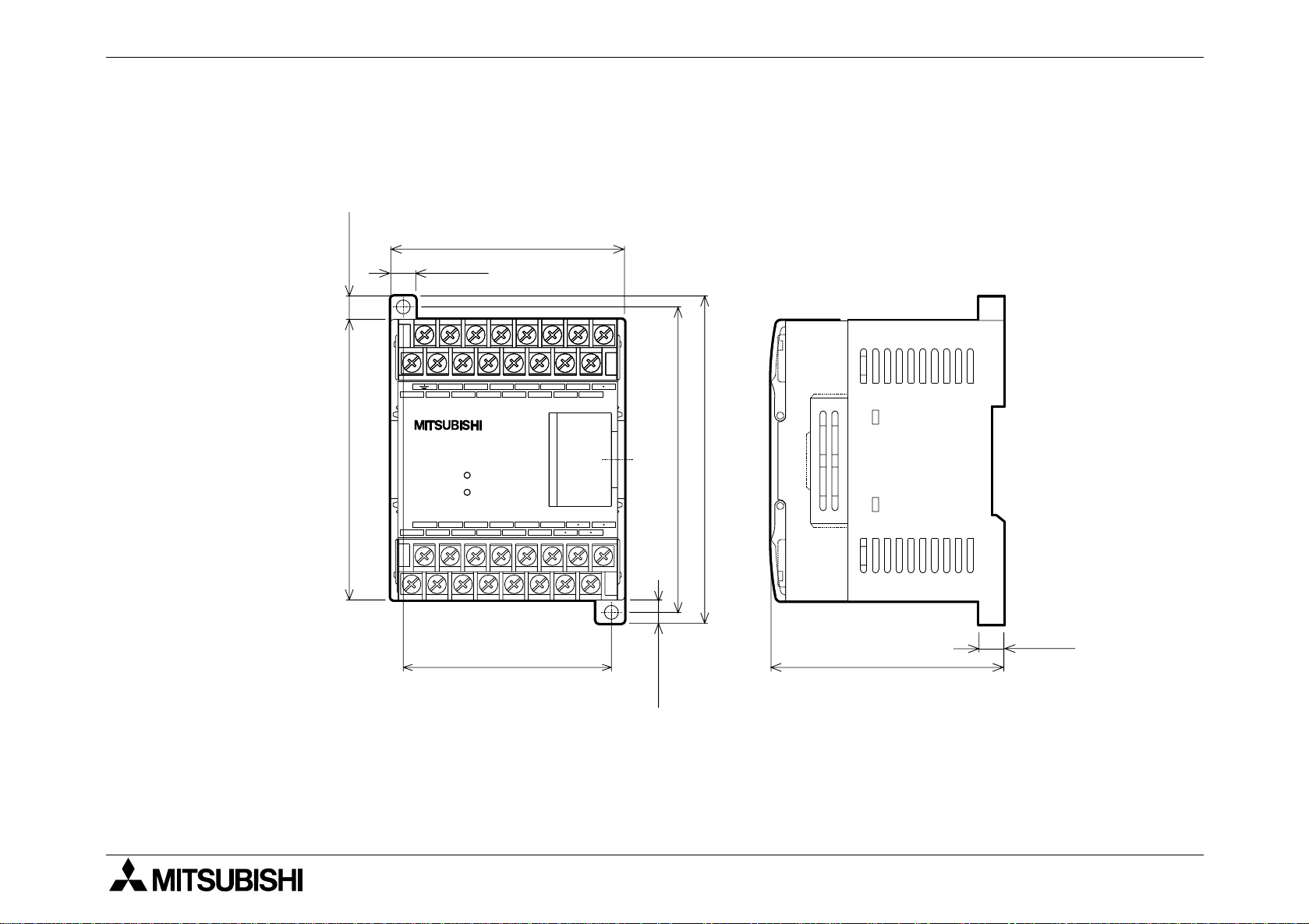

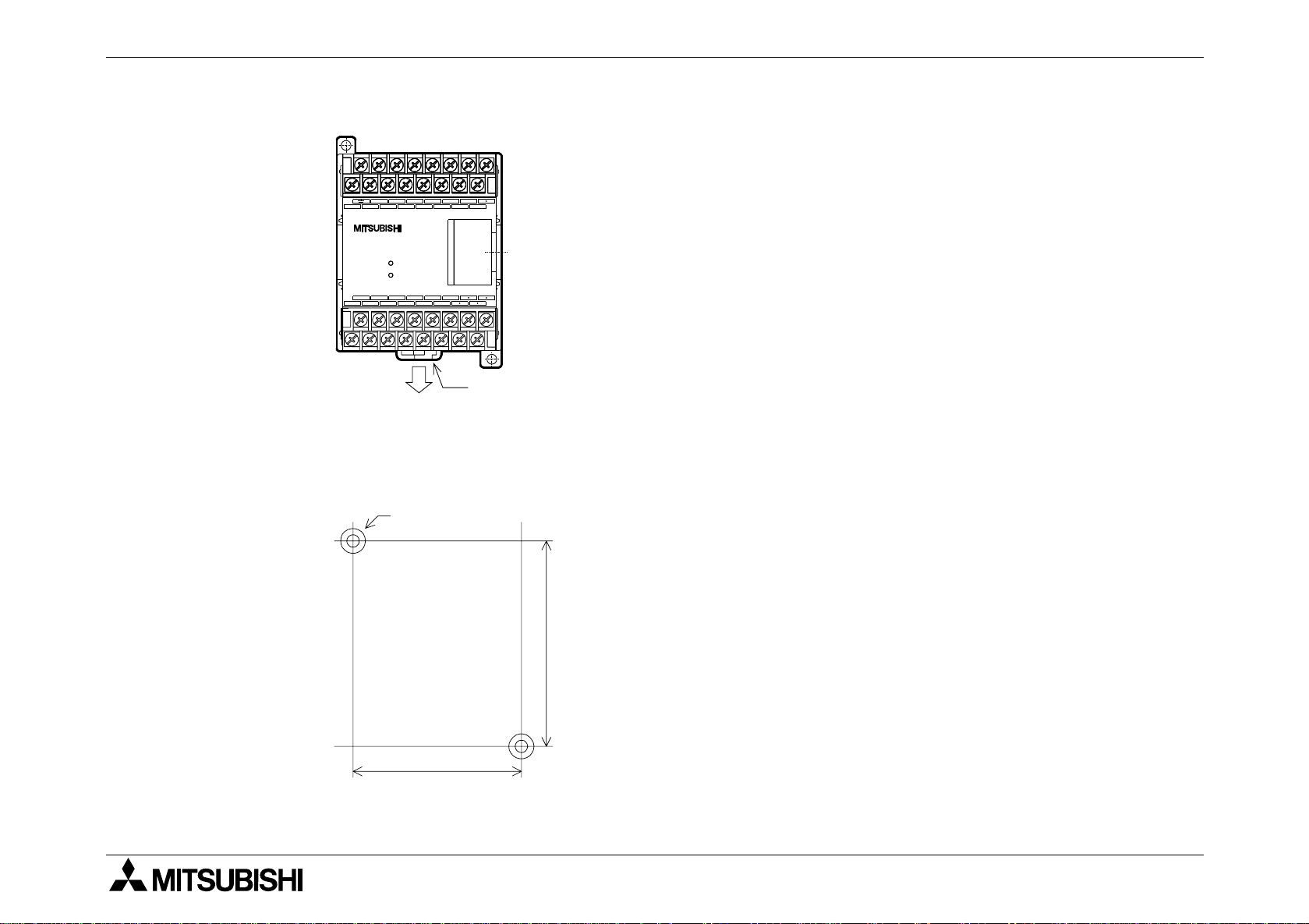

2. External Dimensions

Figure 2.1: External Dimensions

External Dimensions 2

Dimensions: mm(inch)

Mass(Weight): 0.3 kg(0.66 lbs)

2-1

FX2N-8AD Analog input block External Dimensions 2

MEMO

2-2

FX2N-8AD Analog input block

3. Part Name

Part Name 3

Figure 3.1: Part name

Installation hole (screw M4)

Extension

cable

I1+V1+

24-24+

FX2N-8AD

I6+

V6+

V5+

I5+

Hook for DIN rail

COM1 COM3

POWER

24V

COM6

V7+

COM5

V8+

COM2

I7+

Status indicator LED

I3+V3+

V4+I2+V2+

I4+

COM4

I8+

COM8

COM7

Extension

connector

M3

(terminal screw)

Table 3.1: Status indicator LED

Indication Description

POWER

24 V

Lit while 5 V power is normally

supplied from PLC.

