Lennox G61MP User Manual

G61MP

Service Literature

Corp. 0308−L6

Revised 10−2004

G61MP SERIES UNITS

G61MP series units are high−efficiency multi−position (upflow, downflow, horizontal right and left) gas furnaces manufactured with Lennox Duralok Plust heat exchangers formed of aluminized steel. G61MP units are available in heating capacities of 44,000 to 132,000 Btuh (13.0.0 to 38.6 kW) and cooling applications from 2 to 5 tons (7.0 kW to 17.5 kW)) up to 5 tons. Refer to Engineering Handbook for proper sizing.

Units are factory equipped for use with natural gas. Kits are available for conversion to LPG operation. G61MP model units are equipped with the Two−Stage Integrated SureLight control. All G61MP units meet the California Nitrogen Oxides (NOx) Standards and California Seasonal Efficiency requirements. All units use a redundant gas valve to assure safety shut−off as required by C.S.A.

All specifications in this manual are subject to change. Procedures outlined in this manual are presented as a recommendation only and do not supersede or replace local or state codes. In the absence of local or state codes, the guidelines and procedures outlined in this manual (except where noted) are recommendations only and do not constitute code.

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Blower Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

I Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

II Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

III Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

IV Heating System Service Checks . . . . . . . . . . . . . . 31

V Typical Operating Characteristics . . . . . . . . . . . . . . 34

VI Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

VII Wiring and Sequence of Operation . . . . . . . . . . . . 38

VIII Field Wiring and Jumper Setting . . . . . . . . . . . . . 46

IX Control Board Troubleshooting . . . . . . . . . . . . . . . . 48

IMPORTANT

IMPORTANT

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal injury or loss of life. Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WARNING

WARNING

Electric shock hazard. Can cause injury or death. Before attempting to perform any service or maintenance, turn the electrical power to unit OFF at disconnect switch(es). Unit may have multiple power supplies.

WARNING

Sharp edges.

Be careful when servicing unit to avoid sharp edges which may result in personal injury.

Page 1

♥ 2003 Lennox Industries Inc.

