LG TC151, TC80, TC71, TC91, TC51 User Manual

Revision : 05/2004

Manual # : 150-1010

OWNER’S MANUAL

TC SERIES HYDRAULIC COMPACTORS

For Models :

TC51, TC71, TC80, TC91, TC151 & TC301

TECHNOLOGY BREAKER

CONTENTS

General ................................................. |

4 |

TC51 Specifications .............................. |

5 |

TC71 Specifications .............................. |

6 |

TC80 Specifications .............................. |

7 |

TC91S Specifications ............................ |

8 |

TC151S / TC151SH Specifications ....... |

9 |

TC301 / TC301H Specifications ............ |

10 |

Hazard Alerts ........................................ |

11 |

Sizing the Compactor ........................... |

15 |

Typical Hydraulic Circuits ...................... |

17 |

Installation ............................................. |

20 |

Setting Flow & Pressure ....................... |

21 |

Start-Up ................................................. |

23 |

Operation .............................................. |

24 |

Removal & Storage ............................... |

27 |

Product Warranty .................................. |

28 |

Bracket Options .................................... |

29 |

TC51 Parts ............................................ |

30 |

TC71 Parts ............................................ |

32 |

TC80 Parts ............................................ |

34 |

TC91S Parts ......................................... |

36 |

TC151S Parts ....................................... |

38 |

TC151SH Parts ..................................... |

40 |

TC301 Parts .......................................... |

42 |

TC301H Parts ....................................... |

44 |

Compactor Owner’s Manual |

3 |

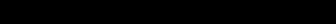

GENERAL

BTI compactors are designed to mount on mini-excavators, backhoes and excavators. BTI compactors combine impulse force, down pressure, and vibration to work as soil compactors or pile/sheet drivers.

The compactor has 3 basic components:

•Mounting Bracket: attaches the compactor to the carrier boom and is complete with adjustable mounting pins.

•Rubber Isolators: act as suspension between the base and the mount & isolate the compactor forces from the carrier.

•Base: includes a hydraulic motor coupled to an eccentric, encased in a steel housing with the base plate attached.