Lit while 24 V power is normally

supplied to “24+” and “24-”

terminals of FX

-8AD.V

2N

Terminal arrangement

V1+ I1+

24+ 24- V2+ I2+ V4+ I4+

COM6

V6+

V5+ I5+

I6+

COM5

COM1

COM2

V8+ I8+

V7+ I7+

V3+ I3+

COM7

COM8

COM3

COM4

• For wiring, refer to Section 6.

• Never perform wiring to terminals.

•

3-1

FX2N-8AD Analog input block Part Name 3

MEMO

3-2

FX2N-8AD Analog input block

4. Installation

Install the FX2N-8AD to the right side of a main unit, extension unit, extension block or special

Installation 4

block of the FX

The FX

-8AD can be installed with a DIN rail (DIN46277 of 35 mm in width) or directly

2N

/FX1N/FX2N/FX

0N

Series PLC.

2NC

installed with screws M4. For the details, refer to the handy manual supplied together with the

PLC main unit.)

4-1

FX2N-8AD Analog input block Installation 4

Figure 4.1: Installation with DIN rail

• The FX2N-8AD can be installed on a DIN rail

I1+V1+

COM1 COM3

V3+

24+

V5+

24-

FX2N-8AD

I6+

V6+

I5+

V2+

COM6

COM5

I2+

POWER

24V

V7+

I3+

I4+

COM2

V8+

I7+

COM4

V4+

I8+

COM8

COM7

Hook for DIN rail

Figure 4.2: Direct installation

Installation

screw M4

(DIN46277) of 35 mm in width as it is. For

removal, pull down on the DIN rail mounting

hook, then remove the FX

2N

-8AD.

•The FX2N-8AD can be installed directly by

inserting screws (M4) into installation holes.

For the pitch and the position of installation

holes, re fer to the figure on the le ft.

67(2.64)

Dimensions: mm(inch)

98(3.86)

4-2

FX2N-8AD Analog input block

5. Connection to PLC

Connect the FX2N-8AD to the right side of a main unit, extension unit or extension block of

Connection to PLC 5

FX

For c onnection t o a basic unit or extension block o f the FX

, FX1N, FX2N, FX

0N

Series PLC with an extension cable.

2NC

Series PLC, use an FX

2NC

2NC

-CNVIF.

Please check power supply availability to deter mine the number of FX

be connected to the FX

, FX1N, FX2N or FX

0N

2NC

PLCs.

-8AD blocks that can

2N

A unit No. 0 to 7 is automatically assigned to each special unit or special block connected to a

PLC basic unit from the one nearest to the basic unit.

The data is read from a nd written to the FX

-8AD by FROM/TO instr uctions given by the

2N

basic unit.