SPECIFICATIONS

Gas |

|

Model No. |

G61MP−36B−045 |

G61MP−36B−070 |

G61MP−48C−090 |

G61MP−60C−090 |

|

Heating |

High |

Input − Btuh (kW) |

44,000 (12.9) |

66,000 (19.3) |

88,000 (25.8) |

88,000 (25.8) |

|

Performance |

|||||||

Fire |

Output − Btuh (kW) |

41,000 (12.0) |

62,000 (18.2) |

83,000 (24.3) |

84,000 (24.6) |

||

|

|||||||

|

|

||||||

|

Temperature rise range − _F (_C) |

25 − 55 (14 − 31) |

35 − 65 (21 − 39) |

35 − 65 (21 − 39) |

25 − 55 (14 − 31) |

||

|

|

|

|

|

|

|

|

|

Low |

Input − Btuh (kW) |

30,000 (8.8) |

45,000 (13.2) |

60,000 (17.6) |

60,000 (17.6) |

|

|

Fire |

Output − Btuh (kW) |

28,000 (8.2) |

43,000 (12.6) |

57,000 (16.7) |

58,000 (17.0) |

|

|

|

||||||

|

Temperature rise range − _F (_C) |

10 − 40 (6 − 24) |

20 − 50 (12 − 30) |

25 − 55 (14 − 31) |

15 − 45 (9 − 27) |

||

|

|

|

|

|

|

|

|

|

|

1 AFUE |

94.1% |

94.1% |

94.1% |

94.1% |

|

|

|

California Seasonal Efficiency |

83.5% |

86.0% |

87.3% |

84.4% |

|

|

High static (CSA) − in. w.g. (Pa) |

0.5 |

0.5 |

0.5 |

0.5 |

||

|

|

|

|

|

|

|

|

Connections |

|

2 Intake Pipe (PVC) |

2 |

2 |

2 |

2 |

|

in. |

|

2 Exhaust Pipe (PVC) |

2 |

2 |

2 |

2 |

|

|

Condensate Drain Trap (PVC pipe) − |

1/2 |

1/2 |

1/2 |

1/2 |

||

|

|

i.d. |

|

|

|

|

|

|

with field supplied (PVC coupling) − o.d. |

3/4 |

3/4 |

3/4 |

3/4 |

||

|

hose with hose clamp − i.d. x o.d. |

1−1/4 x 1 |

1−1/4 x 1 |

1−1/4 x 1 |

1−1/4 x 1 |

||

|

|

Gas pipe size IPS |

1/2 |

1/2 |

1/2 |

1/2 |

|

|

|

|

|

|

|

||

Indoor |

Wheel nominal diameter x width − in. |

10 x 8 (254 x 203) |

10 x 8 (254 x 203) |

10 x 10 (254 x 254) |

11−1/2 x 10 (292 x 229) |

||

Blower |

|

(mm) |

|

|

|

|

|

|

|

Motor output − hp (W) |

1/3 (249) |

1/3 (249) |

1/2 (373) |

1 (746) |

|

|

|

Tons (kW) of add-on cooling |

2.5 − 3 (8.8 − 10.5) |

2.5 − 3.5 (8.8 − 12.3) |

3 − 4 (10.5 − 14.0) |

4 − 5 (14.0 − 17.5) |

|

|

|

|

|

|

|

|

|

Shipping Data |

|

lbs. (kg) − 1 package |

136 (62) |

146 (66) |

168 (76) |

176 (80) |

|

|

|

|

|

|

|

||

Electrical characteristics |

|

120 volts − 60 hertz − 1 phase (less than 12 amps) |

|||||

|

|

|

|

|

|

|

|

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

|

3 Air Filter and Rack Kit |

Horizontal (end) |

87L96 − 18 x 25 x 1 in. |

87L97 − 20 x 25 x 1 in. |

||||

|

Size of filter |

|

|

(457 x 635 x 25 mm) |

(508 x 635 x 25 mm) |

|||

|

|

|

Side Return |

Single 44J22 or Ten Pack 66K63 − (1) 16 x 25 x 1 in. (406 x 635 x 25 mm) |

||||

|

|

|

|

|

|

|

|

|

|

Condensate Drain Heat |

6 ft. (1.8 m) |

26K68 |

26K68 |

26K68 |

26K68 |

||

|

Cable |

|

24 ft. (7.3 m) |

26K69 |

26K69 |

26K69 |

26K69 |

|

|

|

|

||||||

|

|

|

50 ft. (15.2 m) |

26K70 |

26K70 |

26K70 |

26K70 |

|

|

|

|

|

|

|

|

||

|

Heat Cable Tape Fiberglass − 1/2 in. (38 mm) x 66 ft. (20 m) |

39G04 |

39G04 |

39G04 |

39G04 |

|||

|

|

Aluminum foil − 2 in. (25 mm) x 60 ft. (18 |

39G03 |

39G03 |

39G03 |

39G03 |

||

|

|

|

m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EZ Filter Base |

Catalog Number − Ship. Weight − lbs. |

73P56 − 7 (3) |

73P56 − 7 (3) |

73P57 − 8 (4) |

73P57 − 8 (4) |

||

|

|

|

(kg) |

|

|

|

|

|

|

|

Dimensions − H x W x D − in. (mm) |

4 x 17−5/8 x 28−5/8 |

4 x 17−5/8 x 28−5/8 |

4 x 21−5/8 x 28−5/8 |

4 x 21−5/8 x 28−5/8 |

||

|

|

|

|

(102 x 448 x 727) |

(102 x 448 x 727) |

(102 x 549 x 727) |

(102 x 549 x 727) |

|

|

|

Size of field provided filter − in. (mm) |

16 x 25 x 1 |

|

16 x 25 x 1 |

20 x 25 x 1 |

20 x 25 x 1 |

|

|

|

|

||||||

|

|

|

|

(406 x 635 x 25) |

|

(406 x 635 x 25) |

(508 x 635 x 25) |

(508 x 635 x 25) |

|

|

|

|

|

|

|

|

|

|

Down−Flow Additive Base |

|

11M60 |

|

11M60 |

11M61 |

11M61 |

|

|

|

|

|

|

|

|

||

|

4 High Altitude Orifice Kit − Natural Gas |

59M16 |

59M16 |

59M16 |

59M16 |

|||

|

4 High Altitude Pressure Switch Kit − Order two each |

− − − |

56M06 |

− − − |

− − − |

|||

|

|

|

7501−10,000ft. (2286−3048m |

|

|

|

|

|

|

|

|

|

|

|

|||

|

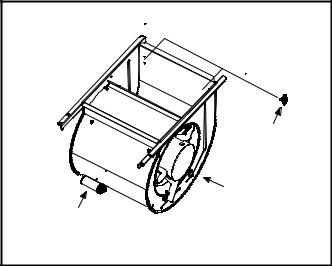

Horizontal Support Frame Kit − Ship. Weight − lbs. (kg) |

56J18 − 18 (8) |

56J18 − 18 (8) |

56J18 − 18 (8) |

56J18 − 18 (8) |

|||

|

|

|

|

|

|

|

|

|

|

LPG/Propane Kit |

|

0−7500 ft. (0−2286 m) |

59M13 |

59M13 |

59M13 |

59M13 |

|

|

|

|

7501−10,000 ft. (2286−3048 m) |

59M14 |

59M14 |

59M14 |

59M14 |

|

|

|

|

|

|

|

|

||

|

Natural to LPG/Propane Kit |

|

59M87 |

59M87 |

59M87 |

59M87 |

||

|

|

|

|

|

|

|

||

|

RAB Return Air Base |

|

− − − |

− − − |

− − − |

RAB60C (12M71) |

||

|

|

|

|

|

|

|

||

|

5 Termination Kits Concen- |

1−1/2 inch (38 mm) |

60G77 |

60G77 |

− − − |

− − − |

||

|

Direct Vent |

tric |

2 inch (51 mm) |

− − − |

− − − |

33K97 |

33K97 |

|

|

||||||||

|

Applications Only |

|

||||||

|

|

3 inch (76 mm) |

− − − |

− − − |

60L46 |

60L46 |

||

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

Wall |

Close Couple − 2 inch (51 mm) |

22G44 |

22G44 |

− − − |

− − − |

|

|

|

|

3 inch (76 mm) |

44J40 |

44J40 |

44J40 |

44J40 |

|

|

|

|

||||||

|

|

Close Couple WTK − 2 inch (51 mm) |

30G28 |

30G28 |

− − − |

− − − |

||

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

5,6 Termination Kits |

Roof |

2 inch (51 mm) |

15F75 |

15F75 |

15F75 |

15F75 |

|

|

Direct Vent or |

|

3 inch (76 mm) |

44J41 |

44J41 |

44J41 |

44J41 |

|

|

Non−Direct Vent |

|

||||||

|

|

|

|

|

|

|

|

|

|

Wall |

Wall Ring Kit 2 inch (51 mm) |

15F74 |

15F74 |

15F74 |

15F74 |

||

|

|

|||||||

|

|

|

|

|

||||

NOTE − Filters and provisions for mounting are not furnished and must be field provided. |

|

|

|

|||||

1 |

Annual Fuel Utilization Efficiency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces. |

|||||||

2 |

Determine from venting tables proper exhaust pipe size and termination kit required. |

|

|

|

||||

3 |

Cleanable polyurethane frame type filter. |

|

|

|

|

|

||

4 |

Required for proper operation at altitudes from 7501 to 10,000 ft. (2286 to 3048 m). |