4 |

www.rockbreaker.com |

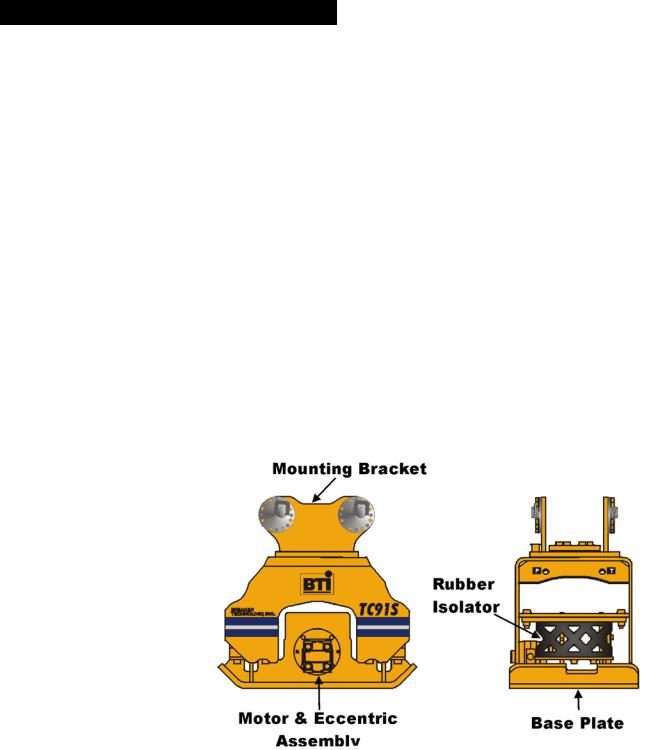

TC51 SPECIFICATIONS

|

TC51L/FC |

TC51H/FC |

||

Impulse Force: |

2,250 |

- 3,000 lb |

2,250 |

- 3,000 lb |

|

1,020 |

- 1,360 kg |

1,020 |

- 1,360 kg |

Oil Flow Req'd: |

8 - 12 US gpm |

12 - 18 USgpm |

||

|

30 - 45 l/min |

44 - 68 l/min |

||

Cycles/Minute: |

1,940 |

- 2,200 |

1,940 |

- 2,200 |

Hydraulic Connections: |

#8 JIC Male |

#8 JIC Male |

||

Minimum Tube I.D.: |

1/2" |

|

1/2" |

|

Operating Pressure: |

1,500 |

- 2,200 psi |

1,500 |

- 2,200 psi |

|

102 - 150 bar |

102 - 150 bar |

||

Base Plate Dimension: |

12.5 x 22" |

12.5 x 22" |

||

|

317.5 x 558.5 mm |

317.5 x 558.5 mm |

||

Compaction Area: |

1.91 sq ft |

1.91 sq ft |

||

|

0.177 sq M |

0.177 sq M |

||

Weight: |

295 lb |

295 lb |

|

|

|

158 kg |

158 kg |

||

Swivel Rotation: |

N/A |

|

N/A |

|

Locking Positions: |

N/A |

|

N/A |

|

Carrier Weight: |

2,000 |

- 10,000 lb |

2,000 |

- 10,000 lb |

|

907 - 4, 536 kg |

907 - 4, 536 kg |

||

Compactor Owner’s Manual |

5 |

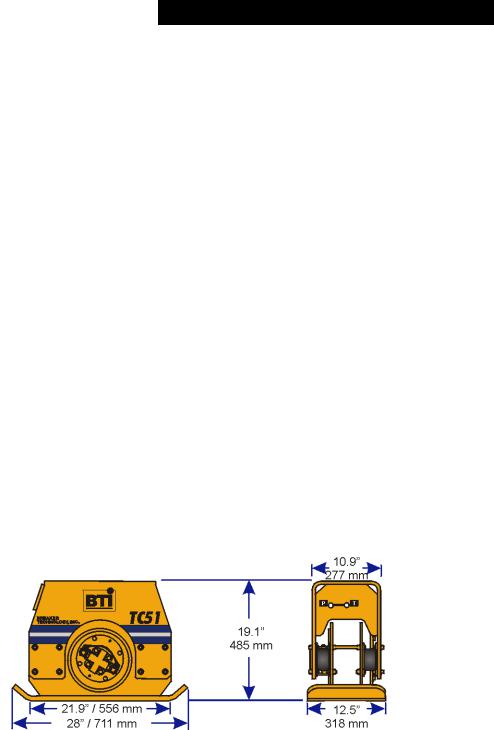

TC71S SPECIFICATIONS

|

TC71S |

TC71FC |

||

Impulse Force: |

3,300 |

- 5,000 lb |

3,300 |

- 5,000 lb |

|

1,497 |

- 2,268 kg |

1,497 |

- 2,268 kg |

Oil Flow Req'd: |

13 - 17 US gpm |

13 - 22 USgpm |

||

|

49 - 63 l/min |

50 - 83 l/min |

||

Cycles/Minute: |

2,020 |

- 2,500 |

2,020 |

- 2,500 |

Hydraulic Connections: |

#12 JIC Male |

#12 JIC Male |

||

Minimum Tube I.D.: |

¾" |

|

¾" |

|

Operating Pressure: |

1,200 |

- 2,000 psi |

1,200 |

- 2,000 psi |

|

81 - 136 bar |

81 - 136 bar |

