Lincoln Electric STT II User Manual

MIG WELDERS

Invertec® STT®II

Featuring the Surface Tension Transfer® (STT) Process

Control Heat Input, Spatter and Fume

The revolutionary STT II power source combines high frequency inverter technology with advanced Waveform Control Technology™ to provide a better welding solution than traditional short arc MIG. Unlike CV MIG machines, the STT machine has no voltage control knob. STT uses current controls to adjust the heat independent of the wire feed speed, so changes in electrode extension do not affect heat. Low heat input welds can be produced without overheating or burning through, and distortion is minimized. Spatter and fumes are reduced because the electrode is not overheated — even when welding with larger diameter wires and 100% CO2 shielding gas.

Processes

GMAW-STT

Advantage Lincoln

•Controlled penetration and outstanding heat input control — Ideal for welding joints with open root, gaps, or on thin material with no burnthrough.

•Reduced spatter and fumes — Current is controlled to achieve optimal metal transfer.

•Reduced welding costs — Ability to use 100% CO2 shielding gas with larger diameter wires.

•Various shielding gases — STT may be used with various gas blends of Argon including Helium.

•Good bead control and faster travel speeds — Can replace TIG (GTAW) in many applications without sacrificing appearance.

•Background and Tailout Current accurately control fine and coarse heat input for reduced distortion and burnthrough as well as proper penetration.

•Adjustable Hot Start controls the heat at the start of the weld.

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•Three-year Lincoln warranty on parts and labor.

Description

Output STT DC |

Input 3 |

60 50 |

|

PHASE |

Hz Hz |

Base Unit Includes

Twist-Mate® Cable Plugs (Qty. 2), STT II Sense Lead Kit, 25 ft. (7.6m)

Recommended General Options

Power Source Remote Output Control, Inverter and Wire Feeder Cart, Dual Cylinder Kit, STT II Sense Lead Kit, Coaxial Cable, Twist-Mate Cable Plug, Twist-Mate Cable Receptacle, Twist-Mate to Lug Adapter

Recommended Wire Feeder Options

STT-10 Wire Feeder, LN-742 Wire Feeder, LN-15 Control Cable Model, Magnum Gun and Cable Assembly, Magnum Connector Kit

Order

K1525-1 |

STT II |

208/230/460/3/60 |

K1526-1 |

STT II |

International 200/220/380/415/440/3/50/60 |

K1526-2 |

STT II |

International 200/208/380/400/415/3/50/60 |

K1527-1 |

STT II |

CE-Approved 200/220/380/415/440/3/50/60 |

K1527-2 |

STT II |

CE-Approved 200/208/380/400/415/3/50/60 |

TECHNICAL SPECIFICATIONS

|

|

|

|

|

|

|

|

Dimensions |

|

|

Product |

Product |

Input |

Rated Output |

Input Current@ |

Output |

H x W x D |

Weight |

|

|

|

Name |

Number |

Power |

Current/Voltage/Duty Cycle |

Rated Output |

Range |

inches (mm) |

lbs. (kg) |

|

|

Invertec |

K1525-1 |

208/230/460/3/60 |

225A / 29V / 60% |

32/30/16A |

Peak Current: |

23.2 x 13.2 x 24.4 |

117 |

|

|

STT II |

|

|

200A / 28V / 100% |

|

0-450A |

(589 x 336 x 620) |

(53) |

|

|

|

K1526-1 |

200/220/380/415/ |

Max. OCV: 85V |

33/30/18/17/16A |

Background |

|

|

|

|

|

International |

440/3/50/60 |

|

|

Current: |

|

|

|

|

|

K1526-2 |

200/208/380/400/ |

|

36/34/20/19/18A |

0-125A |

|

|

|

|

|

|

|

|

|

|||

|

|

|

International |

415/3/50/60 |

|

|

|

|

|

|

|

|

K1527-1 |

200/220/380/415/ |

|

33/30/18/17/16A |

|

|

|

|

|

|

CE-Approved |

440/3/50/60 |

|

|

|

|

|

|

|

|

K1527-2 |

200/208/380/ |

|

36/34/20/19/18A |

|

|

|

|

|

|

CE-Approved |

400/415/3/50/60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Publication E4.52 3/05

www.lincolnelectric.com

A CLOSER LOOK

WHAT IS NEXTWELD®?