|

|

|

||||

5 |

See Installation Instructions for specific venting information. |

|

|

|

|

|

||

6 |

Kits contain enough parts for two, non−direct vent installations. |

|

|

|

|

|

||

Page 2

SPECIFICATIONS

Gas |

|

Model No. |

G61MP−48C−110 |

G61MP−60C−110 |

G61MP−60D−135 |

|

Heating |

High Fire |

Input − Btuh (kW) |

110,000 (32.2) |

110,000 (32.2) |

132,000 (38.7) |

|

Performance |

||||||

|

Output − Btuh (kW) |

104,000 (30.5) |

104,000 (30.5) |

124,000 (36.3) |

||

|

|

|||||

|

Temperature rise range − _F (_C) |

45 − 75 (25 − 42) |

35 − 65 (21 − 39) |

40 − 70 (24 − 42) |

||

|

|

|

|

|

|

|

|

Low Fire |

Input − Btuh (kW) |

75,000 (22.0) |

75,000 (22.0) |

90,000 (26.4) |

|

|

|

Output − Btuh (kW) |

72,000 (21.1) |

72,000 (21.1) |

86,000 (25.2) |

|

|

Temperature rise range − _F (_C) |

30 − 60 (18 − 36) |

25 − 55 (14 − 31) |

30 − 60 (18 − 36) |

||

|

|

|

|

|

|

|

|

|

1 AFUE |

94.1% |

94.1% |

94.1% |

|

|

|

California Seasonal Efficiency |

88.4% |

87.0% |

87.7% |

|

|

High static (CSA) − in. w.g. (Pa) |

0.5 |

0.5 |

0.5 |

||

|

|

|

|

|

|

|

Connections |

|

2 Intake Pipe (PVC) |

2 |

2 |

3 |

|

in. |

|

2 Exhaust Pipe (PVC) |

2 |

2 |

3 |

|

|

|

|||||

|

Condensate Drain Trap (PVC pipe) − i.d. |

1/2 |

1/2 |

1/2 |

||

|

with field supplied (PVC coupling) − o.d. |

3/4 |

3/4 |

3/4 |

||

|

hose with hose clamp − i.d. x o.d. |

1−1/4 x 1 |

1−1/4 x 1 |

1−1/4 x 1 |

||

|

|

Gas pipe size IPS |

1/2 |

1/2 |

1/2 |

|

|

|

|

|

|

||

Indoor |

Wheel nominal diameter x width − in. (mm) |

10 x 10 (254 x 254) |

11−1/2 x 10 (292 x 229) |

11−1/2 x 10 (292 x 229) |

||

Blower |

|

Motor output − hp (W) |

1/2 (373) |

1 (746) |

1 (746) |

|

|

|

|||||

|

|

Tons (kW) of add-on cooling |

3 − 4 (10.5 − 14.0) |

4 − 5 (14.0 − 17.5) |

4 − 5 (14.0 − 17.5) |

|

|

|

|

|

|

|

|

Shipping Data |

|

lbs. (kg) − 1 package |

178 (81) |

186 (84) |

206 (93) |

|

|

|

|

|

|

||

Electrical characteristics |

|

120 volts − 60 hertz − 1 phase (less than 12 amps) |

||||

|

|

|

|

|

|

|

OPTIONAL ACCESSORIES − MUST BE ORDERED EXTRA

|

3, 4 Air Filter and Rack Kit − |

Horizontal (end) |

87L97 − 20 x 25 x 1 in. (508 x 635 x 25 mm) |

87L98 − 25 x 25 x 1 in. |

|||

|

Size of filter |

|

|

|

|

(635 x 635 x 25 mm) |

|

|

|

|

Side Return |

5 Single 44J22 or Ten Pack (66K63) − (1) 16 x 25 x 1 in. (406 x 635 x 25 mm) |

|||

|

Condensate Drain Heat |

6 ft. (1.8 m) |

26K68 |

26K68 |

26K68 |

||

|

Cable |

|

24 ft. (7.3 m) |

26K69 |

26K69 |

26K69 |

|

|

|

|

|||||

|

|

|

50 ft. (15.2 m) |

26K70 |

26K70 |

26K70 |

|

|

|

|

|

|

|

||

|

Heat Cable Tape |

Fiberglass − 1/2 in. (38 mm) x 66 ft. (20 m) |

39G04 |

39G04 |

39G04 |

||

|

|

Aluminum foil − 2 in. (25 mm) x 60 ft. (18 m) |

39G03 |

39G03 |

39G03 |

||

|

|

||||||

|

|

|

|

|

|

||

|

4 EZ Filter Base |

Catalog Number − Shipping Weight |

73P57 − 8 lbs. (4 kg) |

73P58 − 10 lbs. (5 kg) |

73P58 − 10 lbs. (5 kg) |

||

|

|

Dimensions − H x W x D − in. (mm) |

4 x 21−5/8 x 28−5/8 |

4 x 24−5/8 x 28−5/8 |

4 x 24−5/8 x 28−5/8 |

||

|

|

|

|

(102 x 549 x 727) |

(102 x 625 x 727) |

(102 x 625 x 727) |

|

|

|

Size of field provided filter − in. (mm) |

20 x 25 x 1 |

24 x 24 x 1 |

24 x 24 x 1 |

||

|

|

||||||

|

|

|

|

(508 x 635 x 25) |

(610 x 610 x 25) |

(610 x 610 x 25) |

|

|

|

|

|

|

|

||

|

Down−Flow Additive Base |

|

11M61 |

11M61 |

11M62 |

||

|

|

|

|

|

|||

|

5 High Altitude Orifice Kit − Natural Gas Only |

59M16 |

59M16 |

59M16 |

|||

|

6 High Altitude Pressure Switch Kit − Order two each |

− − − |

− − − |

56M93 |

|||

|

|

|

4501−10,000 ft. (1372−3048 m) |

||||

|

|

|

|

|

|

||

|

|

|

|

|

|||

|

Horizontal Support Frame Kit − Ship. Weight − lbs. (kg) |

56J18 − 18 (8) |

56J18 − 18 (8) |

56J18 − 18 (8) |

|||

|

|

|

|

|

|

|

|

|

LPG/Propane Kit |

|

0−7500 ft. (0−2286 m) |

59M13 |

59M13 |

59M13 |

|

|

|

|

7501−10,000ft. (2286−3048m) |

59M14 |

59M14 |

59M14 |

|

|

|

|

|

|

|

||

|

Natural to LPG/Propane Kit |

|

59M87 |

59M87 |

59M87 |

||

|

|

|

|

|

|

||

|

RAB Return Air Base |

|

− − − − |

RAB60C (12M71) |

RAB60D (12M72) |

||

|

|

|

|

|

|

||

7 Termination Kits − |

Concentric |

2 inch (51 mm) |

33K97 |

33K97 |

− − − |

||

Direct Vent |

Roof/Wall |

3 inch (76 mm) |

60L46 |

60L46 |

60L46 |

||

Applications |

|

||||||

|

|

|

|

|

|||

Wall Close−Coupled 3 inch (76 mm) |

44J40 |

44J40 |

44J40 |

||||

|

|

||||||

|

|

|

|

|

|

||

7,8 Termination Kits |

Roof |

2 inch (51 mm) |

15F75 |

15F75 |

− − − |

||

Direct Vent or Non− |

|

3 inch (76 mm) |

44J41 |

44J41 |

44J41 |

||

Direct Vent |

|

||||||

|

|

|

|

|

|||

|

|

Wall |

Ring Kit 2 inch (51 mm) |

15F74 |

15F74 |

9 15F74 |

|

NOTE − Filters and provisions for mounting are not furnished and must be field provided. |

|

|

|||||

1 |

Annual Fuel Utilization Efficiency based on DOE test procedures and according to FTC labeling regulations. Isolated combustion system rating for non-weatherized furnaces. |

||||||

2 |

Determine from venting tables proper exhaust pipe size and termination kit required. |

|

|

||||

3 |

Cleanable polyurethane frame type filter. |

|

|

|

|||

4Not for use with RAB Return Air Base or with 60C and 60D size units with air flow requirements of 1800 cfm (850 L/s) or greater. See Blower Performance tables for additional information.

5 |

Required for proper operation at altitudes from 7501 to 10,000 ft. (2286 to 3048 m). |

6 |

Required for proper operation at altitudes over 4500 ft. (1370 m). |

7 |

See Installation Instructions for specific venting information. |

8 |

Kits contain enough parts for two, non−direct vent installations. |

9 |

Non−direct vent applications only. |

Page 3

BLOWER DATA

G61MP−36B−045 PERFORMANCE (Less Filter)

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

25 |

1555 |

735 |

630 |

1410 |

665 |

585 |

1190 |

560 |

520 |

1030 |

485 |

435 |

0.10 |

25 |

1515 |

715 |

605 |

1385 |

655 |

555 |

1190 |

560 |

485 |

1020 |

480 |

415 |

0.20 |

50 |

1470 |

695 |

580 |

1345 |

635 |

520 |

1170 |

550 |

455 |

1010 |

475 |

400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

1410 |

665 |

555 |

1310 |

620 |

495 |

1155 |

545 |

440 |

1000 |

470 |

385 |

0.40 |

100 |

1350 |

640 |

535 |

1250 |

590 |

465 |

1120 |

530 |

410 |

980 |

465 |

360 |

0.50 |

125 |

1290 |

610 |

505 |

1205 |

570 |

450 |

1080 |

510 |

390 |

950 |

450 |

345 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

1220 |

575 |

485 |

1145 |

540 |

420 |

1020 |

480 |

365 |

905 |

430 |

320 |

0.70 |

175 |

1145 |

540 |

460 |

1080 |

510 |

400 |

975 |

460 |

345 |

860 |

405 |

300 |

0.80 |

200 |

1050 |

495 |

425 |

985 |

465 |

365 |

870 |

410 |

320 |

785 |

370 |

285 |

0.90 |

225 |

945 |

445 |

410 |

900 |

425 |

345 |

825 |

390 |

305 |

730 |

345 |

270 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

|

Air volume based on bottom air return air. Actual air volume may vary on side return air applications. |

|

|

|

|

|

|||||||

G61MP−36B−070 PERFORMANCE (Less Filter)

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

1640 |

775 |

660 |

1415 |

665 |

575 |

1160 |

545 |

485 |

1005 |

475 |

410 |

0.10 |

25 |

1600 |

755 |

635 |

1395 |

660 |

550 |

1160 |

545 |

460 |

1000 |

470 |

385 |

0.20 |

50 |

1540 |

725 |

605 |

1370 |

650 |

525 |

1160 |

545 |

445 |

995 |

470 |

375 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

1495 |

705 |

580 |

1345 |

635 |

505 |

1145 |

540 |

425 |

990 |

465 |

365 |

0.40 |

100 |

1420 |

670 |

545 |

1275 |

605 |

480 |

1125 |

530 |

395 |

965 |

455 |

345 |

0.50 |

125 |

1360 |

640 |

525 |

1245 |

590 |

450 |

1080 |

510 |

375 |

945 |

445 |

325 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

1275 |

600 |

490 |

1165 |

550 |

410 |

1025 |

485 |

350 |

900 |

425 |

305 |

0.70 |

175 |

1170 |

555 |

465 |

1085 |

515 |

385 |

965 |

430 |

335 |

860 |

405 |

295 |

0.80 |

200 |

1080 |

510 |

440 |

1010 |

475 |

360 |

865 |

410 |

310 |

775 |

365 |

270 |

0.90 |

225 |

945 |

445 |

400 |

840 |

395 |

320 |

765 |

360 |

275 |

710 |

335 |

245 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

|

Air volume based on bottom air return air. Actual air volume may vary on side return air applications. |

|

|

|

|

|

|||||||

G61MP−48C−090 PERFORMANCE (Less Filter)

External Static |

|

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Pressure |

|

High |

|

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

in. w.g. |

Pa |

cfm |

L/s |

Watts |

|

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2180 |

1030 |

930 |

|

1835 |

865 |

790 |

1520 |

715 |

630 |

1280 |

605 |

510 |

0.10 |

25 |

2135 |

1005 |

885 |

|

1825 |

860 |

750 |

1510 |

710 |

610 |

1275 |

600 |

495 |

0.20 |

50 |

2085 |

985 |

840 |

|

1810 |

855 |

720 |

1505 |

710 |

580 |

1270 |

600 |

475 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2030 |

955 |

800 |

|

1775 |

835 |

685 |

1500 |

705 |

565 |

1265 |

595 |

460 |

0.40 |

100 |

1940 |

915 |

760 |

|

1735 |

820 |

650 |

1480 |

700 |

535 |

1250 |

590 |

440 |

0.50 |

125 |

1865 |

880 |

725 |

|

1660 |

785 |

600 |

1430 |

675 |

505 |

1215 |

575 |

425 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

1740 |

820 |

670 |

|

1590 |

750 |

575 |

1380 |

650 |

475 |

1175 |

555 |

410 |

0.70 |

175 |

1645 |

775 |

640 |

|

1475 |

695 |

520 |

1290 |

610 |

450 |

1105 |

520 |

375 |

0.80 |

200 |

1540 |

725 |

600 |

|

1340 |

630 |

465 |

1175 |

555 |

405 |

1020 |

480 |

355 |

0.90 |

225 |

1335 |

630 |

540 |

|

1170 |

555 |

440 |

1070 |

505 |

375 |

950 |

450 |

330 |

|

|

|

|

|

|

|

|

|

|

|||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

|||||||

|

Air volume based on bottom air return air. Actual air volume may vary on side return air applications. |

|

|

|

|

|

||||||||

G61MP−48C−110 PERFORMANCE (Less Filter) |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||||