||

Base Plate Dimension: |

15 x 26" |

15 x 26" |

||

|

381 x 660 mm |

381 x 660 mm |

||

Compaction Area: |

2.71 sq ft |

2.71 sq ft |

||

|

0.252 sq M |

0.252 sq M |

||

Weight: |

610 lb |

|

610 lb |

|

|

277 kg |

277 kg |

||

Swivel Rotation: |

N/A |

|

N/A |

|

Locking Positions: |

N/A |

|

N/A |

|

Carrier Weight: |

5,500 |

- 15,500 lb |

5,500 |

- 15,500 lb |

|

2,492 |

- 7,030 kg |

2,492 |

- 7,030 kg |

6 |

www.rockbreaker.com |

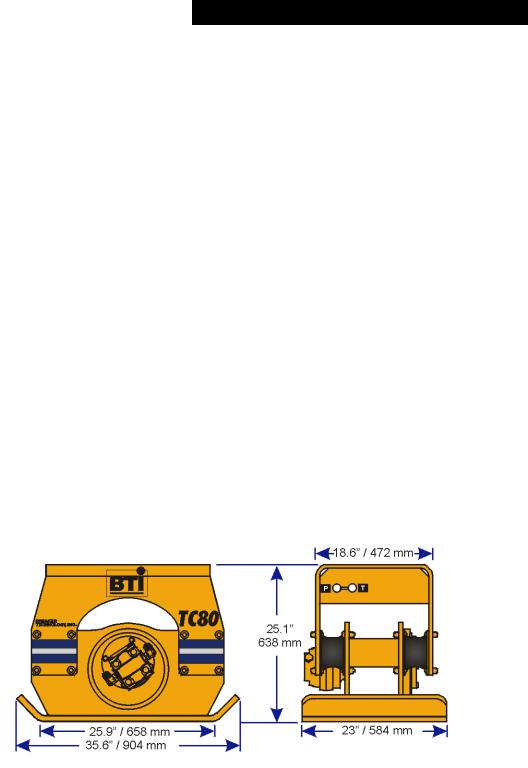

TC80 SPECIFICATIONS

Impulse Force: |

5,000 |

- 8,200 lb |

|

2,270 |

- 3,727 kg |

Oil Flow Req'd: |

20 - 26 US gpm |

|

|

75 - 97 l/min |

|

Cycles/Minute: |

1,659 |

- 2,200 |

Hydraulic Connections: |

#12 JIC Male |

|

Minimum Tube I.D.: |

¾" |

|

Operating Pressure: |

1,300 |

- 2,000 psi |

|

88 - 136 bar |

|

Base Plate Dimension: |

23 x 26" |

|

|

584 x 660 mm |

|

Compaction Area: |

4.15 sq ft |

|

|

0.39 sq M |

|

Weight: |

969 lb |

|

|

441 kg |

|

Swivel Rotation: |

Floating (Optional) |

|

Locking Positions: |

90o, 0o, 90o |

|

Carrier Weight: |

7,700 |

- 25,300 lb |

|

3,500 |

- 11, 500 kg |

Compactor Owner’s Manual |

7 |

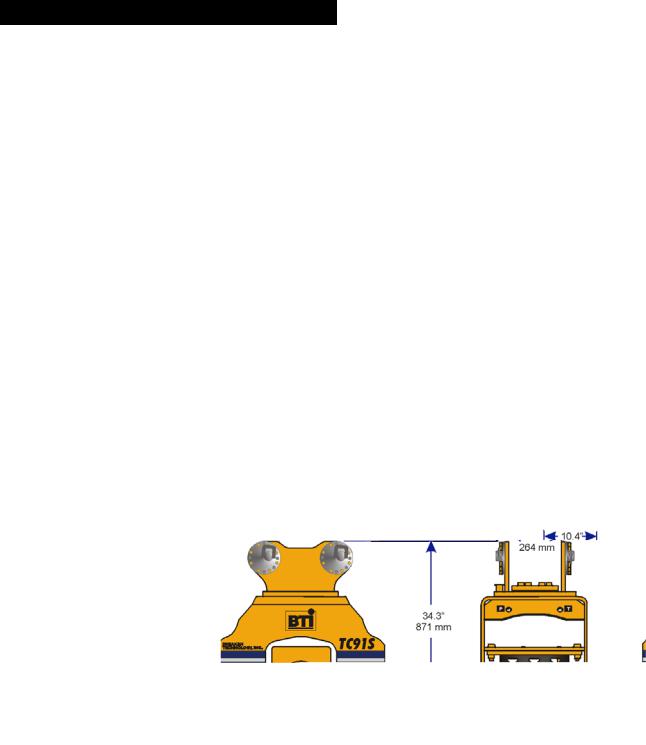

TC91S SPECIFICATIONS

Impulse Force: |

5,000 |

- 8,200 lb |

|

2,270 |

- 3,727 kg |

Oil Flow Req'd: |

20 - 26 US gpm |

|

|

75 - 97 l/min |

|

Cycles/Minute: |

1,659 |

- 2,200 |

Hydraulic Connections: |

#12 JIC Male |

|

Minimum Tube I.D.: |

¾" |

|

Operating Pressure: |

1,300 |

- 2,000 psi |

|

88 - 136 bar |

|

Base Plate Dimension: |

23 x 27" |

|

|

584 x 686 mm |

|

Compaction Area: |

