LG 1400HT User Manual

INSTALLATION AND OPERATION

MANUAL

EPA CERTIFIED

WOOD BURNING

STOVE

P

RETAIN THESE

INSTRUCTIONS

FOR FUTURE MODEL 1400HT

REFERENCE

THIS APPLIANCE MUST BE INSTALLED BY A QUALIFIED INSTALLER.

READ ENTIRE MANUAL THOROUGHLY BEFORE INSTALLATION.

P/N 775000M, Rev. G, 12/03

IMPORTANT WARNINGS

CAUTION: PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW ROOM HEATER. FOR YOUR SAFETY, FOLLOW THE INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS EXACTLY, WITHOUT DEVIATION. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH. IF THIS APPLIANCE IS NOT PROPERLY INSTALLED, A HOUSE FIRE MAY RESULT. CONTACT YOUR LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA.

1.If utilizing an older chimney, it must be inspected for adequate serviceability. Refer to the heading Chimney Inspection on page 8 of this manual.

2.The minimum clearances must be maintained for all combustible surfaces and materials including; furniture, carpet, drapes, clothing, wood, papers, etc. Do not store firewood within this clearance space. Failure to maintain clearances to all combustibles may result in a house fire.

3.This appliance requires non-combustible floor protection as outlined in this manual (see Floor Protection on page 6 for additional information).

4.Minimum ceiling height must be 7 feet (213 cm) (measured from base of appliance to ceiling).

5.DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE CONNECTED TO ANOTHER APPLIANCE.

6.Do not connect this appliance to air ducts or any air distribution system.

7.PREVENT CREOSOTE FIRE: Inspect and clean chimney frequently. Under certain conditions of use, creosote buildup may occur rapidly. Inspect chimney connector and chimney twice monthly and clean if necessary. Using green or inadequately seasoned wood can greatly increase creosote buildup. Use dry wood to minimize creosote buildup.

8.USE SOLID WOOD FUEL ONLY: This appliance is approved for burning dry seasoned natural wood only. CAUTION: BURN UNTREATED WOOD ONLY. DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS SUCH AS GASOLINE, NAPHTHA OR ENGINE OIL.

9.Never use gasoline, gasoline-type lantern fuel, kerosene, charcoal lighter fluid, or similar liquids to start or "freshen up" a fire in this heater. Keep all such liquids well away from the heater while it is in use.

10.DO NOT OVERFIRE: If heater or chimney connector glows, you are overfiring. Overfiring this appliance could cause a house fire. Overfiring is

a condition where the appliance is operated at temperatures above its design capabilities. Overfiring can be caused by improper installation, improper operation, lack of maintenance or improper fuel usage. Damage caused from overfiring is NOT covered under the manufacturer’s limited warranty.

11.NEVER LEAVE AN UNATTENDED STOVE BURNING ON HIGH. Operation of the stove with the primary air control at its highest burn rate setting for extended periods can cause dangerous overfiring conditions. The primary air control should only be positioned at the highest setting during start-up procedures and for short durations. When leaving the stove unattended ensure that the primary air control is set to the low or medium low range.

12.Use a metal container with a tight fitting lid to dispose of ashes.

13.IN THE EVENT OF A COMPONENT FAILURE, USE ONLY COMPONENTS PROVIDED BY THE MANUFACTURER AS REPLACEMENT PARTS.

14.Burning any kind of fuel uses oxygen from the dwelling. Be sure that you allow an adequate source of fresh air into the room where the stove is operating (see Ventilation and Outside Air on page 6).

15.CAUTION: HOT WHILE IN OPERATION. An appliance hot enough to warm your home can severely burn anyone touching it. Keep children, clothing and furniture away. Contact may cause skin burns. Do not let children touch the appliance. Train them to stay a safe distance from the unit.

16.Do not operate this appliance without the firebox baffle brick properly installed.

17.Build fires directly upon the brick hearth inside the stove. Do not use grates, irons or any other method to elevate the fire.

18.SAVE THESE INSTRUCTIONS.