External Static |

|

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

Pressure |

|

High |

|

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

|

|

|

|

|

|

|

|

|

||||||

in. w.g. |

Pa |

cfm |

L/s |

Watts |

|

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2160 |

1020 |

880 |

|

1880 |

890 |

755 |

1490 |

705 |

602 |

1235 |

580 |

485 |

0.10 |

25 |

2100 |

990 |

850 |

|

1855 |

875 |

730 |

1480 |

700 |

585 |

1230 |

580 |

475 |

0.20 |

50 |

2035 |

960 |

805 |

|

1815 |

860 |

690 |

1475 |

695 |

560 |

1225 |

580 |

460 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

1965 |

925 |

750 |

|

1755 |

830 |

650 |

1475 |

695 |

545 |

1220 |

575 |

445 |

0.40 |

100 |

1885 |

890 |

725 |

|

1715 |

810 |

625 |

1465 |

690 |

510 |

1215 |

575 |

430 |

0.50 |

125 |

1780 |

840 |

680 |

|

1630 |

770 |

580 |

1420 |

670 |

490 |

1150 |

540 |

400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

1690 |

800 |

660 |

|

1550 |

735 |

550 |

1360 |

640 |

460 |

1110 |

525 |

380 |

0.70 |

175 |

1575 |

745 |

620 |

|

1410 |

665 |

505 |

1210 |

570 |

405 |

1035 |

490 |

350 |

0.80 |

200 |

1375 |

650 |

550 |

|

1230 |

580 |

450 |

1125 |

530 |

380 |

970 |

460 |

325 |

0.90 |

225 |

1225 |

580 |

520 |

|

1120 |

530 |

415 |

1050 |

495 |

365 |

885 |

420 |

310 |

|

|

|

|

|

|

|

|

|

|

|||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

|||||||

|

Air volume based on bottom air return air. Actual air volume may vary on side return air applications. |

|

|

|

|

|

||||||||

Page 4

BLOWER DATA

G61MP−60C−090 PERFORMANCE (Less Filter) − Single Side Return Air − Air volumes in bold require field fabricated transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) air filter in order to maintain proper air velocity.

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2835 |

1335 |

1495 |

2340 |

1105 |

1155 |

1800 |

850 |

895 |

1440 |

680 |

695 |

0.10 |

25 |

2785 |

1315 |

1475 |

2345 |

1105 |

1135 |

1805 |

855 |

865 |

1515 |

715 |

690 |

0.20 |

50 |

2715 |

1280 |

1435 |

2275 |

1075 |

1080 |

1825 |

860 |

845 |

1560 |

735 |

685 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2620 |

1235 |

1380 |

2260 |

1065 |

1035 |

1840 |

870 |

825 |

1600 |

755 |

680 |

0.40 |

100 |

|

1205 |

1350 |

|

1055 |

1015 |

|

870 |

815 |

|

765 |

670 |

2550 |

2230 |

1845 |

1620 |

||||||||||

0.50 |

125 |

2450 |

1155 |

1305 |

2175 |

1025 |

990 |

1850 |

870 |

790 |

1615 |

765 |

655 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

2365 |

1115 |

1270 |

2130 |

1005 |

940 |

1830 |

865 |

775 |

1615 |

760 |

640 |

0.70 |

175 |

2240 |

1060 |

1205 |

2070 |

975 |

915 |

1815 |

855 |

760 |

1595 |

755 |

620 |

0.80 |

200 |

2185 |

1030 |

1190 |

1965 |

925 |

865 |

1775 |

840 |

745 |

1555 |

735 |

605 |

0.90 |

225 |

2015 |

950 |

1150 |

1820 |

860 |

820 |

1690 |

800 |

715 |

1440 |

680 |

580 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

G61MP−60C−090 PERFORMANCE (Less Filter) − Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or Return Air from Bottom and One Side.

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2840 |

1340 |

1450 |

2345 |

1105 |

1105 |

1895 |

895 |

900 |

1515 |

715 |

700 |

0.10 |

25 |

|

1305 |

1415 |

|

1115 |

1080 |

|

920 |

885 |

|

745 |

700 |

2765 |

2365 |

1950 |

1580 |

||||||||||

0.20 |

50 |

2695 |

1270 |

1385 |

2345 |

1105 |

1050 |

1985 |

935 |

870 |

1620 |

765 |

695 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2605 |

1230 |

1335 |

2315 |

1090 |

1030 |

1990 |

940 |

850 |

1645 |

775 |

690 |

0.40 |

100 |

2530 |

1195 |

1300 |

2265 |

1070 |

990 |

1990 |

940 |

825 |

1665 |

785 |

675 |

0.50 |

125 |

2420 |

1140 |

1260 |

2210 |

1045 |

955 |

1970 |

930 |

800 |

1675 |

790 |

665 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

2330 |

1100 |

1220 |

2145 |

1010 |

925 |

1930 |

910 |

775 |

1665 |

785 |

650 |

0.70 |

175 |

2250 |

1060 |

1190 |

2050 |

965 |

885 |

1875 |

885 |

745 |

1645 |

775 |

630 |

0.80 |

200 |

2135 |

1010 |

1140 |

2000 |

945 |

865 |

1810 |

855 |

715 |

1620 |

765 |

615 |

0.90 |

225 |

2030 |

960 |

1090 |

1885 |

890 |

830 |

1720 |

810 |

685 |

1560 |

735 |

590 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

G61MP−60C−110 PERFORMANCE (Less Filter) − Single Side Return Air − Air volumes in bold require field fabricated transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) air filter in order to maintain proper air velocity.

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2625 |

1240 |

1350 |

2310 |

1090 |

1080 |

1885 |

890 |

885 |

1515 |

715 |

700 |

0.10 |

25 |

2570 |

1215 |

1330 |

2325 |

1095 |

1060 |

1910 |

900 |

865 |

1575 |

745 |

700 |

0.20 |

50 |

2410 |

1135 |

1305 |

2285 |

1080 |

1035 |

1930 |

910 |

845 |

1620 |

765 |

690 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2425 |

1145 |

1265 |

2230 |

1055 |

990 |

1925 |

905 |

825 |

1635 |

770 |

675 |

0.40 |

100 |

2335 |

1100 |

1220 |

2175 |

1025 |

950 |

1910 |

900 |

810 |

1640 |

775 |

660 |

0.50 |

125 |

2270 |

1070 |

1195 |

2120 |

1000 |

935 |

1895 |

895 |

785 |

1640 |

775 |

640 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

2170 |

1025 |

1155 |

2045 |

965 |

885 |

1860 |

875 |

765 |

1630 |

770 |

630 |

0.70 |

175 |

2110 |

995 |

1130 |

1950 |

920 |

855 |

1795 |

845 |

730 |

1590 |

750 |

610 |

0.80 |

200 |

2035 |

960 |

1090 |

1885 |

890 |

820 |

1745 |

825 |

705 |

1540 |

725 |

580 |

0.90 |

225 |

1900 |

895 |

1055 |

1760 |

830 |

780 |

1665 |

785 |

680 |

1470 |

695 |

565 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

Page 5

BLOWER DATA

G61MP−60C−110 PERFORMANCE (Less Filter) − Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or Return Air from Bottom and One Side.