5-1

FX2N-8AD Analog input block Connection to PLC 5

MEMO

5-2

FX2N-8AD Analog input block

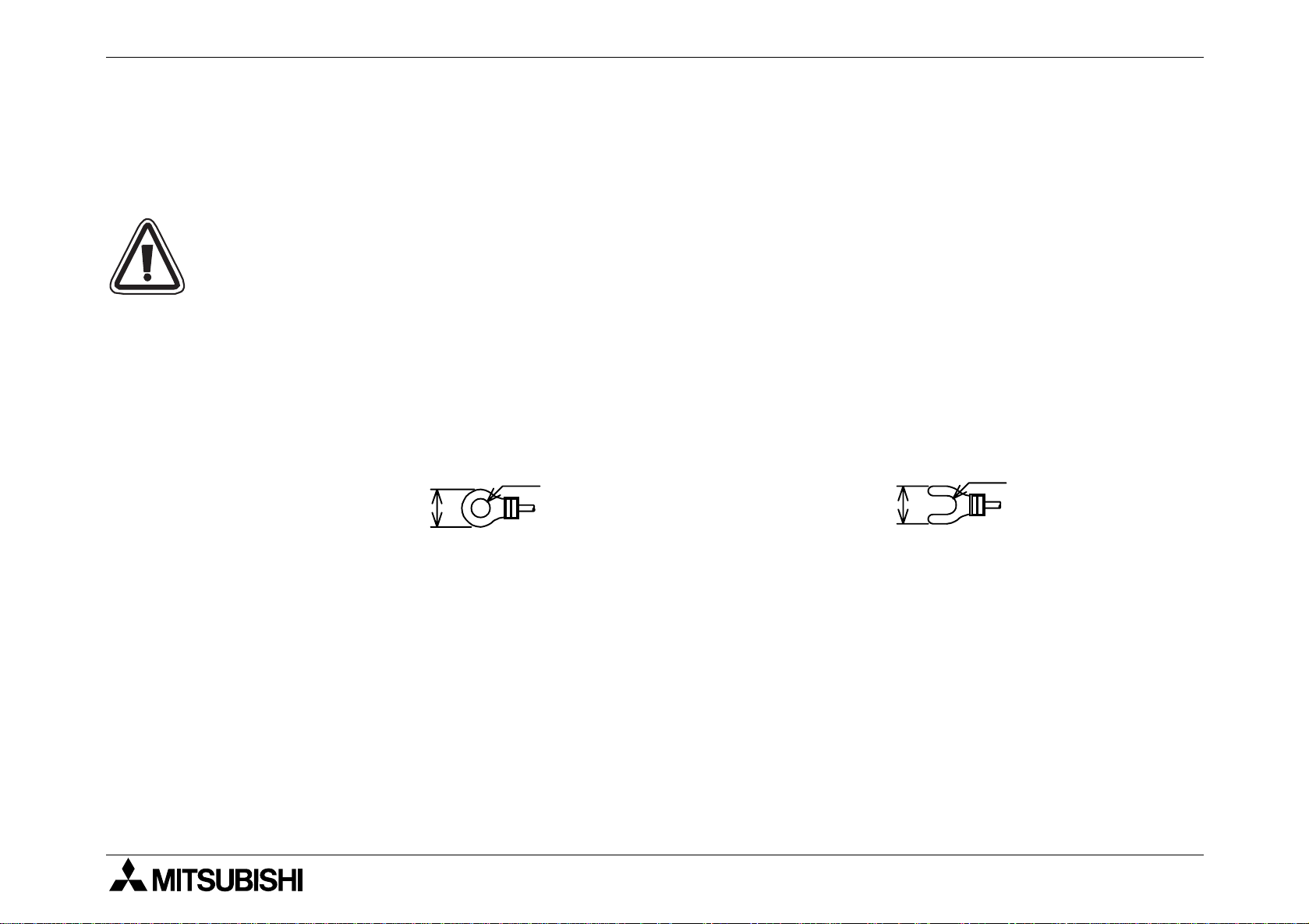

6. Wiring

6.1 Caution

1) Do not lay signal c ab le near to high voltage power cab le or house them in the same trunking

duct. Effects of noise or surge induction may occur. Keep signal cables a safe distance of

more than 100 mm (3.94") from these power cabl es.

Wiring 6

2) The ter minal screws of the FX

-8AD are M3 (0.12"), therefore cr imp style terminals (see

2N

drawing) suitable for use with these screws should be fitted to the cable for wiring.

Figure 6.1: Crimp Terminals

For M3 (0.12")

6.2 mm (0.24" )

or less

For M3 (0.12")

6.2 mm (0.24")

or less

3) The terminal tightening torque is 0.5 to 0.8 Nžm. Tighten securely to avoid malfunction.

4) Cut off all phases of power source before installation or perfor ming wiring work in order to

avoid electric shock or damage of product.

5) Replace the provided terminal cover before supplying power and operating the unit after

installation or wiring work in order to avoid electric shock.

6-1

FX2N-8AD Analog input block Wiring 6

Figure 6.2: Wiring

FX2N-8AD

*6

Thermocouple

(K, J or T type)

*1 Shielded cabl e

Current input

Voltage input

*5

DC24V

*4 Connected to terminal

of PLC main unit

Class D grounding

*3

*2

V3+

I3+

COM3

V2+

I2+

COM2

V1+

I1+

COM1

24+

24-

250

250

250

Ω

Ω

Ω

5.8k

200k

200k

5.8k

200k

AG

Ω

Ω

5.8k

Ω

Ω

Ω

Ω

DC/DC

converter

CH3

CH2

CH1

Note:Use solderless terminals of the following size (M3).

+15V

AG

-15V

Tighten them securely at the tightening torque of 0.5 to 0.8 N•m.

Figure 6.3: Crimp Terminals

For M3 (0.12")

6.2 mm (0.24" )

or less

For M3 (0.12")

6.2 mm (0.24")

or less

6-2

FX2N-8AD Analog input block Wiring 6

*1 Use a two-core, twisted, shielded cable for the analog input line, and separate it from

other power lines or a lines easily induced.