Nextweld integrates Lincoln’s technologies, processes and products to create a comprehensive, flexible, user-friendly welding system that can increase efficiency and reduce fabrication costs. Waveform Control Technology™ and digital communications

provide the foundation for Nextweld innovations like Pulse-On- Pulse™, Power Mode™, STT® and ArcLink®. Look for Nextweld for ultimate arc control, high efficiency/reliability and seamless system integration.

Waveform Control Technology®

Driving Superior Welding Performance

Lincoln’s Waveform Control Technology controls and shapes the output waveforms

(or weld modes) to adapt to virtually any application, material or weld position. Waveform Control Technology makes it possible to take advantage of Lincoln Nextweld innovations like the STT Process using the STT II.

For more information see Nextweld Document NX-1.10

STT® (Surface Tension Transfer®) is a controlled GMAW short circuit transfer process that uses current controls to adjust the heat independent of wire feed speed, resulting in superior arc performance, good penetration, low heat input control, and reduced spatter and fumes.

For more information see Nextweld

Document NX-2.20

Conventional CV short |

STT using CO2 |

circuit transfer using CO2 |

and .045” solid wire. |

and .045” solid wire. |

Note reduced spatter and fume. |

|

|

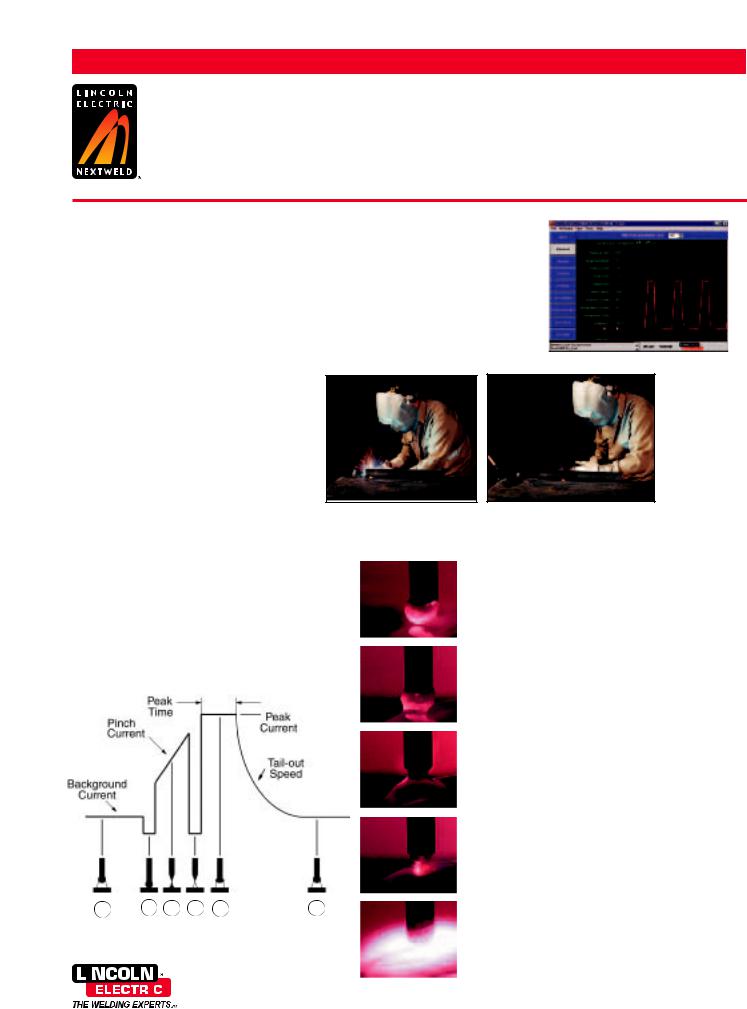

The STT Process |

A. STT produces a uniform molten ball and maintains it |

|

until the "ball' shorts to the puddle. |

B. When the "ball" shorts to the puddle, the current is reduced to a low level allowing the molten ball to wet into the puddle.

C. Automatically, a precision PINCH CURRENT wave form is applied to the short. During this time, special circuitry determines that the short is about to break and reduces the current to avoid the spatter producing "explosion".