4.3 sq ft |

|

|

0.40 sq M |

|

Weight: |

1,130 lb |

|

|

514 kg |

|

Swivel Rotation: |

180o |

|

Locking Positions: |

90o, 45o, 0o, 45o, 90o |

|

Carrier Weight: |

7,700 |

- 25,300 lb |

|

3,500 |

- 11, 500 kg |

8 |

www.rockbreaker.com |

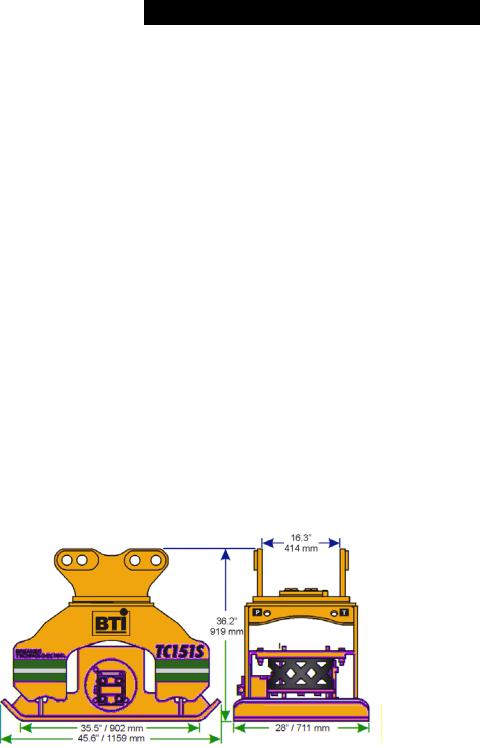

TC151S / 151SH SPECIFICATIONS

|

TC151S |

TC151SH |

Impulse Force: |

11,120 - 16,610 lb |

11,120 - 16,610 lb |

|

5,055 - 7,550 kg |

5,055 - 7,550 kg |

Oil Flow Req'd: |

25 - 31 US gpm |

35 - 43 US gpm |

|

95 - 117 l/min |

132 - 163 l/min |

Cycles/Minute: |

1,800 - 2,200 |

1,800 - 2,200 |

Hydraulic Connections: |

#16 JIC Male |

#16 JIC Male |

Minimum Tube I.D.: |

1" |

1” |

Operating Pressure: |

1,500 - 2,000 psi |

1,100 - 1,600 psi |

|

102 - 136 bar |

75 - 109 bar |

Base Plate Dimension: |

28 x 36.5" |

28 x 36.5” |

|

711 x 927mm |

711 x 927mm |

Compaction Area: |

7.1 sq ft |

7.1 sq ft |

|

0.66 sq M |

0.66 sq M |

Weight: |

1,825 lb |

1,830 lb |

|

830 kg |

832 kg |

Swivel Rotation: |

180o |

180o |

Locking Positions: |

90o,45o,0o,45o,90o |

90o,45o,0o,45o,90o |

Carrier Weight: |

15,400 - 48,400 lb |

15,400 - 48,400 lb |

|

7,000 - 22,000 kg |

7,000 - 22,000 kg |

Compactor Owner’s Manual |

9 |

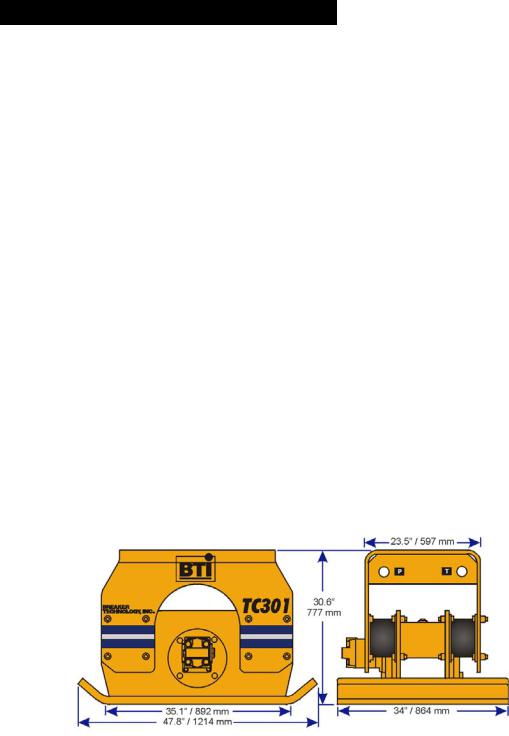

TC301 / TC301H SPECIFICATIONS

|

TC301 |

TC301H |

Impulse Force: |

16,300 - 24,300 lb |

16,300 - 24,300 lb |

|

7,409 - 11,000 kg |

7,409 - 11,000 kg |

Oil Flow Req'd: |

35 - 43 US gpm |

50 - 61 gpm |

|

132 - 163 l/min |

189 - 231 l/min |

Cycles/Minute: |

1,800 - 2,200 |

1,800 - 2,200 |

Hydraulic Connections: |

#16 JIC Male |