*2 If there is voltage ripple in the input or there is noise in the external wiring, connect a

capacitor of approximately 0.1 to 0.47 µF, 25 V.

*3 F or the current input, mak e sure to sho rt-circuit the “V O+” terminal and the “IO+” terminal

(O: input channel No.).

*4 Make sure to connect the terminal to the terminal of the PLC main unit to

which Class D grounding (100 Ω or less) is performed.

*5 The 24 V DC service power supply of the PLC is also available.

*6 Use an isolated type thermocouple.

- When using the thermocouple input, use compensating conductors suitable to the

thermocouple.

- Never perform wiring to terminals.

•

- For the terminal arrangement, refer to Section 3.

6-3

FX2N-8AD Analog input block Wiring 6

MEMO

6-4

FX2N-8AD Analog input block

7. Specifications

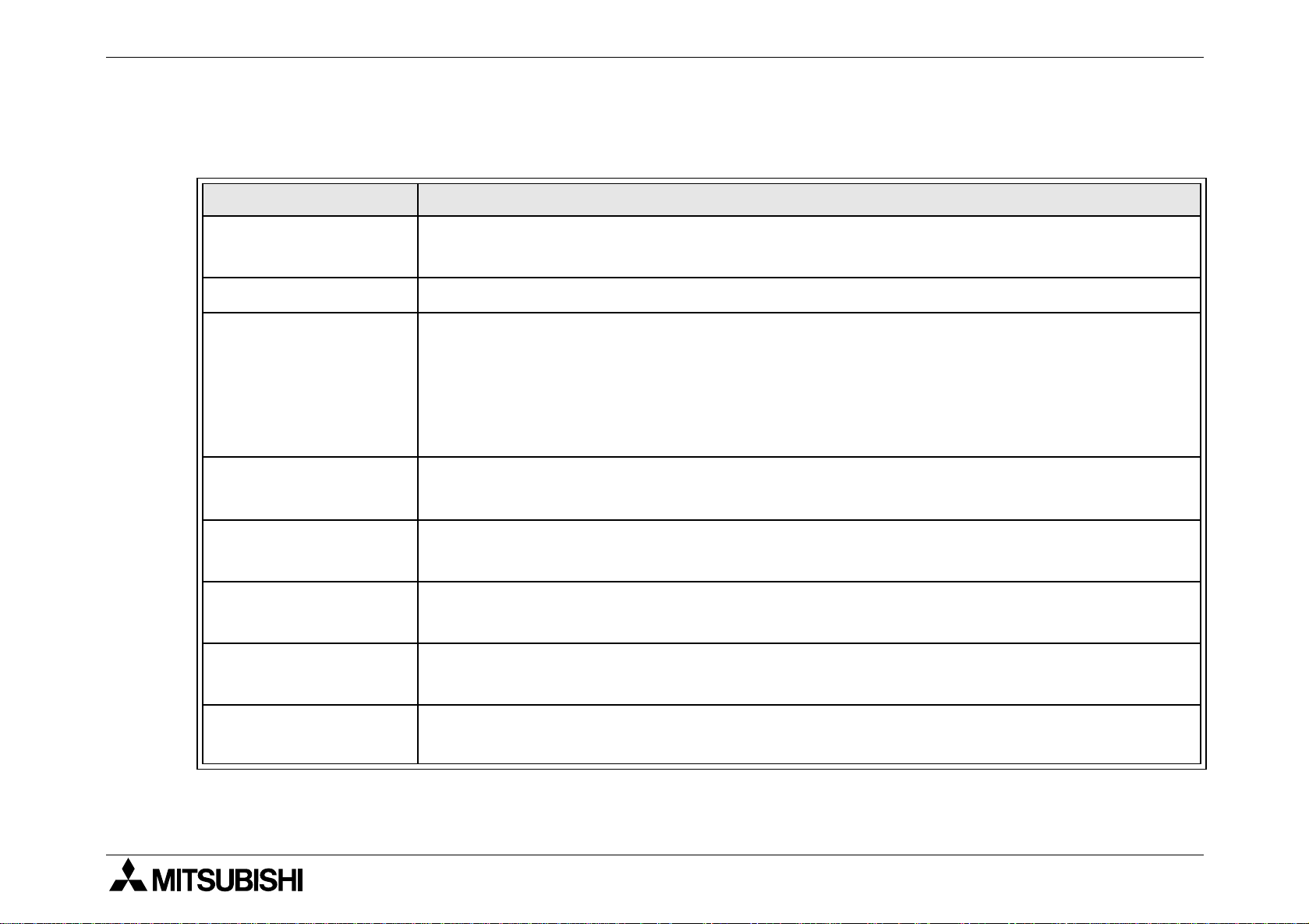

Table 7.1: General specifications

Item Specifications

Specifications 7

Ambient temperature

0 to +55 °C during operation, -20 to +70 °C during storage

range

Ambient humidity 35 to 85 % RH during operation (Dew condensation shall not be allowed.)

In conformance to JIS C0040

F requency 10 to 57 Hz, half amplitude 0.075 mm, 57 to 150 Hz, acceleration 9.8

Vibration resistance

2

m/s

, 10 times in each of X, Y and Z directions (80 times in total)

(For product installed with DIN rail: F requency 10 to 57 Hz, half amplitude 0.035

2

mm, 57 to 150 Hz, acceleration 4.9 m/s

)

In conformance to JIS C0041

Impact resistance

147 m/s

2

for 11 ms, 3 times in each of X, Y and Z directions with half-sine pulses

By noise simulator of noise voltage 1,000 Vp-p, noise width 1 µs and frequency

Noise resistance

30 to 100 Hz

500 V AC for 1 min

Withstand voltage

(between analog input ter m inal and each terminal of PLC main unit)

In conformance to JEM-1021

Insulation resistance

5 MΩ or more by 500 V DC Megger (between all terminals as a whole and case)

Operating

atmosphere

Corrosive gas and much dusts shall not be detected.