19.See the listing label located on the back of stove (or see Safety/Listing Label on page 22).

PAGE 2

TABLE OF CONTENTS |

|

Important Warnings ................................................ |

2 |

Testing/Listing, EPA, Using this Manual.................. |

3 |

Planning Your Installation ..................................... |

4-6 |

Manufactured (Mobile) Home Requirements ........... |

6 |

Installation .......................................................... |

7-11 |

Product Features and Controls .............................. |

12 |

Care and Operation .......................................... |

12-13 |

Recommended Fuel ............................................... |

14 |

Maintenance ..................................................... |

14-15 |

Troubleshooting ................................................ |

16-17 |

Specifications.......................................................... |

18 |

Replacement Parts List..................................... |

19-20 |

Optional Accessories ............................................. |

21 |

Safety/Listing Label ............................................... |

22 |

EPA Label … ......................................................... |

23 |

Ownership Records ............................................... |

24 |

TESTING/LISTING

Model 1400HT has been tested to UL Standards 1482 and ULC-S627 for installation in residential and manufactured (mobile) home construction. The listing laboratory is OMNI Test Laboratories Inc, Beaverton, Oregon, Report #030-S-03-02.

EPA CERTIFICATION

This stove has been tested to rigorous emissions standard, and has been certified by the Environmental Protection Agency.

CONGRATULATIONS ON THE PURCHASE OF YOUR NEW WOODSTOVE MANUFACTURED BY LENNOX HEARTH PRODUCTS.

When you purchased your new woodstove, you joined the ranks of thousands of concerned individuals whose answer to their home heating needs reflects their concern for aesthetics, efficiency and our environment. We extend our continued support to help you achieve the maximum benefit and enjoyment available from your new wood stove.

It is our goal at Lennox Hearth Products to provide you, our valued customer, with an appliance that will ensure you years of trouble free warmth and pleasure.

Thank you for selecting a Lennox Hearth Products stove as the answer to your home heating needs.

Sincerely,

All of us at Lennox Hearth Products

PACKAGING LIST

This appliance is packaged with an accessory package, which contains the following:

One - Installation and operation instructions manual.

One - Warranty. Five - Baffle brick.

USING THIS MANUAL

Please read and carefully follow all of the instructions found in this manual. Please pay special attention to the safety instructions provided in this manual. The Homeowner’s Care and Operation Instructions included here will assure you have many years of dependable and enjoyable service from your appliance.

PAGE 3

PLANNING YOUR INSTALLATION

QUESTIONS TO ASK LOCAL BUILDING OFFICIAL

A correct installation is critical and imperative for reducing fire hazards and perilous conditions that can arise when wood burning appliances are improperly installed. The installer must follow all of the manufacturer’s instructions.

The installation of a wood burning appliance must conform to local codes and applicable state and federal requirements. Familiarity with these requirements before installation is essential. Important considerations to discuss with local building officials include:

1.Applicable codes (i.e. Uniform Mechanical Code, State or Regional Codes)?

Electrical codes: Optional Blower Assemblies have a flexible electrical cord that must be electrically grounded per local codes or per electrical codes:

In USA, NEC, ANSI/NFPA 70-1987 In Canada, CSA C22.1

WARNING: ELECTRICAL GROUNDING INSTRUCTIONS: THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG (GROUNDING) PLUG FOR YOUR PROTECTION AGAINST SHOCK HAZARD AND SHOULD BE PLUGGED DIRECTLY INTO A PROPERLY GROUNDED THREE-PRONG RECEPTACLE. DO NOT CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG.

DO NOT ROUTE POWER CORD UNDER OR IN FRONT OF APPLIANCE.

2.Local amendments?

3.Is a permit required - cost? (You may wish to contact your insurance company to ask if they require this).

4.Is outside combustion air required?

5.Rooms where the installation is not allowed?