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2720 |

1285 |

1385 |

2410 |

1135 |

1090 |

2055 |

970 |

935 |

1620 |

765 |

710 |

0.10 |

25 |

2665 |

1255 |

1355 |

2385 |

1125 |

1075 |

2025 |

955 |

885 |

1730 |

815 |

735 |

0.20 |

50 |

|

1220 |

1315 |

|

1110 |

1015 |

|

955 |

865 |

|

795 |

690 |

2585 |

2350 |

2030 |

1680 |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2505 |

1180 |

1275 |

2290 |

1080 |

990 |

2025 |

955 |

840 |

1695 |

800 |

675 |

0.40 |

100 |

2435 |

1150 |

1250 |

2235 |

1055 |

940 |

2030 |

960 |

830 |

1695 |

800 |

660 |

0.50 |

125 |

2350 |

1110 |

1205 |

2170 |

1025 |

930 |

1975 |

930 |

790 |

1735 |

820 |

665 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

2255 |

1065 |

1185 |

2100 |

990 |

895 |

1915 |

905 |

765 |

1720 |

810 |

650 |

0.70 |

175 |

2160 |

1020 |

1150 |

2005 |

945 |

840 |

1865 |

880 |

730 |

1680 |

795 |

635 |

0.80 |

200 |

2020 |

955 |

1090 |

1905 |

900 |

825 |

1810 |

855 |

710 |

1625 |

765 |

610 |

0.90 |

225 |

1910 |

900 |

1050 |

1820 |

860 |

795 |

1705 |

805 |

675 |

1540 |

725 |

590 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

G61MP−60D−135 PERFORMANCE (Less Filter) − Single Side Return Air − Air volumes in bold require field fabricated transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) air filter in order to maintain proper air velocity.

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

|||||||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|||||

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2665 |

1260 |

1440 |

2325 |

1095 |

1100 |

1865 |

880 |

890 |

1410 |

665 |

690 |

|

0.10 |

25 |

2615 |

1235 |

1405 |

2310 |

1090 |

1065 |

1915 |

905 |

865 |

1465 |

690 |

685 |

|

0.20 |

50 |

2530 |

1195 |

1370 |

2280 |

1075 |

1055 |

1925 |

910 |

850 |

1570 |

740 |

675 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2470 |

1165 |

1330 |

2235 |

1055 |

1015 |

1920 |

905 |

825 |

1590 |

750 |

670 |

|

0.40 |

100 |

2380 |

1125 |

1290 |

2175 |

1025 |

985 |

1910 |

900 |

805 |

1590 |

750 |

655 |

|

0.50 |

125 |

2310 |

1090 |

1265 |

2120 |

1000 |

965 |

1890 |

890 |

790 |

1595 |

755 |

645 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

2200 |

1035 |

1230 |

2055 |

970 |

935 |

1835 |

865 |

765 |

1580 |

745 |

630 |

|

0.70 |

175 |

2120 |

1000 |

1190 |

1970 |

930 |

900 |

1790 |

845 |

740 |

1545 |

730 |

605 |

|

0.80 |

200 |

2025 |

955 |

1160 |

1890 |

890 |

875 |

1720 |

810 |

710 |

1515 |

715 |

590 |

|

0.90 |

225 |

1930 |

910 |

1110 |

1800 |

850 |

835 |

1655 |

780 |

685 |

1440 |

680 |

570 |

|

|

|

|

|

|

|

|

|

|

|

|||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

|||||||

G61MP−60D−135 PERFORMANCE (Less Filter) − Bottom Return Air, Side Return Air with Optional RAB Return Air Base, Return Air from Both Sides or Return Air from Bottom and One Side.

External Static |

|

|

|

Air Volume / Watts at Different Blower Speeds |

|

|

|

||||||

Pressure |

|

High |

|

|

Medium−High |

|

|

Medium−Low |

|

|

Low |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

in. w.g. |

Pa |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

cfm |

L/s |

Watts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.00 |

0 |

2730 |

1290 |

1465 |

2425 |

1145 |

1125 |

2055 |

970 |

915 |

1560 |

735 |

680 |

0.10 |

25 |

2670 |

1260 |

1440 |

2400 |

1135 |

1100 |

2065 |

975 |

890 |

1590 |

750 |

675 |

0.20 |

50 |

2600 |

1225 |

1400 |

2365 |

1115 |

1070 |

2045 |

965 |

865 |

1620 |

765 |

665 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.30 |

75 |

2525 |

1190 |

1360 |

2315 |

1095 |

1045 |

2035 |

960 |

845 |

1615 |

760 |

655 |

0.40 |

100 |

2445 |

1155 |

1325 |

2260 |

1065 |

1015 |

2020 |

955 |

820 |

1615 |

760 |

645 |

0.50 |

125 |

2360 |

1115 |

1280 |

2195 |

1035 |

985 |

1960 |

925 |

790 |

1610 |

760 |

635 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.60 |

150 |

2290 |

1080 |

1255 |

2130 |

1005 |

965 |

1900 |

895 |

755 |

1600 |

755 |

615 |

0.70 |

175 |

2205 |

1040 |

1220 |

2035 |

960 |

910 |

1825 |

860 |

730 |

1570 |

740 |

600 |

0.80 |

200 |

2110 |

995 |

1195 |

1945 |

915 |

880 |

1765 |

830 |

710 |

1540 |

725 |

580 |

0.90 |

225 |

1970 |

930 |

1120 |

1835 |

865 |

830 |

1680 |

795 |

690 |

1540 |

725 |

545 |

|

|

|

|

|

|

|

|

|

|

||||

NOTES − |

All air data is measured external to unit without filter (not furnished − field provided). |