D. STT circuitry re-establishes the welding arc at a low current level.

|

A |

B C D E |

A |

E. STT circuitry senses that the arc is re-established, and |

|||

|

|

|

|

|

|

|

automatically applies PEAK CURRENT, which sets the |

|

|

|

|

|

|

|

proper arc length. Following PEAK CURRENT, internal |

|

|

|

|

|

|

|

circuitry automatically switches to the BACKGROUND |

|

|

|

|

|

|

|

CURRENT, which serves as a fine heat control. |

|

|

|

|

|

|

|

Invertec® STT® II |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[2] |

www.lincolnelectric.com |

|

|

|

|

|

|

||

A CLOSER LOOK

USING STT FOR OPEN ROOT WELDING

Open root welding is used for pipe and single-sided plate welding in situations that preclude welding from both sides of the material. This type of welding is common in the petrochemical and process piping industries.

Advantages of STT Open Root

Penetration Control

•Provides reliable root pass and complete back bead. Ensures excellent sidewall fusion.

Cost Reduction

• Uses 100% CO2, the lowest cost gas, when welding carbon steel.

Flexibility

•Provides the capability of welding stainless steel, nickel alloys, and mild or high strength steels without compromising weld quality.

•Capable of welding out of position.

Low Heat Input

• Reduces burnthrough and distortion.

Low Hydrogen Weld Metal Deposit

Speed

• High quality open root welds at faster travel speeds than GTAW.

Current Control Independent of Wire Feed Speed

• Allows operator to control the heat input to the weld puddle.

Ease of Operator Use

•More forgiving process than conventional short arc welding with CV machines.

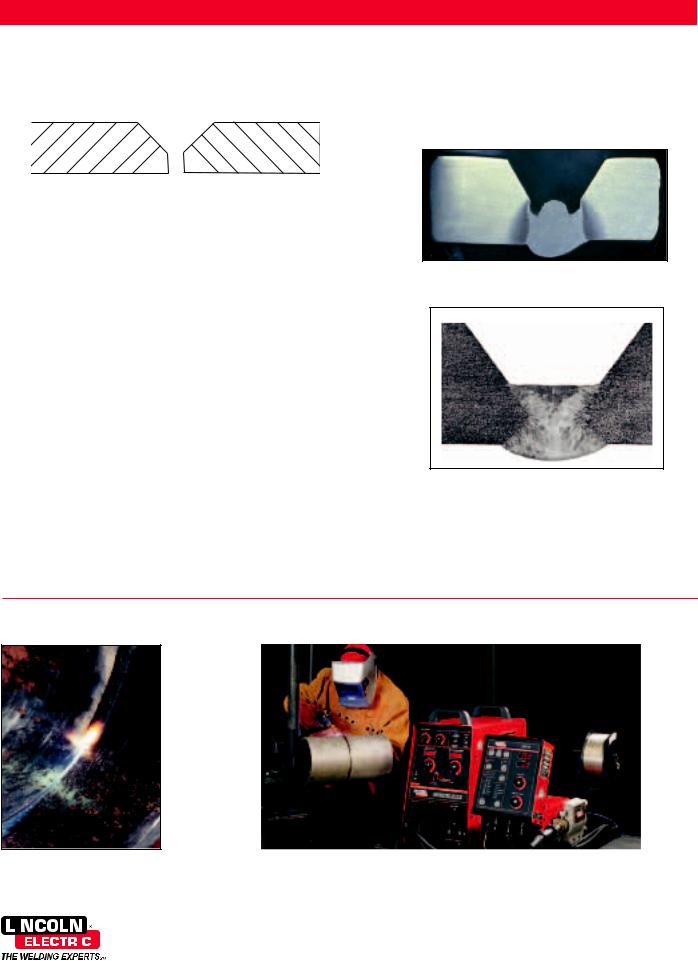

Stick welding with cellulose electrodes provides good fusion characteristics, but leaves deep wagon tracks (requiring more labor for grinding), a very convex root weld, and a high hydrogen deposit.

Open Root Pass with Stick Electrode

Open Root Pass with STT provides a weld ligament thickness of approximately 0.22˝.

•Superior weld profile (no wagon tracks)

•Slight convexity of root weld

•Low hydrogen deposit

STT Open Root Application

Inside of an 8 in. x .375 in. wall API 5L-X52 pipe, welded in 5G position.

STT process using 100% CO2 and .045 in. (1.2mm) wire.

|

|

|

|

|

Invertec® STT® II |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[3] |

www.lincolnelectric.com |

||

|

|||||

Loading...

Loading...