Miller Electric Syncrowave 200 User Manual

Syncrowave 200 |

Issued November 2005 • Index No. AD/4.4 |

® |

TIG/Stick Welding |

|

Power Source |

Quick

Specs

Light Industrial Applications |

Processes |

Input Power Requires 1-Phase Power |

||

Light Metal Fabrication |

TIG (GTAW) Welding |

Amperage Range |

5 – 200 |

A |

Maintenance/Repair Operations |

Stick (SMAW) Welding |

Rated Output 150 A at 26 |

V, 40% Duty Cycle |

|

Light Manufacturing |

Pulsed TIG (GTAW-P) Welding |

|||

Automotive Repair |

|

Weight Base Model: 238 lb (108 kg) |

||

Vocational Training |

|

|||

|

Runner: |

271 lb (123 kg) |

||

Hobbyist |

|

|||

|

|

|

|

|

The Power of Blue®.

Squarewave output with AC balance control features adjustable penetration and cleaning action while increasing arc stability on various aluminum alloys, and helps eliminate tungsten spitting and arc rectification.

NEW! Cable management system uses dual cable hangers and foot control storage conveniently attach to the power source side panels to allow all weld cables and the remote foot control to be neatly stored, preventing torch, cable or remote damage.

NEW! Syncro Start™ allows the operator to choose from three different starting conditions to optimize the application (Soft/Standard/Hot).

NEW! Runner has low cylinder rack to eliminate the need for lifting when changing gas cylinders.

Fan-On-Demand™ improves power |

|

|

|

efficiency and reduces noise and |

Syncrowave |

||

maintenance by lessening the amount |

|||

of airborne contaminants pulled |

200 Runner |

||

through the machine. |

|

|

|

Adaptive Hot Start™ for |

|

|

|

Stick arc starts automatically |

|

|

|

increases the output amperage at |

|

|

|

the start of a weld should the start |

|

|

|

require it. Prevents the electrode from |

|

|

|

sticking and creating an inclusion. |

|

|

|

NEW! Weldcraft® WP1712SFDI50 |

|

|

|

|

|

|

|

TIG torch. 150 A, air-cooled torch |

|

|

|

features super flex (SF) braided nylon |

|

|

|

power cable for maximum flexibility. |

|

|

|

Power source is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

NEW! Auto-Postflow protects the weld end zone and electrode by optimizing postflow time based on welding amperage — for adequate shielding every time without waste and no need for adjustment.

NEW! Dual digital meters with alpha-numeric displays allow for quick and easy viewing and preset values for voltage, amperage and other key variables. Allows for greater accuracy and repeatability in the welding procedure.

NEW! Built-in pulse control enhances weld bead and puddle control for improved appearance and quality — reduce burn through, coordinate the addition of filler material, and reduce the warping effects of distortion by reducing the average heat input.

NEW! 115 V auxiliary power receptacle is conveniently located on the front panel, allowing for operation of a Coolmate™ torch coolant system or other small tools.

Arc hour/cycle counter records actual welding time and number of arc starts.

DIG control allows the arc characteristics to be changed for specific applications and electrodes. Lower the DIG setting for smooth running electrodes like E7018 and increase the DIG setting for stiffer, more penetrating electrodes like E6010.

|

|

|

|

|

Miller Electric Mfg. Co. |

International Headquarters |

Web Site |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

An Illinois Tool Works Company |

Phone: 920-735-4505 |

www.MillerWelds.com |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

1635 West Spencer Street |

USA FAX: 920-735-4134 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Appleton, WI 54914 USA |

Canadian FAX: 920-735-4169 |

|

|

|

|

|

|

|

|

|

|

International FAX: 920-735-4125 |

|

|

|

|

Specifications (Subject to change without notice.)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

575 V |

|

|

|

22 |

12.35 |

6.0 |

|

|

|

|

|

|

|

|

|

|

|

Certified to both the Canadian and U.S. Standards for welding equipment.

Certified to both the Canadian and U.S. Standards for welding equipment.

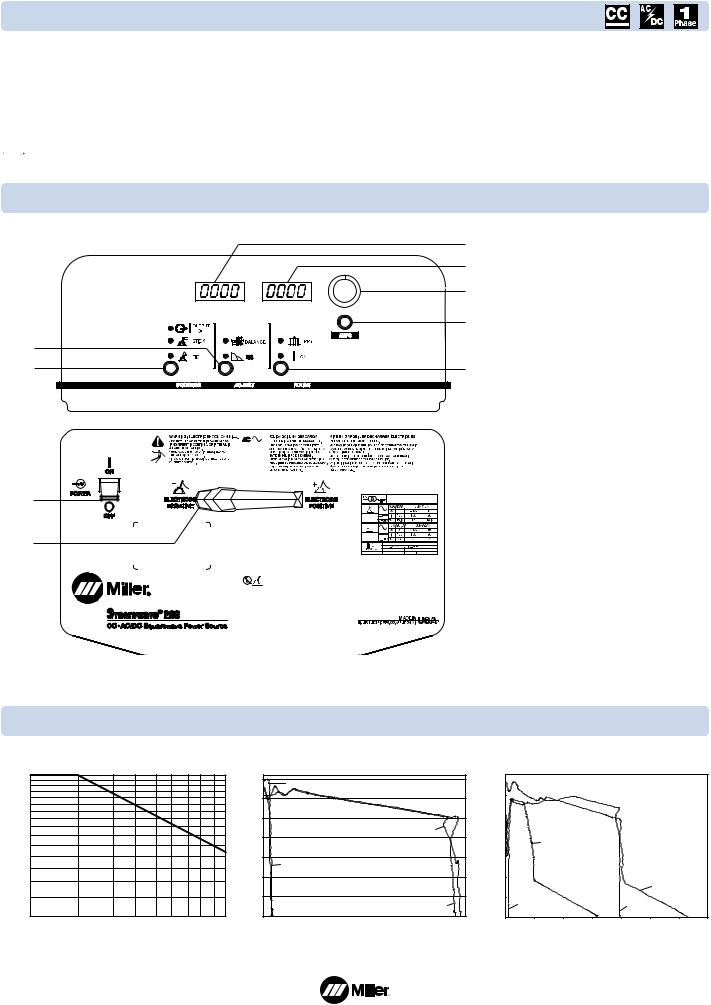

Control Panel

1

2

3

5

6

7

8

1. Balance/DIG Pushbutton Control

9

2. Process Pushbutton Control

3. Power Switch

4. Polarity Switch

5. Voltmeter and Parameter Adjust

6. Ammeter and Parameter Adjust

7. Encoder Adjustment Control

8. Main Amps Pushbutton

(Amperage Control)

9. Pulse Pushbutton Control

4

Loading...

Loading...