|

|

|

|

|

|

||||||

Page 6

|

|

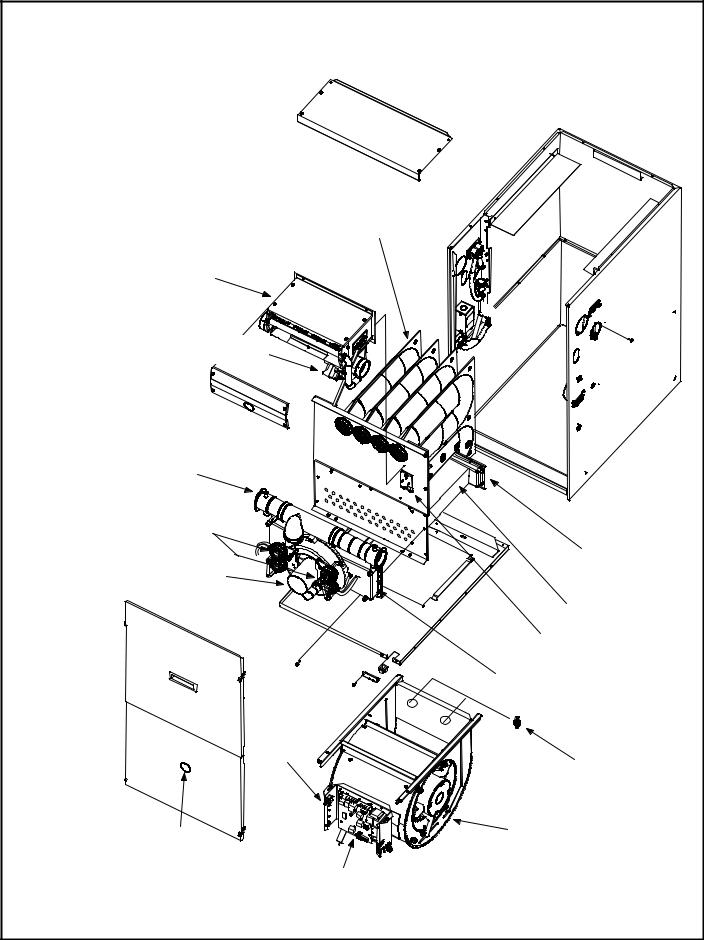

G61MP PARTS ARRANGEMENT |

|

|

|

TOP CAP |

|

|

|

DuralokPlusTM |

|

|

|

HEAT EXCHANGER |

|

|

|

ASSEMBLY |

|

|

|

|

CABINET |

|

BURNER BOX |

|

|

|

ASSEMBLY |

|

|

|

GAS VALVE |

|

|

|

AND MANIFOLD |

|

|

|

FLUE |

|

|

|

COLLAR |

|

|

COMBUSTION |

|

|

|

AIR PROVE PROVE |

|

WARM HEADER |

|

|

SWITCHES* |

|

(COLLECTOR) |

|

|

|

BOX |

|

COMBUSTION AIR |

|

|

|

INDUCER |

|

|

|

|

|

CONDENSER COIL |

BURNER |

|

|

PRIMARY LIMIT |

ACCESS |

|

|

|

|

|

|

|

PANEL |

|

|

|

|

|

|

COLD HEADER |

|

|

|

(COLLECTOR) |

|

|

|

BOX |

BLOWER |

|

DOOR |

|

ACCESS |

|

INTERLOCK |

|

DOOR |

|

SWITCH |

SECONDARY |

|

|

|

|

|

|

|

LIMITS (2) |

*G61MP−090 shown. |

|

|

|

G61MP−045 and −070 |

SIGHT |

|

BLOWER |

are equipped with |

GLASS |

|

ASSEMBLY |

two switches. |

|

|

|

|

|

CONTROL BOX |

|

FIGURE 1

Page 7

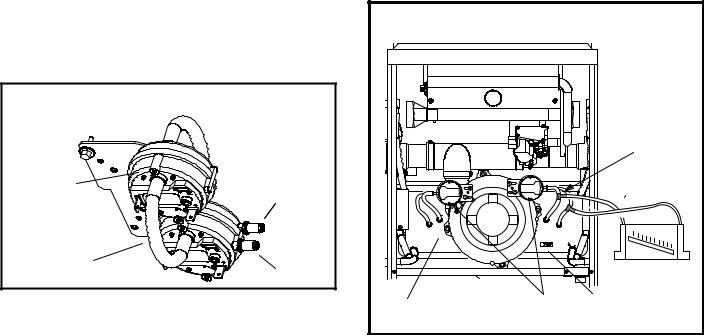

I−UNIT COMPONENTS

G61MP unit components are shown in figure 1. The gas valve, combustion air inducer and burners can be accessed by removing the burner access panel. Electrical components are in the control box (figure 2) found in the blower section.

G61MP units are factory equipped with a bottom return air panel in place. The panel is designed to be field removed as required for bottom air return. Markings are provided for side return air and may be cut out in the field.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

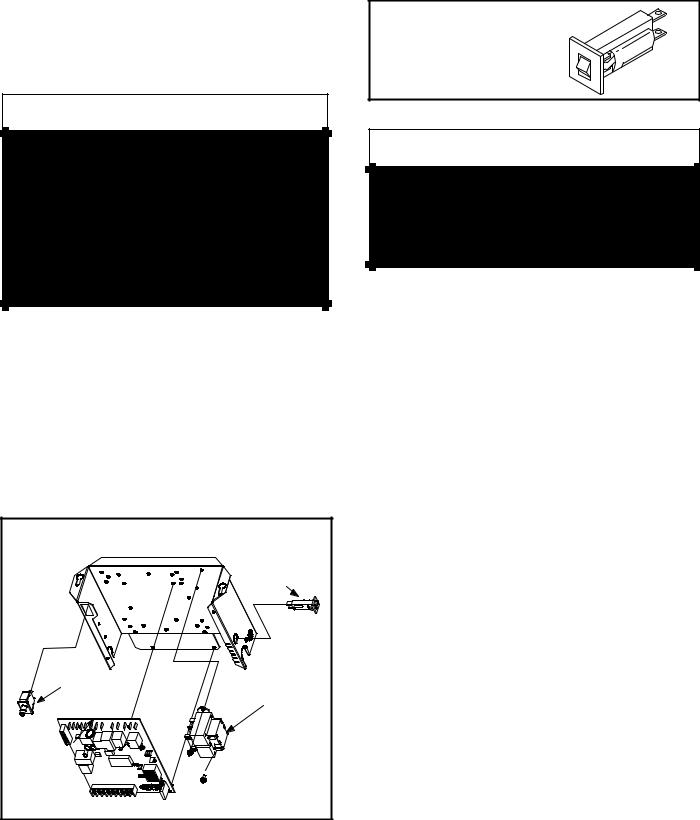

3. Circuit Breaker (CB8)

A 24V circuit breaker is also located in the control box. The switch provides overcurrent protection to the transformer (T1). The breaker is rated 3A at 32V. If the current exceeds this limit the breaker will trip and all unit operation will shutdown. The breaker can be manually reset by pressing the button on the face. See figure 3.

CIRCUIT BREAKER CB8

PRESS TO RESET

CAUTION

CAUTION

Electrostatic discharge can affect electronic components. Take precautions during furnace installation and service to protect the furnace’s electronic controls. Precautions will help to avoid control exposure to electrostatic discharge by putting the furnace, the control and the technician at the same electrostatic potential. Neutralize electrostatic charge by touching hand and all tools on an unpainted unit surface, such as the gas valve or blower deck, before performing any service procedure.

A−Control Box

1. Control Transformer (T1)

A transformer located in the control box provides power to the low voltage section of the unit. Transformers on all models are rated 40VA with a 120V primary and a 24V secondary.

2. Door Interlock Switch (S51)

A door interlock switch rated 14A at 125VAC is wired in series with line voltage. When the blower door is removed the unit will shut down.

CONTROL BOX G61MP |

|

|

CIRCUIT |

|

BREAKER |

DOOR INTERLOCK |

|

SWITCH |

TRANSFORMER |

|

|

SURELIGHT |

|

CONTROL |

|

BOARD |

|

FIGURE 2

FIGURE 3

WARNING

WARNING

Shock hazard.

Disconnect power before servicing. Integrated

Control Board is not field repairable. If control is inoperable, simply replace entire control.

Can cause injury or death. Unsafe operation will result if repair is attempted.

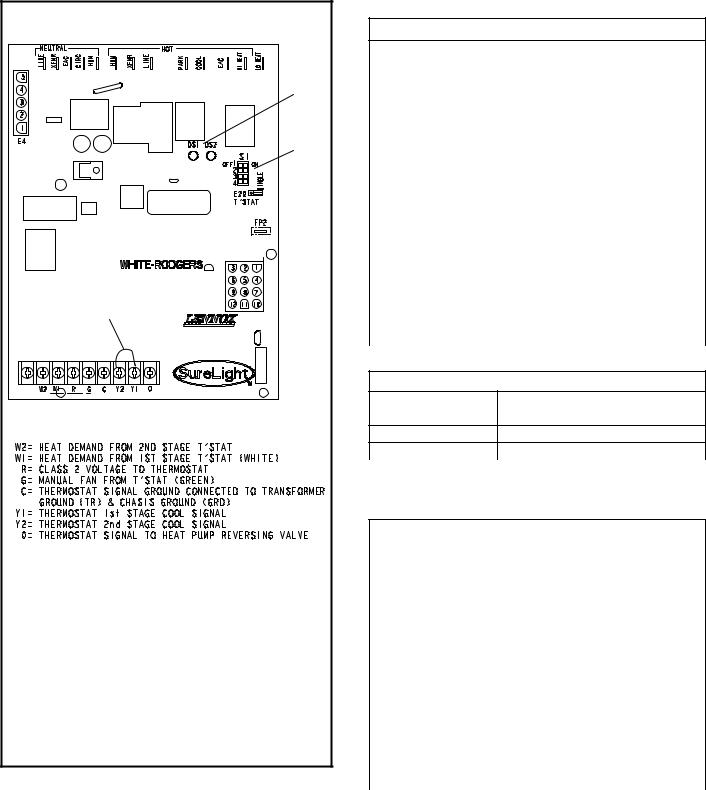

4. Integrated Control Board (A92)

All G61MP units are equipped with the Lennox Two−Stage Integrated control board. The system consists of a ignition control board (figure 4 with control terminal designations in tables 3, 4 and 5) and ignitor (figure 7). The board and ignitor work in combination to ensure furnace ignition and ignitor durability. The board controls all major furnace operations. The board features two LED lights, DS1 and

DS2 for troubleshooting. The board also has two accessory terminals rated at (1) one amp. See table 6 for troubleshooting diagnostic codes.

Electronic Ignition

At the beginning of the heat cycle, SureLight control monitors the first stage and second stage combustion air inducer prove switch. The control will not begin the heating cycle if the first stage prove switch is closed (by−passed). Likewise the control will not begin the second stage heating cycle if the second stage prove switch is closed, and will allow first stage heat only. However if the second stage prove switch closes during the first stage pre−purge, the control will respond to second stage heat. Once the first stage prove switch is determined to be open, the combustion air inducer is energized on low (first stage) heat speed. When the differential in the prove switch is great enough, the prove switch closes and a 15−second pre−purge begins. If the switch is not proven within 2−1/2 minutes, the control goes into Watchguard−Pressure Switch mode for a 5−minute re−set period.