#20 JIC Male |

Minimum Tube I.D.: |

1" |

1 |

|

|

1/4” |

Operating Pressure: |

1,500 - 2,000 psi |

1100 - 1600 psi |

|

102 - 136 bar |

75 - 109 bar |

Base Plate Dimension: |

34 x 37" |

34 x 37" |

|

864 x 940 mm |

864 x 940 mm |

Compaction Area: |

8.74 sq ft |

8.74 sq ft |

|

0.812 sq M |

0.812 sq M |

Weight: |

2,150 lb |

2,155 lb |

|

978 kg |

980 |

Carrier Weight: |

31,900 - 105,600 lb |

31,900 - 105,600 lb |

|

14,500 - 48,000 kg |

14,500 - 48,000 kg |

10 |

www.rockbreaker.com |

HAZARD ALERTS

Danger, Warning, and Caution are hazard alerts used in this manual and on the compactor decals to identify hazards on or near the carrier and compactor.

Danger - Immediate hazards, which WILL result in severe personal injury or death if the proper precautions are not taken.

Warning - Hazards or unsafe practices, which COULD result in personal injury or death if the proper precautions are not taken.

Caution - Hazards or unsafe practices, which COULD result in product or property damage if the proper precautions are not taken.

BTI cannot anticipate every possible circumstance that might involve a hazard. The hazard alerts in this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating technique not specifically recommended by BTI is used, you must satisfy yourself that it is safe for you and others. You should also ensure that the compactor and carrier will not be damaged or made unsafe by the operation, maintenance or repair procedures you choose.

Compactor Owner’s Manual |

11 |

HAZARD ALERTS

Do not operate the compactor with personnel in the immediate area of the carrier and compactor.