7-1

FX2N-8AD Analog input block Specifications 7

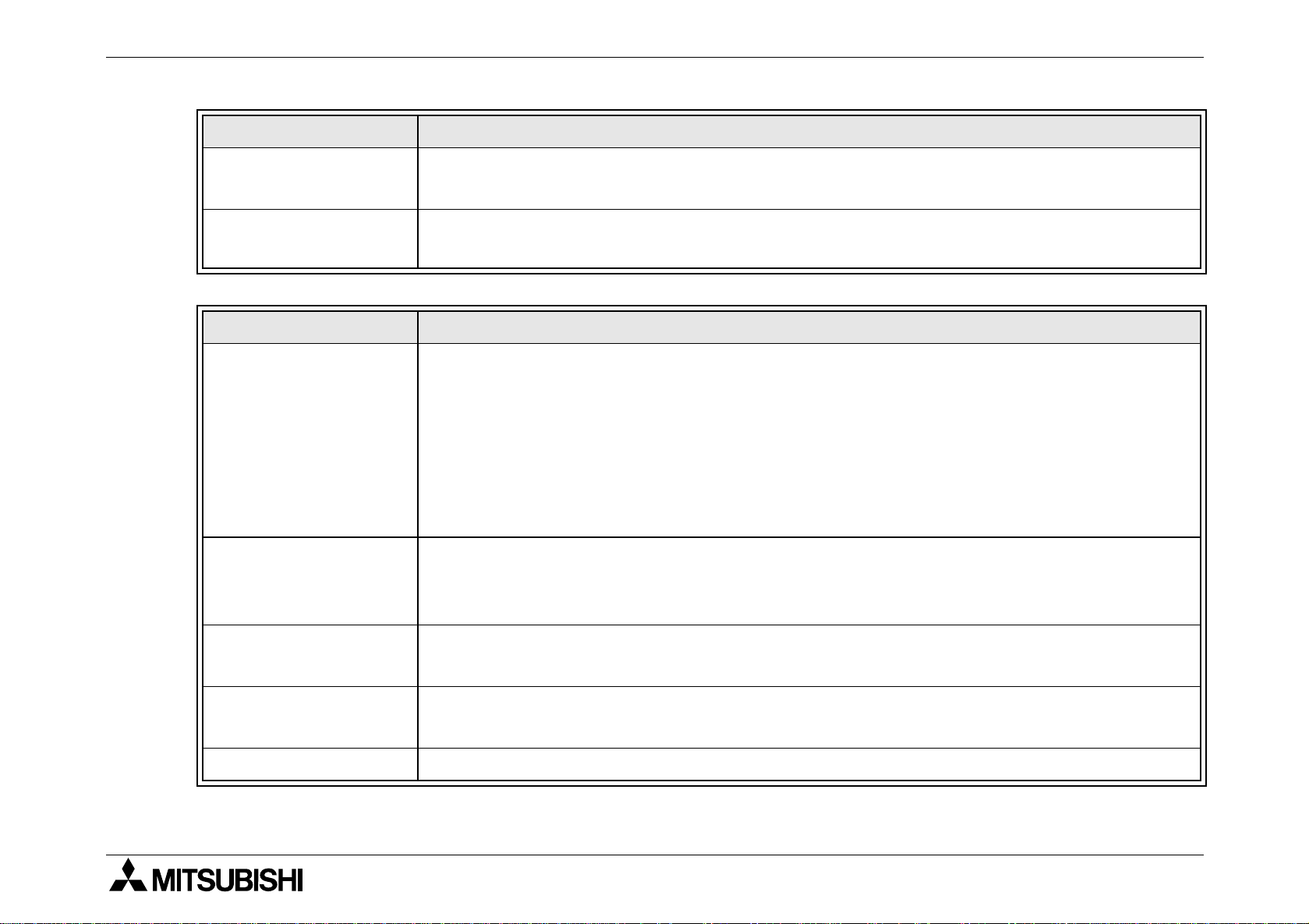

Table 7.2: Power supply specifications

Item Specifications

Interface driving

24 V DC±10%, 80 mA (maximum), supplied via terminal from outside

power supply

CPU driving power

5 V DC, 50 mA, supplied via extension cable from PLC main unit

supply

Table 7.3: Performance specifications

Item Specifications

• When only voltage input and current input are used

500 µs x Number of used channels

• When thermocouple input is used for 1 or more channels

Conv ersion speed

Insulation method

Channel for voltage/current input: 1 ms x Number of used channels

Channel for thermocouple input: 40 ms x Number of use d channels

(Number of used channels indicates number of all channels used for voltage

input, current input or thermocouple input.)

Photocoupler insulates analog inpu t area from PLC.

DC/DC converter insulates power supply from analog I/O.

Channels are not insulated each other.

Number of occupied

8 points (including input points and output points)

I/O points

0N

FX

, FX1N, FX2N, FX

Applicable PLC

(For connection to FX

Built-in memory EEPROM

2NC

Series PLC

2NC

Series PLC, FX

2NC

-CNV-IF is required.)

7-2

FX2N-8AD Analog input block Specifications 7

Table 7.4: Voltage/current input specifications

Item Voltage input Current input

-10 to +10 V DC

(input resistance: 200 kΩ)