After the 15−second pre−purge period, the SureLight ignitor warms up for 20 seconds after which the gas valve opens for a 4−second trial for ignition. The ignitor energizes during the trial until flame is sensed. If ignition is not proved during the 4−second period, the control will try four more times with an inter purge and warm−up time between trials of 35 sec-

Page 8

onds. After a total of five trials for ignition (including the initial trial), the control goes into Watchguard−Flame Failure mode. After a 60−minute reset period, the control will begin the ignition sequence again.

The SureLight control board has an added feature that prolongs the life of the ignitor. After a successful ignition, the SureLight control utilizes less power to energize the ignitor on successive calls for heat. The control continues to ramp down the voltage to the ignitor until it finds the lowest amount of power that will provide a successful ignition. This amount of power is used for 255 cycles. On the 256th call for heat, the control will again ramp down until the lowest power is determined and the cycle begins again.

Two Stage Operation / Thermostat Selection Jumper

The control can be utilized in two modes: SINGLE−STAGE thermostat or TWO−STAGE thermostat. The thermostat selection jumper E20, located just below dip switches 1 through 4 (figure 4), must be positioned for the particular application. The jumper is factory set on TWO" for use with a two−stage thermostat with two stage heat. Re−position jumper to SINGLE" for use with a single stage thermostat with two stage heat.

While in the single−stage thermostat mode (single jumper setting), the burners will always fire on first−stage heat. The combustion air inducer will operate on low speed and indoor blower will operate on low heat speed. After a 10 minute recognition period, the unit will switch to second stage heat. While in the two−stage thermostat mode (two jumper setting) the burners will fire on first−stage heat. The combustion air inducer will operate on low speed and indoor blower will operate on low heat speed. The unit will switch to second−stage heat on call from the indoor thermostat. If there is a simultaneous call for first and second stage heat, the unit will fire on first stage heat and switch to second stage heat after 30 seconds of operation. See Sequence of Operation flow charts in the back of this manual for more detail.

Dip Switch Settings

Dip Switches 1 and 2 − Heating Fan off Delay − The fan on time of 45 seconds is not adjustable. Fan off time (time that the blower operates after the heat demand has been satisfied) can be adjusted by flipping the dip switches 1 and 2 located on the SureLight integrated control. The unit is shipped with a factory fan off setting of 90 seconds. Fan off time will affect comfort and is adjustable to satisfy individual applications. For customized comfort, monitor the supply air temperature once the heat demand is satisfied. Note the supply air temperature at the instant the blower is de−energized. Adjust the fan−off delay to achieve a supply air temperature between 90° − 110° at the instant the blower is de− energized. (Longer delay times allow for lower air temperature, shorter delay times allow for higher air temperature). See table 1 for dip switch settings.

TABLE 1

Heating Fan Off Delay

Delay (Seconds) |

Switch 1 |

Switch 2 |

|

||

|

|

|

60 |

Off |

Off |

|

|

|

90 |

Off |

On |

|

|

|

120 |

On |

Off |

|

|

|

180 |

On |

On |

Switch 3 − Second Stage Delay (Used with Single−Stage

Thermostat Only) −− This switch is used to determine the second stage on delay when a single−stage thermostat is being used. The switch is factory−set in the ON position, which provides a 10−minute delay before second−stage heat is initiated. If the switch is toggled to the OFF position, it will provide a 15−minute delay before second−stage heat is initiated. This switch is only activated when the thermostat selector jumper is positioned for SINGLE−stage thermostat use.

Switch 4 − Cooling Fan off Delay − The fan on delay time of 2 seconds is not adjustable. Fan off time (time that the blower operates after the cool demand has been satisfied) can be adjusted by flipping dip switch 4. The unit is shipped with a factory fan off setting of 45 seconds. Fan off time will affect comfort and is adjustable to satisfy individual applications. See table 2 for cool fan off time settings.

TABLE 2

Cooling Fan Off Delay

Delay (Seconds) |

Switch 4 |

|

|

2 |

Off |

|

|

45 |

On |

|

|

Diagnostic LED’s (DS1 and DS2)

Two diagnostic LED’S are located on the two−stage integrated control board. See figure 4. These light flashes correspond with the codes detailed in table 6.

Factory Installed Jumper Y1 to Y2

A factory−installed jumper from Y1 to Y2 terminals on the integrated control board terminal strip must be clipped for two−stage cooling.

Page 9

TWO−STAGE INTEGRATED CONTROL BOARD

LEDs

DIP

SWITCHES 1 − 4

W915 FACTORY INSTALLED JUMPER (MUST CLIP FOR 2 STAGE COOL)

THERMOSTAT CONNECTIONS (TB1)

DIP SWITCH(ES) |

FUNCTION |

|

|

1 and 2 |

Blower Off Delay (Heating Mode) |

3 |

Second Stage ON Delay (Single−stage t’stat) |

4 |

Blower Off Delay (Cooling Mode) |

FIGURE 4

TABLE 3

Integrated Control Board Terminals

120VAC Neutral

LINE |

Line |

|

|

XFMR |

Transformer |

|

|

EAC |

Electronic Air Cleaner |

|

|

CIRC |

Indoor Blower |

|

|

HUM |

Humidifier |

|

|

|

120VAC Line |

|

|

HUM |

Humidifier |

|

|

XMFR |

Transformer |

|

|

LINE |

Line |

|

|

PARK |

For Unused Leads |

|

|

COOL |

Cooling Speed |

|

|

EAC |

Electronic Air Cleaner |

|

|

HI HEAT |

HIigh Heat Speed |

|

|

LO HEAT |

Low Heat, Low Cool and Continuous Fan |

|

Speed |

|

|

TABLE 4

Integrated Control Board 5 Pin Terminal

PIN # |

Function |

|

|

1 |

Ignitor |

2Combustion Air Inducer High Speed

3Combustion Air Inducer Low Speed

4 |

Combustion Air Inducer Neutral |

|

|

5 |

Ignitor Neutral |

|

|

TABLE 5

Integrated Control Board 12Pin Terminal

PIN # |

Function |

|

|

1 |

Gas Valve 2nd Stage (High Fire) |

|

|

2 |

Second Stage Prove Switch |

|

|

3 |

Not Used |

|

|

4 |

Ground |

|

|

5 |

24V Hot |

|

|

6 |

Primary Limit In |

|

|

7 |

Gas Valve 1st stage (Low Fire) |

|

|

8 |

Gas Valve Common |

|

|

9 |

24V Neutral |

|

|

10 |

Ground |

|

|

11 |

Primary Limit Out |

|

|

12 |

1st Stage Prove Switch |

|

|

Page 10

|

|

TABLE 6 |

|

|

|

DIAGNOSTIC CODES |

|

|

Diagnostic LEDs are labeled DS1 and DS2. See figure 4 for location of diagnostic LEDs. |

||

|

|

|

|

DS1 |

DS2 |

DESCRIPTION |

|

SIMULTANEOUS |

SIMULTANEOUS |

Power on − Normal operation. |

|

SLOW FLASH |

SLOW FLASH |

Also signaled during cooling and continuous fan. |

|

SIMULTANEOUS |

SIMULTANEOUS |

Normal operation − signaled when heating demand initiated at thermostat. |

|

|

|

||

FAST FLASH |

FAST FLASH |

|

|

SLOW FLASH |

ON |

Primary, secondary, backup secondary or rollout limit switch open. Limits must |

|

close within 3 minutes or unit goes into 1 hour Watchguard. |

|||

|

|

||

|

|

Low prove switch open; |

|

OFF |

SLOW FLASH |

OR: Blocked inlet/exhaust vent; |

|

|

|

OR: Low prove switch closed prior to activation of combustion air inducer. |

|

|

|

|

|

|

|

High prove switch open; |

|

OFF |

FAST FLASH |

OR: Blocked inlet/exhaust vent; |

|

|

|

OR: High prove switch closed prior to activation of combustion air inducer. |

|

|

|

|

|

ALTERNATING |

ALTERNATING |

Watchguard −− burners failed to ignite; OR limit open more than 3 minutes; |

|

OR lost flame sense 5 times in one heating cycle; |

|||

SLOW FLASH |

SLOW FLASH |

||

OR pressure switch opened 5 times in one heating cycle. |

|||

|

|

||

|

|

|

|

SLOW FLASH |

OFF |

Flame sensed without gas valve energized. |

|

ON |

ON |

|

|

ON |

OFF |

Circuit board failure or control wired incorrectly. Check 24 and 115 volts to board. |

|

OFF |

ON |

|

|

|

|

|

|

FAST FLASH |

SLOW FLASH |

Main power polarity reversed. Switch line and neutral. |

|

SLOW FLASH |

FAST FLASH |

Low flame signal. Measures below 0.23 microAmps. Replace flame sense rod. |

|

|

|

The following conditions are sensed during the ignitor warm−up period only: |

|

|

|

1) Improper main ground; |

|

ALTERNATING |

ALTERNATING |

2) Broken ignitor; OR: Open ignitor circuit; |

|

FAST FLASH |

FAST FLASH |

3) Line voltage below 75 volts. |

|

|

|

(If voltage lower than 75 volts prior to ignitor warm-up, control will signal waiting on |

|

|

|

call from thermostat, and will not respond. |

|

|

|

|

|

NOTE − Slow flash rate equals 1 Hz (one flash per second). Fast flash rate equals 3 Hz (three flashes per second).