SMOKE DETECTORS

Since there are always several potential sources of fire in any home, we recommend installing smoke detectors. If possible, install the smoke detector in a hallway adjacent to the room (to reduce the possibility of occasional false activation from the heat produced by the stove). If your local code requires a smoke detector be installed within the same room, you must follow the requirements of your local code. Check with your local building department for requirements in your area.

NOTE – This appliance is NOT approved for installation into a Manufactured (Mobile) Home in Canada

SELECTING A LOCATION

The design of your home and where you place your stove will determine its value as a source of heat. A wood stove depends primarily on air circulation (convection) to disperse its heat, and therefore, a central location is often best. There are other practical considerations, which must be considered before a final selection of locations is made.

♦Existing Chimneys

♦Wood Storage

♦Aesthetic Considerations

♦Roof Design (Rafter Locations & Roof Pitch)

♦Room Traffic

♦Proximity to Combustibles

♦Electrical Wiring

The installation of this stove will require some research. Once your options are determined, consult with your local building department who will be able to give you the necessary installation requirements for your area (Is a building permit required, Rooms where installation may not be allowed, etc.).

WARNING: CHECK ALL LOCAL BUILDING AND SAFETY CODES BEFORE INSTALLATION. THE INSTALLATION INSTRUCTIONS AND APPROPRIATE CODE REQUIREMENTS MUST BE FOLLOWED EXACTLY AND WITHOUT COMPROMISE. ALTERATIONS TO THE STOVE ARE NOT ALLOWED. DO NOT CONNECT THE STOVE TO A CHIMNEY SYSTEM SERVING ANOTHER STOVE, APPLIANCE, OR ANY AIR DISTRIBUTION DUCT. FAILURE TO FOLLOW THESE INSTRUCTIONS WILL VOID THE MANUFACTURER’S WARRANTY.

If you plan to vent your stove into an existing masonry chimney, have it inspected by a local fire marshal or qualified installer. Remember that a stove's performance is heavily influenced by the chimney and its location on the roof. An oversized flue may not provide effective draw, and a flue liner may be required (see Draft Requirements on page 9). Consult your dealer or qualified installer before final selection is made.

This stove requires pre-installation work to be completed before installation can take place. This will include the preparation of the floor and appropriate hearth pad for acceptance of outside air (if applicable), and for modification for flue and chimney.

PAGE 4

PLANNING YOUR INSTALLATION

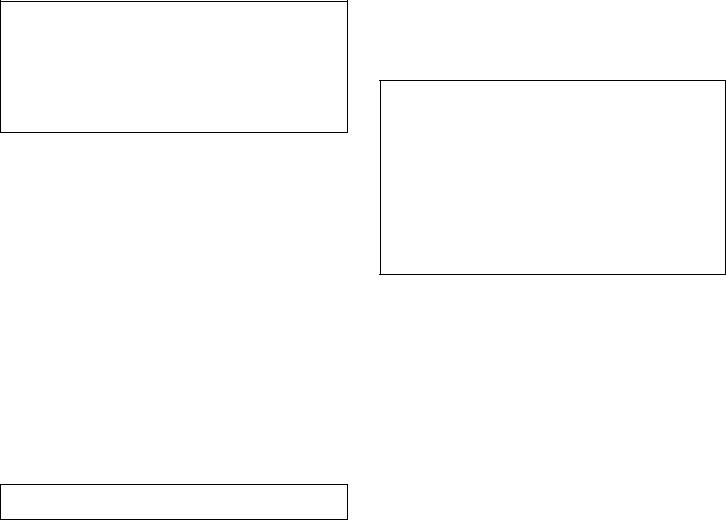

COMBUSTIBLE WALL CLEARANCE

WARNING: IT IS VERY IMPORTANT THAT YOU OBSERVE THE MINIMUM CLEARANCES.

There are listed clearances for your stove which were determined in a Laboratory test using various "classes" of stove pipe or chimney. Minimums are first established for the stove itself and increased based on how much heat is transferred by each class of pipe.

Note: Manufactured (mobile) home installations require the use of a Type L Vent Chimney connector only. Use of a single wall flue pipe connection is not permitted.