Adjustment is ena b led in following condition:

Offset value: -10 to +9 V

Analog input range

Digital output Signed 16-bit binary Signed 16-bit binary

Resolution

Gain val ue: 10 V or less

"Gain - Offset": > 1 V

(Resolution is constant.)

However, change is disabled while an alog

value direct display is used.

Maximum absolute input: ±15 V

0.63 mV (20 V × 1/32000)

•

2.5mV (20 V × 1/8000)

•

-20 to +20 mA DC, +4 to +20 mA DC

(input resistance: 250 Ω)

Adjustment is enabled in following condit ion:

Offset v alue: -20 to +17 mA

Gain value: 30 mA or less

"Gain - Offset": > 3 mA

(Resolution is constant.)

However, change is disabled while analog

value direct displa y is used.

Maximum absolute input: ±30 mA

2.50 µA (40 mA × 1/16,000)

•

during input of -20 to +20 mA

5.00 µA (40 mA × 1/8,000)

•

during input of -20 to +20 mA

2.00 µA (16 mA × 1/8,000)

•

during input of +4 to +20 mA

4.00 µA (16 mA × 1/4,000)

•

during input of +4 to +20 mA

Total accuracy

Ambient temperature: 25 °C ± 5 °C

±0.3% (±60 mV) against full scale 20 V

Ambient temperature: 0 to +55 °C

±0.5% (±100 mV) against full sc ale 20 V

Ambient temperature: 25 °C ± 5 °C

µ

±0.3% (±120

+4 to +20mA input is same (±120

Ambient temperature: 0 to +55 °C

±0.5% (±200

+4 to +20mA input is same (±200

A) against full scale 40 mA

µ

A) against full scale 40 mA

7-3

µ

µ

A)

A)

Loading...

Loading...