Low flame sense current = 0.17−0.22 microAmps.

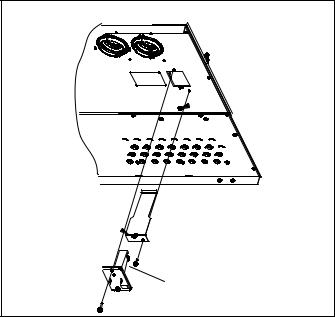

B−Blower Compartment

1. Blower Motor (B3) and Capacitor (C4)

All G61MP units use direct drive blower motors. All motors are 120V permanent split capacitor motors to ensure maximum efficiency. Ratings for capacitors will be on motor nameplate. See SPECIFICATIONS section for motor specifications.

NOTE − Shafts on 1 HP motors have 2 flat sides and are matched with blower wheels with 2 set screws.

2. Secondary Limit Controls (S21)

The secondary limits (S21) on G61MP units are located in the blower compartment on the back side of the blower housing.

See figure 5. All G61MP units are equipped with two secondary limts. When excess heat is sensed in the blower compartment, the limit will open. If the limit is open, the furnace control energizes the supply air blower and closes the gas valve. The limit automatically resets when unit temperature returns to normal. The switch is factory set to open at 125°F and cannot be adjusted.

SUPPLY AIR BLOWER

AND SECONDARY LIMITS

SECONDARY

LIMIT (S)

MOTOR/BLOWER ASSEMBLY

CAPACITOR

To Remove Blower From Unit: Disconnect Power, Remove Control Box, Remove Bolts and Unplug Motor Wires From Control Board.

Then Slide Out Front of Unit.

FIGURE 5

Page 11

C−Heating Components

3. Flame Sensor

A flame sensor is located on the left side of the burner support. See figure 6. The sensor is mounted through the bottom of the burner box and the tip protrudes into the flame envelope of the left−most burner. The sensor can be removed for service without removing any part of the burners. During operation, flame is sensed by current passed through the flame and sensing electrode. The SureLight control allows the gas valve to remain open as long as flame signal is sensed.

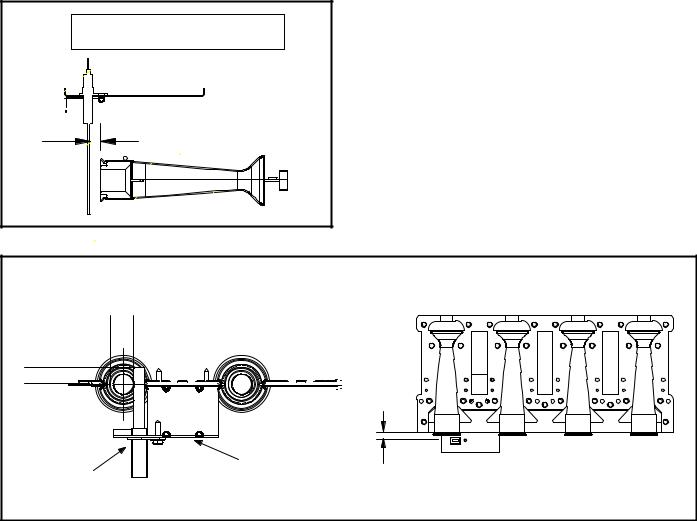

4. Ignitor

The SureLight ignitor is made of durable silicon nitride. Ignitor longevity is enhanced by controlling voltage to the ignitor. The board finds the lowest ignitor temperature which will successfully light the burner, thus increasing the life of the ignitor. Due to this feature of the board, voltage cannot be measured so ignitor must be ohmed. Ohme value should be 10.9 to 19.7. See 7 for ignitor location.

NOTE − The G61MP furnace contains electronic components that are polarity sensitive. Make sure that the furnace is wired correctly and is properly grounded.

NORMAL FLAME SIGNAL > 0.23 MICROAMPS

LOW FLAME SIGNAL |

< 0.22 MICROAMPS |

DROP OUT SIGNAL |

= 0.16 MICROAMPS |

5/16"

FIGURE 6

5. Burners (Figure 7)

All units use inshot burners. Burners are factory set and do not require adjustment. The manifold brackets are slotted so burners can be removed as an assembly for service. Burner maintenance and service is detailed in the MAINTENANCE section of this manual. Each burner uses an orifice which is precisely matched to the burner input and is threaded into the burner manifold. All G61MP natural gas units are fitted with

.089" sized orifices. See SPECIFICATIONS" tables for LP kits and high altitude.

A flame retention ring in the end of each burner maintains correct flame length and shape and keeps the flame from lifting off the burner head. In addition, the burner entrance to each clamshell is fitted with a corbel cup (orifice) used to direct the flow of combustion products.

|

SureLight Ignitor Location |

|

5/8" |

MEASUREMENT IS TO I.D. |

|

OF RETENTION RING |

|

|

13/32’ |

|

|

|

5/16" |

|

IGNITOR |

BRACKET |

|

|

|

|

BURNERS FRONT VIEW |

BURNERS TOP VIEW |

|

FIGURE 7

Page 12

6. Clamshell Heat Exchanger

G61MP units use an aluminized steel primary and stainless steel secondary heat exchanger assembly. Heat is transferred to the air stream from all surfaces of the heat exchanger. The shape of the heat exchanger ensures maximum efficiency.

The combustion air inducer pulls fresh air through the air intake box. This air is mixed with gas in the burner venturi and at the corbel orifices. The gas / air mixture is then burned at the entrance of each clamshell. Combustion gases are then pulled through the primary and secondary heat exchangers and exhausted out the exhaust vent pipe.

7. Flame Rollout Switches (S47)

Flame rollout switch S47 is a high temperature limit located on each side of the burner box. Each furnace is equipped with two identical switches. The limit is a N.C. SPST manu- al-reset limit connected in series with the primary limit S10. When S47 senses rollout, the circuit breaks and the ignition control immediately stops ignition and closes the gas valve.

If unit is running and flame rollout is detected, the gas valve will close and ignition control will be disabled. Rollout can be caused by a blocked heat exchanger, flue or lack of combustion air. The switch is factory set to trip (open) at 250°F and cannot be adjusted. The switch can be manually reset. To manually reset a tripped switch, push the reset button located on the control.

8. Primary Limit Control (S10)

Figure 8 shows the primary limit (S10) used on G61MP units located in the heating vestibule panel. S10 is provided with a shield on some models (figure 8) and must not be removed. Note orientation of shield and limit if limit is replaced. When excess heat is sensed in the heat exchanger, the limit will open.

Once the limit opens, the furnace control energizes the supply air blower and de−energizes the gas valve. The limit automatically resets when unit temperature returns to normal. The switch is factory set and cannot be adjusted.

9.Backup Secondary Limit Control (S113) (G61MP−090, 110, 135 only)

Backup secondary limit control S113 is a N.C. auto−reset switch located on the combustion air inducer. S113 acts as a backup to primary limit S10 in the event of an indoor blower failure. S113 contacts open when temperature on the CAI reaches 142°.

10. Gas Valve (GV1)