Residential Reduced Clearance

Using Listed L-Vent pipe (double wall air insulated) to the top of the stove. Approved brands are: JakesEvans, Dura-Vent, Security, Pro-Vent, Ameri-Tek, Metal Bestos.

Clearances (inches / millimeters)

A. 10 |

½ / 267 |

C. 15 |

/ 381 |

E. 9 ½ / 241 |

B. 20 |

/ 508 |

D. 8 / |

203 |

F. 5 / 127 |

Residential Standard (not approved for manufactured [mobile] homes)

Using single wall pipe connector to the top of the stove.

Clearances (inches / millimeters)

A. 15 / 381 |

C. 15 / 381 |

E. 8 ½ / 216 |

B. 19 / 483 |

D. 13 / 330 |

F. 5 / 127 |

Manufactured (Mobile) Home Standard Clearance

Using Approved L-Vent only. Approved brands are Dura-Vent, Security, Pro-Vent, and Ameri-Tek. Manufactured (Mobile) Home installations must use a rain

cap with a spark arrester. |

|

||

Clearances (inches / millimeters) |

|

||

A. 10 |

½ / 267 |

C. 15 / 381 |

E. 9 ½ / 241 |

B. 20 |

/ 508 |

D. 8 / 203 |

F. 5 / 127 |

CORNER

INSTALLATION

PARALLEL

INSTALLATION

*ALCOVE CLEARANCE

Required pipe: Type L-Vent pipe to top of stove. Approved brands are Dura-Vent, Pro-Vent, Ameri-I-Tek, Standex, and Metal Bestos.

Alcoves must have minimum dimensions of 84" (213 cm) height minimum, 46" (117 cm) width minimum and 24" (610 mm) depth maximum.

ALCOVE CLEARANCES:

Back wall to pipe O.D. |

10 1/2" (267 mm) Minimum |

Side wall to pipe O.D. |

20" (508 mm) Minimum |

Back wall to stove |

8" (203 mm) Minimum |

Side wall to stove |

9 1/2" (241 mm) Minimum |

*NOTE: Alcove dimensions cannot be reduced by the use of non-combustible materials such as brick, stone, etc. Alcove dimensions listed are minimum dimensions and are not measurements for building an Alcove. You will need to consider these clearances, as well as other dimensional requirements before you build the alcove and install this appliance.

OPTIONAL ARCH TREATMENT

An alcove depth of 24" (610 mm) (or less) will allow for a minimum height of 84" (213 cm) and may be trimmed with a 2 1/4" (57 mm) maximum arch treatment if desired.

PAGE 5

PLANNING YOUR INSTALLATION

REDUCED MASONRY STRUCTURE CLEARANCE (ALCOVE)

Your Earth Stove can be installed in a masonry structure with reduced clearances if the structure was built to National Building Code for fireplaces and chimneys (UBC 37).

The firebox of the masonry structure must be of adequate size to allow a minimum of 6" (152 mm) clearance to the sides and top of the stove and 2" (51 mm) clearance to the rear. All stove models must be installed on their original listed legs or base unless otherwise specified by OMNI Testing Laboratory.