Note and avoid all hazards and obstructions such as overhangs, ledges, slide areas, electrical lines, underground cables, water mains, gas lines, etc. When operating close to electrical lines, underground cables, water mains or gas lines, contact the responsible authority and request assistance.

Do not operate this machine unless you have read and understood the instructions and warnings in the Compactor Owner's Manual. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility. Contact your distributor or BTI for replacement manuals or decals.

12 |

www.rockbreaker.com |

HAZARD ALERTS

Hydraulic fluids are under high pressure. Fluid escaping under pressure can penetrate the skin causing serious injury. Relieve all pressure before disconnecting hoses. Do not use your hand to check for hydraulic leaks. If any fluid is injected into the skin, a doctor must surgically remove it within a few hours or gangrene may set in.

Do not attempt to repair or modify the compactor unless you are a qualified service technician. Read and understand your owner's manuals. Failure to follow the instructions or heed the warnings could result in severe personal injury or death. Proper care is your responsibility. Contact your distributor or BTI for replacement parts.

Some compactor components are heavy or awkward, plan carefully how you will handle them when installing, removing, or disassembling.

Compactor Owner’s Manual |

13 |

HAZARD ALERTS

Head |

Foot |

Eye |

Hearing |

Protection |

Protection |

Protection |

Protection |

Do not operate or service the compactor unless you are qualified.

Avoid loose fitting clothing, loose or uncovered long hair, jewelry and loose personal articles. These can get caught in moving parts. Jewelry may also ground a live circuit.

Know and use the protective equipment that is to be worn when operating or servicing the carrier. Hard hats, protective glasses, protective shoes, gloves, reflector type vests and ear protection are types of equipment that may be required.

Never drive or operate any carrier while you are under the influence of alcohol or drugs.

Consult your supervisor if you do not understand the Compactor Owner's Manual.

14 |

www.rockbreaker.com |

Typical

Production Rate

Lift Sizes

SIZING THE COMPACTOR

The compactor must be sized properly for both the carrier on which it will be mounted and the work to be done.

Sizing the Compactor based on the Type of Work

Most applications require the soil under a road or load bearing surface to be compacted to 95% or greater than the density of the original material removed. This can be achieved with a compactor, provided the soil is the correct type and moisture.

Uniform materials like clay and sand are difficult to compact. Virgin dirt, pit run gravel, or soil with non-uniform particle size is preferred. The moisture content in most material should be less than ten percent for best results.

A typical production rate to compact soils to over 95% their original density;

TC51: 1422 cu yds /hr |

(11 - 17 cu M/hr) |

TC71: 1827 cu yds /hr |

(14 - 21 cu M/hr) |

TC80: 2332 cu yds /hr |

(18 - 25 cu M/hr) |

TC91S: 2535 cu yds /hr |

(19 - 27 cu M/hr) |

TC151S: 6575 cu yds/hr |

(50 - 57 cu M/hr) |

TC151SH: 6575 cu yds/hr |

(50 - 57 cu M/hr) |

TC301: 110130 cu yds/hr |

(84 - 99 cu M/hr) |

TC301H: 110130 cu yds/hr |

(84 - 99 cu M/hr) |

For proper compaction we recommend the following lift size;

TC51: .5- 1 foot |

(0.15 - 0.3 M) |

TC71: .5- 1 foot |

(0.15 - 0.3 M) |

TC80: 1- 2 foot |

(0.3 - 0.6 M) |

TC91S: 1- 2 foot |

(0.3 - 0.6 M) |

TC151S: 2- 3 foot |

(0.6 - 0.9 M) |

TC151SH: 2- 3 foot |

(0.6 - 0.9 M) |

TC301: 2- 4 foot |

(0.6 - 1.2 M) |

TC301H: 2- 4 foot |

(0.6 - 1.2 M) |

Using a higher depth of material may result in less than 95% compaction.

Compactor Owner’s Manual |

15 |

Loading...

Loading...