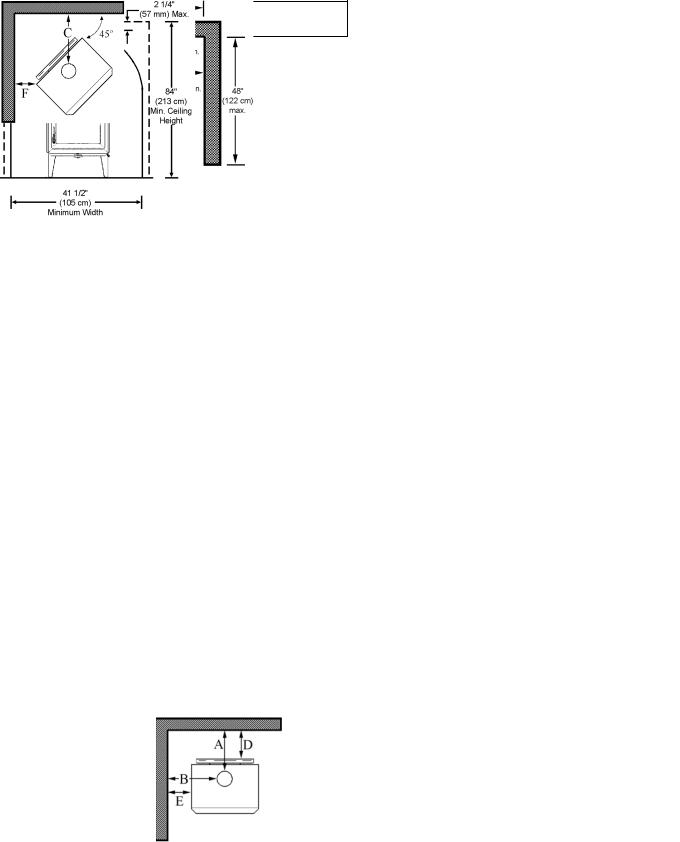

FLOOR PROTECTION

This appliance requires a non-combustible floor protection for ember protection. If the floor protection is to be stone, tile, brick, etc., it must be mortared or grouted to form a continuous non-combustible surface. If a chimney connector extends horizontally over the floor, protection must cover the floor under the connector and at least 2" (51 mm) to either side.

The floor protection must extend completely beneath the stove and to the front, sides, and rear as indicated:

USA Requirements

16” (406 mm) min. to the front of the fuel door glass

8” (203 mm) min. beyond the sides of the fuel door opening

Canada Requirements

18” (457 mm) min. to the front of the fuel door glass 8” (203 mm) min. beyond the sides of the stove body

STANDARD PARALLEL HEARTH PAD SHOWN

0” - USA

8” – Can.

8” (203 mm) |

8” (203 mm) |

Canada |

Canada |

8” - USA |

|

8” - USA |

|

18” |

(457 mm) – Canada |

|

16” |

(406 mm) - USA |

PROTECTED WALL CLEARANCE

Some local codes will allow reduced clearances when the stove is installed adjacent to a protected wall system. The variance must be approved by your local building official. Normally, the protected wall system is defined as a noncombustible material with a minimum of 1" (25.4 mm) air space behind. Check your local building codes or with a qualified installer (Ref. NFPA 211).

OUTSIDE AIR

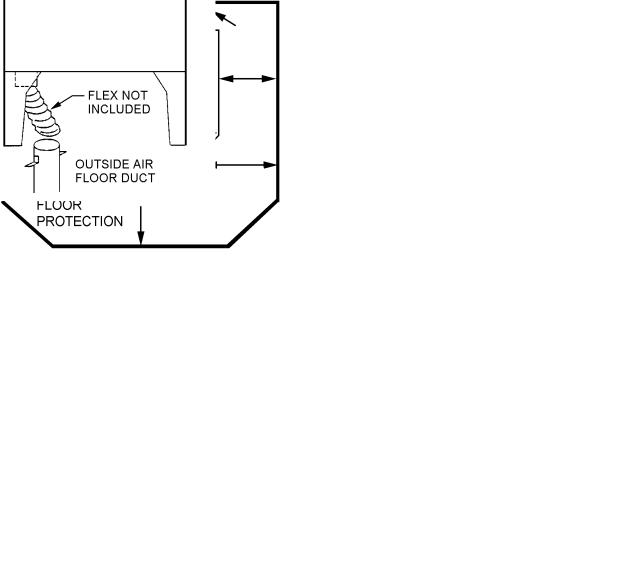

In all manufactured (mobile) homes and in many site built residences (subject to local code), a stove may be required to use outside air for combustion. A 3” (76 mm) diameter outside air floor duct is available through your dealer.

This appliance utilizes a 3" (76 mm) diameter outside air floor duct (Catalog # 14M66). Outside air can be taken from beneath the home or through an outside wall. The collar for connecting flex to stove in on the underside of the stove as shown here.

PAGE 6

INSTALLATION

MANUFACTURED (MOBILE) HOME REQUIREMENTS

This stove is certified as a Room Heater, Solid Fuel Type and may be used in Manufactured Housing providing the following requirements are followed:

•An outside air inlet must be provided for combustion and be unrestricted while unit is in use.

•WARNING: DO NOT INSTALL APPLIANCE IN A SLEEPING ROOM.

•CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE HOME FLOOR, WALL, AND CEILING/ROOF MUST BE MAINTAINED.

•Regulations require that the appliance must be secured to the floor and grounded to the chassis. See Securing the Stove to the Floor (and) Grounding Stove below.

•Required venting is 6” (152 mm) diameter Type L-Vent connector pipe with listed factory-built 103HT chimney suitable for use with solid fuels or a code approved masonry chimney. Approved brands of factory built chimney are listed in this manual. A rain cap and spark arrestor are required (see Clearances, page 5).

•The chimney must provide for a section joint so that any parts extending above 13' 6" (343 mm) from ground level can be removed for transportation of the mobile dwelling.

SECURING THE STOVE TO THE FLOOR Manufactured (Mobile) Homes Only

Once the outside air floor duct is in position, replace the floor protector. Make sure that the floor protector's hole is aligned with the outside air opening. Next position and align the stove on the hearth pad. Manufactured (Mobile) home installations require that the stove be secured to the floor.

This ensures that the stove will not shift when the manufactured (mobile) home is moved. To do this, mark where the

from the stove to the chassis of the manufactured (mobile) home.

INSTALLING THE BAFFLE BRICKS

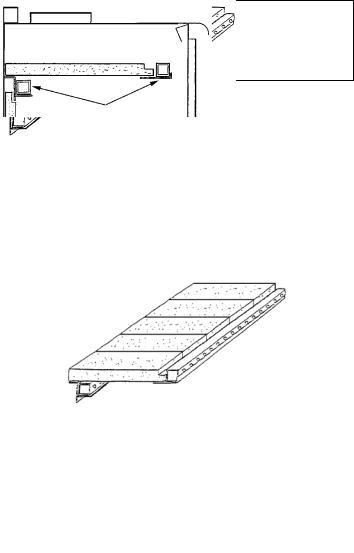

There are 2 brick retainer tube assemblies located below the ceiling of the firebox which require baffle brick before the stove can be operated. Install the baffle brick as follows:

1.Place the first three brick onto the brick retainers with the notch facing up and toward the front. Next, slide the three brick all the way to the right (as you face the stove. See top view illustration below).

2.Place the fourth brick on top of the three brick. Position it so the notch is facing up and pointing to the left.

3.Install the fifth brick and slide all the way to the left.

4.Rotate the fourth brick into position (notch to the front and facing up) until it drops into place.

IMPORTANT: The baffle brick requires periodic inspection and replacement for proper operation. If the baffle bricks are fractured or crumbling, they should be replaced. Do not operate this appliance without the baffle brick properly installed.

Installing Baffle Brick

Right

Left

Top View of Baffle Brick Installed

holes are to be drilled using a marking instrument long enough and small enough to fit through the (4) four holes in the stove legs. Mark holes, then remove the stove. Drill the

(4) four holes, with a 1/4" (7 mm) drill bit. Drill down through the floor protector and the manufactured (mobile) home floor. Use 1/4" (7 mm) lag bolts and secure to the manufactured (mobile) home floor.

NOTE: If the composition of the manufactured (mobile) home floor is of light particleboard construction, you will be required to secure the stove with regular hex head bolts and nuts. This will ensure that the bolts will not rip out of the floor when the manufactured (mobile) home is being moved.

GROUNDING STOVE Manufactured (Mobile) Homes Only

Regulations require that all stoves installed in manufactured (mobile) homes must be grounded. To do this simply attach a piece of No. 8 copper wire, at least 18" (457 mm) in length

PAGE 7

Side View of Baffle Brick Installed

Brick Retainer / Tube Assembly

INSTALLATION

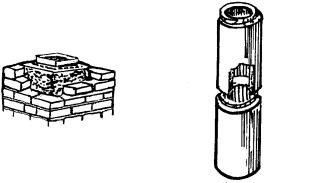

TYPES OF CHIMNEYS

The chimney is a vital part of your stove installation. A properly built masonry chimney or a properly installed factory built chimney will assure a consistent draft under a variety of weather conditions (a smoking stove is usually caused by a chimney problem). The stove flue size is 6 (152 mm) inches diameter, which is approximately 28 square inches (711 square mm) minimum. The maximum flue size should be no more than (3)-three times the cross sectional area of the size of the stove flue collar. In this case, that would be no larger than a 10-inch (254 mm) diameter stack, or approximately 85 square inches (216 square cm) maximum.

All chimneys must be installed as specified by local building codes and according to the chimney manufacturer instructions (in the case of a factory built chimney). See the chimney manufacturer instructions for exact specifications. Factory built chimneys must comply with UL 103HT or ULC S629.

Factory

Built

Chimney

Tile-lined

Masonry

Chimney

ACCEPTABLE CONNECTOR PIPE FOR INSTALLATIONS

For Standard Residential Clearances: Six (6) inch (152 mm) minimum, single wall, 25 gage minimum thickness, stove pipe is acceptable. Three (3) predrilled holes are provided in the flue collar for fastening the pipe securely to the stove. Use sheet metal screws to do this. Additional sections of single wall pipe should be fastened together with at least three (3) sheet metal screws each section. When connecting to the factory built ceiling support package, use the manufacturer's transition piece, usually called a dripless connector, to join single wall pipe to their factory built chimney section.

Minimum Flue Size: The required minimum diameter and area required for the flue size is (respectively) 6 inches / 152 mm diameter, which is approximately 28 square inches / 711 square mm. The maximum flue size should be no more than (3) three times the cross sectional area of the size of the 6 inches / 152 mm diameter flue collar. In this case, that would be no larger than a 10 inch (254 mm) diameter (area = approx. 85 sq. inches [216 sq. cm]).

Connection To A Factory Built Chimney: This space heater is to be connected to a factory-built chimney conforming to CAN / ULC – S629, Standard for 650°C Factory-Built Chimneys.

For Reduced Residential Clearances: Type L and listed double wall connector pipe is acceptable. Install any factory built brand of pipe according to the manufacturer's instructions.

Vapor Barrier at Chimney Penetration

Install all venting components per the Vent Manufacturer’s installation instructions. Ensure that there is an effective vapor barrier at the location where the chimney penetrates to the exterior of the structure. This can be accomplished by applying a non-hardening waterproof sealant to the following components:

•Around the chimney at the point where the storm collar will meet the chimney just above the Flashing.

•Along the vertical seam of the chimney pipe, where it is exposed to the weather.

•On each nail head on the flashing.

•Around the chimney at the point where the storm collar will meet the chimney just above the flashing.

Notes:

•On a flat or tarred and graveled roofs, nail and seal the flat roof flashing to the roof on all sides with roofing compound.

•Do not put screws through the flashing into the chimney pipe.

CHIMNEY INSPECTION

Existing chimneys must be inspected before installing your stove. Consult your local building department for chimney code requirements. A masonry chimney must have a code approved liner. This liner must not have broken or missing pieces. Some non-code masonry chimneys may be brought up to code by being relined. (Consult your dealer or qualified chimney sweep). Factory built chimneys should also be inspected, first for creosote deposits (which should be removed), and then for integrity of the stainless steel liner. Look for obvious bulges in the lining which may indicate the need to replace that section (use a bright flashlight). Also, inspect the attic to see that the chimney has proper clearance to combustible framing members. For interior masonry chimneys and most factory built chimneys, this must be a (2) two inch (51 mm) air space clearance, which must not be filled with insulation or any other material. An exterior masonry chimney must have a (1) one-inch (25.4 mm) air space clearance.

PAGE 8

Loading...

Loading...